Patents

Literature

59results about How to "Achieve staged combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

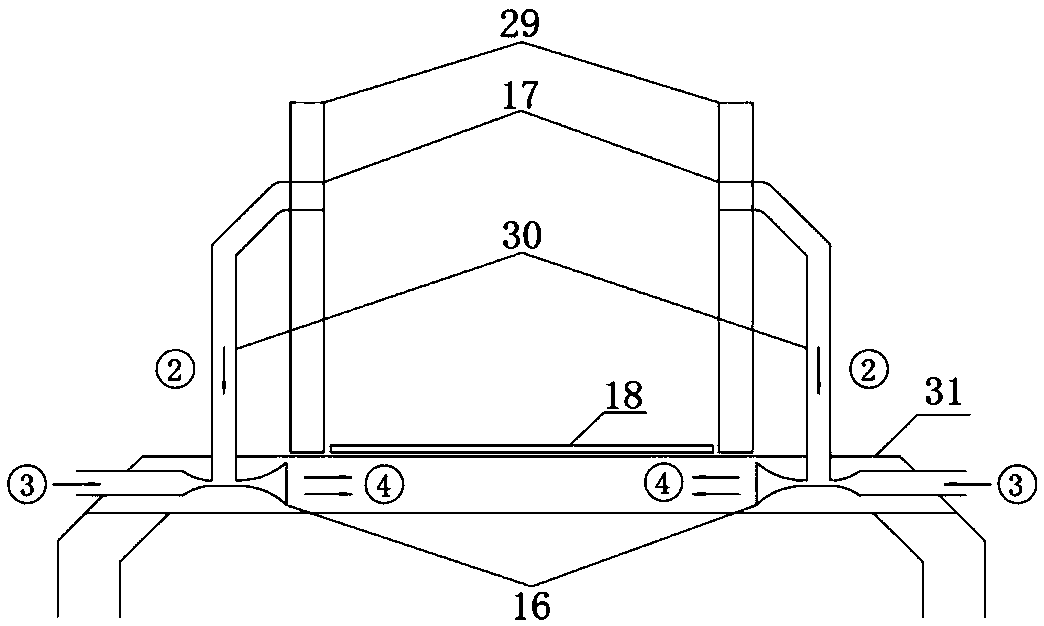

Low emission high efficiency grate-firing combustion device and method

InactiveCN102506418AImprove combustion efficiencyReduce conversionSolid fuel combustionNon-combustible gases/liquids supplyCombustorCombustion chamber

The invention relates to a low emission high efficiency grate-firing combustion device and a method. The method is characterized in that coal dust and a sulfur-fixing agent are fully mixed so as to enter into a grate-fired furnace through a hopper, a gas recirculation and spray water combined technology is utilized to rapidly pyrolyze coal dust so as to generate reducing gas, recirculation fume is utilized to carry the reducing gas and part of fine granule semicoke to enter into a recrudescence region in the furnace, and the combustion flow of the furnace is strengthened; and the purpose of reduction NOx is achieved, the no-burnout grains are continually combusted above a combustor, staged combustion of a fuel in the furnace is realized in a hearth, and meanwhile, and the combustion efficiency of the grate-fired furnace is also improved. According to the invention, the grate-fired furnace is introduced through a fuel staged combustion technology, on the one hand, the NOx and SOx discharge of the grate-fired furnace is reduced through combustion adjustment, namely, the NOx deprivation rate is 35%-55%, the SOx deprivation rate is more than 80%, thereby protecting an atmospheric environment; on the other hand, the combustion efficiency of the grate-fired furnace is improved by 1%-2%.

Owner:SHANDONG UNIV

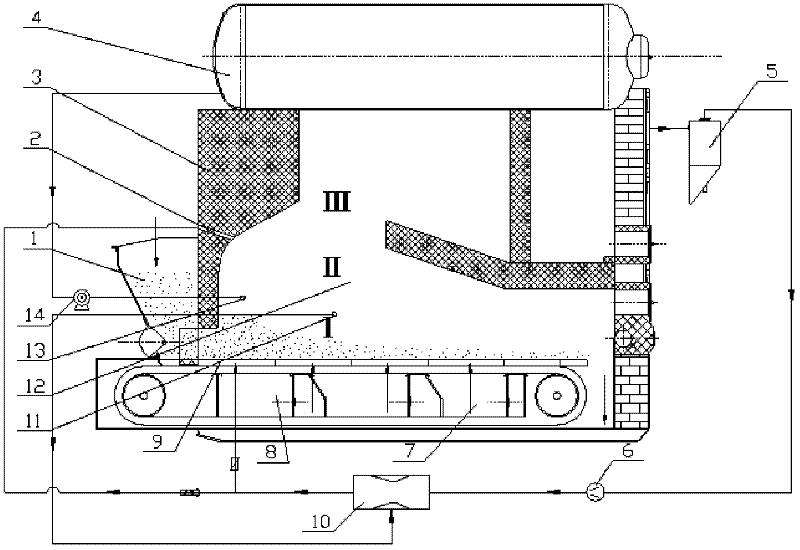

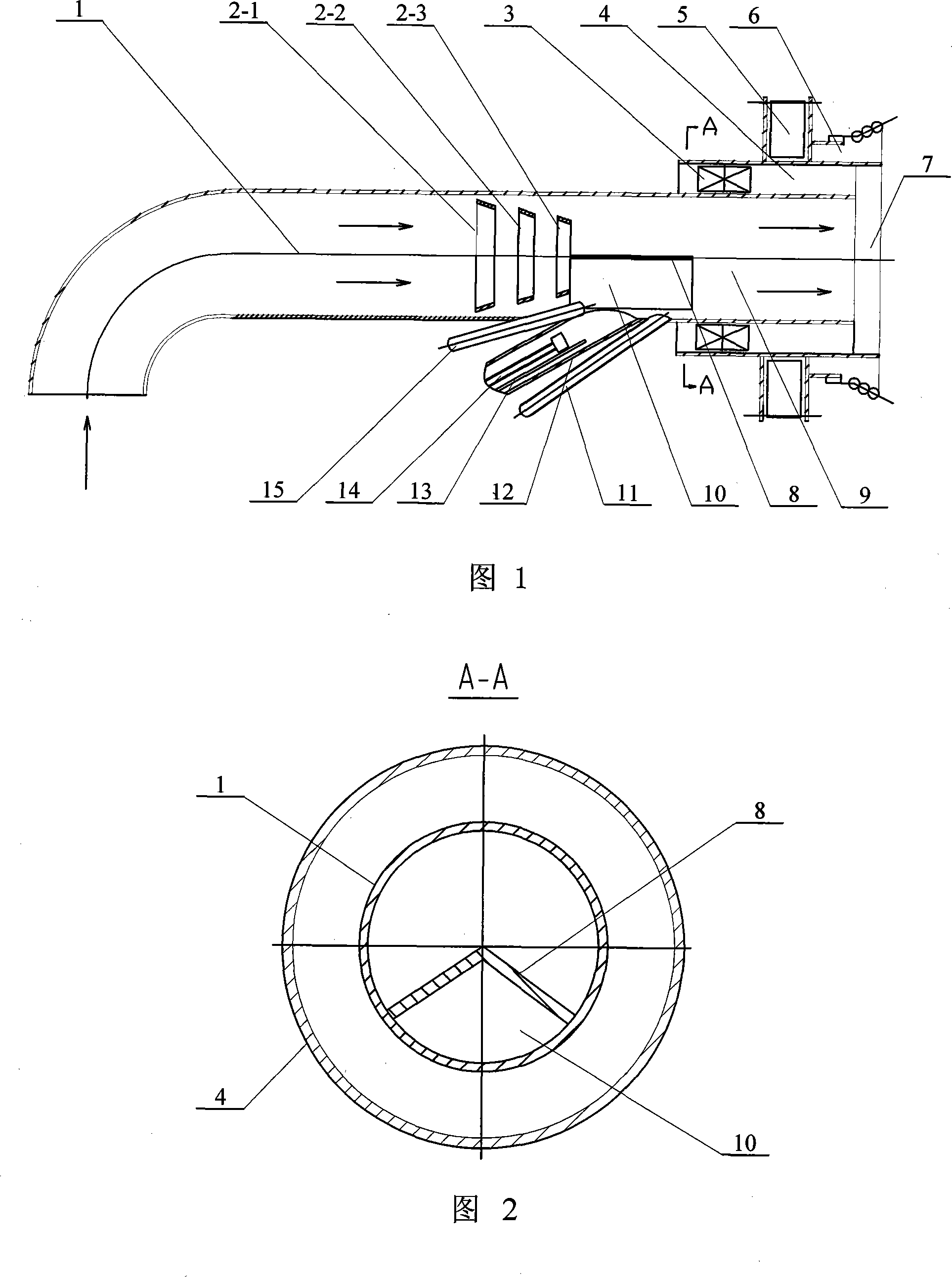

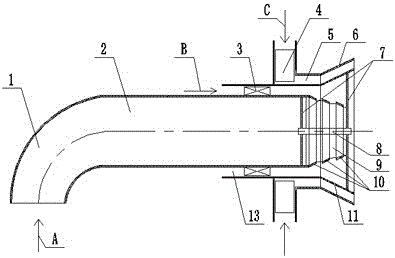

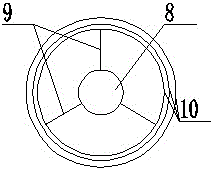

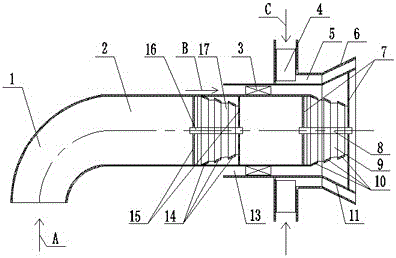

Low-nitric-oxide direct-current pulverized coal combustor adaptive to meager coal boiler

ActiveCN103267279AReduce generationReduce carbon contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

The invention relates to a low-nitric-oxide direct-current pulverized coal combustor adaptive to a meager coal boiler, which can achieve stable and economical combustion, and also reduces nitric oxide emission to the lowest level, so that the low-nitrogen combustion modifying technique of the meager coal boiler is improved. The low-nitric-oxide direct-current pulverized coal combustor adaptive to the meager coal boiler comprises main combustor groups which are arranged on four corners of a hearth of the meager coal boiler in a four-angle tangential circle combustion mode, are matched with a water-cooling wall high-temperature-prevention corrosion system of the hearth, and are identical in structure; each main combustor group comprises pulverized coal combustors arranged at intervals and secondary air spray ports; the upper parts of the main combustor groups are provided with corresponding separation burnout air groups; a layer of precombustion chamber back flow combustor is arranged in each n-layer of pulverized coal combustors; the jet flow rotation direction of the main combustor groups is the anticlockwise direction; the rotation direction of secondary air ports close to the upper parts of the precombustion chamber back flow combustors is the clockwise direction, and the imaginary tangential circle diameter is greater than the imaginary tangential circle diameter of the main combustors; separation burnout air groups include upper groups and lower groups; and the jet flow of the lower groups is in an imaginary tangential circle mode, and the jet flow of the upper groups is in an opposed combustion mode.

