Wall flow type net plate apparatus with reverse jet regenerating unit for collecting microparicle discharged by diesel vehicle

A particle trap, metal mesh plate technology, applied in exhaust devices, machines/engines, mufflers, etc., can solve the problems of low utilization rate of filter materials, slow regeneration process, and complicated channel tortuousness, etc., to achieve simple structure, Effects of small exhaust back pressure loss and high collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

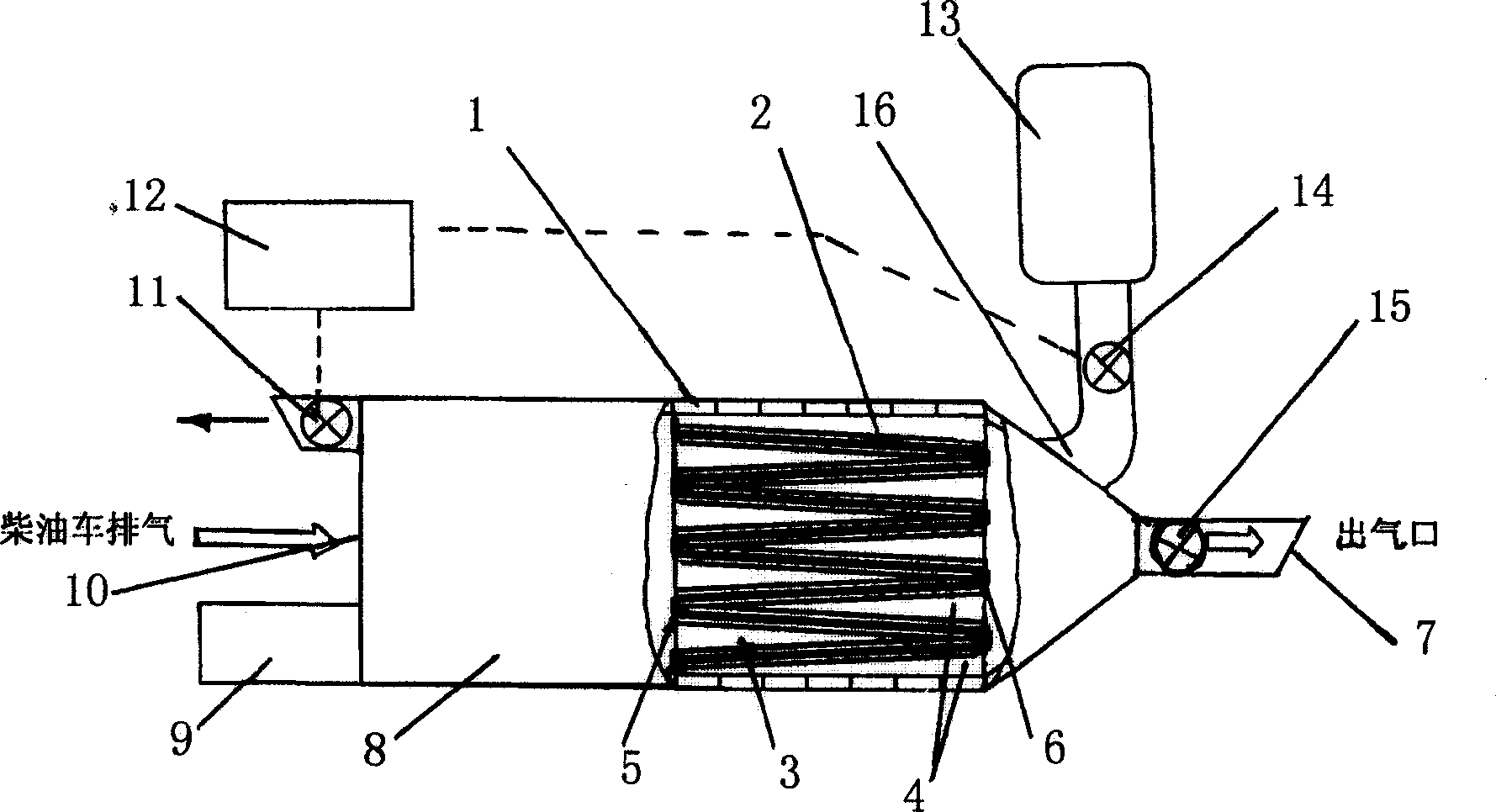

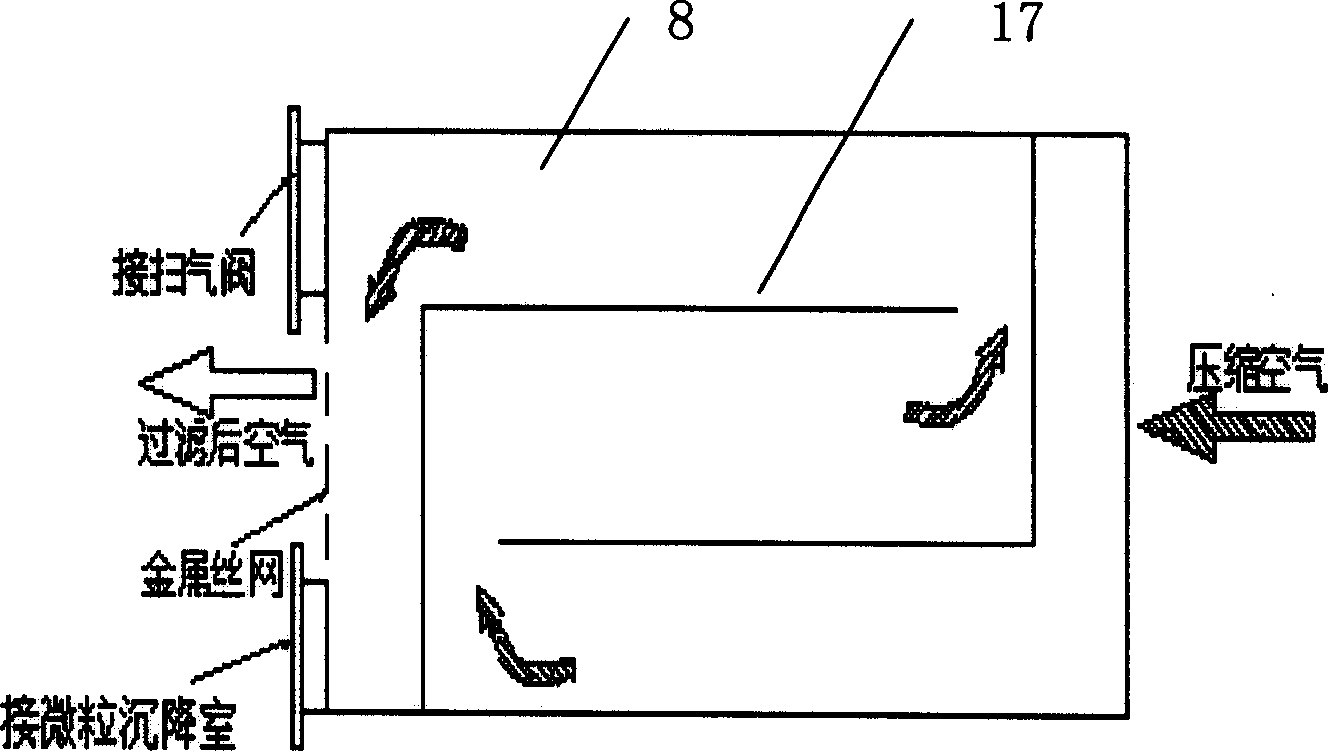

[0013] The invention provides a reverse jet regeneration wall-flow type metal mesh plate diesel vehicle exhaust particulate filter for filtering and trapping the particulate matter in the exhaust gas of a diesel engine and reducing the pollution caused by the particulate discharge. exist figure 1 In the structural schematic diagram of the wall-flow metal mesh plate diesel engine exhaust particulate filter shown in the reverse jet regeneration device, the two ends of the shell 1 are the air inlet 10 and the air outlet 7, and in the shell 1, the composite metal mesh filter layer 2 is inclined at a certain angle, and is connected into a "WW" structure through the front baffle 5 and the rear baffle 6, and is fixed in the shell 1; the air intake channel 3 and the exhaust channel 4 are formed on both sides of the composite metal mesh filter layer 2 An expansion chamber 8 is set between the air inlet 10 and the composite metal mesh filter layer 2, the upper end of the expansion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com