Nitrogen azole metal salt absorbent solution for acid gases and application thereof

A technology of metal salt solution and acid gas, which is applied in the direction of absorption, adsorption, and separation of dispersed particles, can solve the problems of complex synthesis process, high cost of raw materials and synthesis, high viscosity, etc., and achieve simple preparation method, absorption/desorption Fast speed and low absorption enthalpy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0040] CO on 5% TrizNa-PEG200 solution system 2 The absorption capacity is tested, the absorption condition is 30°C, 1atm, pure CO 2 atmosphere, CO 2 The flow rate is 50ml / min. Measured CO after 80min 2 The absorption capacity is 28.3mg CO 2 / g solution.

[0041] Under the same test conditions, the CO of TrizNa-PEG200 solution system with different concentrations 2 Absorption data are listed in Table 1.

[0042] Table 1 CO of TrizNa-PEG200 solution system with different concentrations 2 absorb data

[0043]

Embodiment 5-8

[0045] CO on 5% TrizK-PEG200 solution system 2 The absorption capacity is tested, the absorption condition is 10 ℃, 1atm, pure CO 2 atmosphere, CO 2 The flow rate is 50ml / min. Measured CO after 100min 2 The absorption capacity is 27.3mg CO 2 / g solution.

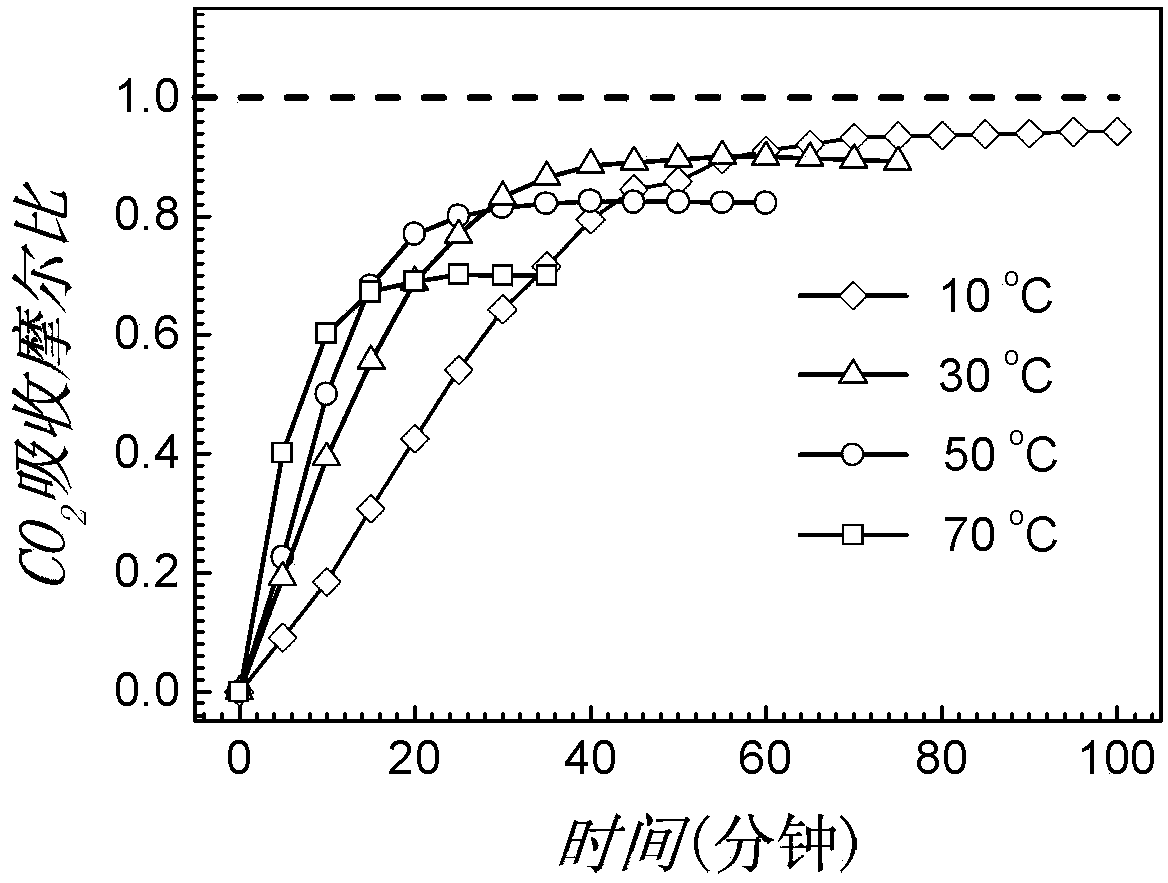

[0046] For the 5% TrizK-PEG200 solution system, keeping other test conditions unchanged, measure the CO of the system at different temperatures 2 absorption capacity. Such as figure 1 As shown, when the temperature rises to 50°C, CO 2 The absorption capacity can still reach more than 80% of the theoretical value.

[0047] The specific absorption data are listed in Table 2.

[0048] Table 2 CO of 5% TrizK-PEG200 solution system at different temperatures 2 absorb data

[0049]

Embodiment 9-12

[0051] CO on 10% TrizNa-PEG200 solution system 2 The absorption capacity is tested, the absorption condition is 30°C, 1atm, pure CO 2 atmosphere, CO 2 The flow rate is 50ml / min. Measured CO after 150min 2 The absorption capacity is 51.2mg CO 2 / g solution.

[0052] Under the same test conditions, the CO of the TrizNa solution system (wherein the mass fraction of TrizNa is 10%) prepared by different polar solvents 2 Absorption data are listed in Table 3.

[0053] Table 3 CO of 10% TrizNa solution system in different solvents 2 absorb data

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com