Owner:STATE GRID CORP OF CHINA +1

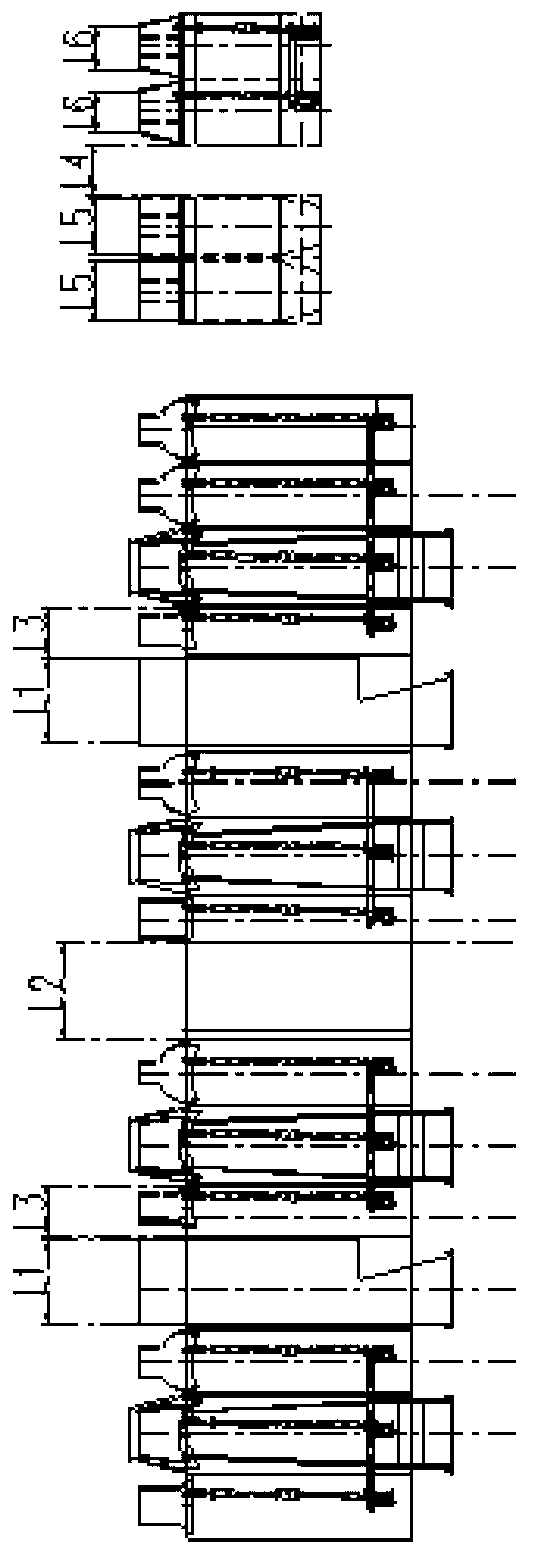

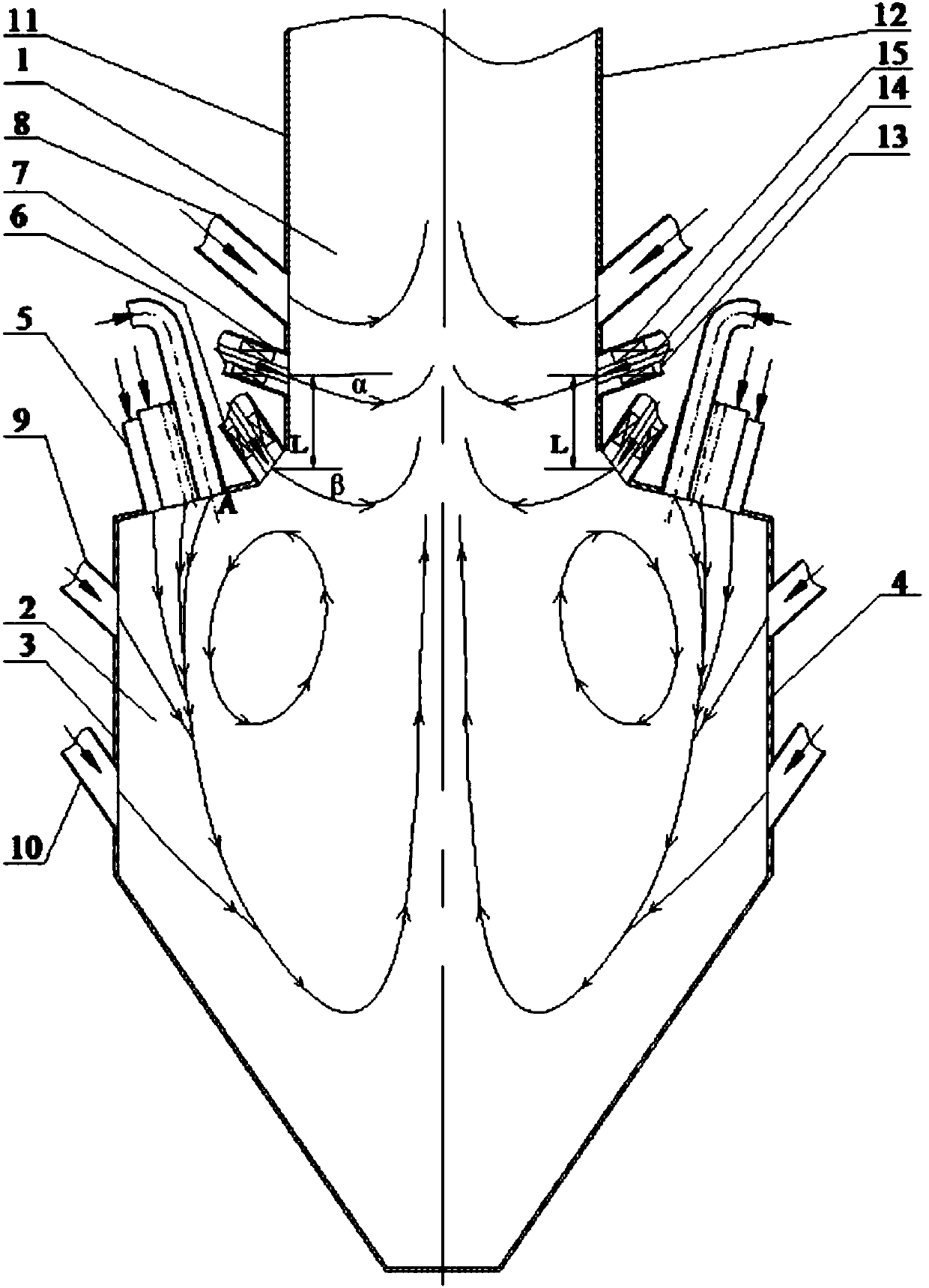

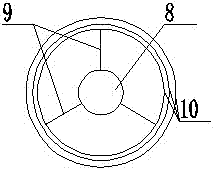

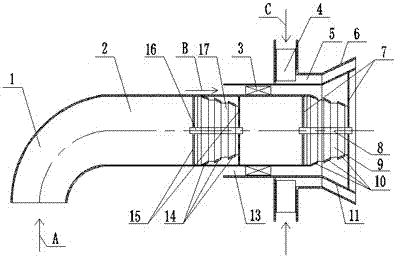

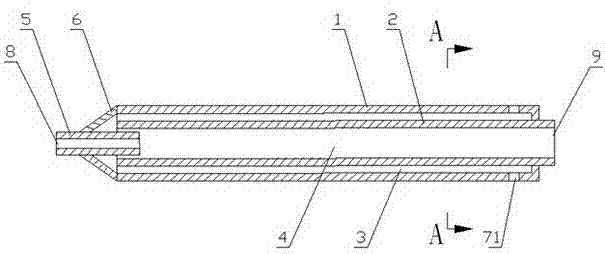

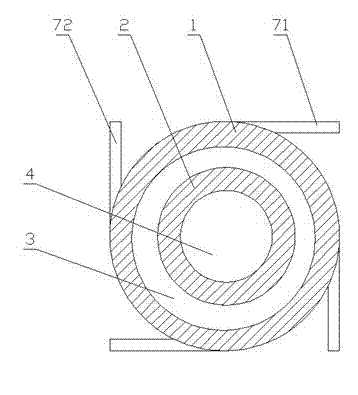

W flame boiler of turbulent burner with inner direct flow and outer turbulent flow ammonia spraying device

ActiveCN107559858AReduce NOxIncrease the degree of mixingDispersed particle separationCombustion apparatusNH3 compoundNozzle

The invention provides a W flame boiler of a turbulent burner with an inner direct flow and outer turbulent flow ammonia spraying device and relates to the W flame boiler. The W flame boiler solves the problems that an existing W flame boiler of the turbulent burner is high in NOx discharge amount and low in denitrifying efficiency. The center of a first stage ammonia spraying device is placed atthe upper edge of a front furnace arch or a back furnace arch, the distance L from the center line of a second stage ammonia spraying device to the upper edge of the front furnace arch or the back furnace arch is 1-2m, the center of the first stage ammonia spraying device is located in a same horizontal plane, and the center of the second stage ammonia spraying device is located on a same horizontal plane; the first stage ammonia spraying device and the second stage ammonia spraying device comprise inner tubes, outer rubes and a plurality of turbulent blades, the inner tubes and the outer tubes are arranged coaxially, the plurality of turbulent blades are uniformly distributed between the inner tubes and the outer tubes, the inner tubes are direct flow nozzles, and the plurality of turbulent blades arranged between the outer tubes and the inner tubes are turbulent nozzles which form the ammonia spraying device with an inner direct flow and an outer turbulent flow. The W flame boiler provided by the invention belongs to the technical field of NOx emission reduction.

Owner:HARBIN INST OF TECH

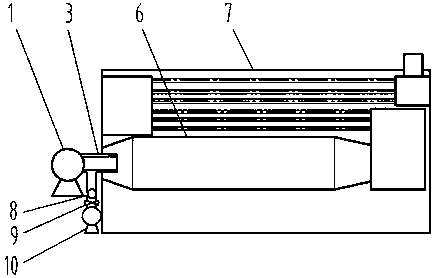

Smokeless coal gasification micro grease gun igniting pulverized coal burner

ActiveCN101012928APromote combustionAchieve staged combustionPulverulent fuel combustion burnersCombustion chambersCombustorStaged combustion

The invention relates to a non-smoke gasify micro oil gun ignition powder coal burner, wherein, the cooling air cylinder (7) is arranged outside the outer tube (9) of burner; the cooling air cylinder (7) and the outer tube (9), the secondary burning room reducing section (10) and the cooling air reducing section (12) are formed by the cooling air channels (5) between them; one end of oxygen tube (6) is communicated with the secondary burning straight section (8), while another end is communicated with outer space. The invention mounts an oxygen tube to feed oxygen into the secondary burning room, to improve the oxidization speed, improve the burnt degree, and realize non-smoke burning.

Owner:STATE GRID CORP OF CHINA +2

Micro double-bed solid fuel decoupling combustion reaction dynamic analyzer

ActiveCN103543237AAchieve pyrolysisRealize the coke combustion processChemical analysis using combustionAir atmosphereGas detector

The invention provides a micro double-bed solid fuel decoupling combustion reaction dynamic analyzer which comprises a fuel pyrolytic reaction generation device, a residual coke combustion reaction generation device, a double-bed high-temperature coupling device, a gas path device and an analysis test device, wherein solid fuel is firstly pyrolyzed under an inert atmosphere in a micro gas flow bed; then residual cokes enter the micro gas flow bed for combustion test under an air atmosphere; a quick gas detector is used for judging a reaction mechanism by measuring a generation sequence and a generation quantity characteristic of gas components in a fuel pyrolysis process and a coke combustion process, so that reaction dynamic parameters can be calculated. According to the micro double-bed solid fuel decoupling combustion reaction dynamic analyzer, the combustion dynamic parameters of the solid fuel can be tested through direct decoupling combustion through independent and quick switching of the atmospheres and the temperature; the pyrolyzed residual cokes are directly subjected to the combustion test without a cooling process; the temperature rising rates of the gas flow bed and a fluidized bed are high, so that a combustion condition in an actual boiler can be well simulated; the measured reaction dynamic parameters are close to intrinsic reaction dynamic parameters.

Owner:HUAZHONG UNIV OF SCI & TECH

Ultralow-nitrogen gas burner

ActiveCN107559827AAchieving Circumferential GradingImprove the mixIndirect carbon-dioxide mitigationGaseous fuel burnerHearthProcess engineering

The invention relates to an ultralow-nitrogen gas burner. The ultralow-nitrogen gas burner comprises a first-stage gas header, a second-stage gas collecting ring, a furnace body, an igniter and an airflue with openings in the two ends, and the outlet of the air flue penetrates through a furnace wall of the furnace body to enter a hearth; the air flue at least comprises a central air flue, a primary air flue and a secondary air flue which are sequentially arranged from inside to outside in a sleeved mode, and the first-stage gas header and the second-stage gas collecting ring are connected with a fuel gas main pipe; the first-stage gas header is connected with a central spray gun and a plurality of first-stage gas spray guns, the first-stage gas spray guns are uniformly distributed on theperiphery of the central spray gun, and the central spray gun and the first-stage gas spray guns extend into the central air flue; the second-stage gas collecting ring is uniformly connected with a plurality of second-stage gas spray guns, and the second-stage gas spray guns extend into the secondary air flue; and the igniter is arranged in the central spray gun, and an ignition end of the igniterextends out of an outlet end of the central spray gun. According to the ultralow-nitrogen gas burner, a double-header and pipe group type supply mode is adopted, so that circumferential grading of the fuel is realized, air / gas mixing condition is improved, combustion balance is realized, and NOx generation is reduced.

