Method for mixing amido ionic liquid and ethanol amine in micro-channel for adsorbing carbon dioxide

A carbon dioxide and ionic liquid technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as strong corrosion of equipment, difficulty in ensuring equipment safety, and high volatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

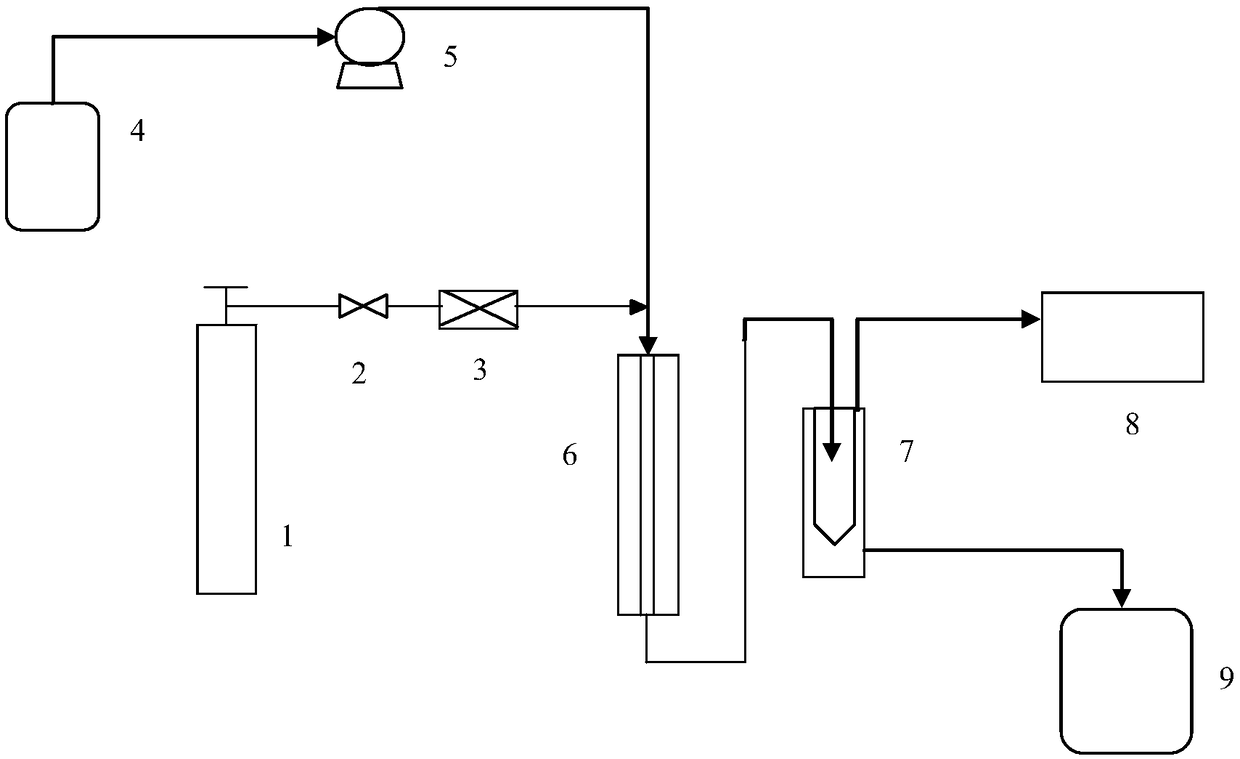

[0012] The absorption process is shown in the figure. The microchannel reactor has a diameter of 2mm and a length of 30cm. The operating conditions are: temperature 25°C, pressure 1atm, and the mass ratio of amine-based ionic liquid to ethanolamine in the absorbent is 3:7. Carbon dioxide enters from the gas inlet as a gas phase, and the gas phase flow rate is controlled at 20mL min -1 , the mixed solution of amine-based ionic liquid and ethanolamine enters from the liquid inlet as an absorbent, and the liquid phase flow rate is 200mL·h -1 , and the removal rate of carbon dioxide is 0.953 at this time, which shows that the technology of absorbing carbon dioxide by this method can significantly remove carbon dioxide in the material compared with the traditional method. Desorption is carried out under certain conditions to remove the carbon dioxide contained therein. The desorption operating conditions are: temperature 110°C, pressure 1atm, time 2h, and the absorbent can be recy...

Embodiment 2

[0018] The absorption process is shown in the figure. The microchannel reactor has a diameter of 2mm and a length of 30cm. The operating conditions are: temperature 25°C, pressure 1atm, and the mass ratio of amine-based ionic liquid to ethanolamine in the absorbent is 2:8. Carbon dioxide enters from the gas inlet as a gas phase, and the gas phase flow rate is controlled at 20mL min -1 , the mixed solution of amine-based ionic liquid and ethanolamine enters from the liquid inlet as an absorbent, and the liquid phase flow rate is 200mL·h -1 , the removal rate of carbon dioxide is 0.888 at this time, indicating that compared with the traditional method, the technology of absorbing carbon dioxide by this method can significantly remove carbon dioxide in the material. Desorption is carried out under certain conditions to remove the carbon dioxide contained therein. The desorption operating conditions are: temperature 110°C, pressure 1atm, time 2h, and the absorbent can be recycled...

Embodiment 3

[0024] The absorption process is shown in the figure. The microchannel reactor has a diameter of 2mm and a length of 30cm. The operating conditions are: temperature 25°C, pressure 1atm, and the mass ratio of amine-based ionic liquid to ethanolamine in the absorbent is 1:9. Carbon dioxide enters from the gas inlet as a gas phase, and the gas phase flow rate is controlled at 20mL min -1 , the mixed solution of amine-based ionic liquid and ethanolamine enters from the liquid inlet as an absorbent, and the liquid phase flow rate is 200mL·h -1 , the removal rate of carbon dioxide is 0.821 at this time, which shows that the technology of absorbing carbon dioxide by this method can significantly remove carbon dioxide in the material compared with the traditional method. The absorbent rich in carbon dioxide flowing out from the reactor is heated and reduced Desorption is carried out under certain conditions to remove the carbon dioxide contained therein. The desorption operating cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com