Lip type seal

A technology of lip seal and sealing parts, applied in the direction of engine seal, variable capacity pump parts, pump components, etc., can solve the problems of reduced sealing performance and blistering of the sealing lip 75, and achieve the effect of improving the blistering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

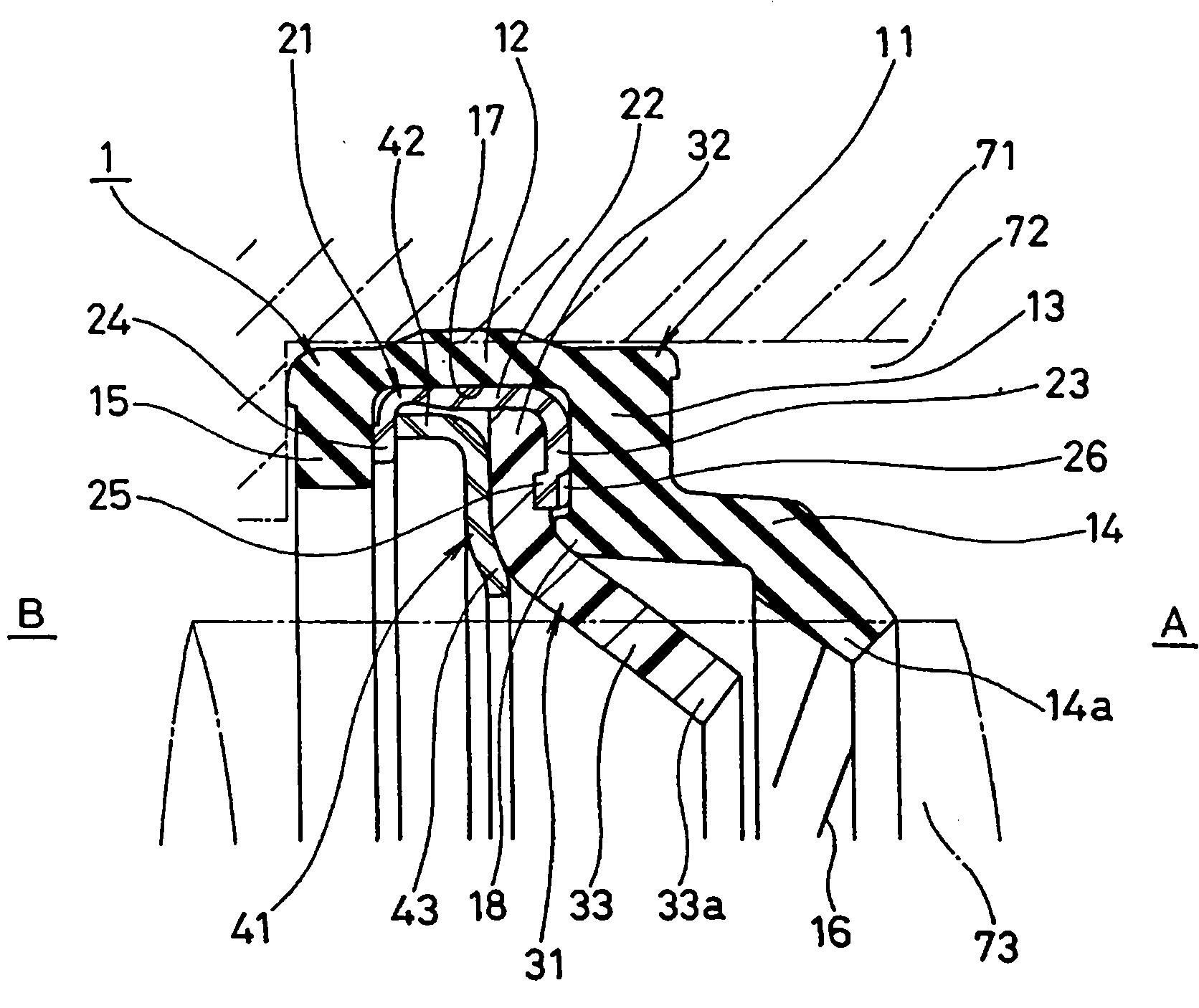

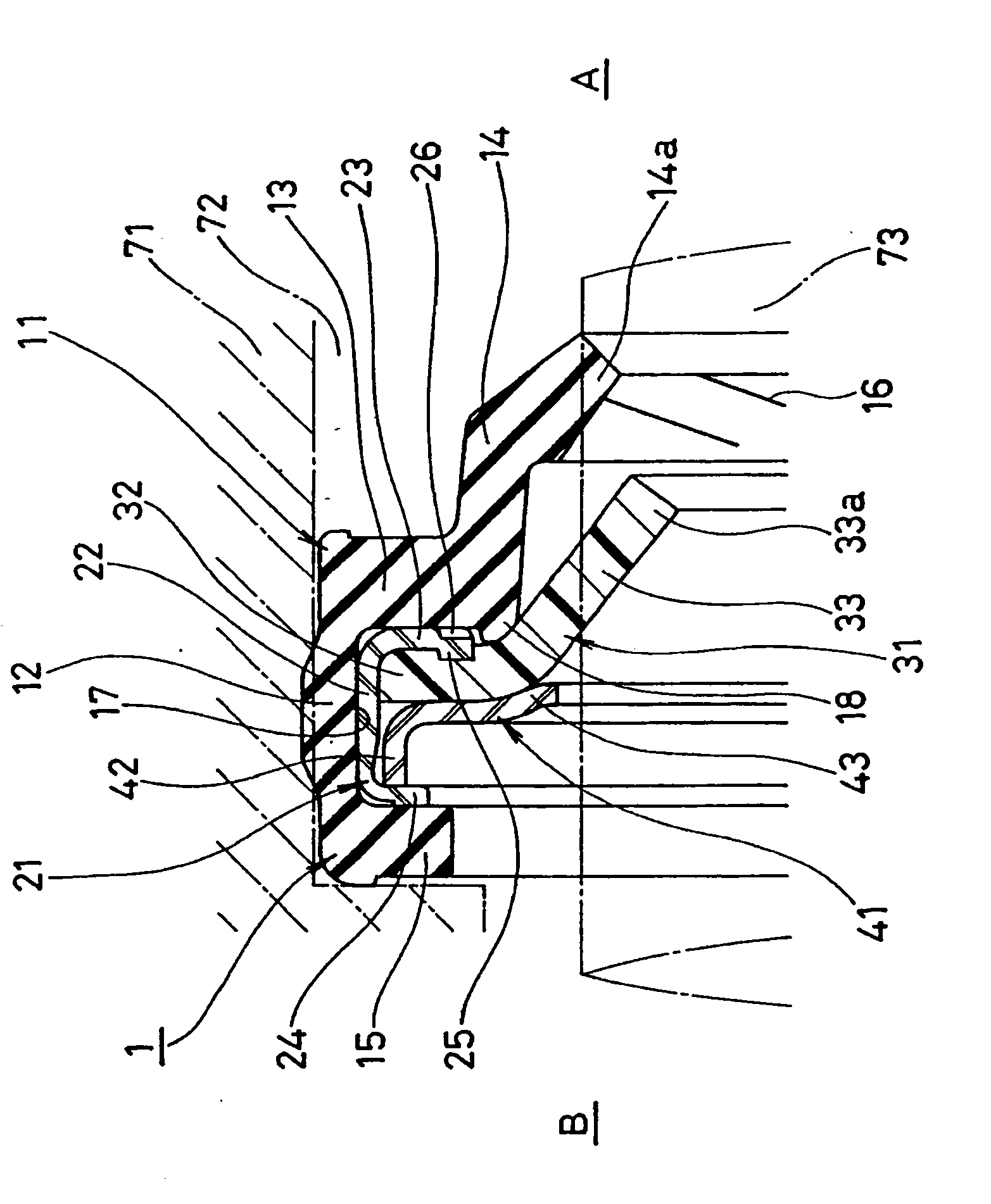

[0078] FIG. 1 shows a cross section of a main part of a lip seal 1 related to a first embodiment of the present invention, and the lip seal 1 is constituted as follows. In addition, this lip seal 1 is used as a water pump seal for automobiles to seal cooling water. The right side of the figure is the cooling water, that is, the seal fluid side A, and the left side of the figure is the atmospheric side B.

[0079] That is, the lip seal 1 is mounted on the inner periphery of the shaft hole (hole) 72 of the casing (pump casing) 71, and is slidably in close contact with the peripheral surface of the shaft (rotation shaft) 73, and is configured to have A double-layered lip structure of the rubber-like elastic sealing lip 14 on the fluid side A and the resin sealing lip 33 arranged on the atmospheric side B.

[0080] In addition, as the components of the lip seal 1, there are the following four parts: the first lip seal member 11 made of a rubber-like elastic body fitted in the inn...

no. 2 example

[0097] In addition, in the above-mentioned first embodiment, although the lip seal 1 is directly fitted into the inner periphery of the shaft hole 72 of the casing 71 through the cylindrical portion 12 of the first lip seal member 11, as shown in FIG. It can be installed on the inner periphery of the shaft hole 72 of the casing 71 through the sleeve (metal ring) 51 .

