Take-up and pay-off device for belt winding mechanism of belt conveyor

The technology of a belt conveyor and a belt winding mechanism is applied in the field of the belt winding and unwinding device of the belt winding mechanism, which can solve the problem of unreasonableness, increase the work intensity and working time, and load the coil that cannot be rolled into the mine car. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

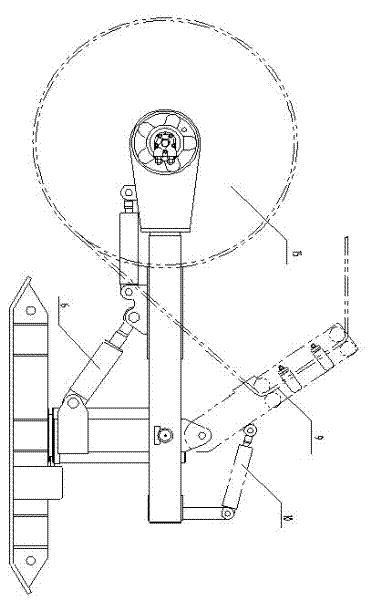

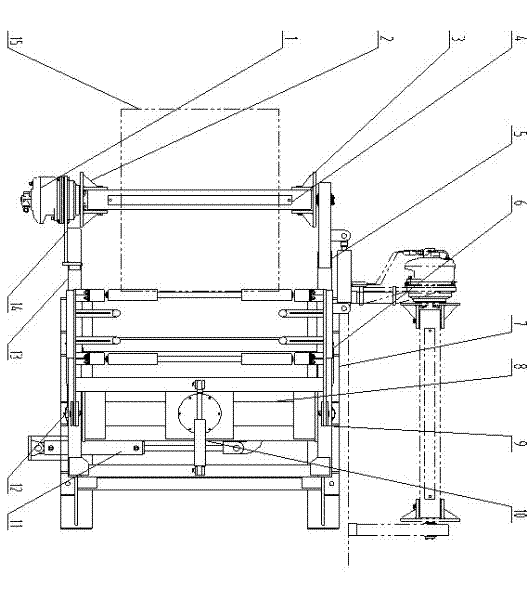

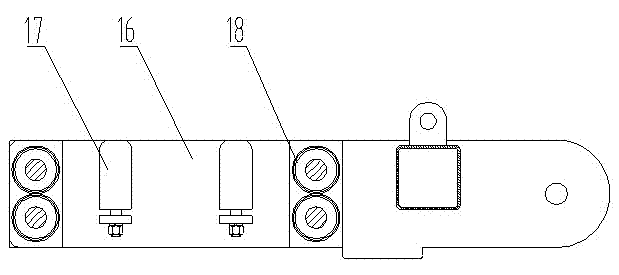

[0014] like figure 1 , figure 2 and image 3 As shown, the present invention includes a winding motor 1, coupling disc I2, coupling disc II3, reel 4, lifting cylinder 6, chassis 7, support base 8 and rotating cylinder 11; also includes moving cantilever 14, static cantilever 13, cantilever telescopic cylinder 5. The guide device 9 and the guide cylinder 10; the support base 8 is installed on the chassis 7, and is connected by the rotating cylinder 11; the static cantilever 13 is installed on the support base 8, and is connected by the lifting cylinder 6; the static cantilever 13 is connected by the cantilever telescopic cylinder 5 Connect the moving cantilever 14; the moving cantilever 14 is equipped with a winding motor 1, connecting disc I2, connecting disc II3, reel 4, cantilever telescopic oil cylinder 5, guide device 9 and guiding oil cylinder 10; reel 4 passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com