Dry type venturi paint mist trapping device and application thereof

A Venturi and dry technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as difficult to be widely used, adhesion of overspray, complex structure, etc., to improve the capture capacity, The effect of reducing the number of replacements and reducing the consumption of filter materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

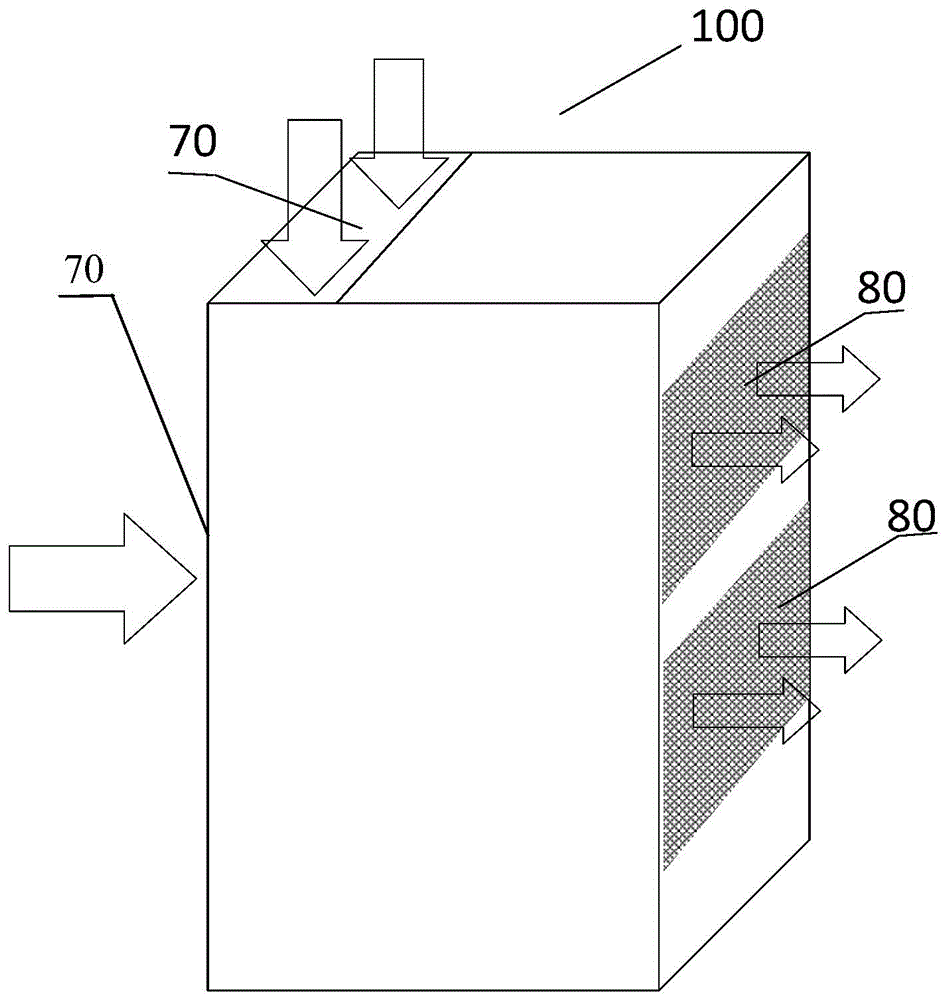

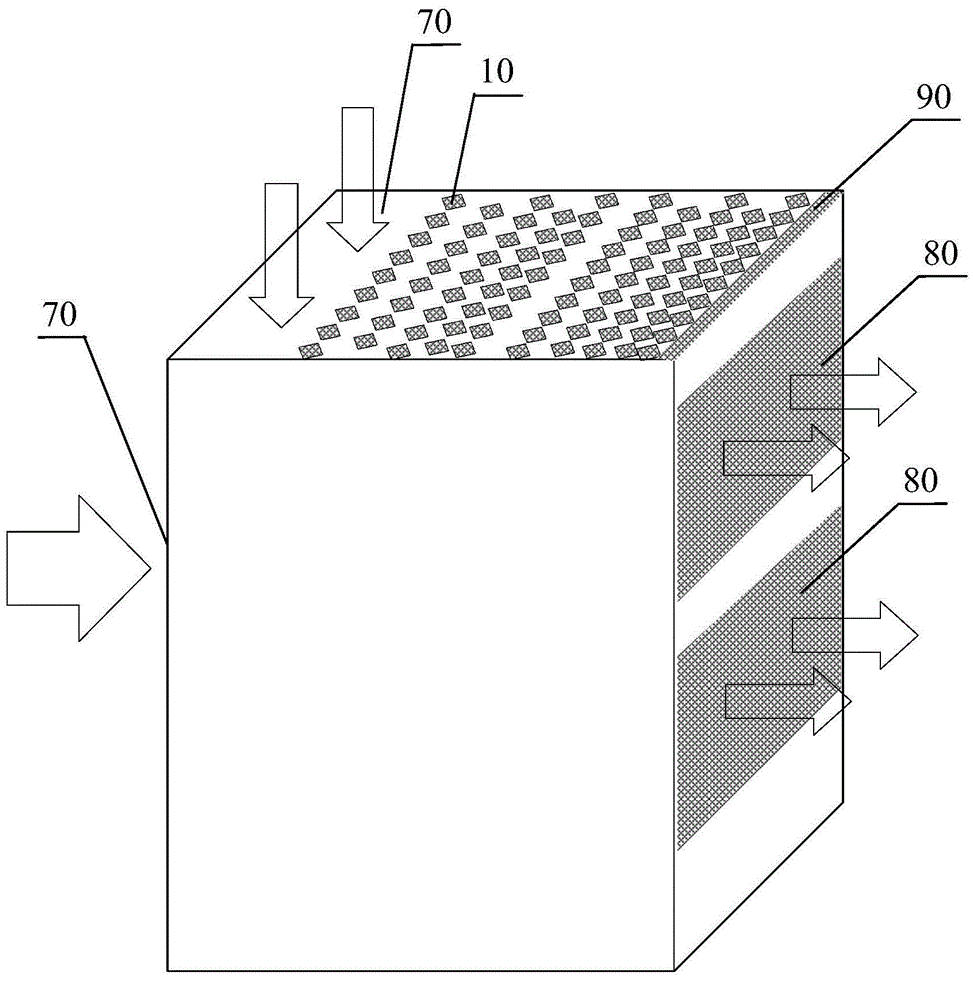

[0036] This embodiment provides a dry Venturi paint mist collection device, which includes a device casing, each box is an independent unit, the exterior is made of cardboard, and there are multiple rows of paint mist filtering and intercepting units inside. The mist filter and interception units are arranged alternately, and there is a gap between the adjacent paint mist filter and interception units, and the gap and the surfaces of the paint mist filter and interception units on both sides form a suddenly narrowed air flow channel with a Venturi structure. The paint mist filtering and intercepting unit and the cavity between adjacent paint mist filtering and intercepting units form a paint mist separation mechanism. The paint mist filter and interception unit is a filter column with a rhombus or square cross-section. The longer diagonals of the cross-section of the filter column in the same row are in the same straight line, and each air flow channel with a rapidly decreasing...

Embodiment 2

[0067] refer to Figure 2-Figure 6As shown, this embodiment provides a dry Venturi paint mist collection device similar to the embodiment, the difference from Embodiment 1 is that the material of the paint mist filtering and intercepting unit is a non-woven material.

Embodiment 3

[0069] refer to Figure 2-Figure 6 As shown, this embodiment provides a dry Venturi paint mist collection device similar to the embodiment, the difference from Embodiment 1 is that the density of the material used in the paint mist filter and interception unit is in the main flow direction of the air Gradually get bigger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com