Xanthic acid-based attapulgite adsorbent as well as preparation method and application thereof

A technology based on attapulgite and xanthic acid, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, and can solve problems affecting performance, dyes that cannot be reused, and high production costs. Achieve the effects of easy operation, environmental protection and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

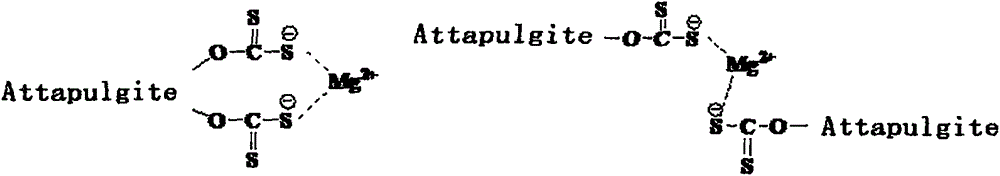

[0044] Add 20g of attapulgite to 120mL of distilled water, stir to disperse evenly, add 8g of NaOH, stir at 35°C for 1h, add CS dropwise 2 2.41mL, after reacting for 1h, add 5.0g soluble magnesium salt and 50mLH 2 O, continue to stir at a constant temperature of 35°C for 30min, filter with suction, wash with dilute magnesium salt solution (5-10%) for 3-5 times until the filtrate is colorless, and then wash with acetone for 3 times to obtain a light blue-green solid. After vacuum drying for 10 h, the XA1 product was obtained with a yield of 30.2 g.

Embodiment 2

[0046]Add 20g of attapulgite to 120mL of distilled water, stir to disperse evenly, add 8g of NaOH, stir at 35°C for 1h, add CS dropwise 2 7.23mL, after reacting for 1h, add 5.0g soluble magnesium salt and 50mLH 2 O, continue to stir at a constant temperature of 35°C for 30min, filter with suction, wash with dilute magnesium salt solution (5-10%) for 3-5 times until the filtrate is colorless, and then wash with acetone for 3 times to obtain a light blue-green solid. After vacuum drying for 10 h, the XA2 product was obtained with a yield of 29.2 g.

Embodiment 3

[0048] Add 20g of attapulgite to 120mL of distilled water, stir to disperse evenly, add 8g of NaOH, stir at 35°C for 1h, add CS dropwise 2 7.23mL, after reacting for 6h, add 5.0g soluble magnesium salt and 50mLH 2 O, continue to stir at a constant temperature of 35°C for 30min, filter with suction, wash with dilute magnesium salt solution (5-10%) for 3-5 times until the filtrate is colorless, and then wash with acetone for 3 times to obtain a light blue-green solid. After vacuum drying for 10 h, the XA3 product was obtained with a yield of 26.3 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com