A used to extract from the co 2 desorb co from the solution 2 film and its preparation method

A technology of CO2 and solution, which is applied in the field of CO2 desorption membrane and its preparation, can solve the problems of large solvent loss, high energy consumption, unsuitable solvent recovery, etc., and achieve the effect of reducing desorption energy consumption and reducing absorbent loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

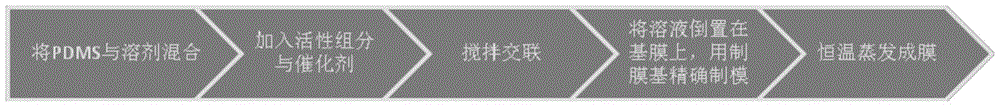

[0021] according to figure 1 The flow chart shown is prepared for the preparation from CO containing 2 CO desorbed from the solution 2 Membrane: take PDMS12.3g, add solvent n-heptane 40g, stir evenly, add active component vinyltrimethoxysilane 2g, add catalyst dibutyltin dilaurate 0.5g, stir at 25°C for 3h, use Mechanism film, the base film is polyacrylonitrile, the thickness of the active layer is controlled to 30 μm, the film is evaporated, and the absorption and desorption system is methanol-CO 2 , the permeation flux of this membrane is 0.7kg / (h*m2), and the enrichment factor reaches 23.

Embodiment 2

[0023] according to figure 1 The flow chart shown is prepared for the preparation from CO containing 2 CO desorbed from the solution 2 Membrane: take PDMS12.3g, add solvent n-hexane 50g, stir evenly, add active components ethyl silicate 0.5g, phenyltriethoxysilane 1.8g, add catalyst dibutyltin dilaurate 0.6g, at 25 Stir at ℃ for 4 hours, use a film-making mechanism to make a film, the base film is polydimethylsulfoxide, control the thickness of the film layer to 15 μm, evaporate to form a film, and the absorption and desorption system is dimethyl carbonate-CO 2 , the permeation flux of this membrane is 0.8kg / (h*m2), and the enrichment factor reaches 35.

Embodiment 3

[0025] according to figure 1 The flow chart shown is prepared for the preparation from CO containing 2 CO desorbed from the solution 2 Membrane: take PDMS12.3g, add solvent n-hexane 50g, stir evenly, add active components ethyl silicate 0.5g, N-aminoethyl-3-aminopropyltrimethoxysilane 0.8g, polydopamine 2.1g Add the catalyst dibutyltin dilaurate 0.65g, stir at 25°C for 4 hours, use a film-making mechanism to make a film, the base film is polydimethylsulfoxide, control the thickness of the film layer to 70 μm, evaporate to form a film, and the absorption and desorption system is propylene carbonate -CO 2 , the permeation flux of this membrane is 0.78kg / (h*m2), and the enrichment factor reaches 50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| enrichment factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com