Method for producing a filtering element

A filter element and filter plate technology, which is applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems that cannot simply ensure the sealing continuity of filter elements, reduce the risk of bad positioning, and reduce waste Quantity and number of manufacturing steps, the effect of reducing cycle time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

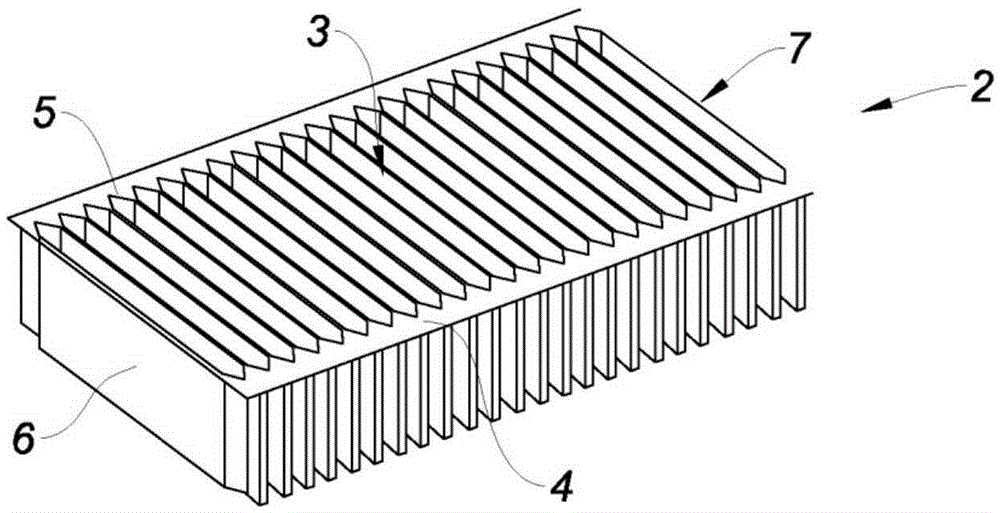

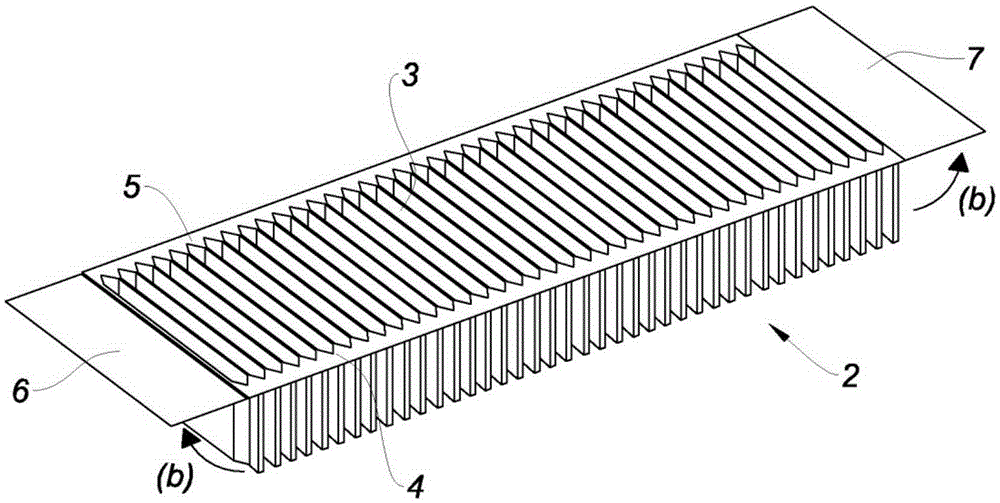

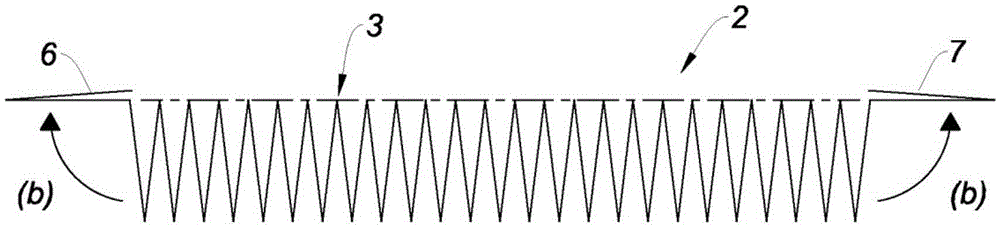

[0046] Figures 1 to 6 The manufacturing method of the filter element 1 is shown. like figure 1 As shown, the method comprises a first step a) consisting in providing a filter panel 2 consisting of a filter medium layer, eg of polyester elastic non-woven material. The synthetic material comprises in particular fibers whose core is of polyester material and whose sheath is of copolyester material, the sheath having a much lower melting point than the core. This layer is pleat folded to present a set of parallel pleats extending transversely between the first and second longitudinal edges 4,5. Usually, this layer is preformed by mooring, by gluing or welding (joining) the longitudinal ends of the folds 3 two by two, shaped with two tailless screws to form the first and second longitudinal ends 4 , 5 . The layer is then kept flat by providing a longitudinal connection, such as an adhesive strip or thin strip on top of the folds 3 (in the figure 1 The face shown is opposite to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com