Owner:XI AN JIAOTONG UNIV

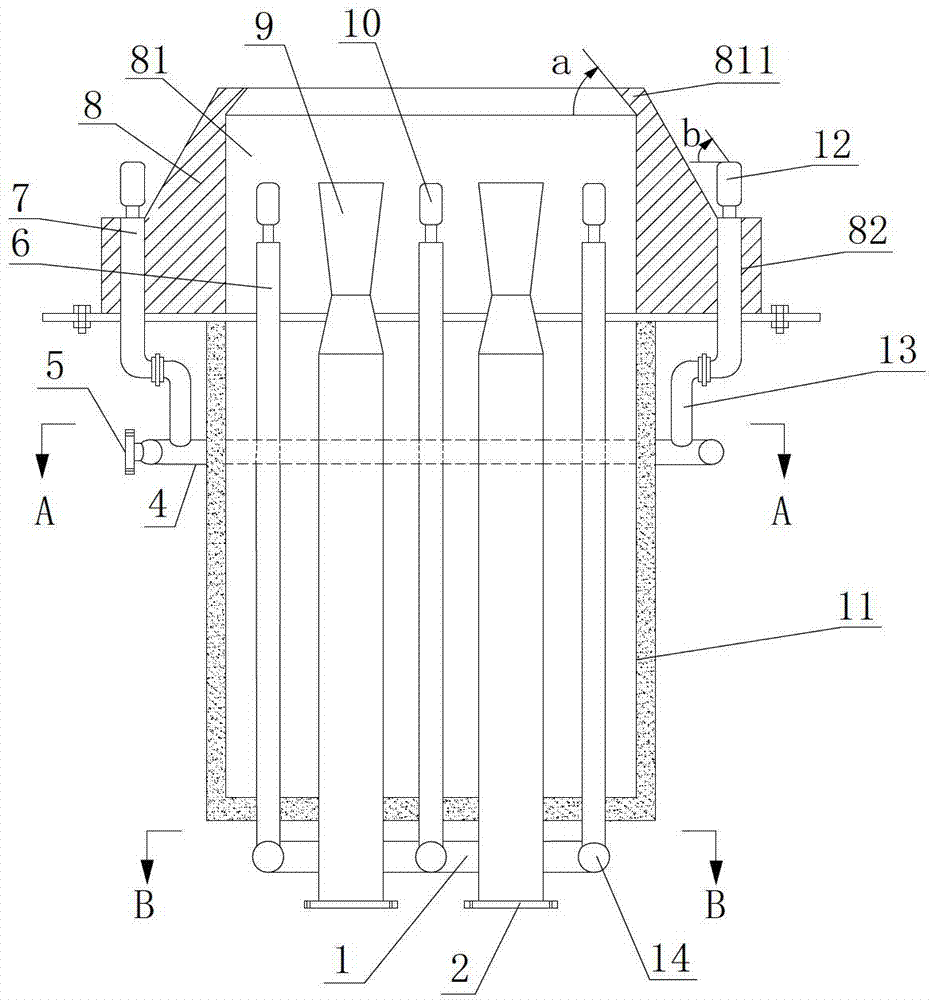

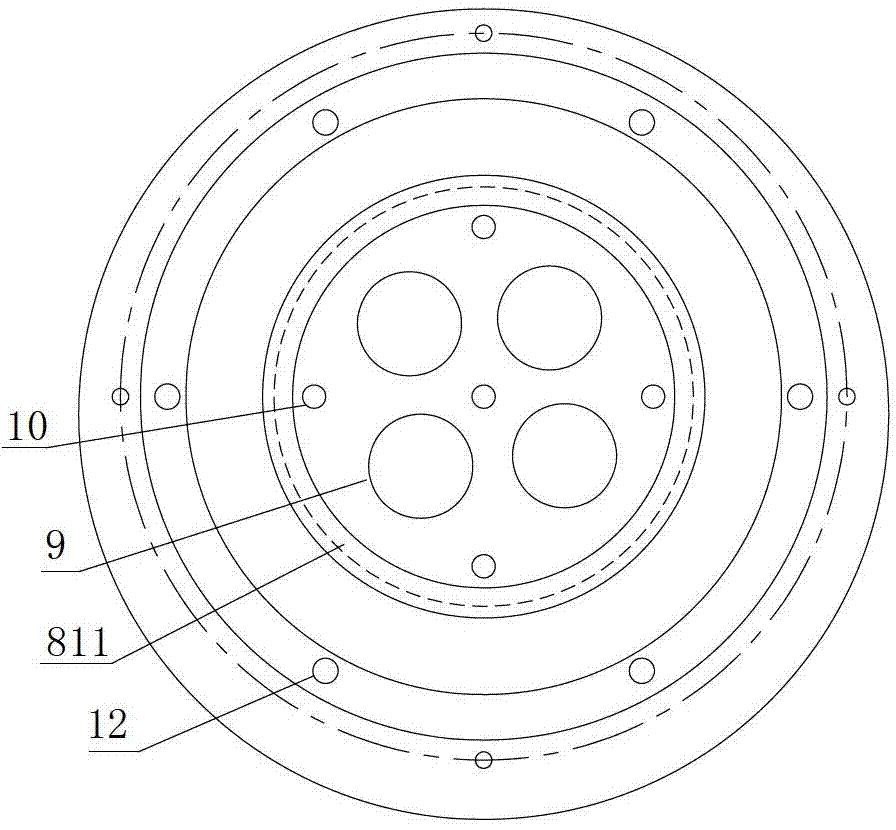

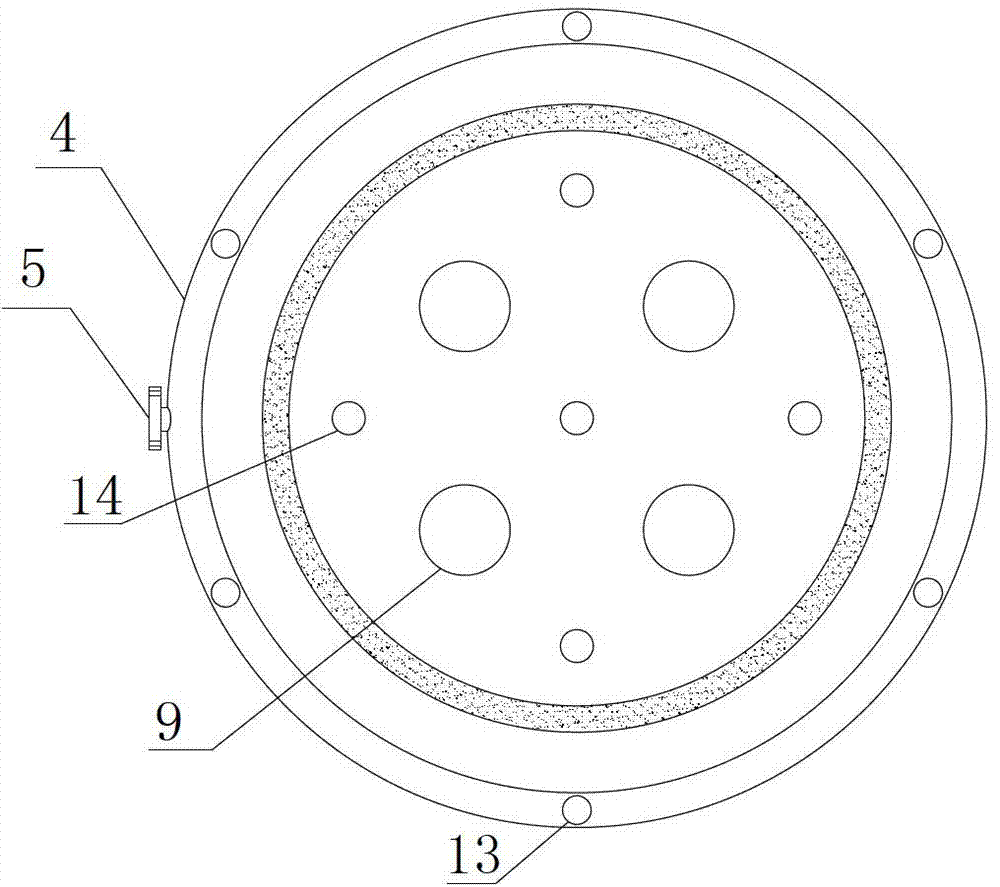

Low NOx fuel gas burner based on venturi tubes

InactiveCN103486572AReduce NOx formationPromote mixingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermal insulationEngineering

The invention disclose a low NOx fuel gas burner based on venturi tubes, which comprises a burner body, primary burners, secondary burners, a thermal insulation tile and the venturi tubes, wherein a first passage and a second passage are arranged on the thermal insulation tile; the thermal insulation tile is connected with the burner body; the first passage is communicated with a cavity of the burner body; necking mouths are formed in the first passage; primary fuel injection nozzles and secondary fuel injection nozzles are respectively arranged at the top ends of the primary burners and the secondary burners; the venturi tubes and the primary burners are arranged in the first passage; the secondary burners are arranged in the second passage; the top end surfaces of the primary fuel injection nozzles and the top end surfaces of the venturi tubes are parallel, and are arranged in the first passage respectively. Through the adoption of the design of the hierarchic arrangement of the venturi tubes, the necking mouths and the burners, the problem that local high temperature produced in a conventional fuel gas burner due to the nonuniform mixing of the fuel gas and combustion air in a furnace chamber can be overcome, meanwhile the flame stability of the burner is improved, and the generating of NOx is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

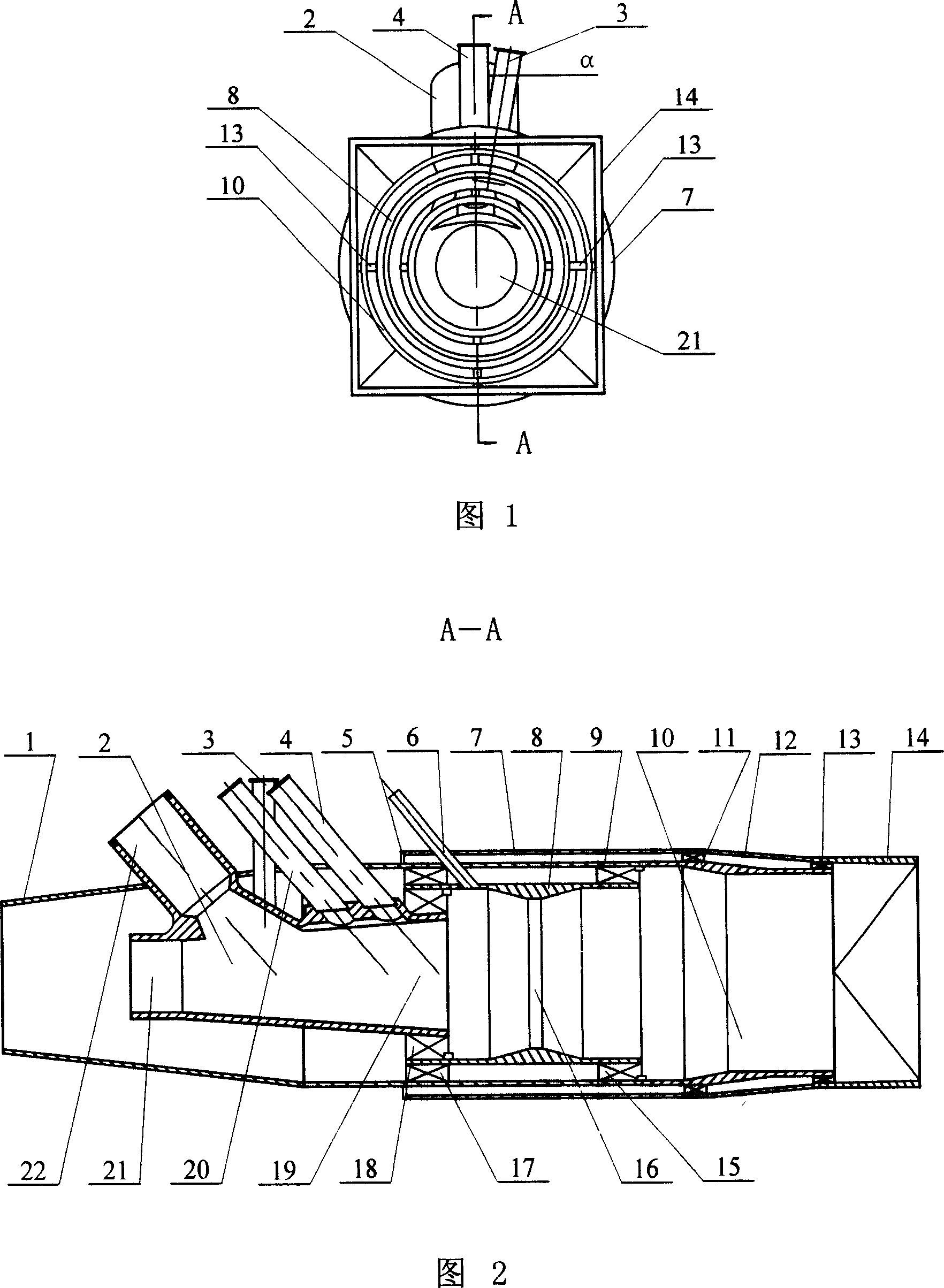

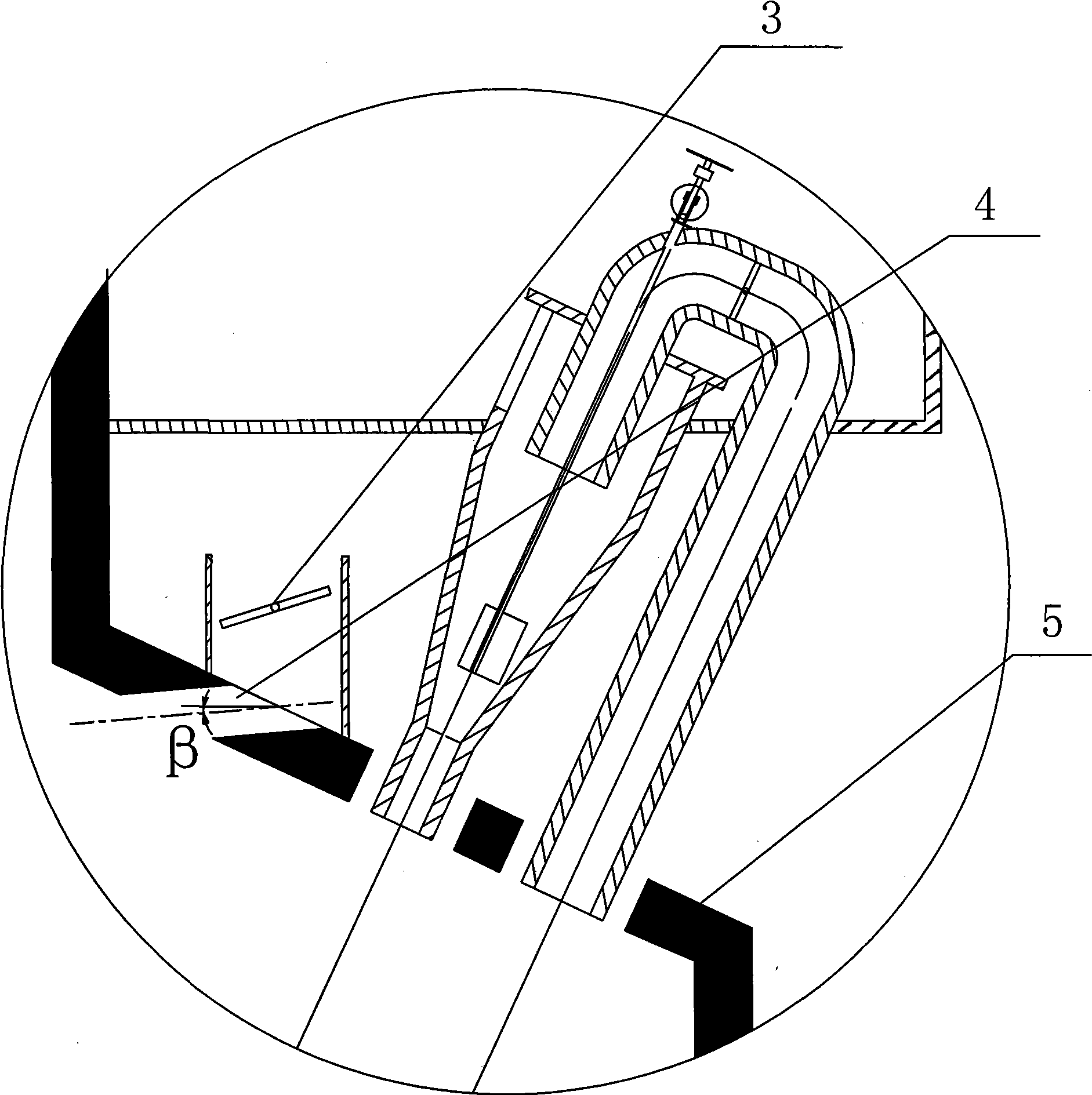

Little oil gasification and burning lateral-igniting center coal powder-feeding swirling burner

InactiveCN101101115ASolve the fuel saving problemSolve wear and tearCatalytic ignitersPulverulent fuel combustion burnersStart stopCombustor

The invention relates to swirl-flow burner. The first, second, and third truncated cone shape separating rings are orderly set at the middle of the burner primary flue in which the backward V shape separator is fixed at the right of the third truncated cone shape separating ring. The invention can greatly reduce initiation energy, satisfy the demands of start stop, and under load stable combustion for boiler, prolong coal dust residence time, control NOx production, form fractional combustion to combine with center feeding, realize NOx low discharge owing to secondary draft is divided into inner and outer two parts.

