An intelligent hoisting device for building glass curtain walls

A technology of architectural glass and hoisting equipment, which is applied in the directions of transportation and packaging, load suspension components, non-rotational vibration suppression, etc., can solve the problems of slow transportation speed, and achieve the effects of stable transportation, high degree of intelligence, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

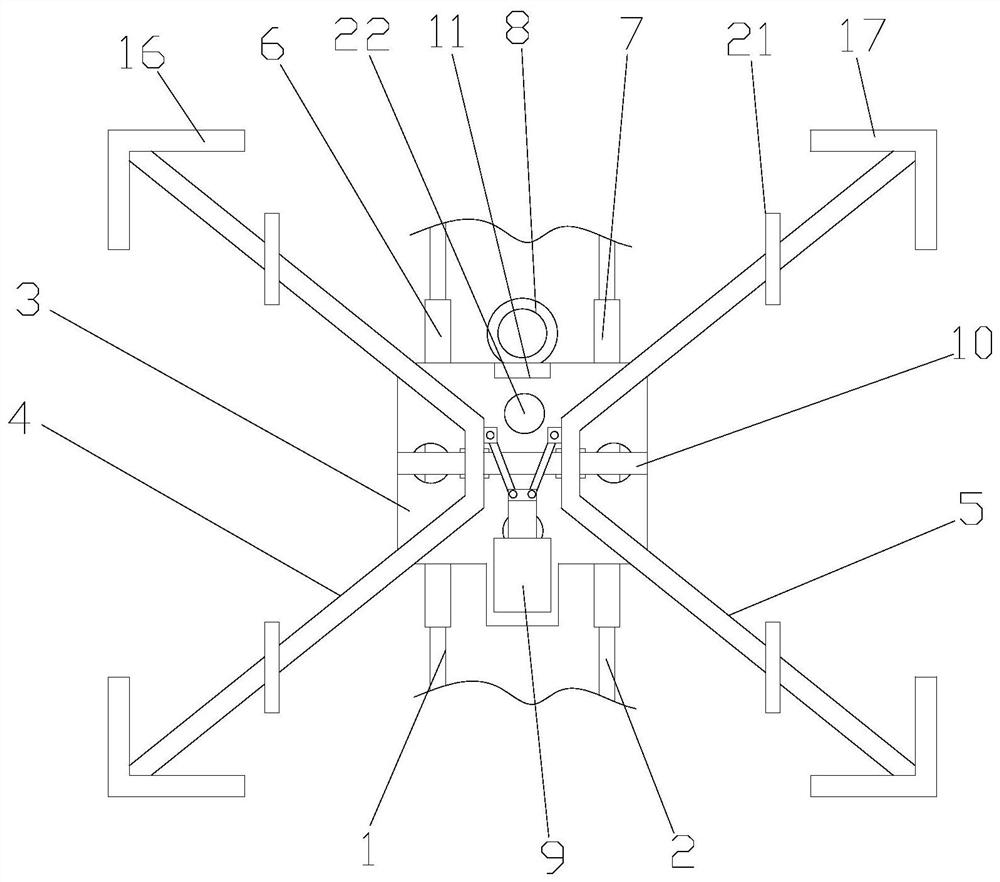

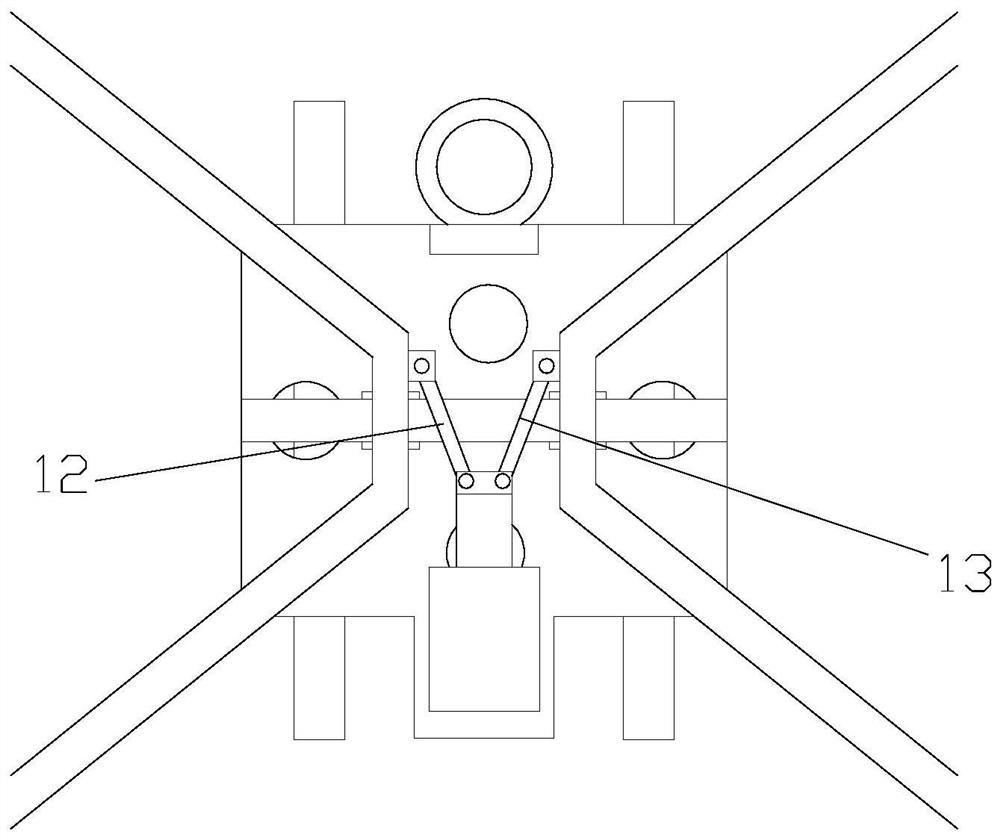

[0026] Such as Figure 1-2 As shown, a building glass curtain wall intelligent hoisting equipment includes a hoist (not shown), a first guide cable 1, a second guide cable 2, and a glass curtain wall fixture. The glass curtain wall fixture includes a connecting middle plate 3, a left V Type clamp arm 4 and right V-shaped clamp arm 5, the back of the connecting middle plate 3 is provided with a first linear bearing 6 matched with the first guide cable 1 and a second linear bearing matched with the second guide cable 2 7. The connecting middle plate 3 is provided with a connecting ring 8 bound by the hoist rope, and the front of the connecting middle plate 3 is provided with a driving cylinder 9, a guiding linear guide rail 10 and a control device 11, and the driving