Heat treatment method and heat treatment apparatus

A heat treatment method and technology of a heat treatment device, which are applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as metal gate oxidation, silicon dioxide film thickness increase, etc., achieve short recovery pressure, increase production capacity, and heat treatment The effect of reaction homogenization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

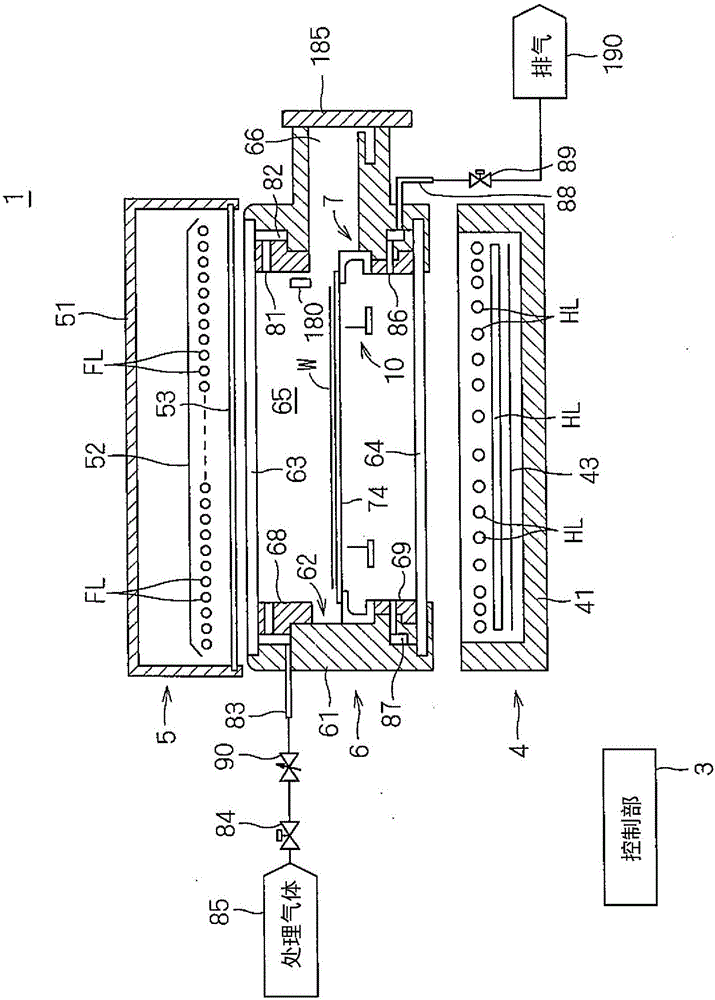

[0121] figure 1It is a longitudinal sectional view showing the structure of the heat treatment apparatus 1 of the present invention. The heat treatment apparatus 1 of this embodiment is a flash lamp annealing apparatus which heats the semiconductor wafer W by irradiating flash light to the disc-shaped semiconductor wafer W which is a board|substrate. The size of the semiconductor wafer W to be processed is not particularly limited, for example, or A high dielectric constant film is formed on the semiconductor wafer W before being carried into the heat treatment apparatus 1 , and post deposition annealing (PDA: Post Deposition Annealing) of the high dielectric constant film is performed by heat treatment of the heat treatment apparatus 1 . In addition, in figure 1 In each of the following figures, the size and quantity of each part are enlarged or simplified as necessary for ease of understanding.

[0122] The thermal processing apparatus 1 has a chamber 6 for accommodati...

no. 2 approach

[0186] Next, a second embodiment of the present invention will be described. The structure of the heat treatment apparatus 1 of the second embodiment is completely the same as that of the first embodiment. In addition, the processing procedure of the semiconductor wafer W in the thermal processing apparatus 1 of the second embodiment is also substantially the same as that of the first embodiment. The second embodiment differs from the first embodiment in that the pressure in the chamber 6 is restored after the pressure in the chamber 6 is decompressed once.

[0187] Figure 11 It is a figure which shows the pressure change in the chamber 6 in 2nd Embodiment. exist Figure 11 in, with Figure 10 Similarly, the horizontal axis represents the time, and the vertical axis represents the pressure in the chamber 6 . in addition, Figure 11 The pattern shown by the dotted line in is the pressure change pattern ( Figure 10 picture of).

[0188] As in the first embodiment, when...

no. 3 approach

[0201] Next, a third embodiment of the present invention will be described. The structure of the heat treatment apparatus 1 of the third embodiment is completely the same as that of the first embodiment. In addition, the processing procedure of the semiconductor wafer W in the thermal processing apparatus 1 of the third embodiment is also substantially the same as that of the first embodiment. The third embodiment differs from the first embodiment in that the pressure inside the chamber 6 changes.

[0202] Figure 12 It is a figure which shows the pressure change in the chamber 6 in 3rd Embodiment. exist Figure 12 in, with Figure 10 Similarly, the horizontal axis represents the time, and the vertical axis represents the pressure in the chamber 6 .

[0203] As in the first embodiment, when the semiconductor wafer W on which the high dielectric constant film 103 is formed is accommodated in the chamber 6 and the transfer opening 66 is closed, the pressure in the chamber 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com