Owner:HARBIN INST OF TECH

Grading catalytic combustion device capable of coupling strong and weak heat release

The invention discloses a grading catalytic combustion device capable of coupling strong and weak heat release, which comprises an inner barrel, an outer barrel, a conical sleeve and a circular air inlet pipe; one end of the outer barrel is sealed with the inner barrel; one end of the inner barrel extends out of the sealing end of the outer barrel; the circular air inlet pipe extends into the other end of the inner barrel; the conical sleeve is hermetically connected between the outer barrel and the circular air inlet pipe; a plurality of air inlet pipes communicated with the inside of the outer barrel are uniformly distributed on the circumference of the outer barrel; a gas inlet pipe communicated with the inside of the outer barrel is arranged between the adjacent air inlet pipes; and the inner wall of the outer barrel and the wall of the inner barrel are coated with catalytic agents. The grading catalytic combustion device centralizes the inner barrel and the outer barrel into a reaction device to carry out grading catalytic combustion to generate the coupling reaction, thereby enhancing the oxidation reaction; the air inlet pipes are tangentially and crosswise arranged to facilitate the uniform mixing of gas and air and the adherence flowing; and the retention time of gas swirl in a micro space is increased so as to enhance the combustion stability and ensure that the reaction is easier to generate, the combustion is more complete, and the combustion efficiency is further improved.

Owner:CHONGQING UNIV

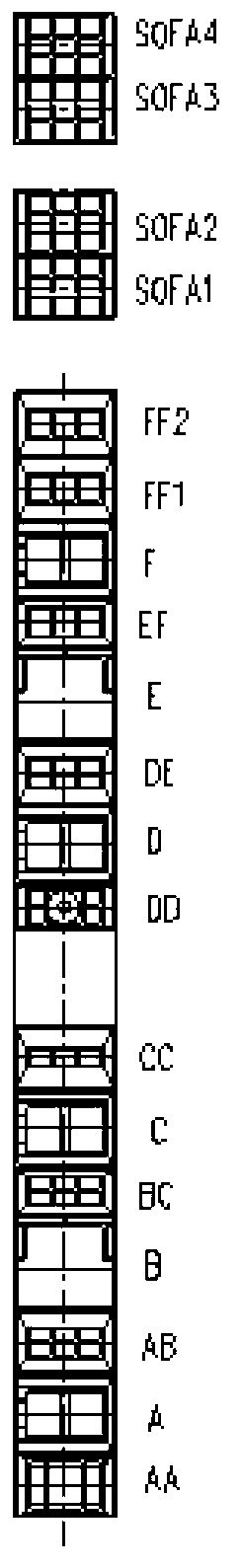

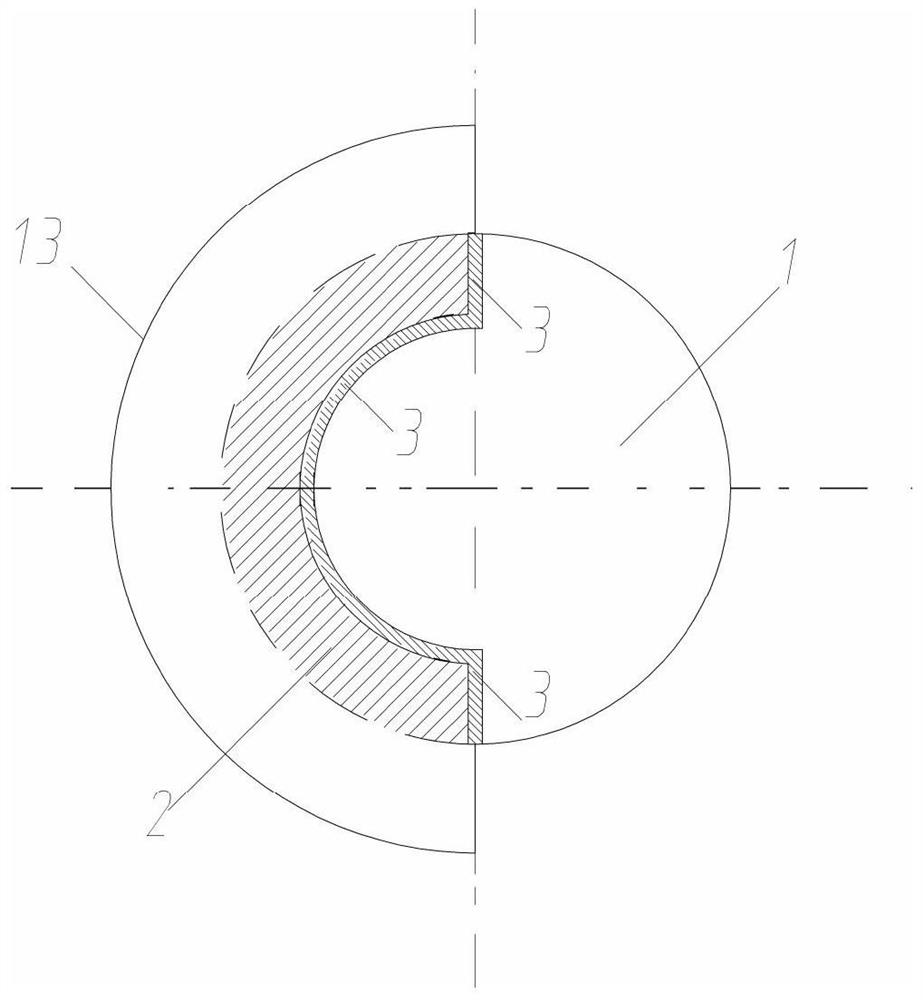

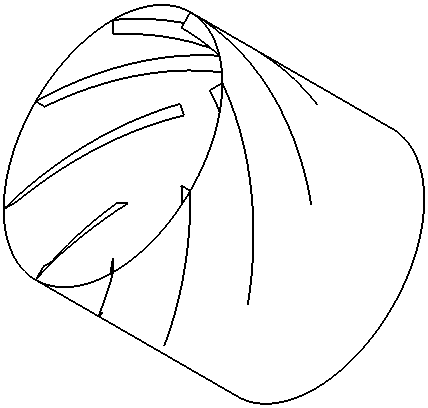

An intensified concentrated swirl pulverized coal burner

InactiveCN105737145BSolving Diffusion ProblemsAchieve staged combustionPulverulent fuel combustion burnersCyclonePowder mixture

The invention discloses a reinforcement and concentration type cyclone pulverized coal burner. The cyclone pulverized coal burner comprises a primary wind channel, an inner secondary wind channel and an outer secondary wind channel coaxially arranged in sequence from inside to outside; a primary wind nozzle is formed in an outlet end of the primary wind channel; an inner secondary wind nozzle is formed in an outlet end of the inner secondary wind channel; an outer secondary wind nozzle is formed in an outlet end of the outer secondary wind channel; the inner secondary wind nozzle and the outer secondary wind nozzle are both conically expanded; the inner diameters of the inner secondary wind nozzle and the outer secondary wind nozzle are gradually increased in a primary wind airflow direction; and the inner secondary wind nozzle is positioned in the outer secondary wind nozzle. The cyclone pulverized coal burner solves the problem of primary wind pulverized coals dispersed to a secondary wind flowing area, realizes the concentration classified combustion of the pulverized coals, solves the problem of too early mixing of a secondary wind and primary wind-powder mixture, realizes the air classification combustion, and achieves the purpose of reducing the generation of NOX.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY +1

