Vacuum electromagnetic stirring suction-casting system used for composite material

A technology of electromagnetic stirring and composite materials, which is applied in the field of preparation of alloys and composite materials, can solve problems such as segregation of alloy components and easy settlement of reinforcements, and achieve high production efficiency, adjustable filling speed, and stable filling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

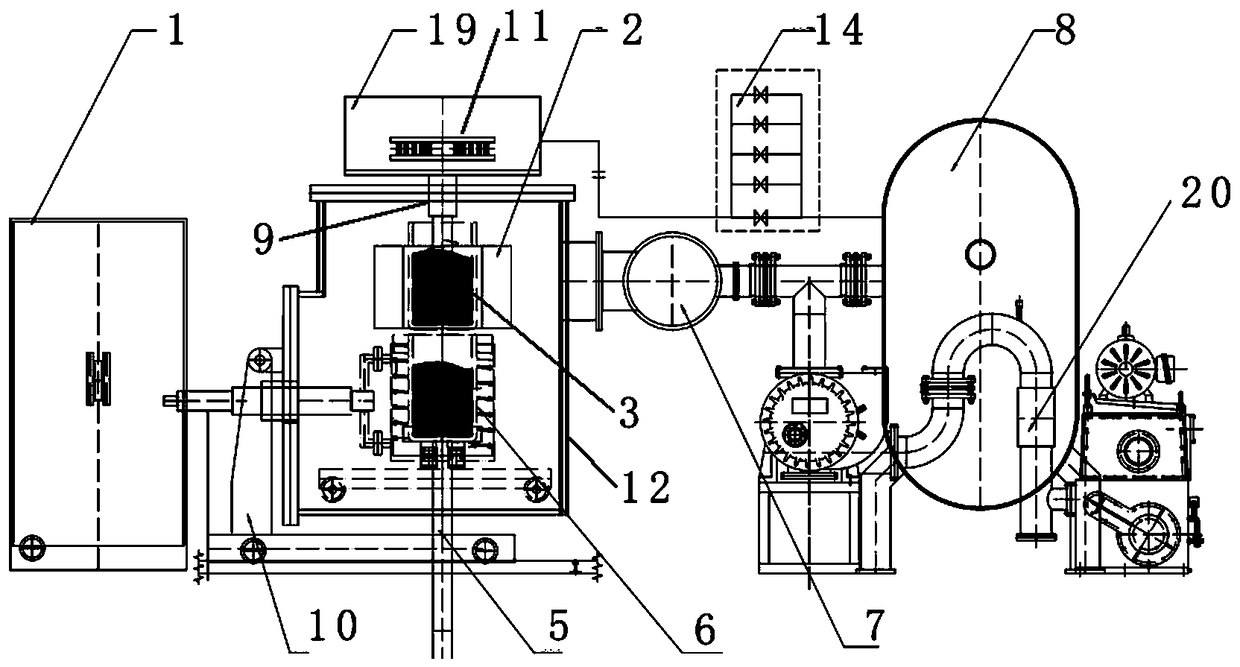

[0020] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 The vacuum electromagnetic stirring suction casting system for composite materials described in this embodiment includes a control cabinet 1, an electromagnetic stirring device 2, a crucible 3, a crucible lifting device 5, an induction melting device 6, a dust filter tube 7, and a vacuum tank 8. Suction casting pipe 9, mold 11, furnace body 12, controller 14, a furnace door track is fixed on the ground at the bottom of the furnace body 12, a furnace door 10 is installed on the furnace door track, and the furnace door 10 on one side of the furnace body 12 The upper part is equipped with a coaxial power feeding device, and an induction melting device 6 is installed on the coaxial power feeding device. The crucible 3 is placed in the induction melting device 6 and can be pushed out along the track wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com