[0098] The sleeve 51 shown in FIG. 2 is made of a predetermined steel material such as metal, such as a stamped product of a metal plate, and is integrally formed into a ring shape. The lip seal 1 having the above-mentioned structure is fitted into the inner peripheral surface of the cylindrical portion 52, and at the same time The outer peripheral surface of the cylindrical portion 52 is fitted into the inner peripheral surface of the shaft hole 72 of the casing 71 . The outer peripheral surface of the cylindrical portion 52 is covered with an outer peripheral seal 53 interposed between the sleeve 51 and the in...

no. 3 example

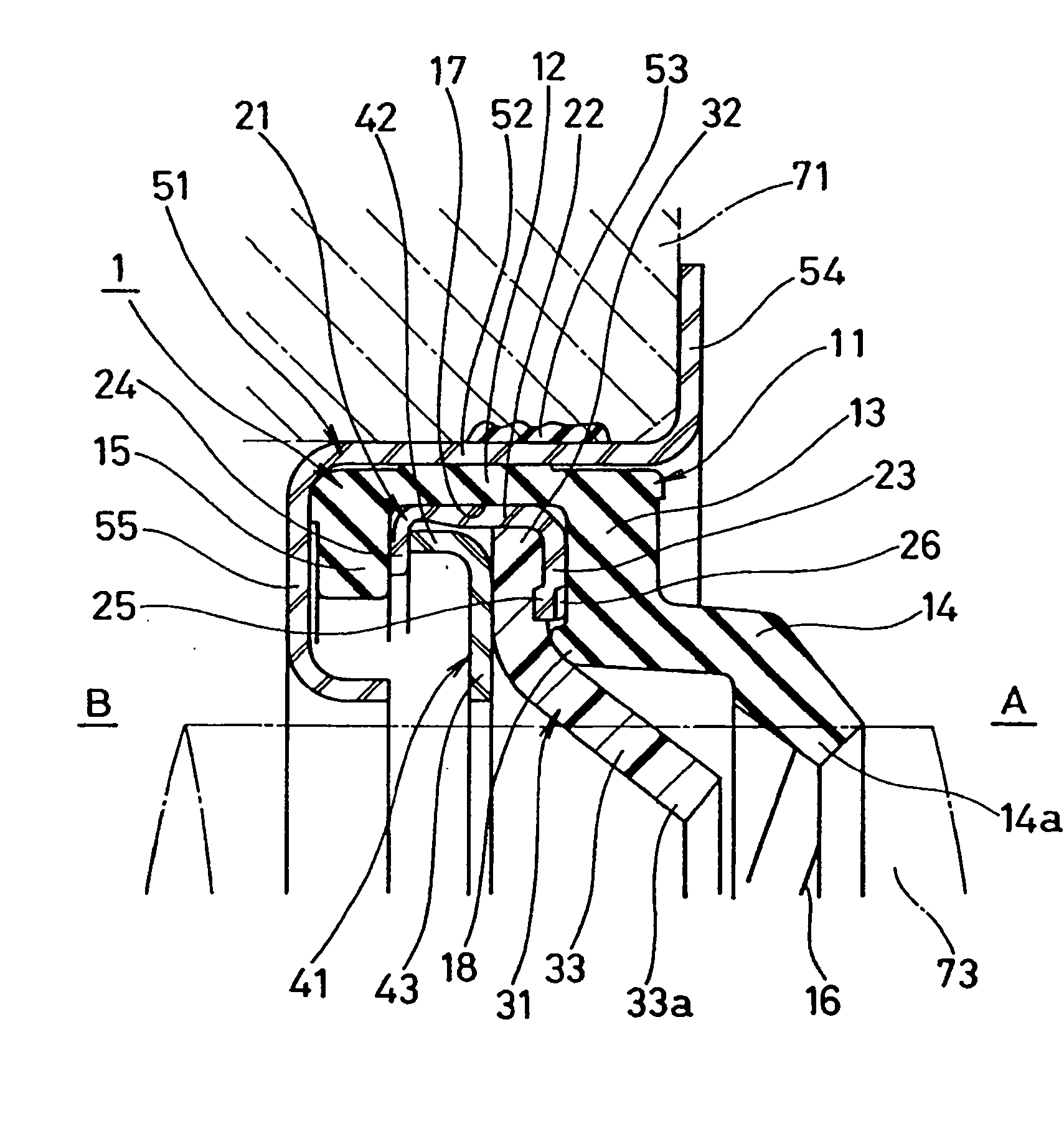

[0100] In addition, the sleeve 51 may be provided with a stepped shape in a planar shape at right angles to the axis on the cylindrical portion 52, or may be provided with a stepped shape with an S-shaped cross section on the cylindrical portion 52. In the above case, the size (diameter) of the sleeve 51 depends on The radial width of the stepped shape is formed in various ways. Therefore, when the lip seal 1 is installed on the actual machine, by selecting the sleeve 51 consistent with the shaft hole diameter of the actual machine, the lip seal 1 can be installed relative to shaft holes 72 of various sizes, thereby improving the lip seal 1. The versatility of type seal 1.

[0101] FIG. 3 shows an example of a sleeve 51 of this type, which is constructed as follows.

[0102] That is, the sleeve 51 is made of a predetermined steel material such as metal, such as a stamped product of a metal plate, is integrally formed in an annular shape, and has a small-diameter cylindrical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com