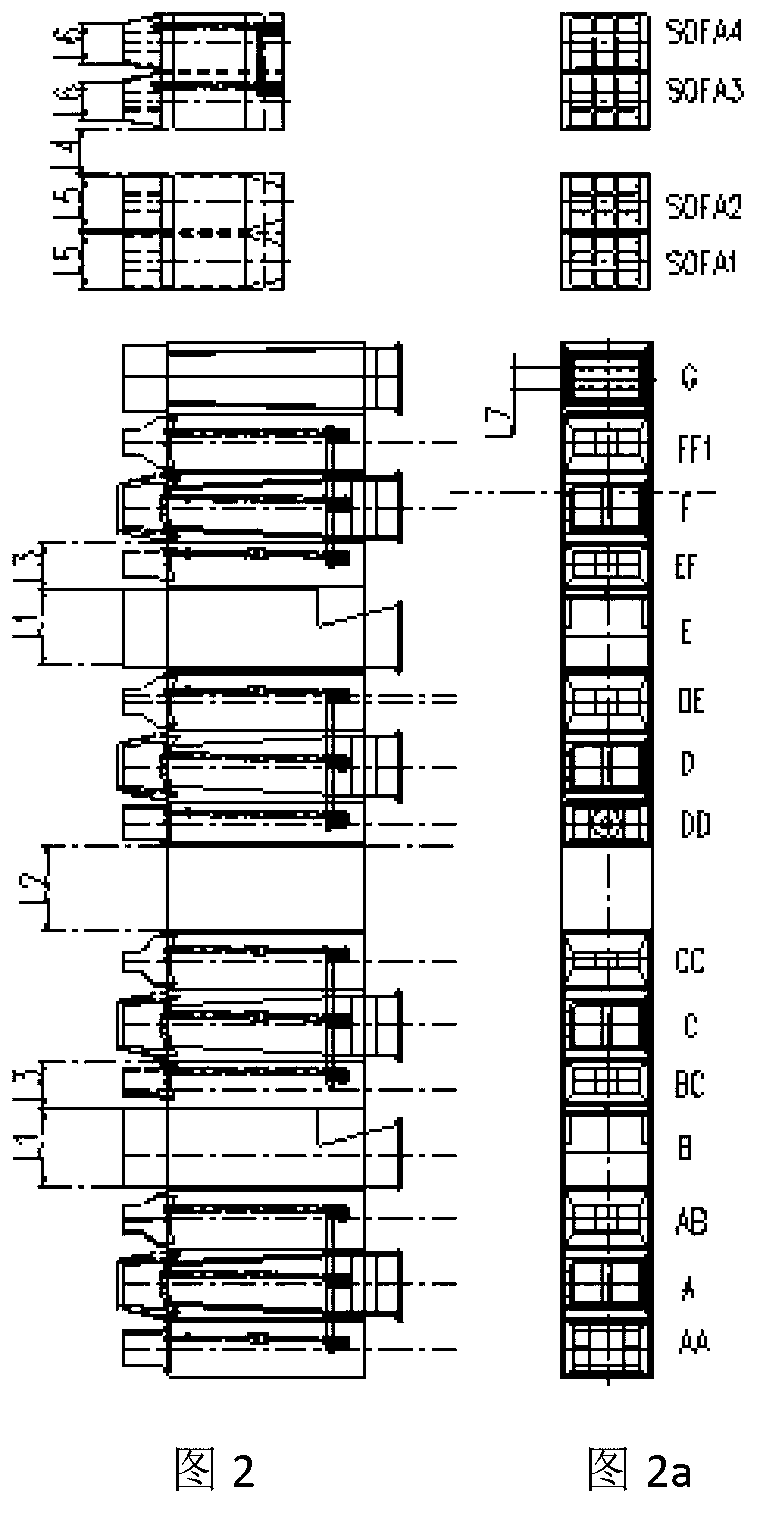

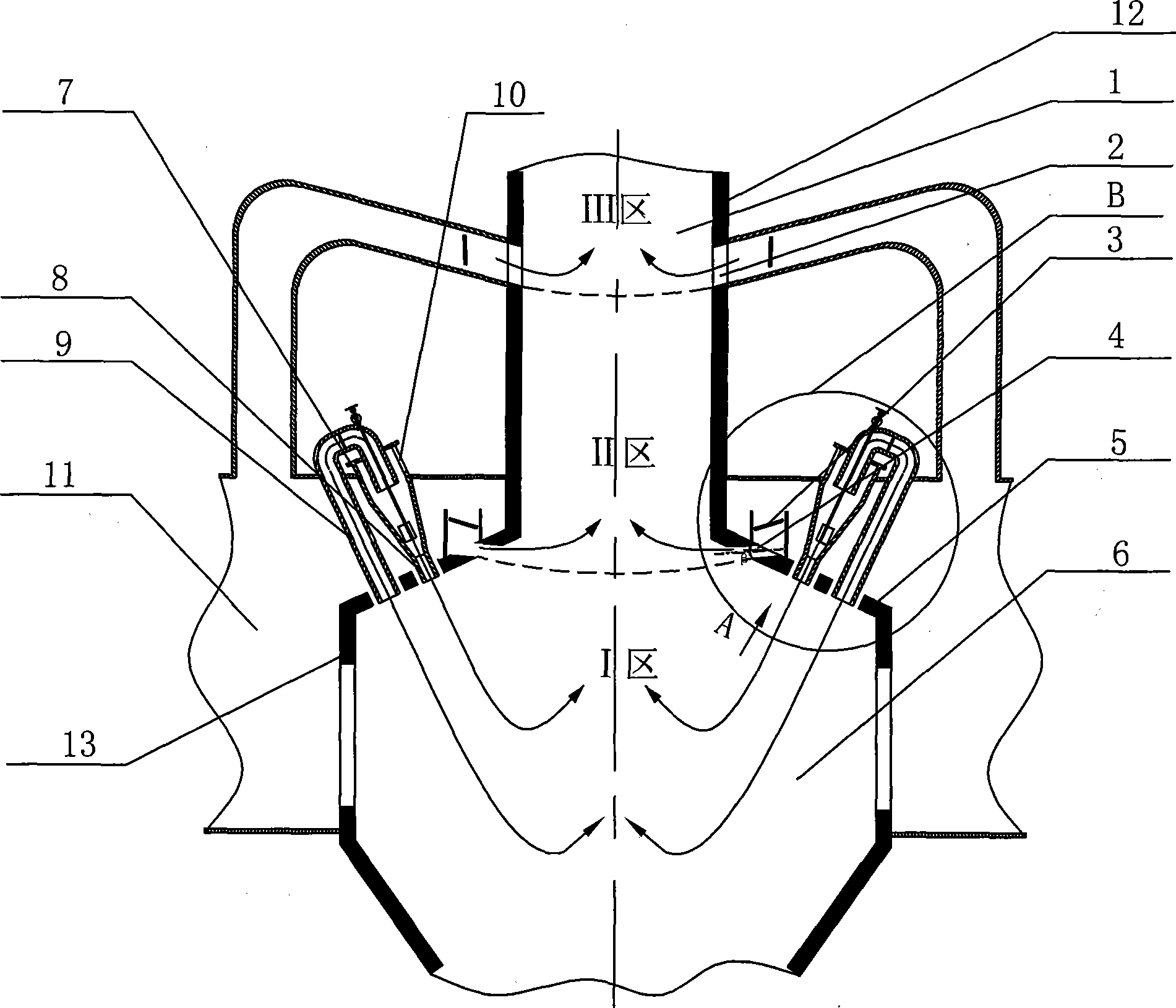

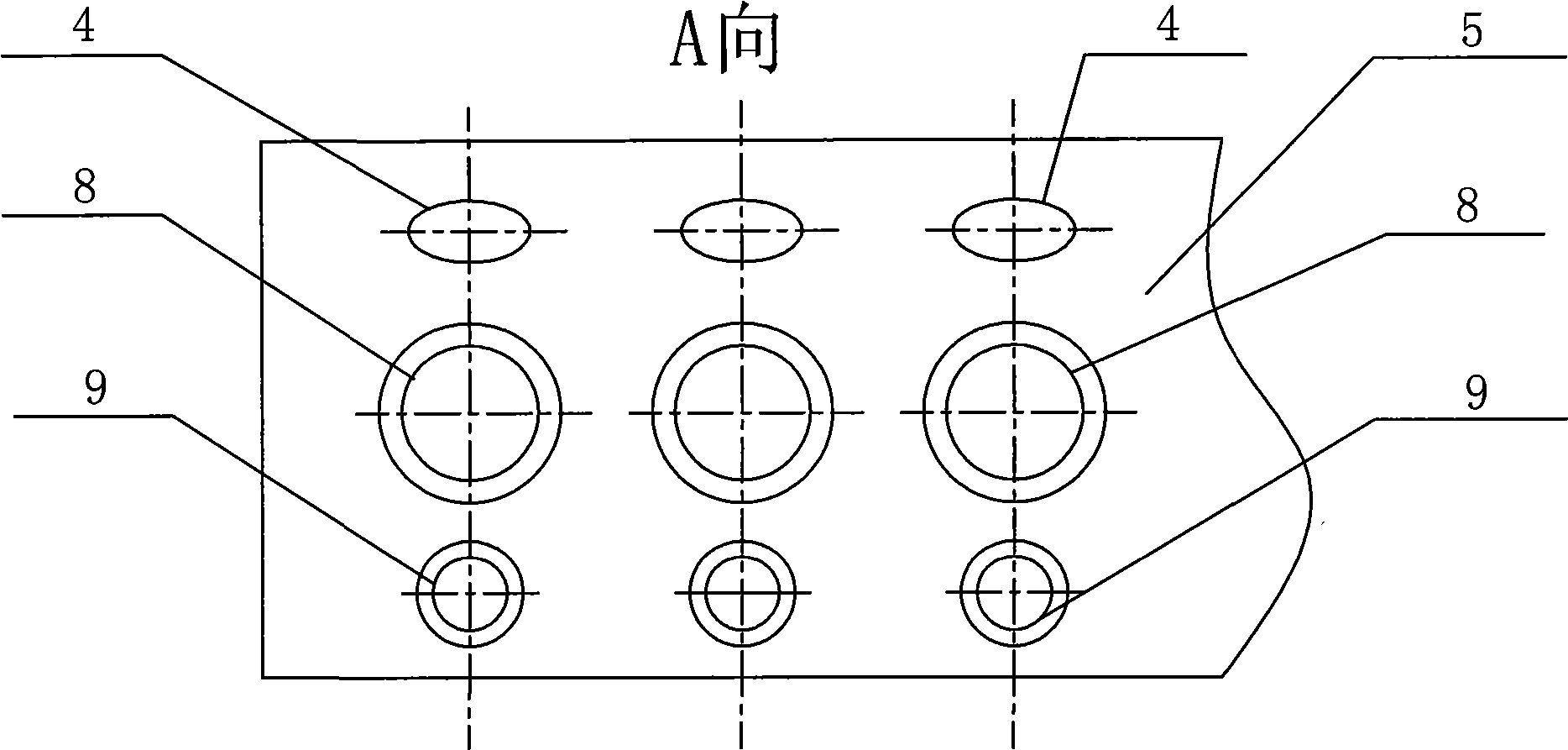

W-shaped flame boiler with two-stage over-fire wind

InactiveCN101476739AGuaranteed burnout rateGood for burnoutNon-combustible gases/liquids supplyCombustorSingle stage

The invention discloses a W-shaped flame boiler with two stages of burn-out wind, which relates to the W-shaped flame boiler and aims at the problems that the W-shaped flame boiler of the prior single-stage burn-out wind device has high content of fly ash inflammable matters and low burn-off rate of coal dust. The W-shaped flame boiler comprises a superior OFA nozzle (2) and an inferior OFA nozzle (4) which is arranged on a furnace arch (5) close to an hearth throat inlet, is communicated with a lower hearth (6), is arranged on the outer side of a burner (8), and is communicated with a secondary wind box (11). The W-shaped flame boiler not only can replenish air for the unburned coal dust in time to benefit the burnout of the coal dust and greatly reduce the content of the fly ash inflammable matters, but also can better achieve the fractional combustion of the coal dust and greatly reduce the emission of NOx.

