Coal-fired ultrafine grain chemical agglomeration promotor

An ultra-fine particle, chemical agglomeration technology, applied in the fields of energy and environment, can solve the problems of insignificant promotion of ultra-fine particle agglomeration, poor wettability, inability to effectively adjust the specific resistance of particles, etc., to achieve easy operation, environmental friendliness, The effect of price economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the agglomeration accelerator of the present invention is: add tap water in the mixer (when two polymer compounds of reducing gum and sodium carboxymethyl cellulose are selected as components, the tap water should be warmed up to 40-60°C to promote its dissolution) , while stirring, add the water-soluble polymer compound. After the polymer compound is completely dissolved, add the surfactant, pH regulator, and inorganic salt additive and stir until completely dissolved and mixed evenly.

[0015] The agglomeration accelerator can be stored independently according to the components before use, or it can be stored in a high-concentration solution in proportion (diluted with tap water in proportion when used), but the time should not exceed one week.

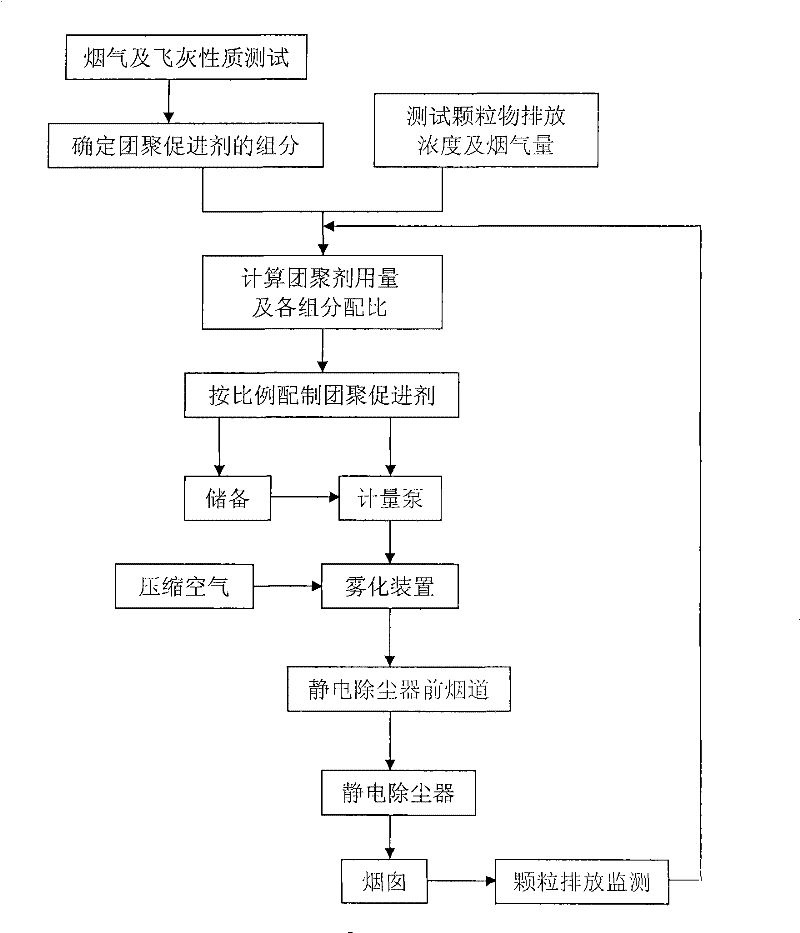

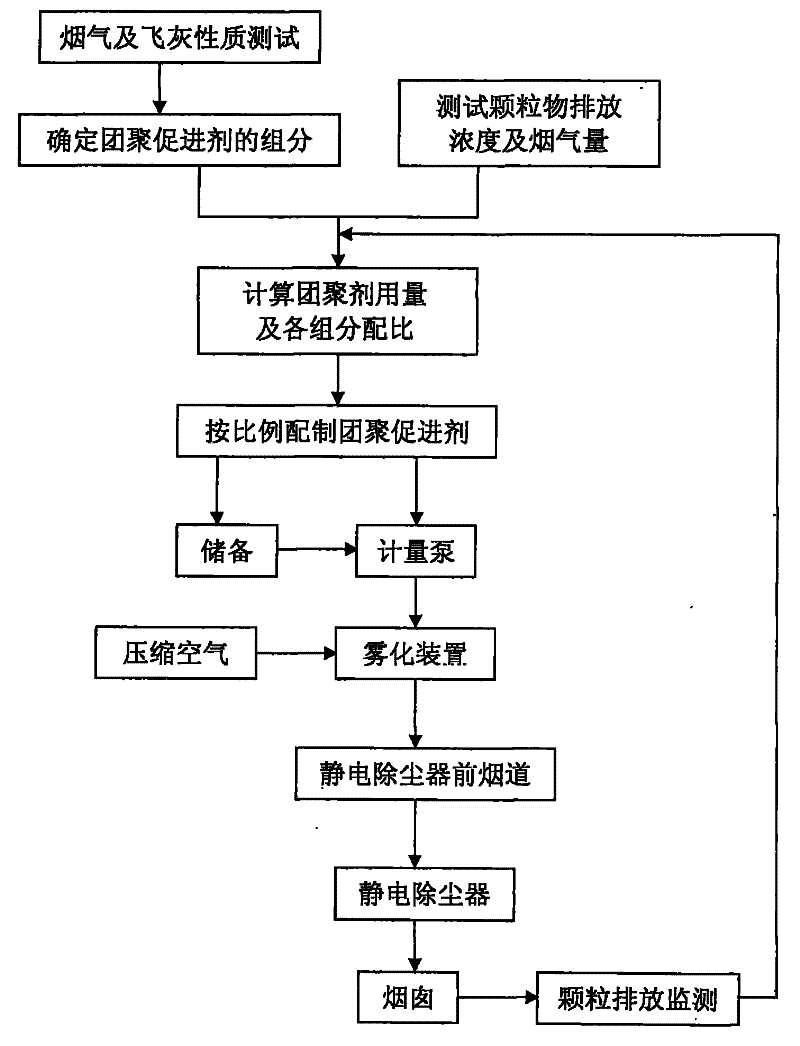

[0016] Such as figure 1 As shown, the agglomeration accelerator of the present invention is used in the following manner to carry out chemical agglomeration technical transformation of the electrosta...

example (1

[0020] Triton X 100 0.001%

[0021] Xanthan Gum 0.0001%

[0022] Phosphoric acid 0.1%

[0023] Ammonium Phosphate 0.001%

[0024] Water 99.8979%

example (2

[0026] Sodium dodecylbenzenesulfonate 0.05%

[0027] Reductive gum 0.005%

[0028] Phosphoric acid 0.005%

[0029] Sodium polyphosphate 0.01%

[0030] Tap water 99.93%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com