Waste gas absorption and purification equipment

A technology for purifying equipment and waste gas, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as difficulty in eliminating exhaust gas, low efficiency and effect of liquid separation, and difficulty in removing fine droplets, etc. The effect of improving absorption efficiency, increasing gas-liquid contact area, and strong trapping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

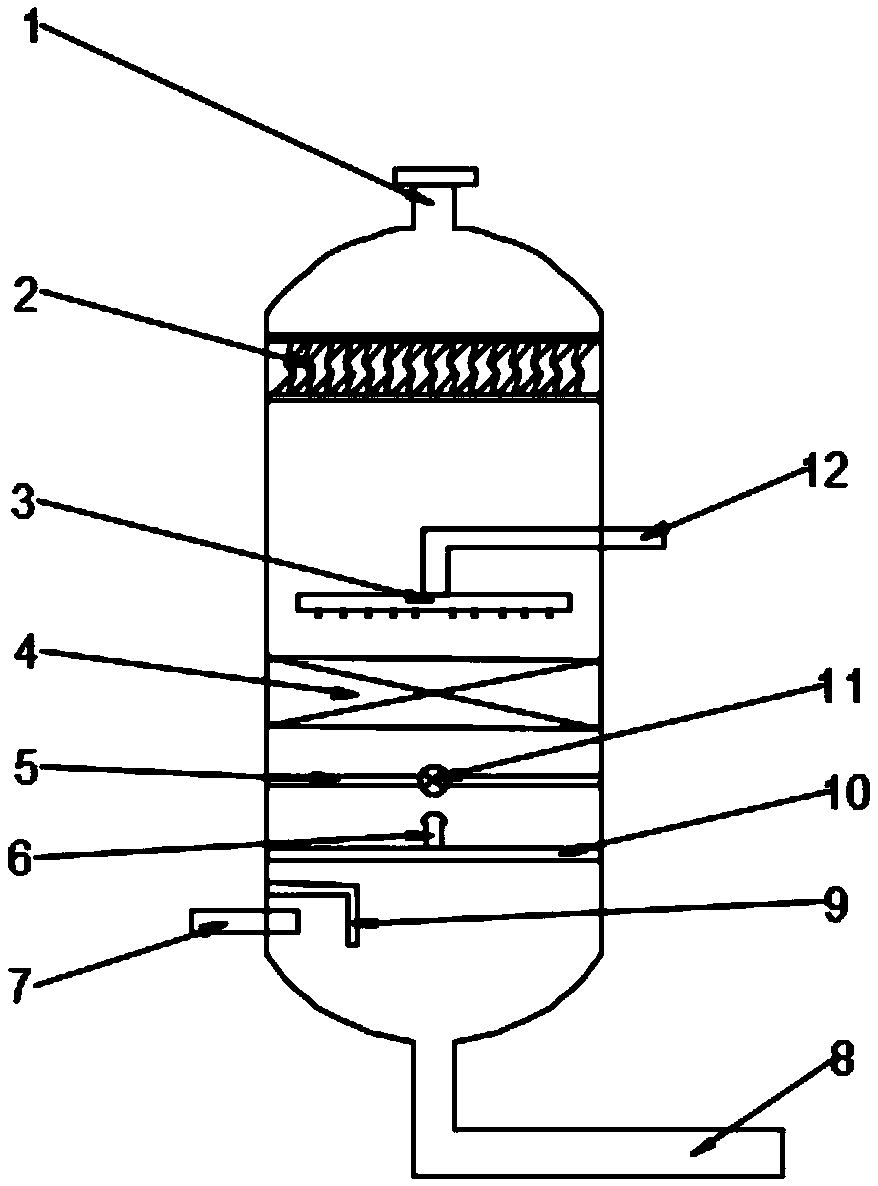

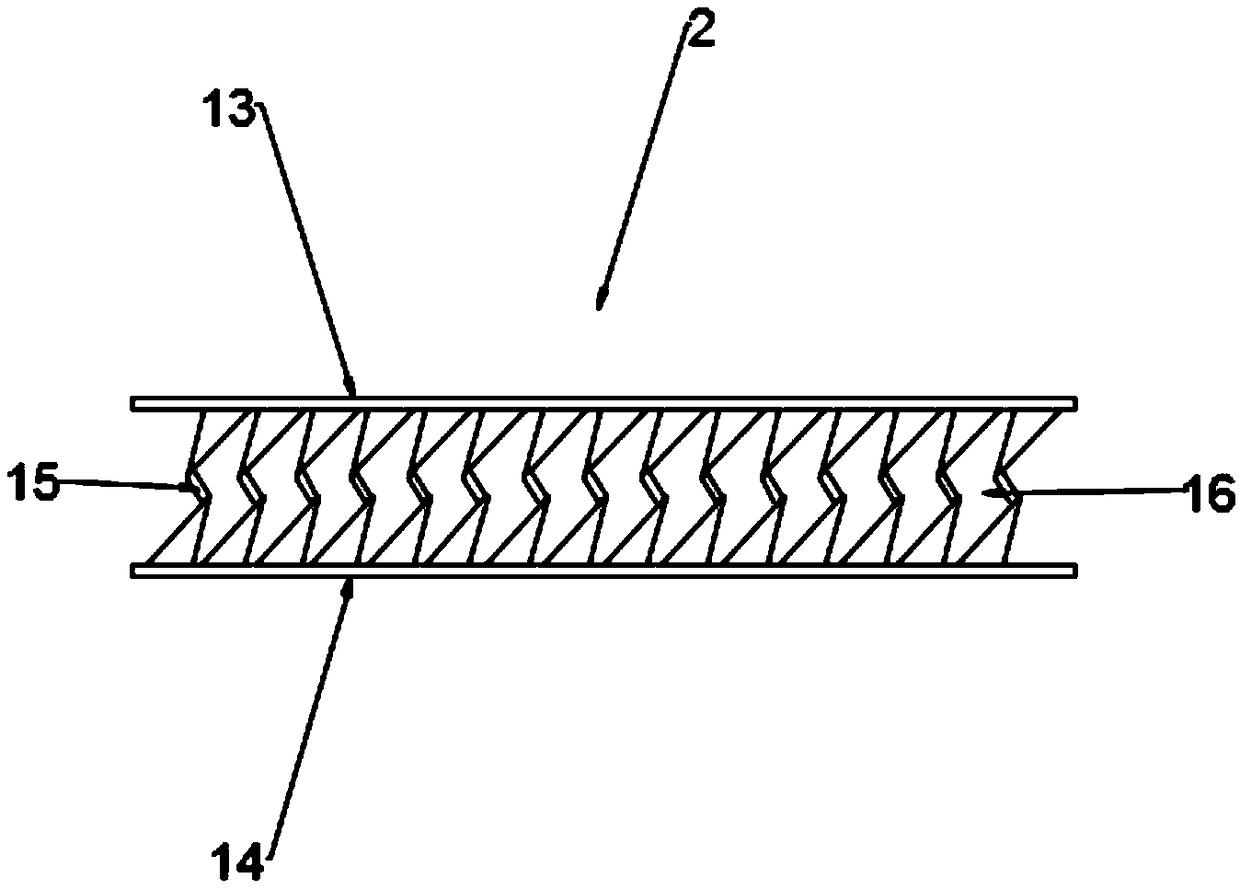

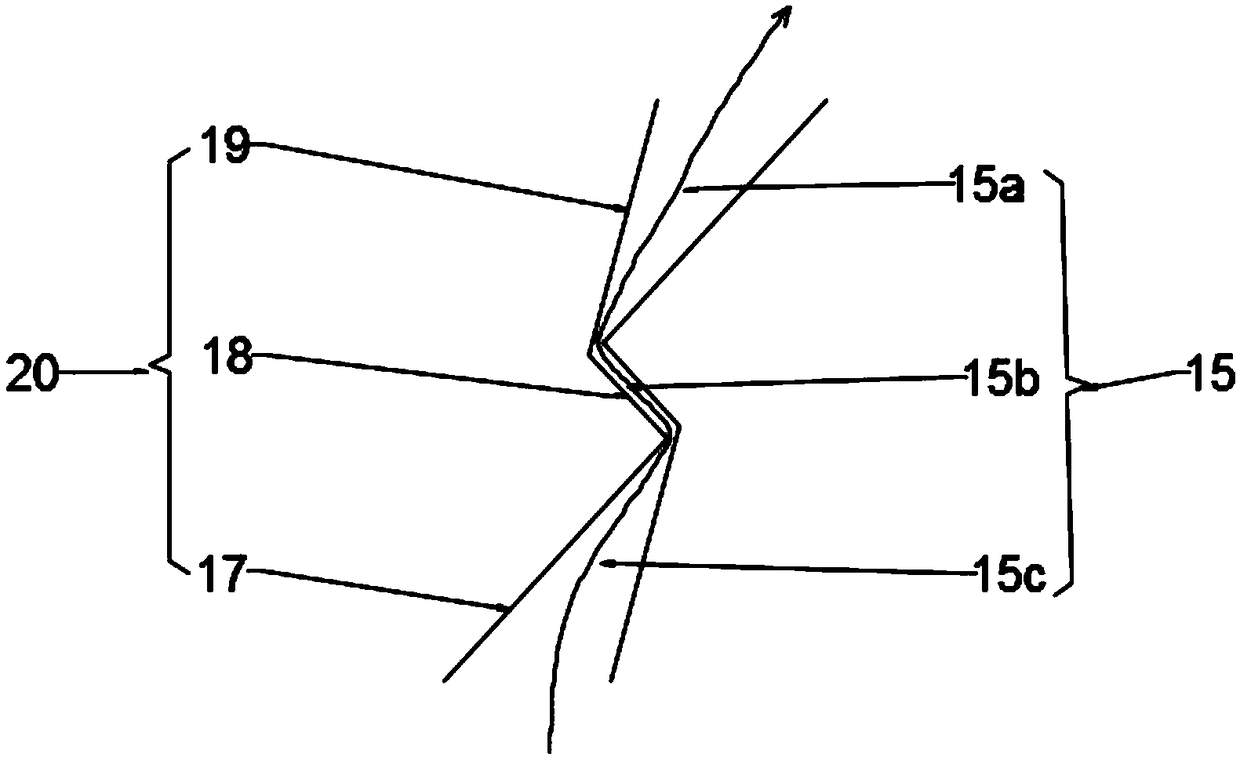

[0023] see Figure 1-4 , a waste gas absorption and purification equipment, comprising a gas outlet 1, a gas inlet 7, a liquid outlet 8 and a liquid inlet 12, the liquid inlet 12 is connected to a liquid distributor 3, and a gas-liquid separation device 2 is arranged above the liquid distributor 3, The gas-liquid separation device 2 is located on the upper part of the absorption tower, between the gas outlet 1 and the liquid inlet 12; the gas-liquid separation device 2 includes a first support 13 and a second support 14, the first support 13 and the second support A first baffle 17, a second baffle 18 and a third baffle 19 are arranged between the supports 14; the first baffle 17, the second baffle 18 and the third baffle 19 form a The baffles 20, the gas-liquid separation device 2 includes a plurality of baffles 20 arranged in parallel, and the first flow channels 15 and the second flow channels 16 arranged in a staggered manner are formed between adjacent baffles 20; After ...

Embodiment 2

[0029] Compared with Example 1, a gas-liquid separation plate 9 is arranged above the gas inlet 7 corresponding to the gas inlet 7, as figure 1 As shown, the gas-liquid separation plate 9 is located below the second separator 10, and the gas-liquid separation plate 9 can separate the gas passed through for the first time from gas to liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com