Owner:HARBIN INST OF TECH

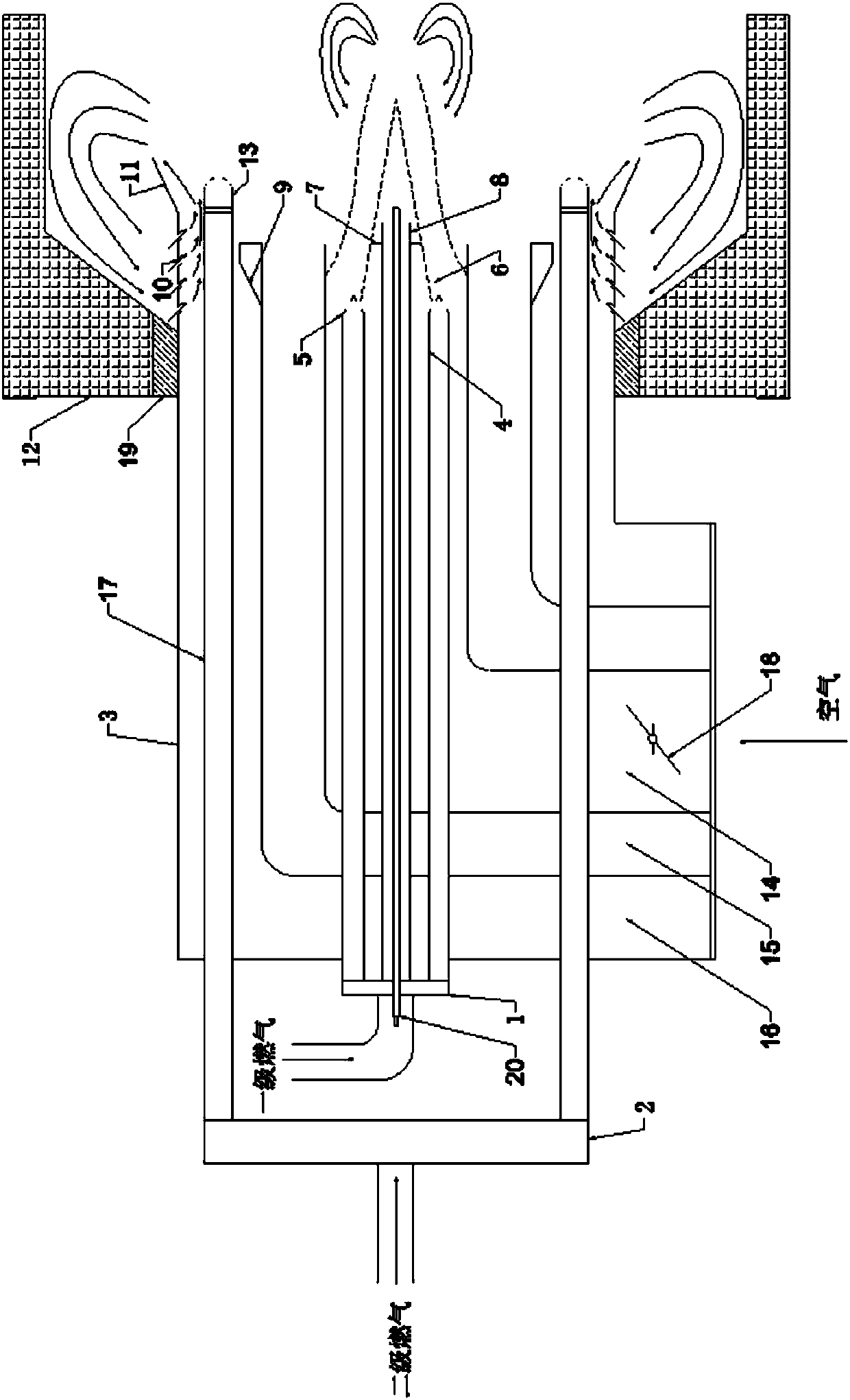

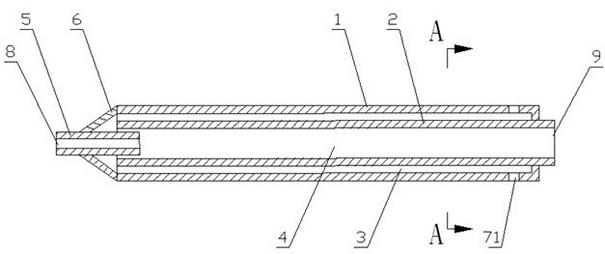

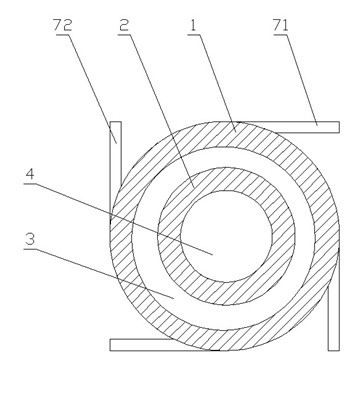

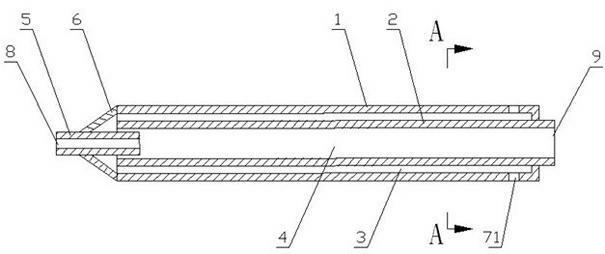

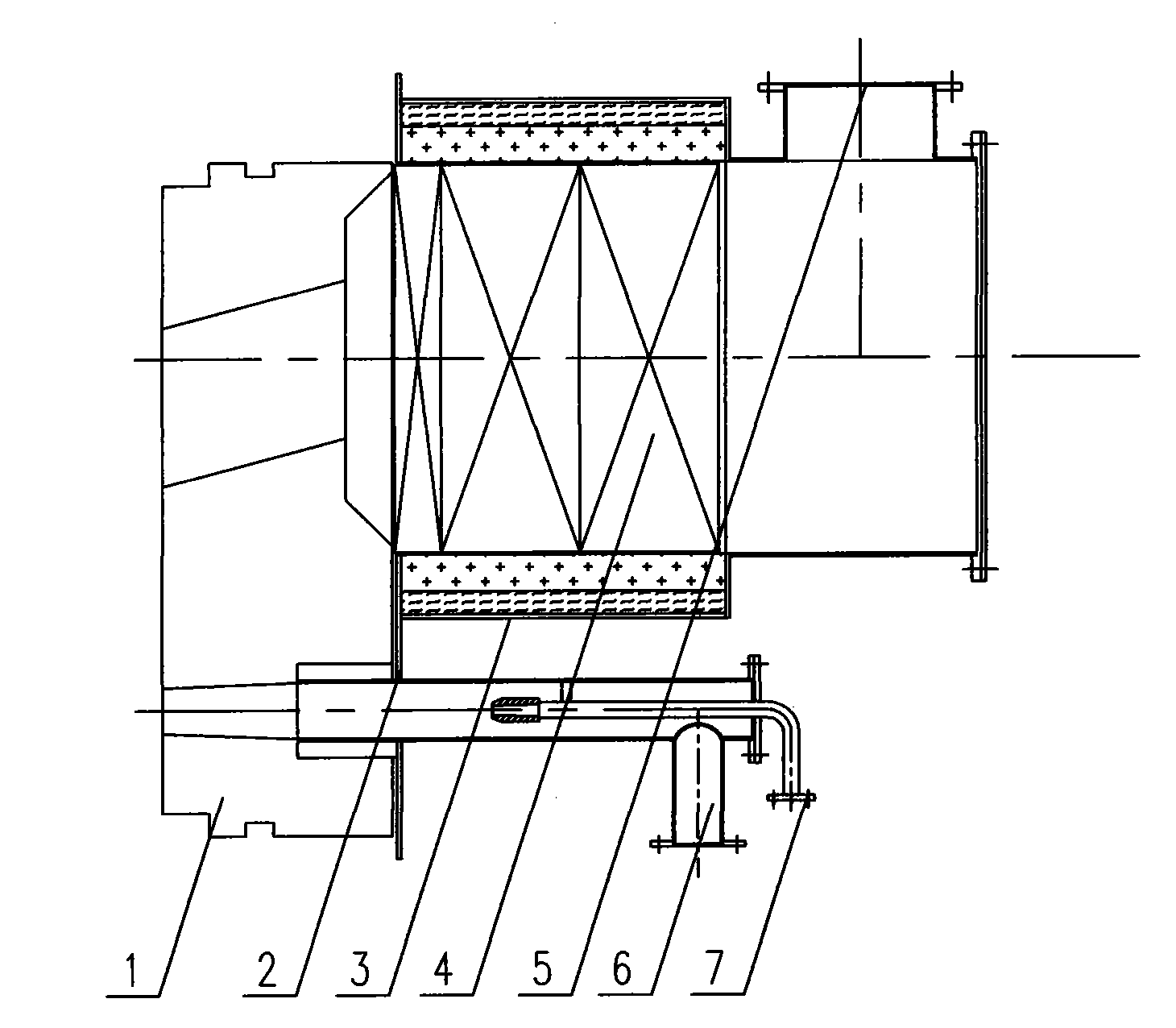

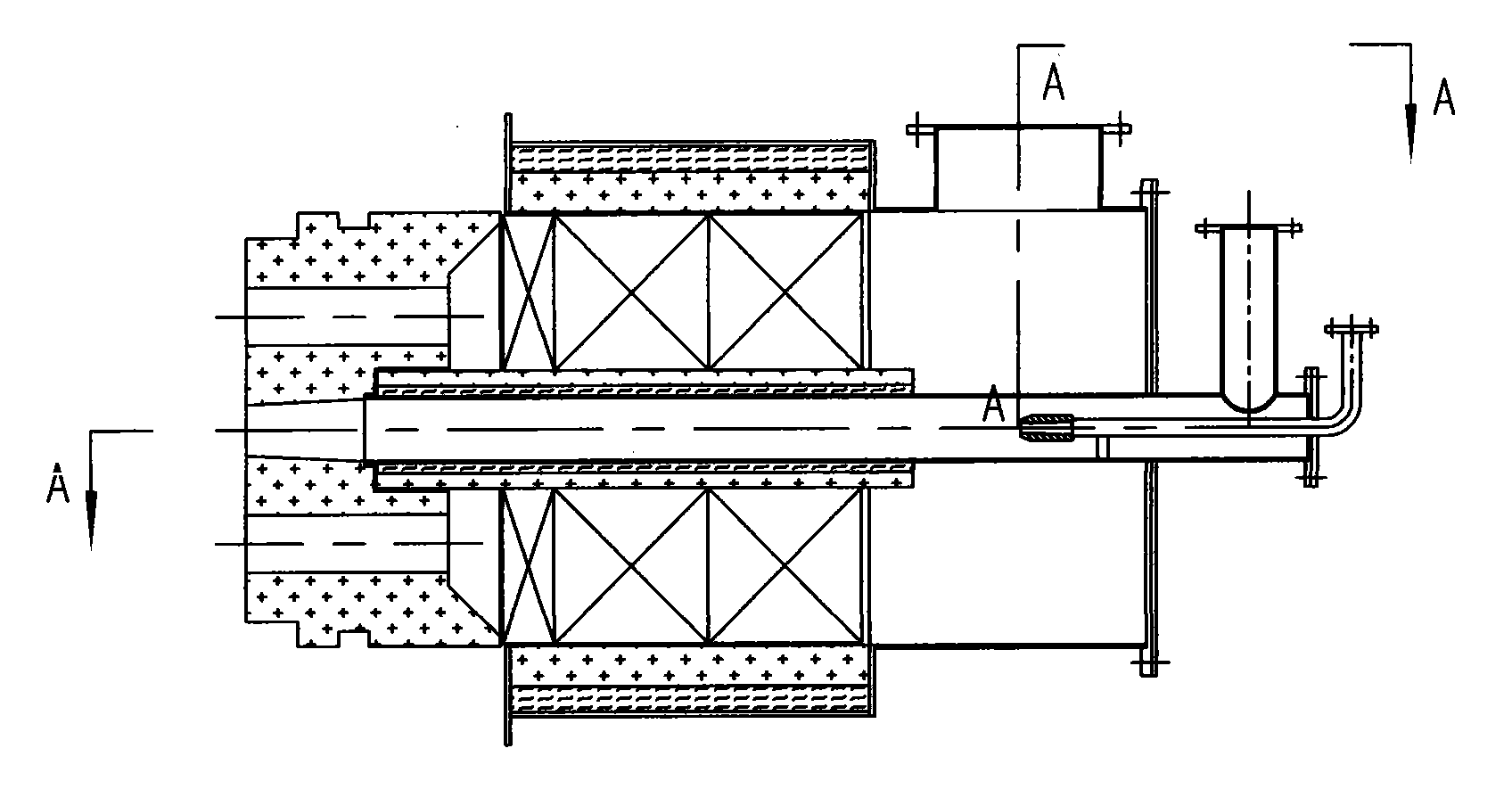

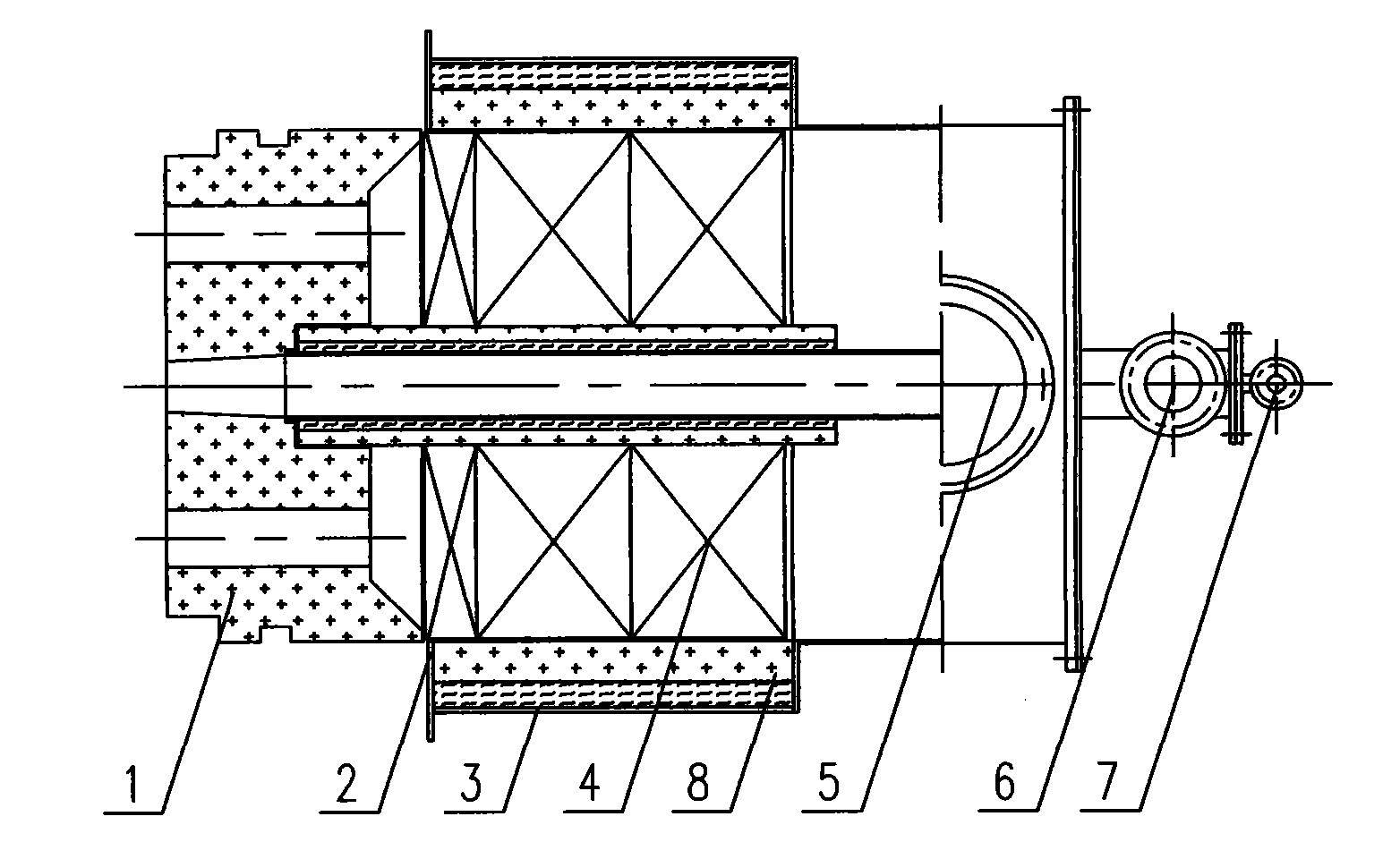

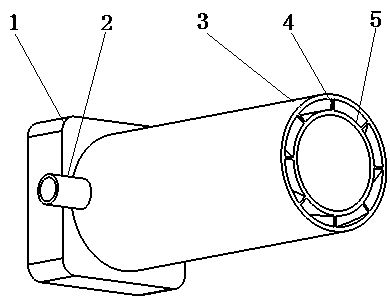

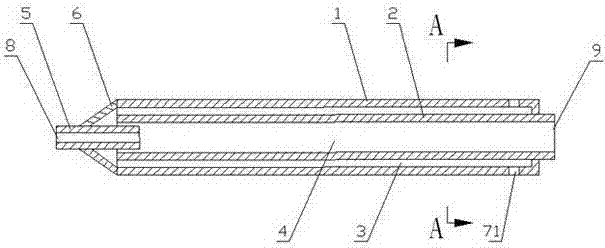

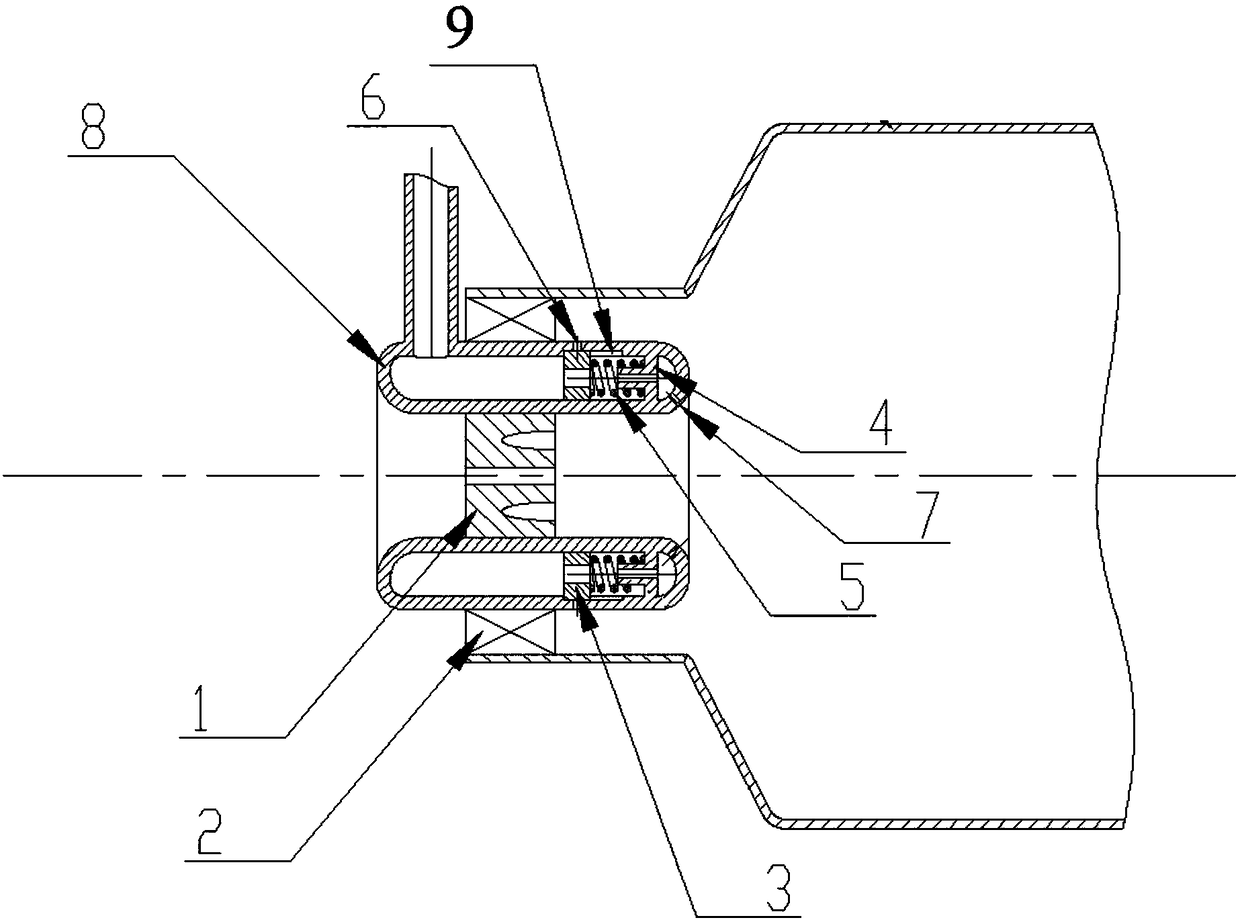

Air single regenerative burner

InactiveCN101799158APrevent backfireImprove securityIndirect carbon-dioxide mitigationGaseous fuel burnerBrickHearth

The invention discloses an air single regenerative burner, which comprises a burner brick (1) and a burner mounting plate (2). A burner shell (3) is arranged on the burner mounting plate (2); a heat accumulator (4) is arranged in the burner shell (3); a secondary air pipeline (5) leading to a hearth is arranged on the burner shell (3); a gas pipeline (6) is arranged outside the burner shell (3); the tail end of the gas pipeline (6) is inserted into the burner brick (1); a primary air pipeline (7) is arranged in the gas pipeline (6); and the gas pipeline (6) and the primary air pipeline (7) can also be arranged in the burner shell (3). The air single regenerative burner of the invention can fully burn fuel in industrial furnaces and kilns so as to reduce the generation of NOX, save energy and protect environment, can effectively prevent backfire in the gas pipeline and has good safety.

