High-efficiency antibody fixing method of biological chip

A biochip, antibody immobilization technology, applied in biological testing, material inspection products, instruments, etc., can solve the problems of low spot uniformity, low detection limit, low signal intensity, etc., to solve the problem of weak adsorption and avoid antibody shedding , the effect of increasing the capture capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

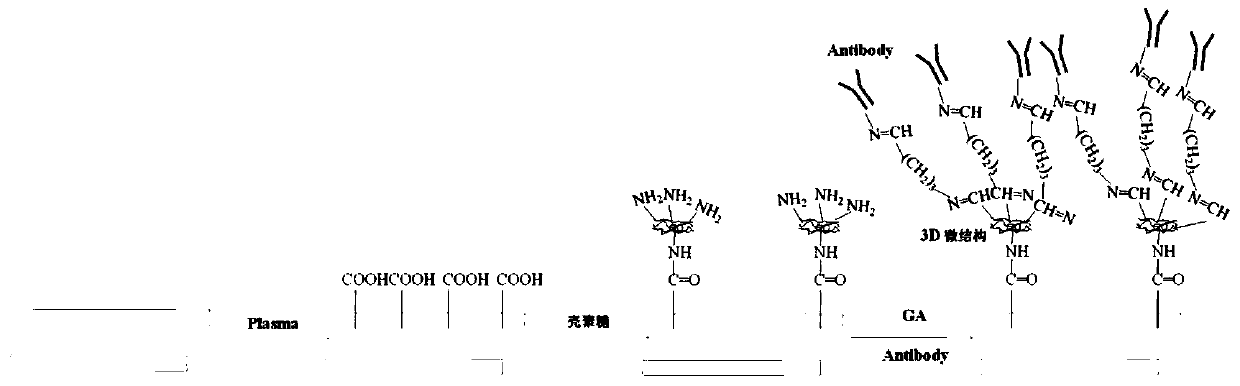

[0056] In this embodiment, a high-efficiency antibody immobilization method for biochips specifically includes the following steps:

[0057] (1) Cleaning of biochips: The untreated PS substrate chips were ultrasonically cleaned with deionized water and dried with nitrogen gas.

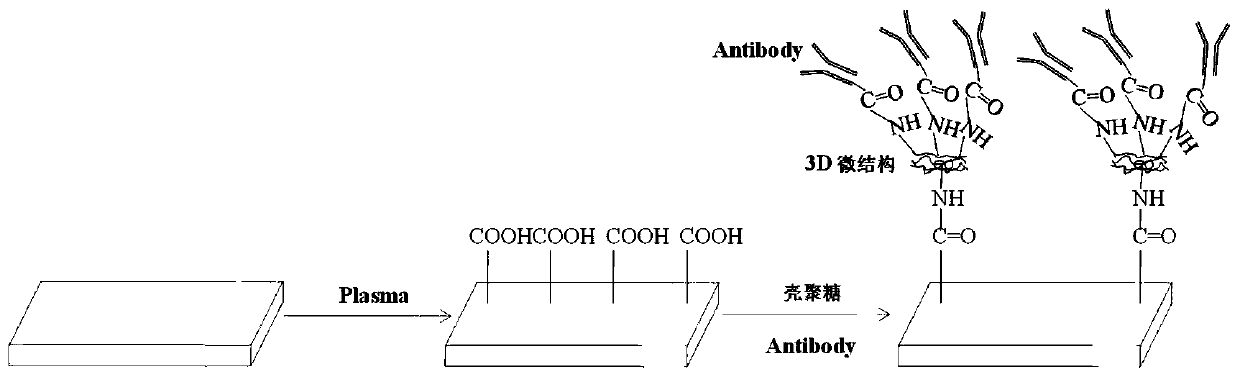

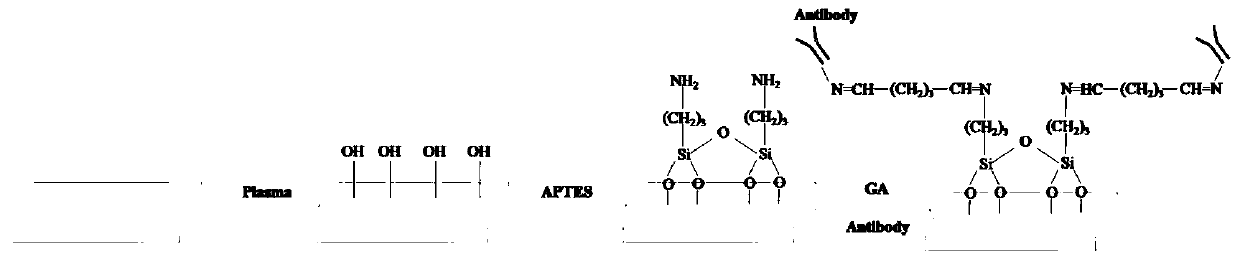

[0058] (2) Biochip surface activation treatment: the cleaned PS substrate chip was activated for 90 s under the conditions of a plasma oxygen flow rate of 500 mL / min and a generation power of 150 w.

[0059] (3) 3D microstructure construction: the plasma-activated PS substrate chip was placed in a chitosan-acetic acid solution with a mass concentration of 0.5 mg / mL, and treated at 37°C for 60 minutes to obtain a 3D microstructure treatment of biochips.

[0060] (4) Grafting of the coupling layer: the obtained 3D microstructure biochip was placed in a glutaraldehyde solution with a volume fraction of 2%, treated at 37° C. for 30 minutes, washed with deionized water and dried for later use.

[0061] (5...

Embodiment 2

[0070] In this embodiment, a high-efficiency antibody immobilization method for biochips specifically includes the following steps:

[0071] The previous 4 steps of biochip cleaning, biochip surface activation treatment, 3D microstructure construction, coupling layer grafting are the same as those in Example 1.

[0072] (5) Immobilization of antibodies: Using a biochip spotter, spot 2uL of antibodies coupled with fluorescent microspheres to a specific area on the chip surface, and incubate for 2 hours at a temperature of 37°C and a humidity of 80%.

[0073] (6) A fluorescence quantitative analyzer is used to detect the fluorescence intensity value of the spotting area.

[0074] (7) Blocking and elution: Soak the chip in BSA solution with a mass concentration of 1% for 30 minutes, then use 0.5% PBST and deionized water to clean the surface of the chip in turn, blow dry with nitrogen, and detect the spotting area with a fluorescence quantitative analysis instrument the fluoresc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com