Sulfur dioxide removal composition, and preparation method and desulfurization method thereof

A technology for desulfurization and composition, applied in the field of desulfurization composition, which can solve the problems of slow absorption speed, high desorption energy consumption, and low desorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

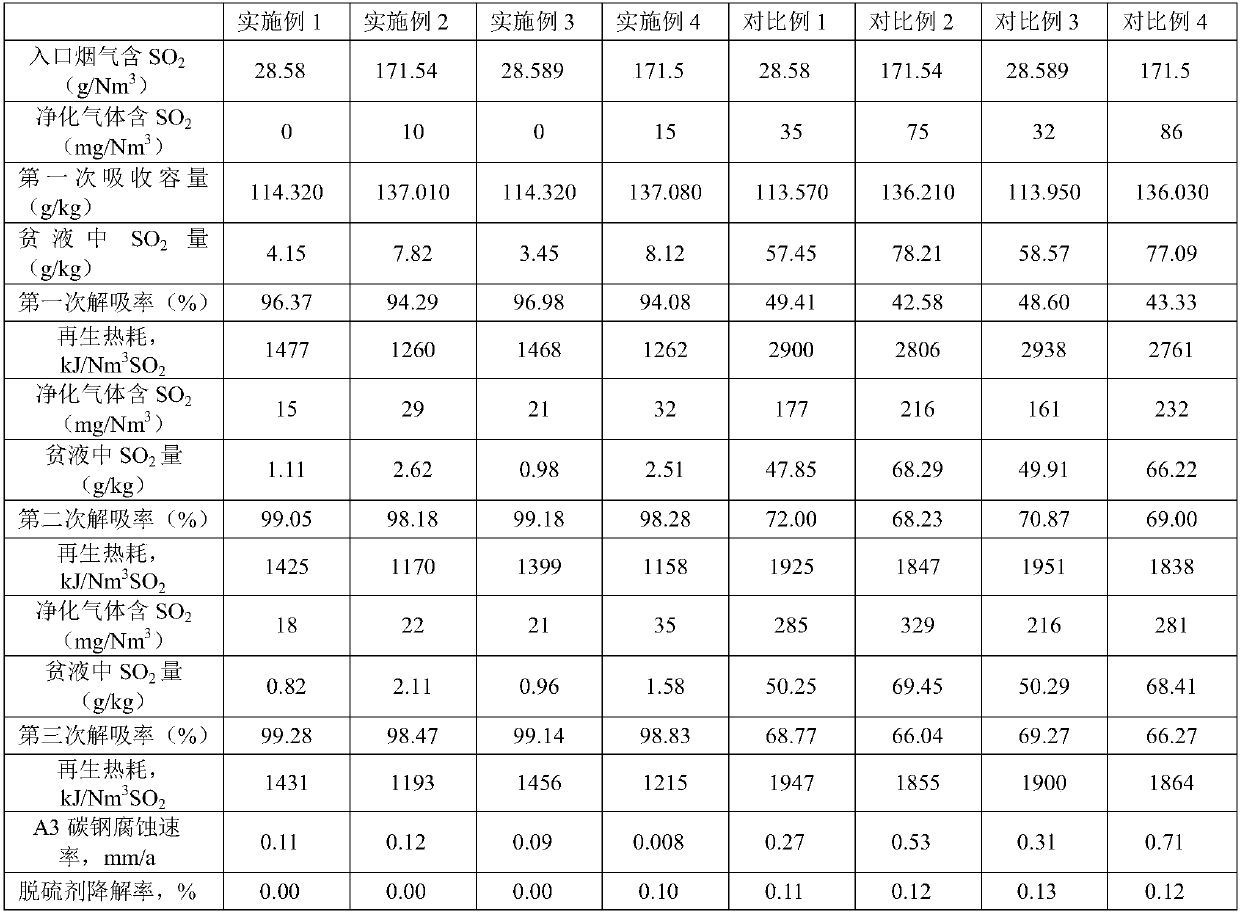

Examples

preparation example Construction

[0030] The present invention provides a preparation method for the above-mentioned sulfur dioxide removal composition, comprising: mixing a main absorbent, an activator, a corrosion inhibitor, an acid, and water to obtain a sulfur dioxide removal composition; when an antioxidant is also included, the main absorbent , an activator, an antioxidant, a corrosion inhibitor, and an acid are added to water and mixed to obtain a desulfurization composition.

[0031] Furthermore, the temperature at which the above components are mixed is 20-50°C.

[0032] The sulfur dioxide removal composition provided by the invention can remove and recover sulfur dioxide gas mixed with limestone roasting kiln flue gas, blast furnace gas, natural gas, etc., and can remove and recover sulfur dioxide in gases such as power plant boiler flue gas and sulfuric acid dioxide industrial tail gas. Sulfur dioxide solution has the advantages of large absorption capacity, high purification degree, fast absorption...

Embodiment 1

[0046] The composition of the simulated flue gas in this embodiment is calculated by volume: SO 2 : 1%; CO 2 : 5.4%; O 2 : 14.7%; H 2 O: 10.2%; CO: 1.05%; NOx: 0.05%, and the rest is nitrogen.

[0047] The preparation method of the sulfur dioxide removal composition of this embodiment: 180 grams of diazabicyclooctane, 20 grams of tetraethylenepentamine, 6 grams of dodecyl hydroquinone, 4 grams of antimony potassium tartrate, 3 grams of mono-oil Add imidazoline to 500 ml of water, adjust the pH of the solution with 0.5 mol / L sulfuric acid, stir evenly, and quantify it to 1000 g with distilled water, the pH of the solution is 4.70, so as to obtain the flue gas desulfurization composition solution.

[0048] The method for removing sulfur dioxide in the flue gas in this embodiment: heat 1000 grams of the sulfur dioxide removal composition solution prepared in this embodiment to 50° C., and use a micro vacuum pump to send the sulfur dioxide removal agent from the upper end of th...

Embodiment 2

[0057] The composition of the simulated flue gas in this embodiment is calculated by volume: SO 2 : 6%; CO 2 : 5.4%; O 2 : 14.7%; H 2 O: 10.2%; CO: 1.05%; NOx: 0.05%, and the rest is nitrogen.

[0058] The preparation method of the sulfur dioxide removal composition of this embodiment: 280 grams of diazabicyclooctane, 20 grams of diethylenetriamine, 50 grams of tetraethylenepentamine, 5 grams of dodecyl hydroquinone, 3.5 grams of tartaric acid Add antimony potassium and 4.5 grams of mono-oil imidazoline into 500 milliliters of water, adjust the pH of the solution with 0.5 mole / liter of sulfuric acid, stir evenly, and quantify it to 1000 grams with distilled water, and the pH of the solution is 4.70, thereby obtaining flue gas desulfurization Composition solution.

[0059] The method for removing sulfur dioxide in the flue gas, desorption steps, determination of absorption capacity, desorption amount and absorption rate in this embodiment are the same as those in Example 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com