Efficient energy-saving non-aqueous absorbent used for capturing carbon dioxide and application

A carbon dioxide, high-efficiency and energy-saving technology, used in reagents, chemical industry, organic chemistry, etc., can solve the problems of high material cost, high viscosity in the absorption process, low capture capacity, etc., to improve mass transfer capacity and reduce energy consumption for desorption. , the effect of increasing the capture capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

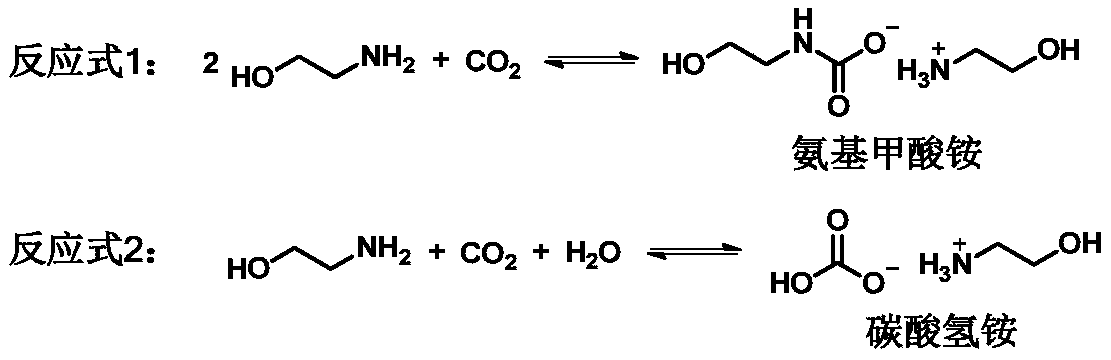

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 2mL of N-(2-methoxyethyl)-N,N'-dimethylethylenediamine into a 10mL glass container with an inner diameter of 1.5cm, and then slowly introduce carbon dioxide gas at a flow rate of 40mL / min. The absorption temperature is 0.1MPa, and the absorption temperature is controlled at 25°C. Weigh and record the absorption amount with an electronic balance every five minutes. Three consecutive readings are close to reach the absorption balance, and take samples to measure the absorption saturation viscosity with a viscometer. The absorption saturation viscosity of N-(2-methoxyethyl)-N,N'-dimethylethylenediamine is 124cP, and the carbon dioxide capture capacity is 0.72mol CO 2 / mol absorbent (22wt%), the absorption time is 25min.

Embodiment 2

[0028] Add 2mL of N-(2-methoxyethyl)-N,N'-dimethylethylenediamine into a 10mL glass container with an inner diameter of 1.5cm, and then slowly introduce carbon dioxide gas at a flow rate of 40mL / min. The absorption temperature is 0.1MPa, the absorption temperature is controlled at 40°C, the absorption is recorded by weighing with an electronic balance every five minutes, and the absorption balance is reached when the readings are similar for three consecutive times, and the absorption saturation viscosity is measured with a viscometer. The absorption saturation viscosity of N-(2-methoxyethyl)-N,N'-dimethylethylenediamine is 41cP, and the carbon dioxide capture capacity is 0.70mol CO 2 / mol absorbent (21wt%), the absorption time is 20min.

