Optical fiber processing method

A processing method and optical fiber technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., can solve the problems of reduced strength, easy breakage of optical fibers, and insufficient performance of optical fibers to achieve the effect of reducing tension, preventing breakage, and facilitating handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

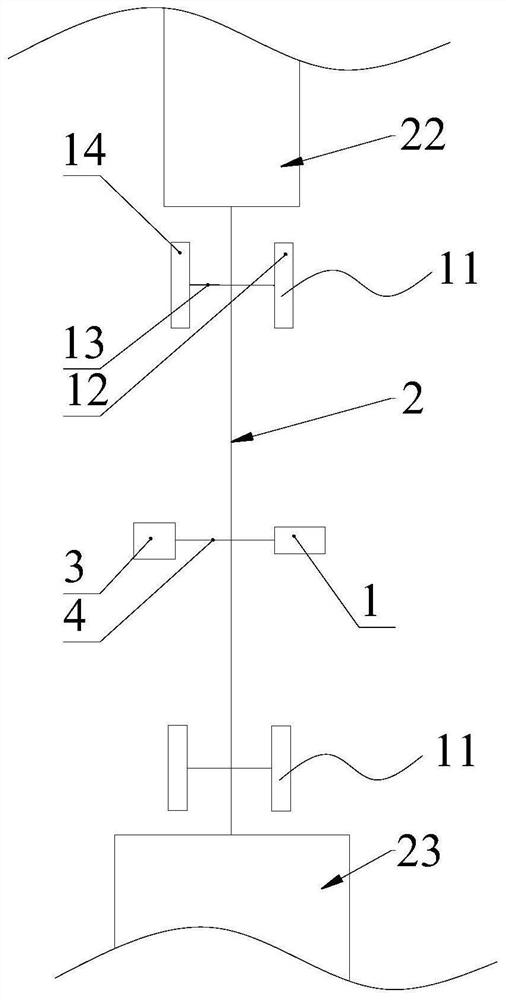

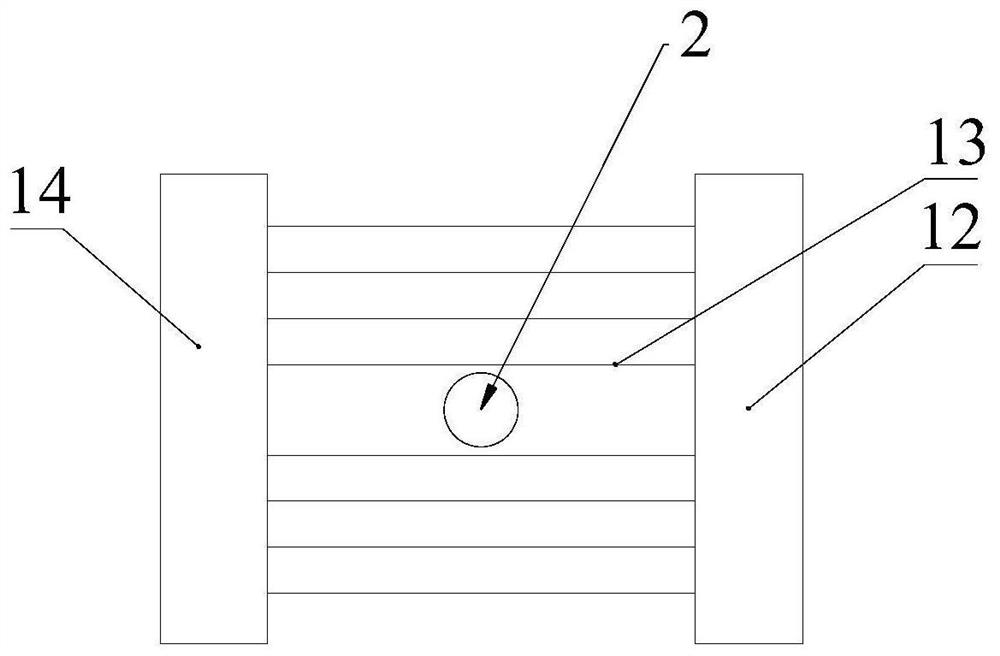

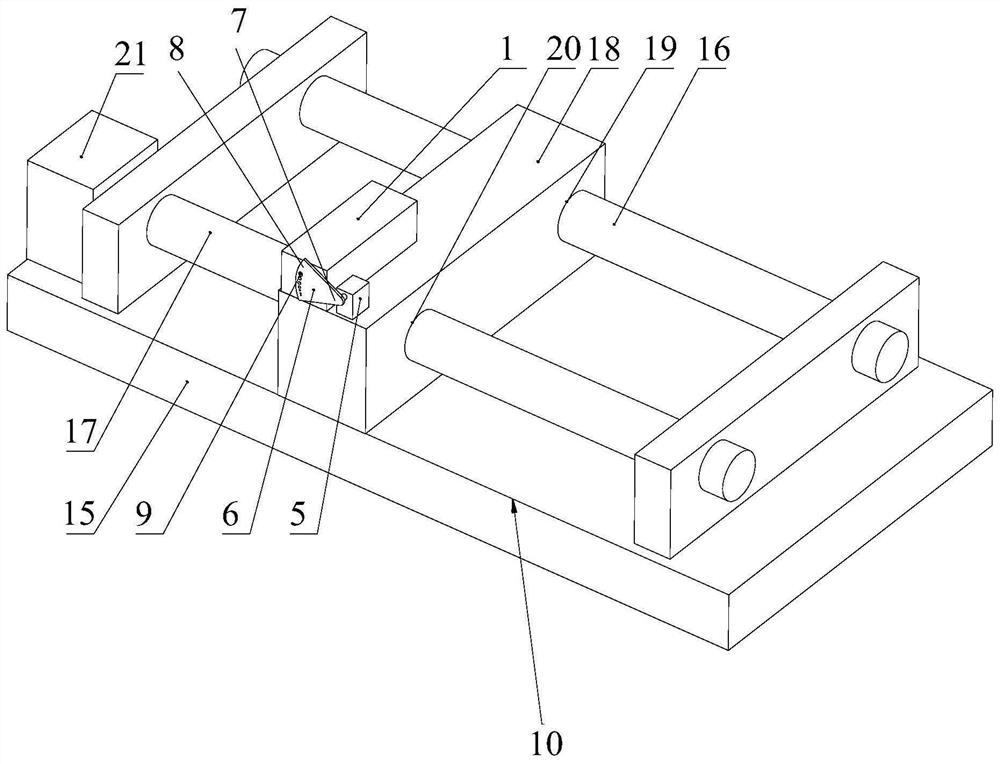

[0044] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0045] Such as figure 1 As shown, a processing method for an optical fiber includes a melting process, a cooling process, a coating and solidification process, and a winding process. There is also a gas line detection process between the cooling process and the coating and solidification process. The gas line detection process includes the following steps :

[0046] 1) Send a beam of laser light 4 perpendicular to the optical fiber 2 to the optical fiber 2 through the laser transmitter 1, and receive it through the laser receiver 3;

[0047] 2) When the signal intensity received by the laser receiver 3 changes suddenly, it is judged that a gas line appears in the optical fiber 2, the starting position of the gas line is recorded, and the winding device is controlled to reduce the winding speed;

[0048] 3) When the signal intensity received by the laser receiver 3 reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com