Surface layer tin plating equipment for copper wire treatment

A technology of tinning equipment and surface layer, which is applied in the field of surface tinning equipment for copper wire processing, and can solve the problems of cumbersome operation and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

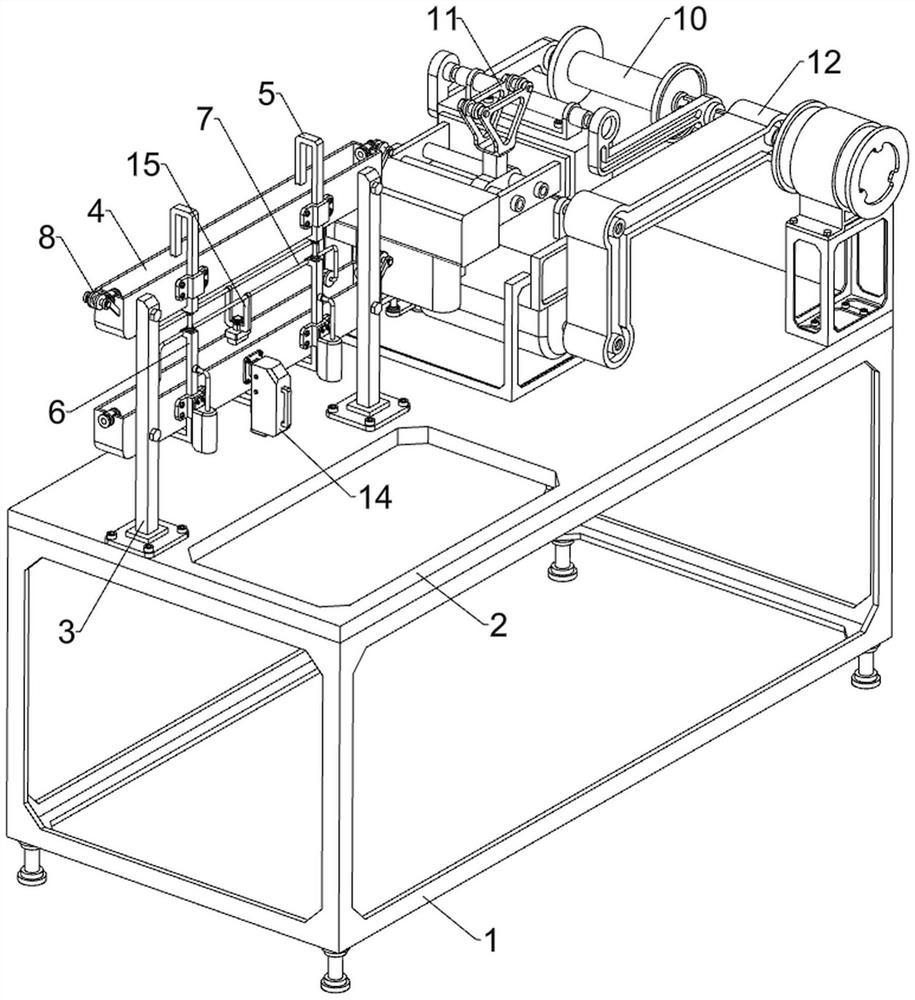

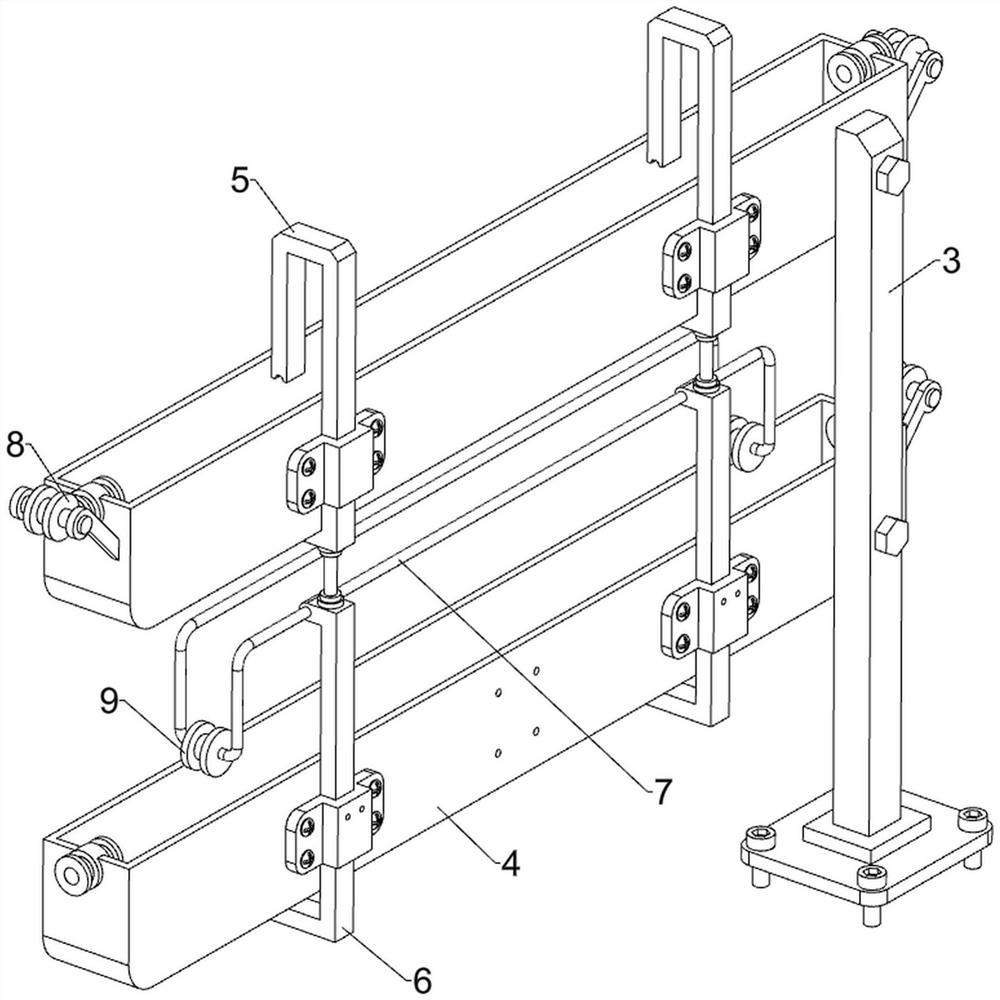

[0036] A surface tinning equipment for copper wire processing, such as Figure 1-10As shown, it includes a bracket 1, a backing plate 2, a supporting plate 3, a processing frame 4, a pressing plate 5, a moving plate 6, a frame rod 7, a first fixed pulley 8, a second fixed pulley 9, a winding assembly 10, and an adjustment assembly 11 and drive assembly 12, the backing plate 2 is welded on the top of the bracket 1, the left and right sides of the left rear side of the backing plate 2 are fixed with support plates 3 by bolts, and the upper and lower parts between the left and right support plates 3 are fixed by bolts. The processing frame 4 is connected, and the left and right sides of the processing frame 4 are provided with guide cylinders, which are used to guide the copper wire. line, the lower processing frame 4 is slidingly provided with a moving plate 6, the bottom of the pressing plate 5 is connected to the top of the moving plate 6, the upper part of the moving plate 6 ...