cylinder 9 is connected to the connecting middle plate 3. The plate 3 is fixedly connected, and the first slider (not shown) and the second slider (not shown) are arranged on the guide linear guide rail 10, and the ...

Embodiment 2

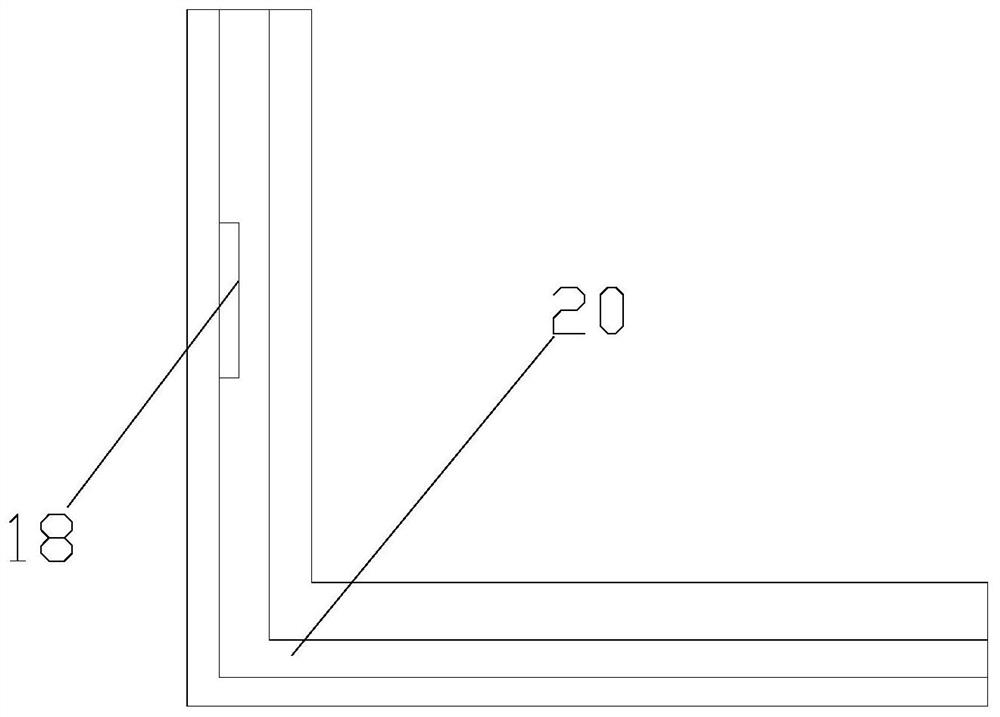

[0029] Such as Figure 1-4 As shown, a building glass curtain wall intelligent hoisting equipment includes a hoist (not shown), a first guide cable 1, a second guide cable 2, and a glass curtain wall fixture. The glass curtain wall fixture includes a connecting middle plate 3, a left V Type clamp arm 4 and right V-shaped clamp arm 5, the back of the connecting middle plate 3 is provided with a first linear bearing 6 matched with the first guide cable 1 and a second linear bearing matched with the second guide cable 2 7. The connecting middle plate 3 is provided with a connecting ring 8 bound by the hoist rope, and the front of the connecting middle plate 3 is provided with a driving cylinder 9, a guiding linear guide rail 10 and a control device 11, and the driving cylinder 9 is connected to the connecting middle plate 3. The plate 3 is fixedly connected, and the first slider (not shown) and the second slider (not shown) are arranged on the guide linear guide rail 10, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com