Compressor baffle, compressor and air conditioner

A compressor and baffle technology, applied in the field of compressors, air conditioners, and compressor baffles, can solve problems such as high stiffness and noise generation, and achieve the effects of enhancing ductility, improving performance, and reducing compressor noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

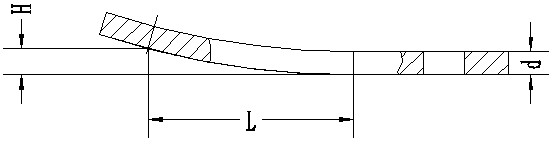

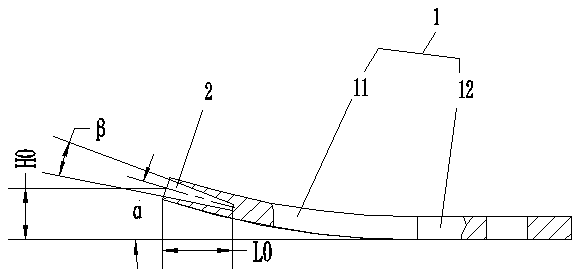

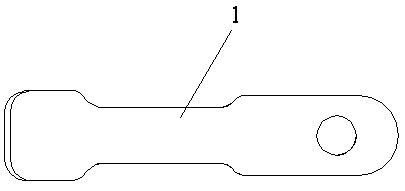

[0019] like figure 2 , image 3 As shown, the present invention proposes a compressor baffle. The baffle 1 is divided into two sections, one section is a vertical section 12, and the other section is a bending section 11 that is bent (or upwardly offset) corresponding to the movement track of the valve plate. , and the end surface of the end that bears the impact of the valve plate is provided with a groove 2, and the baffle 1 is divided into two layers along the thickness direction, so that the end of the baffle 1 is bifurcated along the length direction of the baffle to form a flexible structure that can absorb stress , the two-layer flexible structure stacked along the thickness direction can effectively relieve the impact speed and stress changes of the valve plate on the valve seat and the baffle when the valve plate impacts. The ductility of the exhaust valve also helps to relieve the impact of the exhaust valve plate on the valve plate baffle, reduce exhaust resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com