Kitchen waste desanding device

A technology of food waste and sand settling device, which is applied in the swirl device, the device whose axial direction of the swirl can be reversed, and grain processing, etc., can solve the problems of polluting water and the atmosphere, rotting, spreading diseases, etc., to avoid The effect of blocking the pipeline, improving efficiency, and improving crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

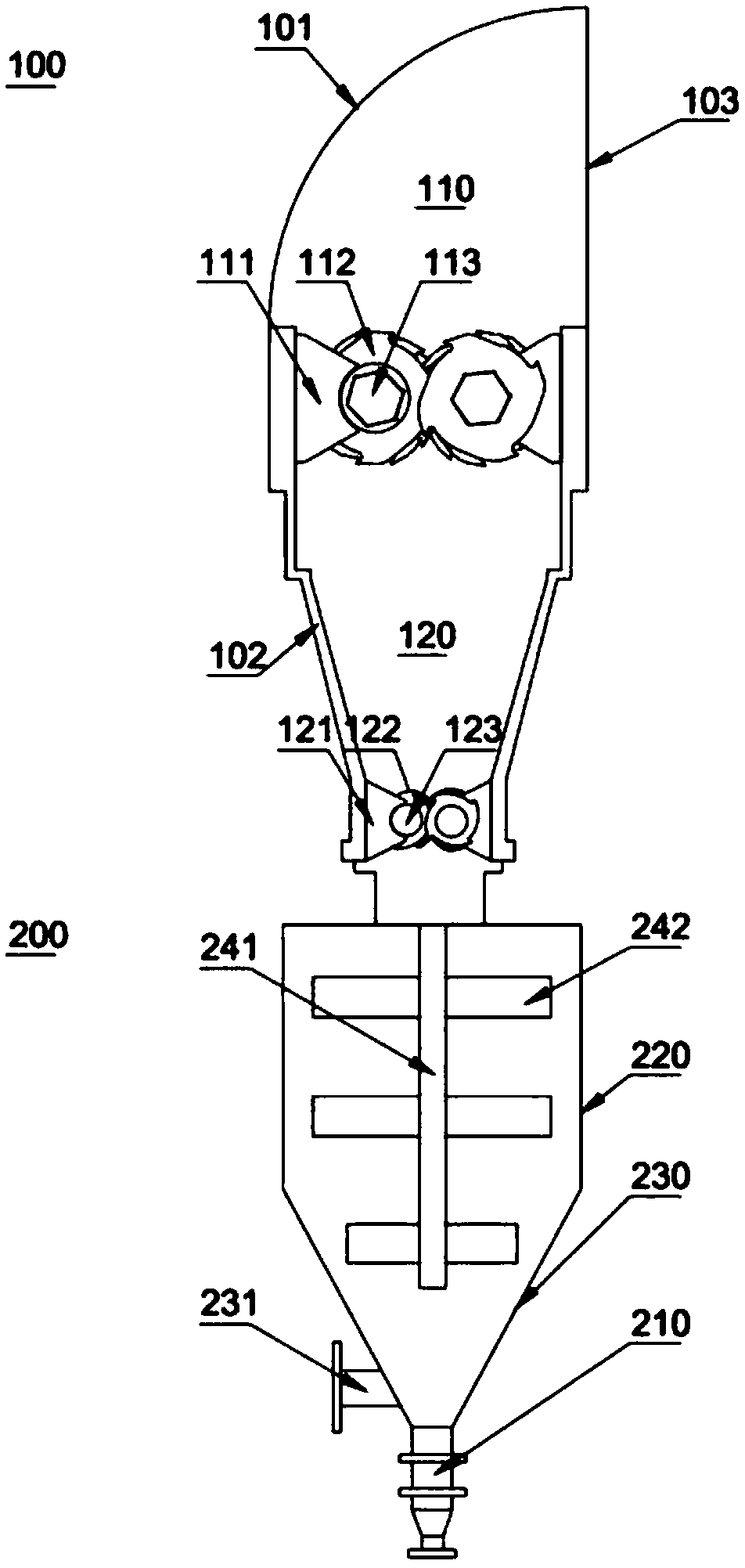

[0027] Such as figure 1 As shown, a food waste desanding device includes a sand settler 200 and a pulverizer 100 arranged on the sand settler 200 .

[0028] The pulverizer 100 includes an upper chamber 101 and a lower chamber 102 which communicate with each other, the upper chamber 101 is provided with a first pulverizing mechanism 110, and the lower chamber 102 is provided with a second pulverizing mechanism 120, so The blade size of the first crushing mechanism 110 is greater than the blade size of the second crushing mechanism 120, so that the size of the material obtained by crushing the first crushing mechanism is greater than the size of the material obtained by crushing the second crushing mechanism; the pulverizer feed port 103 is set On the upper chamber 101 , the pulverizer outlet is arranged on the lower chamber 102 .

[0029] The first crushing mechanism 110 includes a first fixed knife set and a first moving knife set, the first fixed knife set includes a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com