Embodiment 3

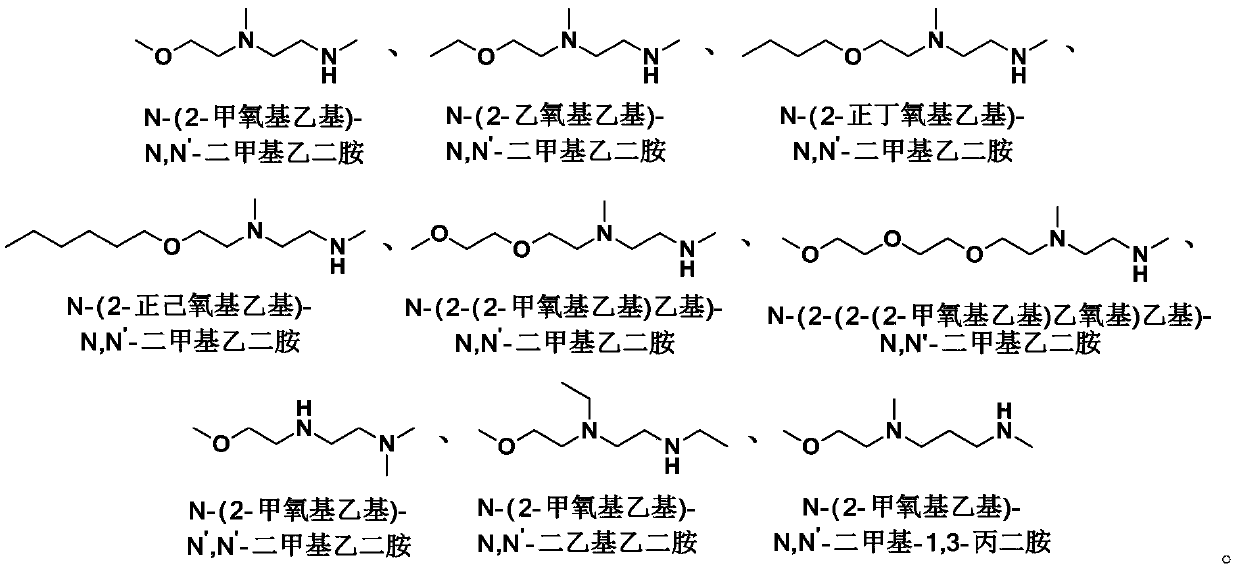

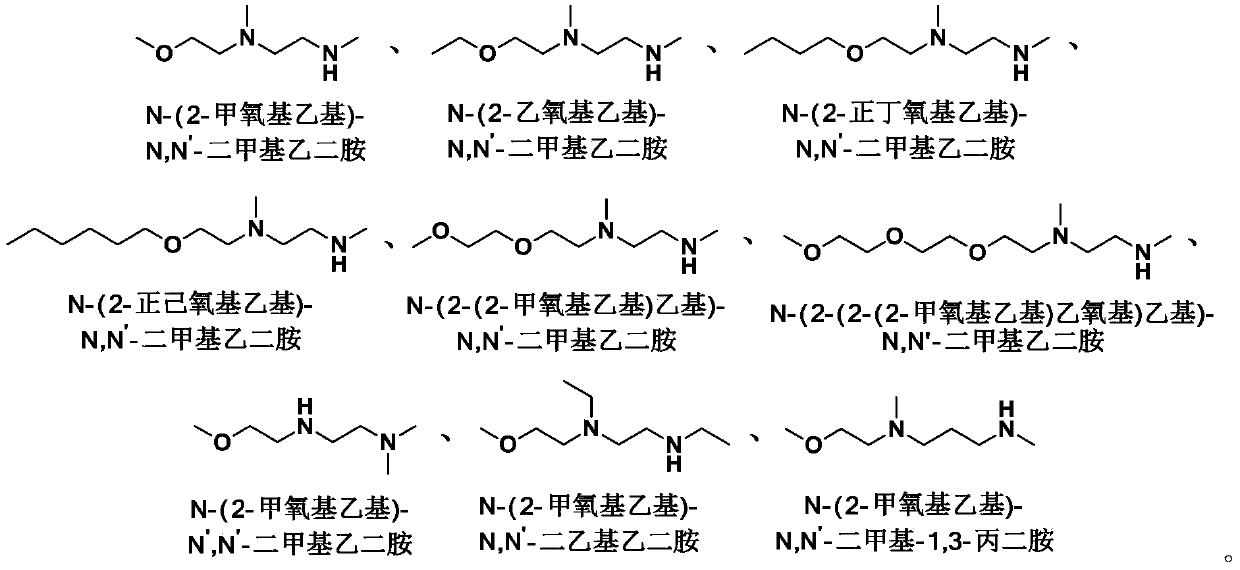

[0030] Similar to Example 1 and Example 2, control the carbon dioxide absorption pressure to 0.1MPa, the absorption temperature to 25°C or 40°C, change the type of alkoxy-functionalized fatty diamine, and obtain the absorption at 25°C or 40°C Saturation viscosity and collection capacity are shown in the following table (Table 1).

[0031] Table 1 Effect of structures of different alkoxy functionalized aliphatic diamines on carbon dioxide capture

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com