Owner:HUATIAN ENG & TECH CORP MCC +1

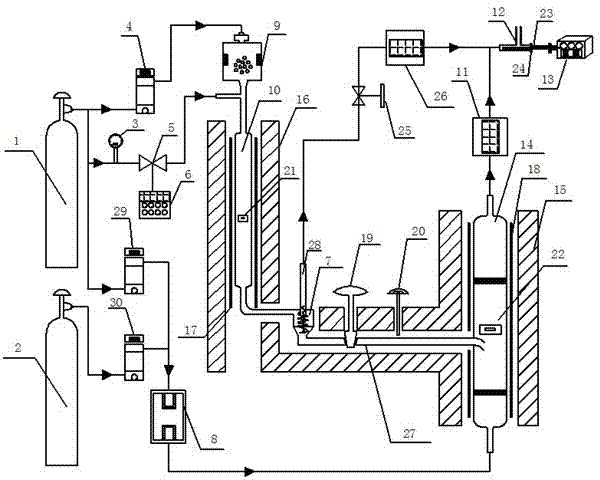

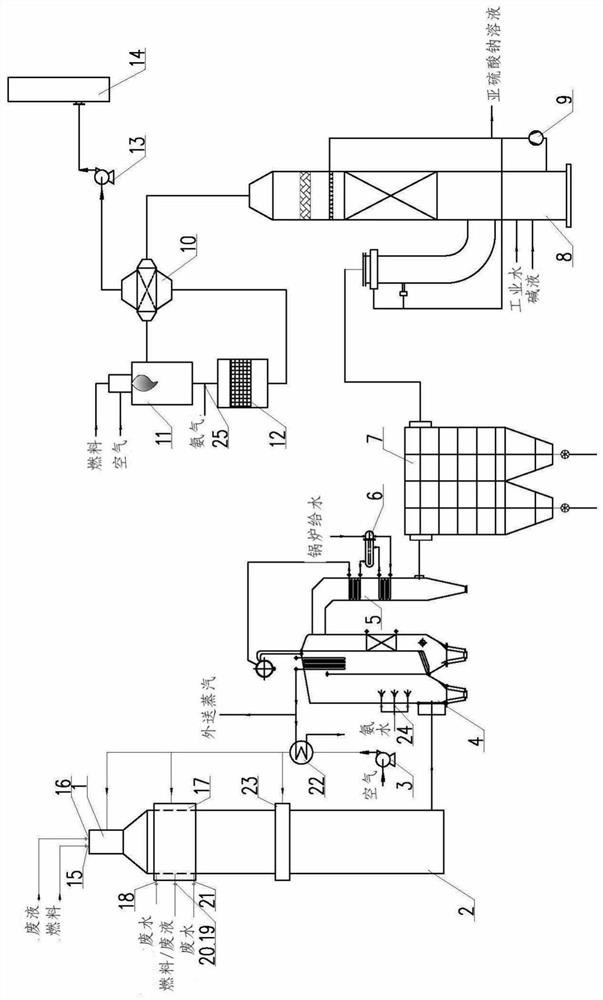

Incineration system for treating sulfur-containing, nitrogen-containing and salt-containing waste liquid

PendingCN113864789AAvoid cloggingAvoid corrosionEmission preventionIncinerator apparatusHazardous substanceSulfur containing

The invention discloses an incineration system for treating sulfur-containing, nitrogen-containing and salt-containing waste liquid. The system comprises an incinerator, a waste heat boiler, an economizer, a desulfurization tower and a denitration device, and the incinerator is provided with a waste liquid conveying pipeline and a fuel conveying pipeline; high-temperature flue gas generated after incineration of the incinerator enters the waste heat boiler from an outlet of the incinerator; the economizer is connected with the waste heat boiler, and after high-temperature flue gas treated by the waste heat boiler enters the economizer from an outlet of the waste heat boiler, heat continues to be recycled; the high-temperature flue gas treated by the coal economizer enters the desulfurization tower to be subjected to desulfurization treatment; and the high-temperature flue gas treated by the desulfurization tower enters the denitration device for denitration treatment. According to the invention, a process technical route of staged combustion-waste heat recovery-first desulfurization and then denitration is adopted, and toxic and harmful substances are oxidized and decomposed through high-temperature incineration; and by adopting the mode that the flue gas is desulfurized, heated and then denitrated, the blockage and corrosion of ammonium bisulfite and ammonium bisulfate to downstream equipment such as the coal economizer are avoided, and the environment-friendly emission requirement of NOx is met.

Owner:上海瑞鼎环境工程技术有限公司 +1

Reinforcement and concentration type cyclone pulverized coal burner

InactiveCN105737145ASolving Diffusion ProblemsAchieve staged combustionPulverulent fuel combustion burnersAirflowNozzle

The invention discloses a reinforcement and concentration type cyclone pulverized coal burner. The cyclone pulverized coal burner comprises a primary wind channel, an inner secondary wind channel and an outer secondary wind channel coaxially arranged in sequence from inside to outside; a primary wind nozzle is formed in an outlet end of the primary wind channel; an inner secondary wind nozzle is formed in an outlet end of the inner secondary wind channel; an outer secondary wind nozzle is formed in an outlet end of the outer secondary wind channel; the inner secondary wind nozzle and the outer secondary wind nozzle are both conically expanded; the inner diameters of the inner secondary wind nozzle and the outer secondary wind nozzle are gradually increased in a primary wind airflow direction; and the inner secondary wind nozzle is positioned in the outer secondary wind nozzle. The cyclone pulverized coal burner solves the problem of primary wind pulverized coals dispersed to a secondary wind flowing area, realizes the concentration classified combustion of the pulverized coals, solves the problem of too early mixing of a secondary wind and primary wind-powder mixture, realizes the air classification combustion, and achieves the purpose of reducing the generation of NOX.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY +1

