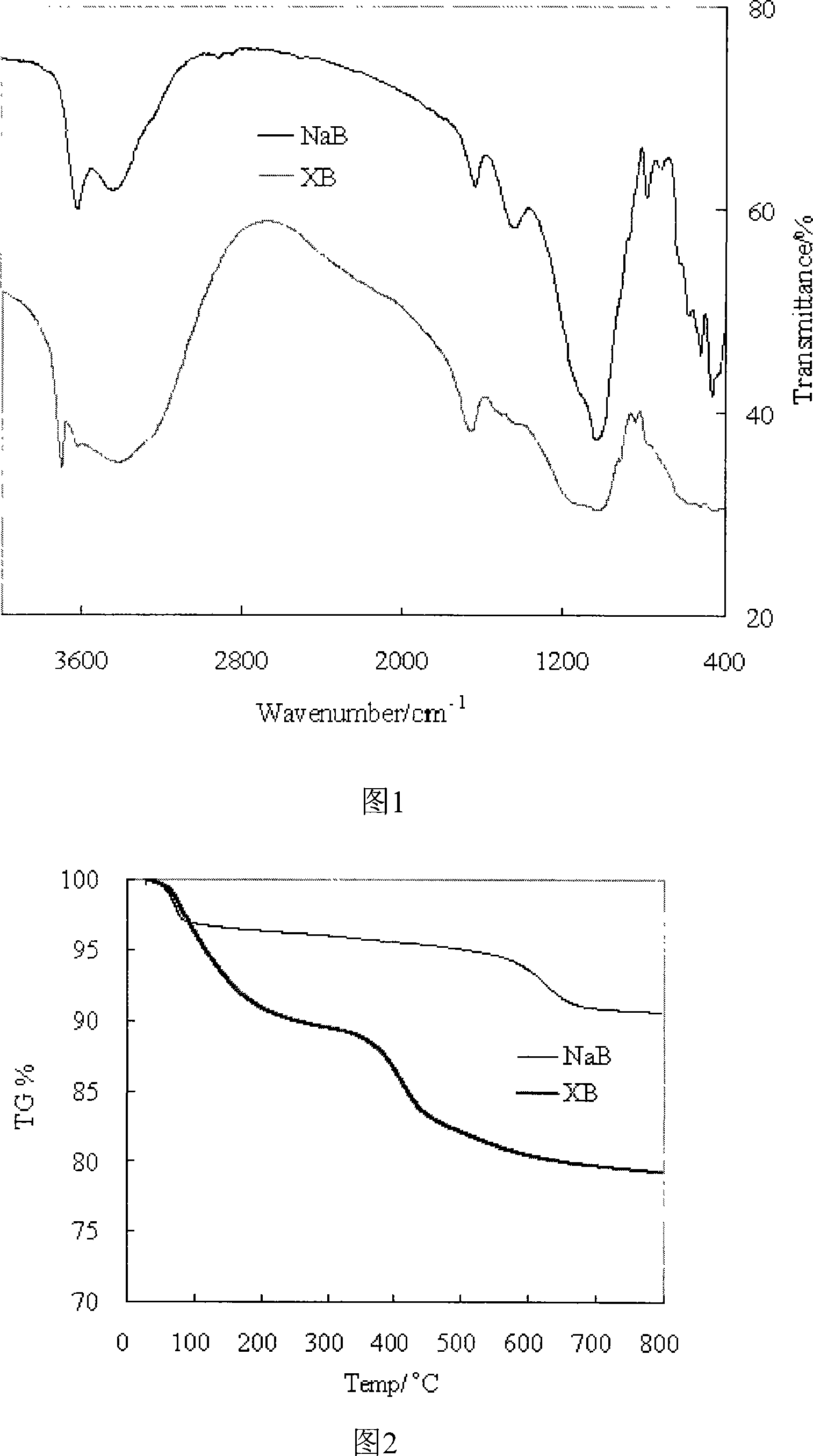

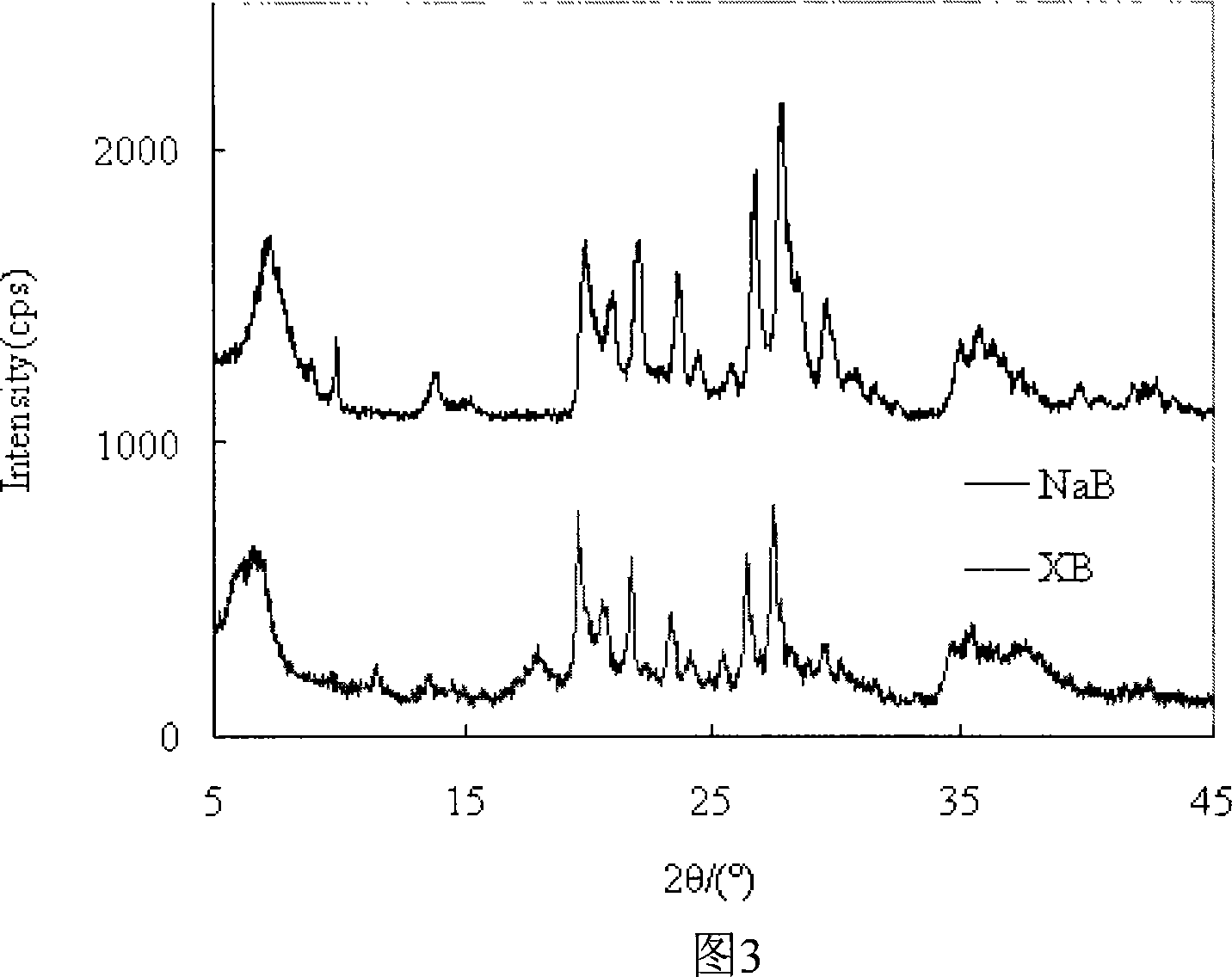

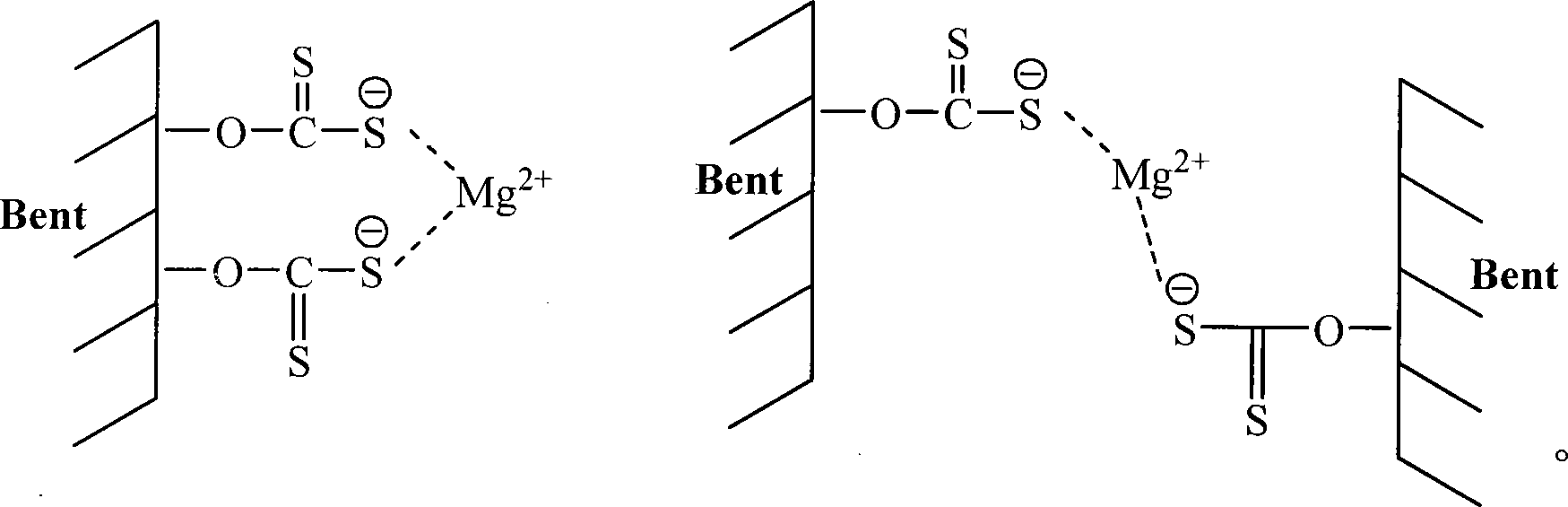

Xanthation bentonite absorbingsubstance and method for preparing the same

A technology of xanthate and sodium bentonite, which is applied in the fields of xanthate bentonite, preparation of xanthate bentonite, and heavy metal ion adsorbent, can solve the xanthate of bentonite and its application that have not been reported, preparation process and equipment requirements High, time-consuming and labor-intensive application process, etc., to achieve the effects of environmental protection, less dosage, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Add 20g of sodium bentonite to 120mL of distilled water, stir to disperse evenly, add 8g of NaOH, stir at 35°C for 1 hour, add CS dropwise 2 2.41mL, after reacting for 1h, add 5.0g magnesium sulfate and 50mL H 2 O, continue to stir at a constant temperature of 35°C for 30min, filter with suction, wash with 5-10% magnesium sulfate solution for 3-5 times until the filtrate is colorless, and then wash with acetone for 3 times to obtain a light blue-green solid. Vacuum dried for 10 h to obtain product XB1 with a yield of 31.3 g.

Embodiment 2

[0033] Embodiment 2: preparation process and raw material etc. are identical with embodiment 1, and wherein, the add-on of NaOH is 8g, CS 2 The amount of dropping was 7.23mL, and the reaction time was 1h to obtain the XB2 product with a yield of 28.4g.

Embodiment 3

[0034] Embodiment 3: preparation process and raw material etc. are identical with embodiment 1, and wherein, the add-on of NaOH is 8g, CS 2 The amount of the dropwise addition was 7.23mL, and the reaction time was 6h to obtain the XB3 product with a yield of 26.4g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com