Semi-automatic wire take-up machine

A wire take-up machine, semi-automatic technology, applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of easy deviation or damage, reduce the efficiency of wire take-up, and take a long time, so as to improve efficiency , the effect of preventing damage to parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with accompanying drawing:

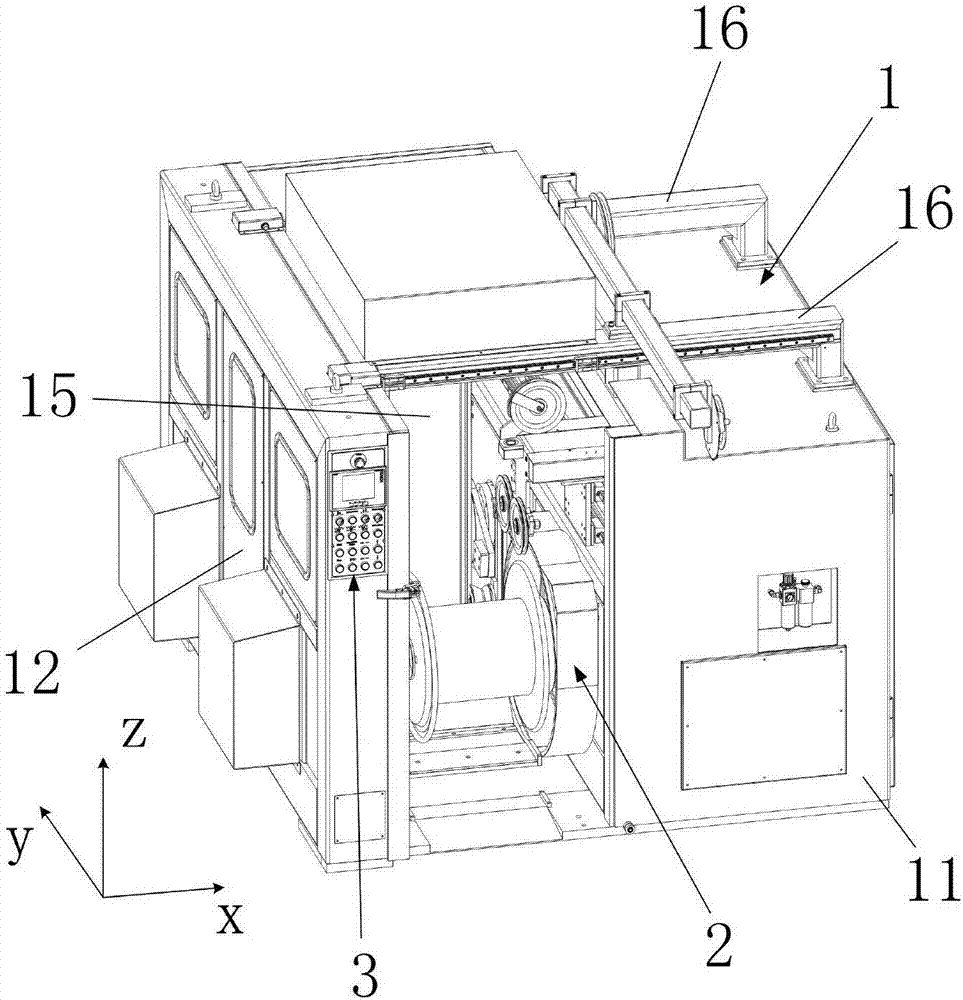

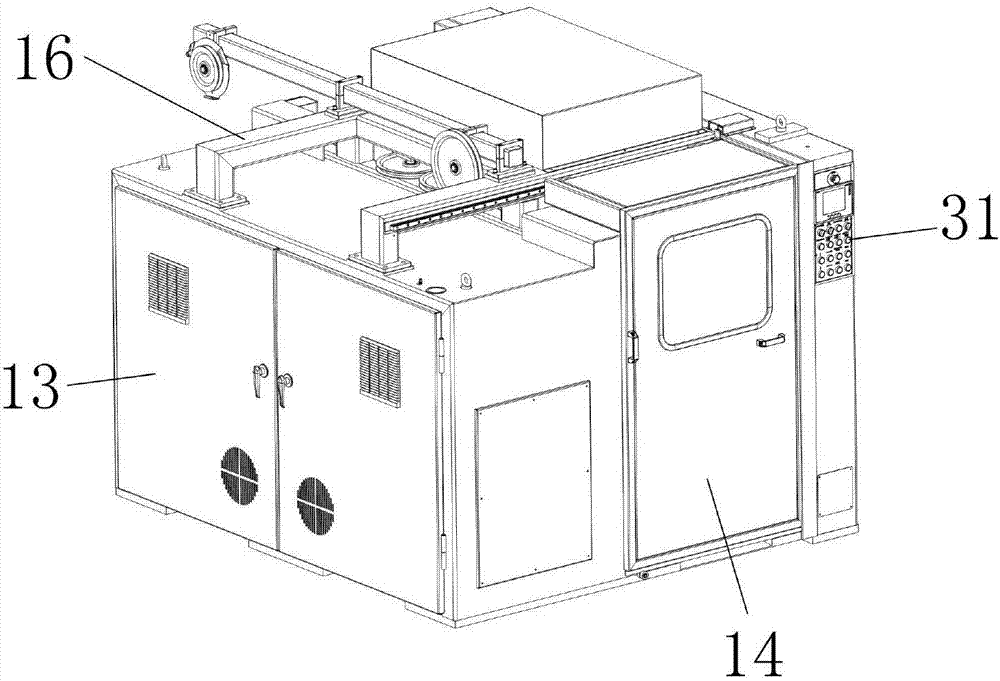

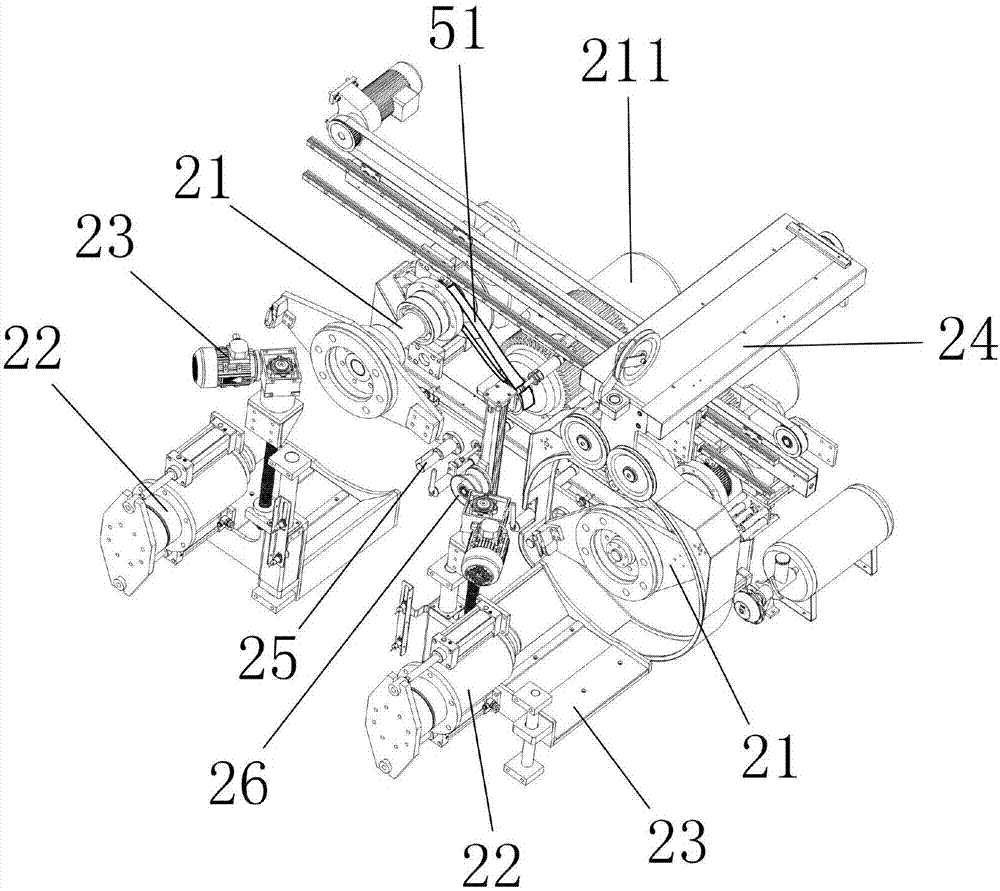

[0030] The wire take-up machine of the present invention needs manual replacement of the wire reel, and therefore belongs to the semi-automatic wire take-up machine. combine figure 1 and figure 2 As shown, the wire take-up machine includes: a chassis 1 , a wire take-up assembly 2 and a controller 3 . The wire take-up assembly 2 is located inside the case 1 , and the controller 3 is used to control the operation of the wire take-up assembly 2 . The wire take-up machine has an x-axis, a y-axis and a z-axis, and the x-axis, y-axis and z-axis are perpendicular to each other.

[0031] Cabinet 1 comprises: casing 11, front maintenance door 12, rear maintenance door 13, two side doors 14 ( figure 1 One of the side doors 14), safety door 15 and top bracket 16 are hidden in it. The front maintenance door 12 is located at the front end of the box body 11, the rear maintenance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com