Wet process desulphurization demisting device and wet process desulphurization device

A wet desulfurization and demisting device technology, applied in separation methods, chemical instruments and methods, vapor condensation, etc., can solve the problems of low capture capacity of fine droplets and solid particles, reduced demisting efficiency, scaling, etc. , to achieve good demisting effect, avoid gypsum rain, and not easy to scale and block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

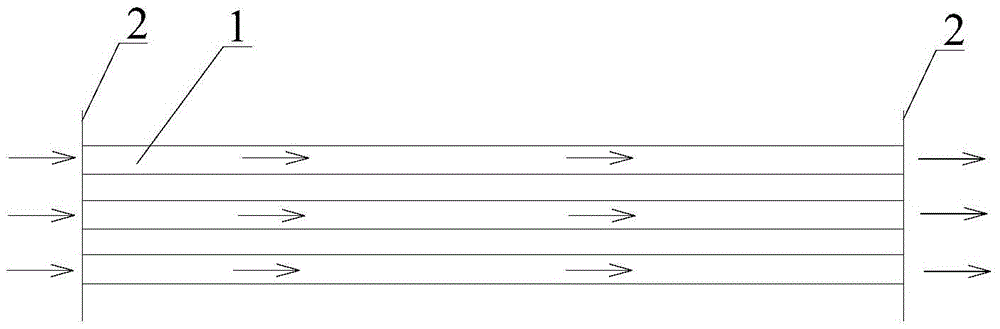

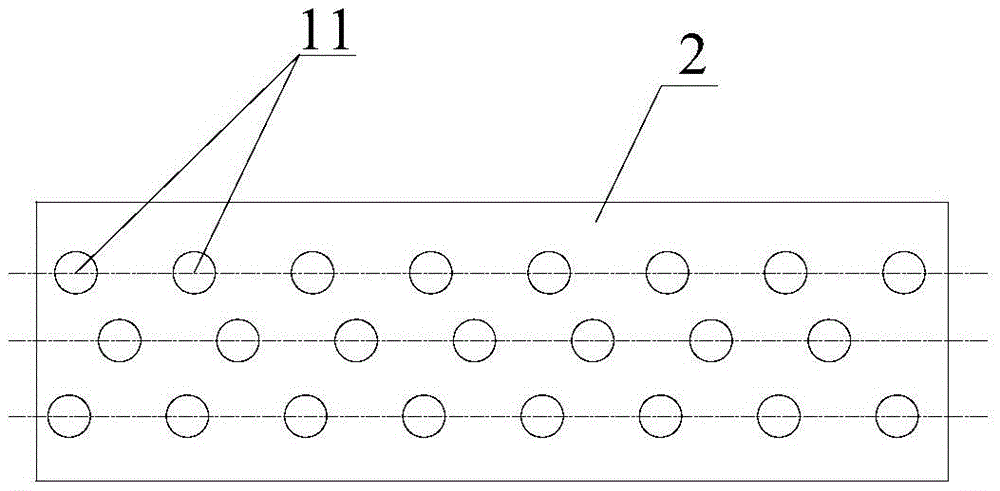

[0026] This embodiment provides a wet desulfurization and mist removal device, such as figure 1 with figure 2 As shown, it includes at least two layers of parallel pipe rows 1, the two ends of the pipe rows 1 are respectively supported on the support member 2, and the adjacent two layers of pipe rows 1 are arranged in a staggered manner, and each layer of pipe rows 1 includes a plurality of The parallel hollow tubes 11 also include a cooling medium source (not shown), at least part of the hollow tubes 11 communicate with the cooling medium source, and the cooling medium source is used to provide a cooling medium for the hollow tubes 11 to cool the hollow tubes 11. The cooling medium in the cooling medium source is preferably cooling water, which is non-toxic, low in cost and good in cooling effect, but the cooling medium is not limited to water, and can also be some other non-toxic medium with cooling effect. There is no specific limitation on the structural shape of the su...

Embodiment 2

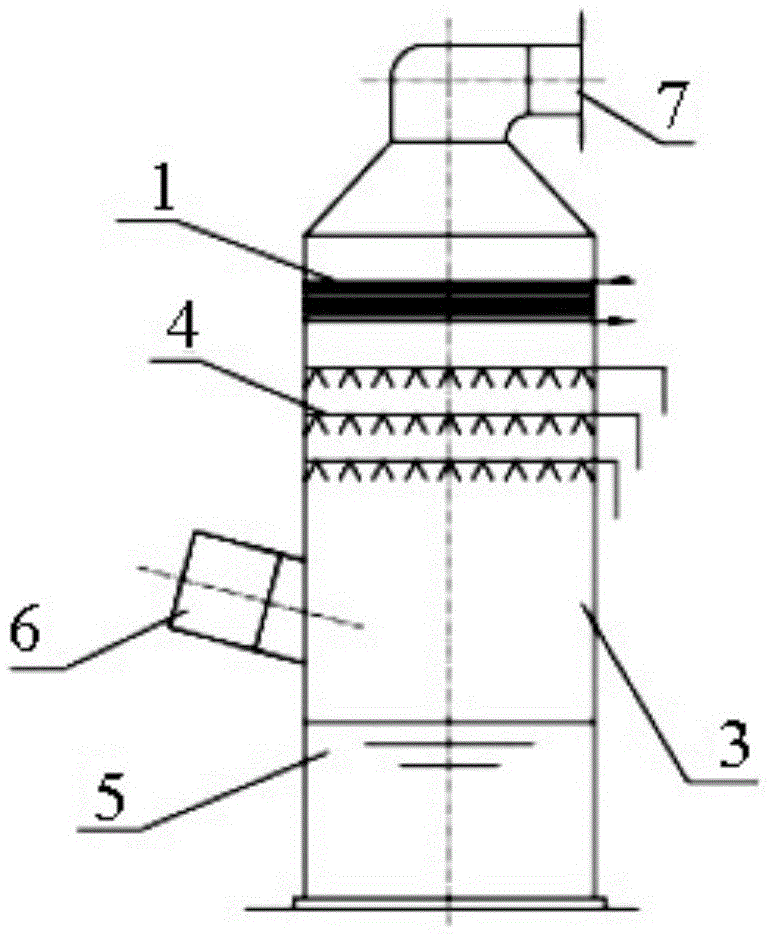

[0035] This embodiment provides a wet desulfurization device including the wet desulfurization and demisting device described in Embodiment 1, such as image 3 As shown, it includes a wet desulfurization tower 3, and the wet desulfurization demisting device is placed above the spray layer 4 of the wet desulfurization tower.

[0036] More specifically, the bottom of the wet desulfurization tower is provided with a slurry pool 5, the side wall of the desulfurization tower 3 is provided with a desulfurization tower inlet 6, the top of the desulfurization tower 3 is provided with a desulfurization tower outlet 7, and the inside of the desulfurization tower 3 is provided with the above-mentioned nozzle The spray layer 4, the wet desulfurization and demisting device is placed above the spray layer 4 of the wet desulfurization tower. The flue gas first enters the desulfurization tower through the entrance of the desulfurization tower, and then passes through the spray layer. The flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com