Automatic cable winding device

A winding device and cable technology, applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material processing, can solve the problems of high labor intensity, degumming of cables, uneven winding of cables, etc. The effect of product quality, labor intensity reduction, and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

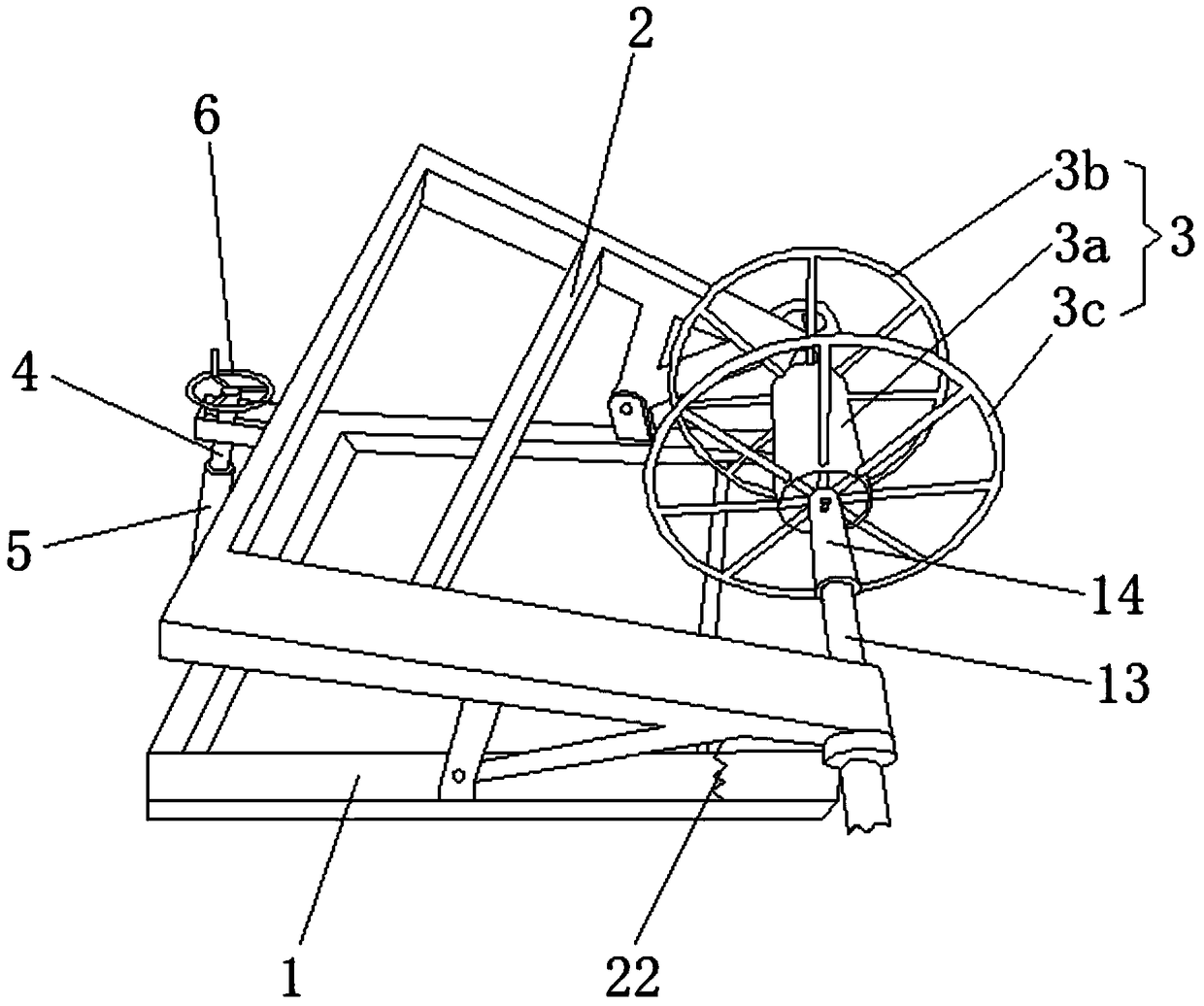

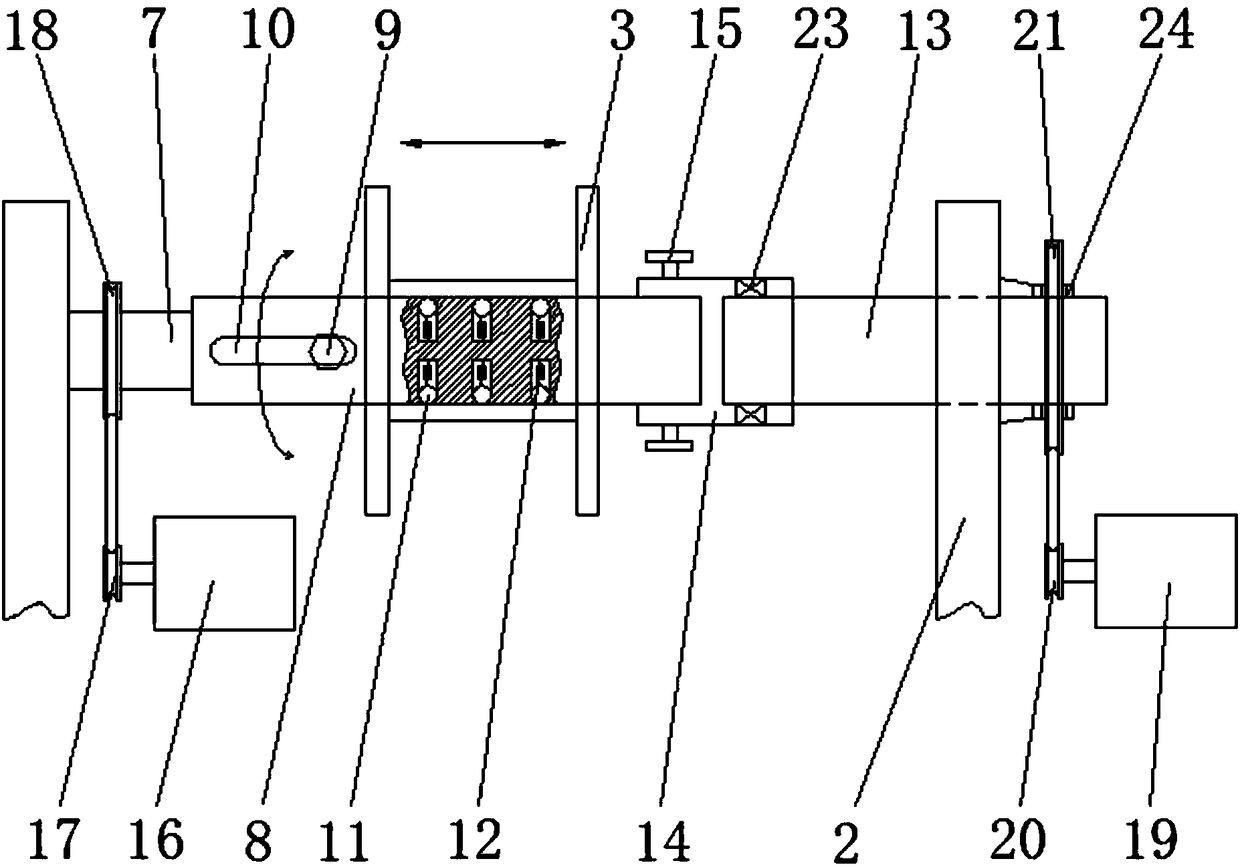

[0021] refer to Figure 1-2 , an automatic cable winding device of the present invention, comprising a base 1 and a support frame 2, wherein both the base 1 and the support frame 2 are frame-type structures, and the middle parts of the two are hingedly connected so that the two can be relatively Turn, one end of the support frame 2 is provided with a reel 3 for rewinding the cable, and the other end is provided with a lifting assembly for lifting the reel 3. When a roll of cable is full, the lifting assembly can be operated to move the cable The coil is lowered to the ground or on a trolley without manual movement. A retractable support assembly for installing the reel 3 is provided on the support frame 2, and a pullable coil is provided on the support frame 2 on the opposite side of the support assembly. The transmission mechanism of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com