Novel dry type paint mist separated vehicle coating equipment

A paint mist separation and coating equipment technology, applied in separation methods, dispersed particle separation, paint spray booths, etc., can solve problems such as difficulty in environmental governance, a large amount of waste gas, waste liquid and solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages of the present invention from the content disclosed in this specification.

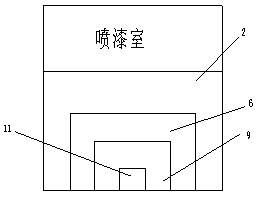

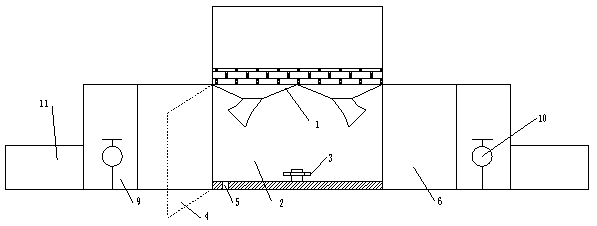

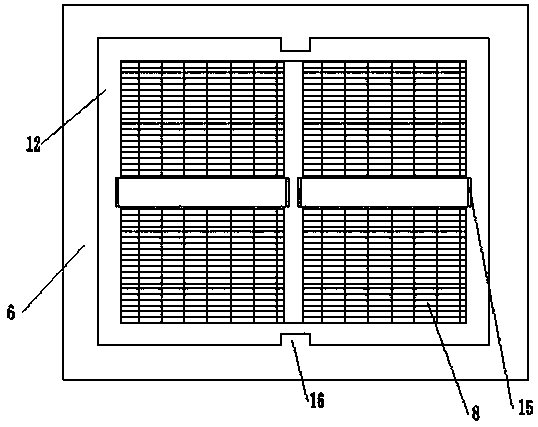

[0024] Such as Figure 1-4 , a new type of dry-type paint mist separation automobile painting equipment, including a spray booth, a diversion chamber 2, and a grille is arranged under the spray booth. There is a grille under the spray booth, and a guide device 1 is provided under the grille. During the spraying process, the spray booth will produce overspray, and the air carrying the overspray will flow through the grille to guide the flow under the action of the pressure difference. Chamber 2, the diversion device 1 is set in the diversion chamber 2, which speeds up the downward spraying speed of the overspray and plays a guiding role. There is at least one inspection door 4 on the left and right sides of the diversion chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com