Method for implementing trapping and separation of CO2 in flue gas by adopting magnesium-based absorbent

An absorbent and flue gas technology, applied in the field of CO2 capture and separation in flue gas, can solve the problems of large equipment investment, high capture cost, large energy consumption, etc. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

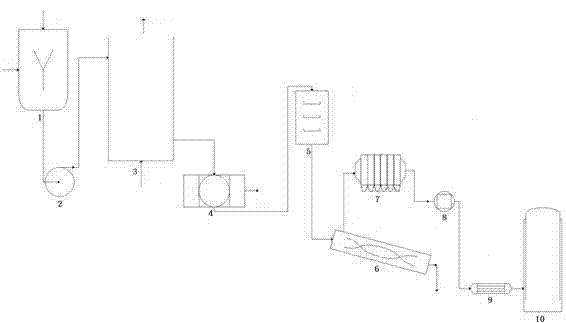

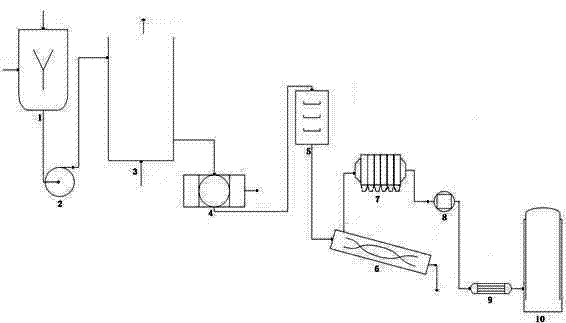

[0026] This embodiment combines the attached figure 1 Process of the present invention is further described in detail:

[0027] Add MgO to Absorbent Preparer 1, then add water to prepare Mg(OH) 2 Suspension, the solid-to-liquid ratio (mass ratio) of the suspension is controlled to be 3.5, and the suspension is transported by the slurry pump 2 to the CO with stirring function 2 In the absorber 3, the CO in the flue gas passed from the bottom of the absorber 2 Carry out carbonation reaction, control the pH value of the absorption system to 10.2, the temperature is 13.5°C, the CO in the flue gas passed into the absorber 2 The ratio of the amount of substance to the total amount of magnesium in the absorbent is 1.0, and the volume ratio of the absorbent to the flue gas in the absorber is 3.5;

[0028] from CO 2 The treated flue gas from the absorber 3 is discharged from the top, and the reacted mixture enters the centrifuge 4 for solid-liquid separation, and the obtained liqui...

Embodiment 2

[0031] Add MgO to the Absorbent Maker, then add water to make Mg(OH) 2 Suspension, the solid-liquid ratio (mass ratio) of the suspension is controlled to be 0, and the suspension is transported by the slurry pump to the CO with stirring function 2 In the absorber, with the CO in the flue gas 2Carry out carbonation reaction, control the pH value of the absorption system to 8.5, the temperature is 50.0°C, and the CO in the flue gas passed into the absorber 2 The ratio of the amount of substance to the total amount of magnesium in the absorbent is 0.9, and the volume ratio of the absorbent to the flue gas in the absorber is 1.8;

[0032] from CO 2 The reacted mixture from the absorber enters the centrifuge for solid-liquid separation, and the obtained liquid is circulated to the absorbent preparation process for recycling, and the obtained solid MgCO 3 ·3H 2 The O crystal is heated and dried to remove the physical moisture and chemical moisture in it, and the temperature is c...

Embodiment 3

[0035] Add MgO to the Absorbent Maker, then add water to make Mg(OH) 2 Suspension, the solid-to-liquid ratio (mass ratio) of the suspension is controlled to be 2.0, and the suspension is transported by the slurry pump to the CO with stirring function 2 In the absorber, with the CO in the flue gas 2 Carry out carbonation reaction, control the pH value of the absorption system to 9.0, the temperature is 30°C, and the CO in the flue gas passed into the absorber 2 The ratio of the amount of substance to the total amount of magnesium in the absorbent is 0.95, and the volume ratio of the absorbent in the absorber to the flue gas is 3.0 times;

[0036] from CO 2 The reacted mixture from the absorber enters the centrifuge for solid-liquid separation, and the obtained liquid is circulated to the absorbent preparation process for recycling, and the obtained solid MgCO 3 ·3H 2 The O crystal is heated and dried to remove the physical moisture and chemical moisture in it, and the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com