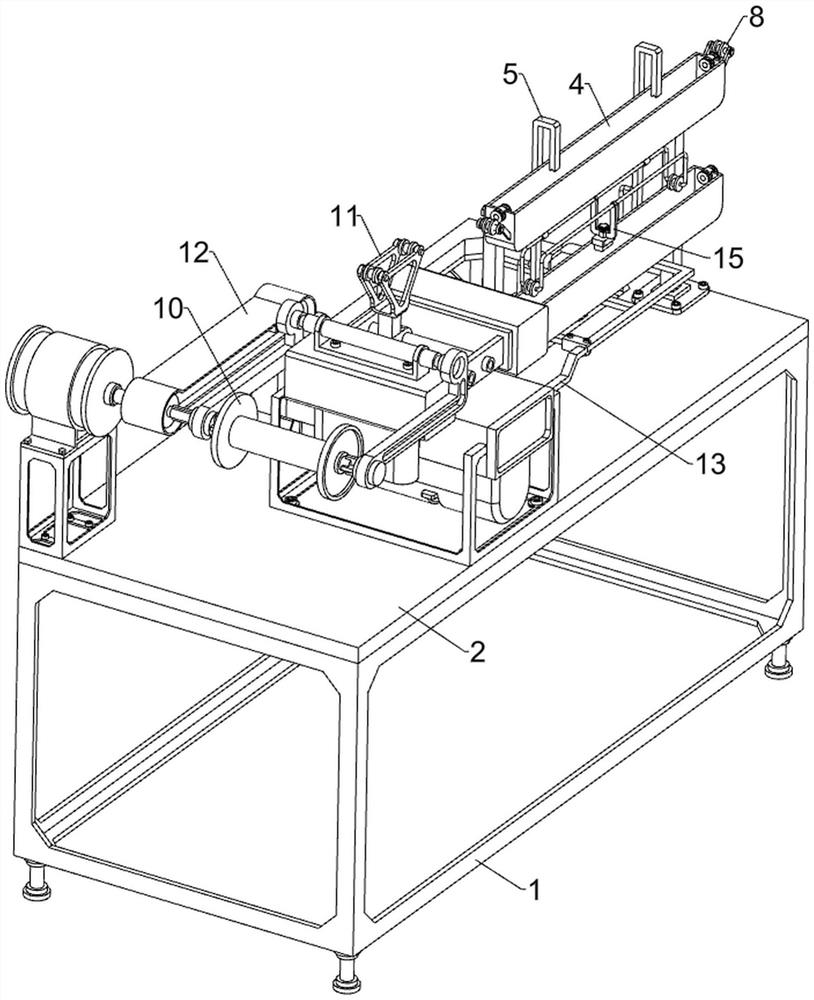

Embodiment 2

[0043] On the basis of Example 1, such as figure 1 , figure 2 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, it also includes a pressing assembly 13. The pressing assembly 13 includes a vertical plate 131, a second push rod 132, a strip plate 133 and a horizontal plate 134. The lower rear side of the protective shell 102 is welded with a vertical plate 131. On the plate 131, the rotation type is provided with a second push rod 132, the second push rod 132 is connected with the rear side of the rotating rod 124 of the bottom, and the lower right part of the moving plate 6 is fixedly connected with a strip plate 133 by bolts, and the right side of the strip plate 133 is provided with a strip plate 133. There is a horizontal plate 134 , and the second push rod 132 rotates and contacts with the horizontal plate 134 .

[0044] Also includes a fixed assembly 14, the fixed assembly 14 includes an arc-shaped shell 141, a second slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com