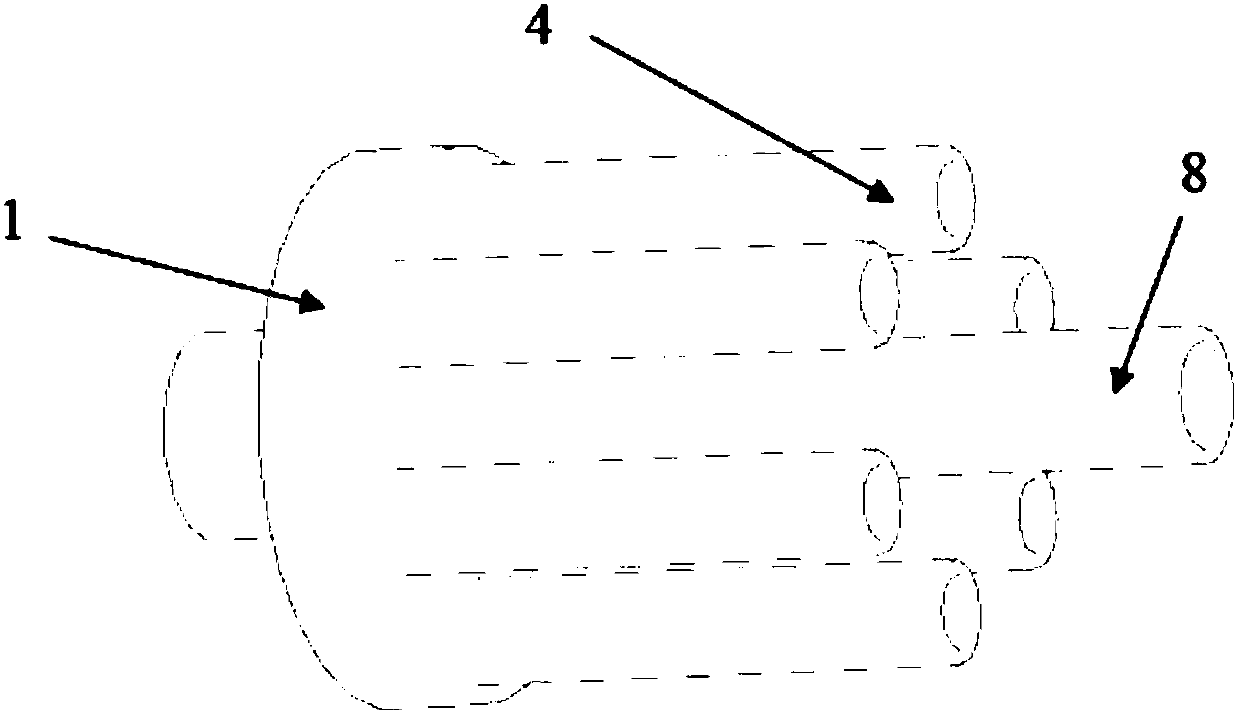

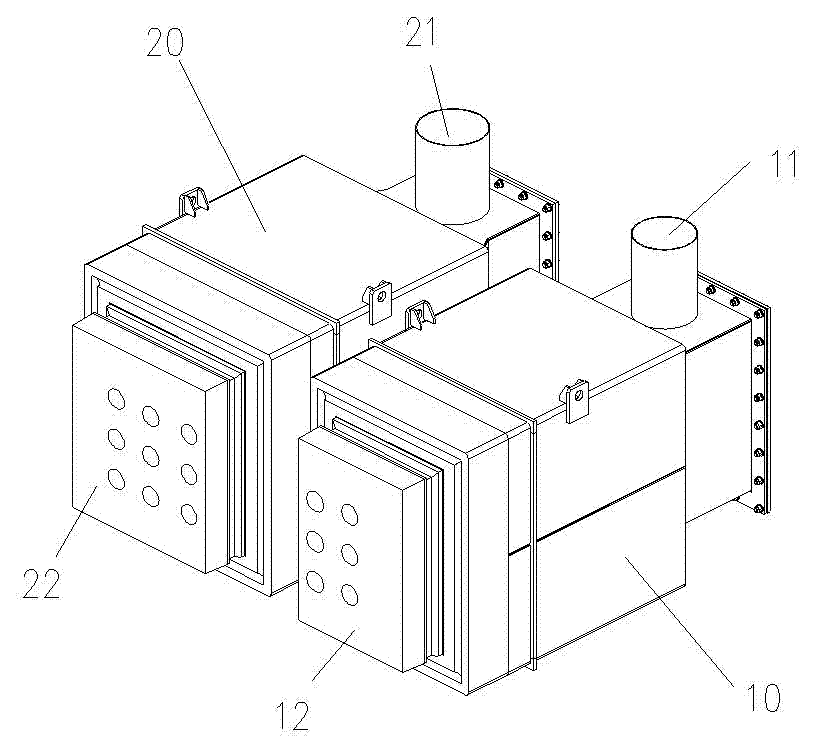

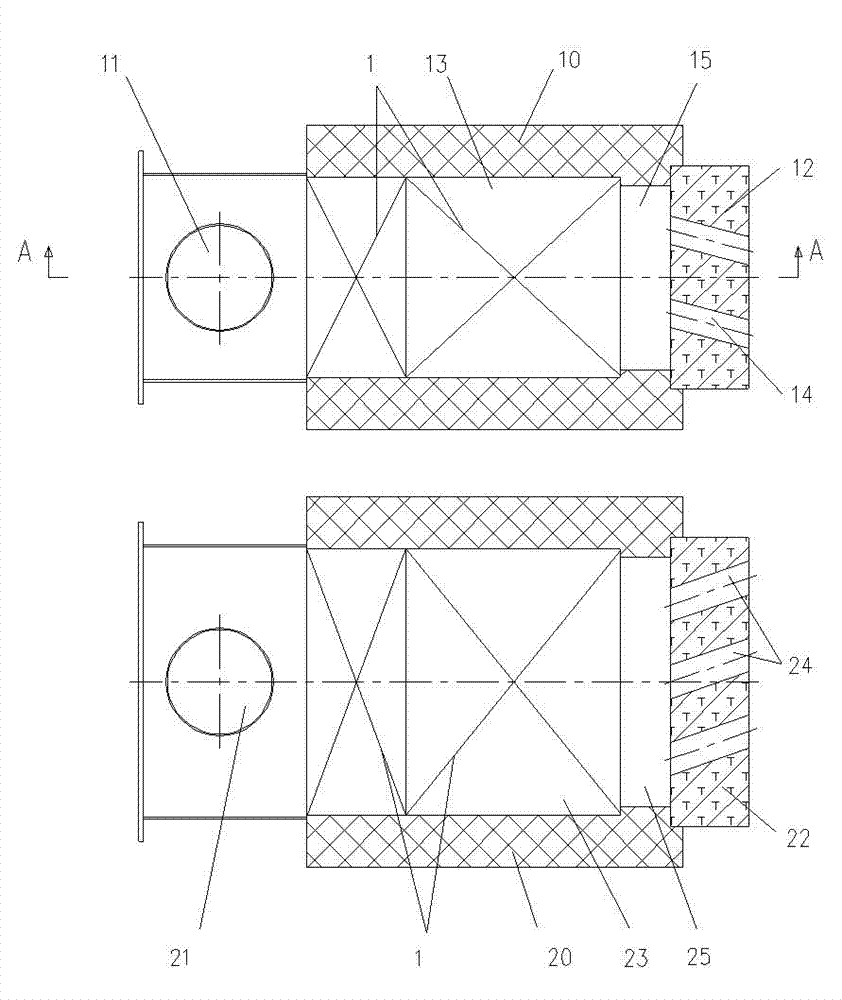

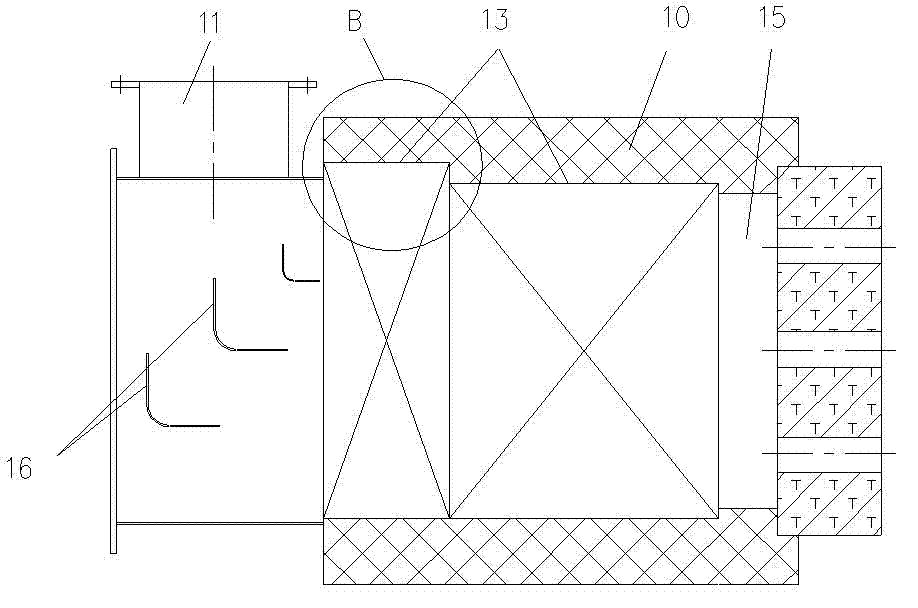

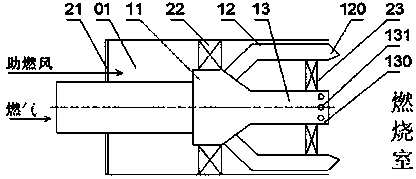

Air and gas double-heat-accumulation combustion device

ActiveCN103047654AGuaranteed heat storage and heat exchange capacityHeat storage and heat exchange capacity maintenanceGaseous fuel feeder/distributionIndirect carbon-dioxide mitigationBrickCombustion

An air and gas double-heat-accumulation combustion device comprises an air heat accumulation case and a gas heat accumulation case. An air inlet and an air nozzle brick are arranged on the air heat accumulation case, and a gas inlet and a gas nozzle brick are arranged on the gas heat accumulation case; at least two air heat accumulation cavities are arranged inside the air heat accumulation case, the top of one of each two adjacent air heat accumulation cavities is higher / lower than that of the other air heat accumulation cavity, each air heat accumulation cavity with the top higher / lower than that of the corresponding adjacent air heat accumulation cavity is close to the air inlet while the corresponding adjacent air heat accumulation cavity is close to the air nozzle brick, and a heat accumulator is arranged in each air heat accumulation cavity; and at least two gas heat accumulation cavities are arranged inside the gas heat accumulation case, the top of one of each two adjacent gas heat accumulation cavities is higher / lower than that of the other gas heat accumulation cavity, each gas heat accumulation cavity with the top higher / lower than that of the corresponding adjacent gas heat accumulation cavity is close to the gas inlet while the corresponding adjacent gas heat accumulation cavity is close to the gas nozzle brick, and a heat accumulator is arranged in each gas heat accumulation cavity. The air and gas double-heat-accumulation combustion device has the advantages that short circuit of gas flow can be prevented even under the condition that the heat accumulators contract or are locally damaged, heat accumulation and heat exchange capacities of the heat accumulators are kept, and the service life of each heat accumulator can be prolonged.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

Low-nitrogen burning device applicable to fuel gas with low heat value

InactiveCN110056873AMulticastAchieving mixed combustionGaseous fuel burnerNitrogen oxidesCombustion chamber

The invention discloses a low-nitrogen burning device which is applied to a kiln furnace or a boiler and is used for burning gaseous fuel with a low heat value. The burning device consists of a fuel gas distribution tank, a main burning spray gun, a stable burning spray gun, a flow-equalizing plate, a stable burning disc and a swirl generator, wherein the fuel gas is distributed through the distribution tank and then uniformly flows into the stable burning spray gun and the main burning spray gun; the fuel gas is fed into a burning chamber through various nozzles; and the burning-supporting air is introduced into the burning device through the flow-equalizing plate, is then separately injected into the burning chamber through the stable burning disc and a swirling device, and is mixed andburned together with fuel gas which is fed from the stable burning disc and the swirling device. Through a burning way, the fuels and the burning-supporting air are supplied into the burning chamber in a grading manner, so that control of a burning temperature of the fuel gas is facilitated, and the aim of reducing generation of nitrogen oxide as much as possible is fulfilled. Meanwhile, because the situation that a certain amount of fuel gas and burning-supporting air can be fired and burned in time nearby an axis of a burner outlet is ensured, the device is applied to stable burning of the fuel gas with the low heat value.

Owner:山东博然电力科技有限公司

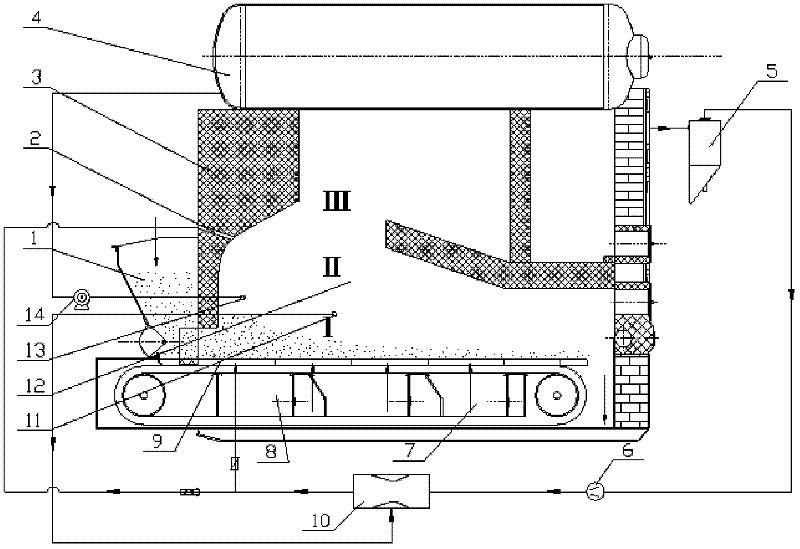

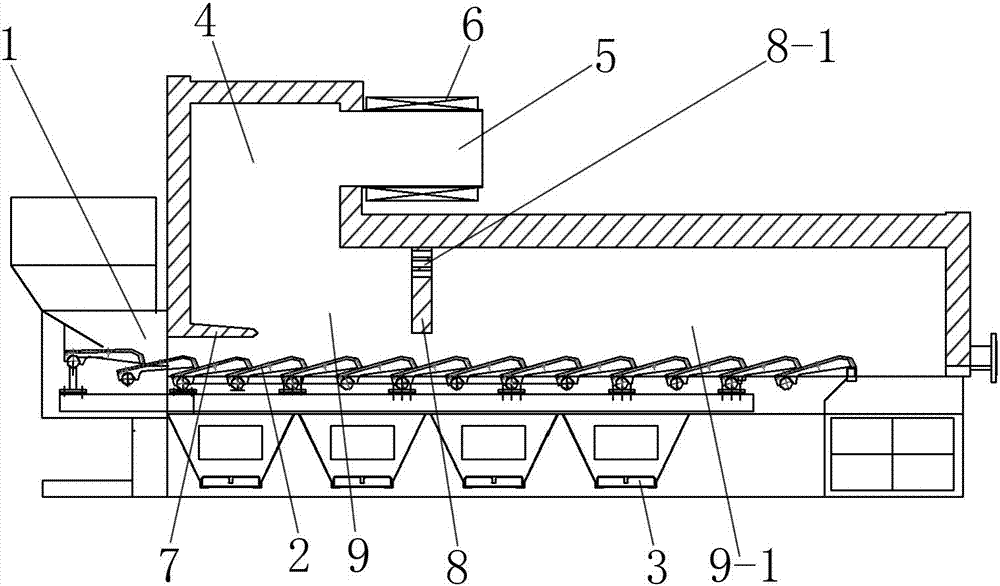

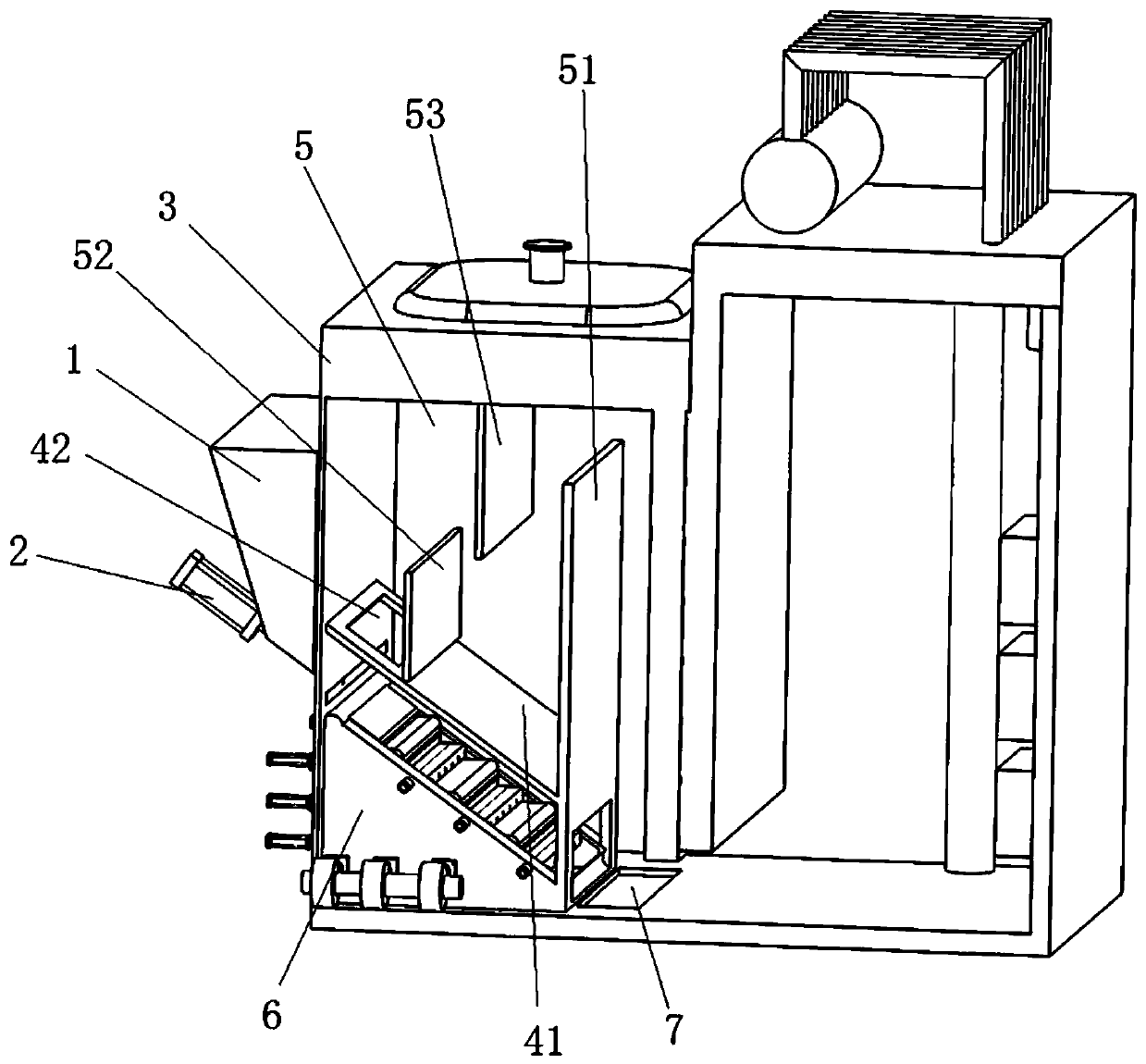

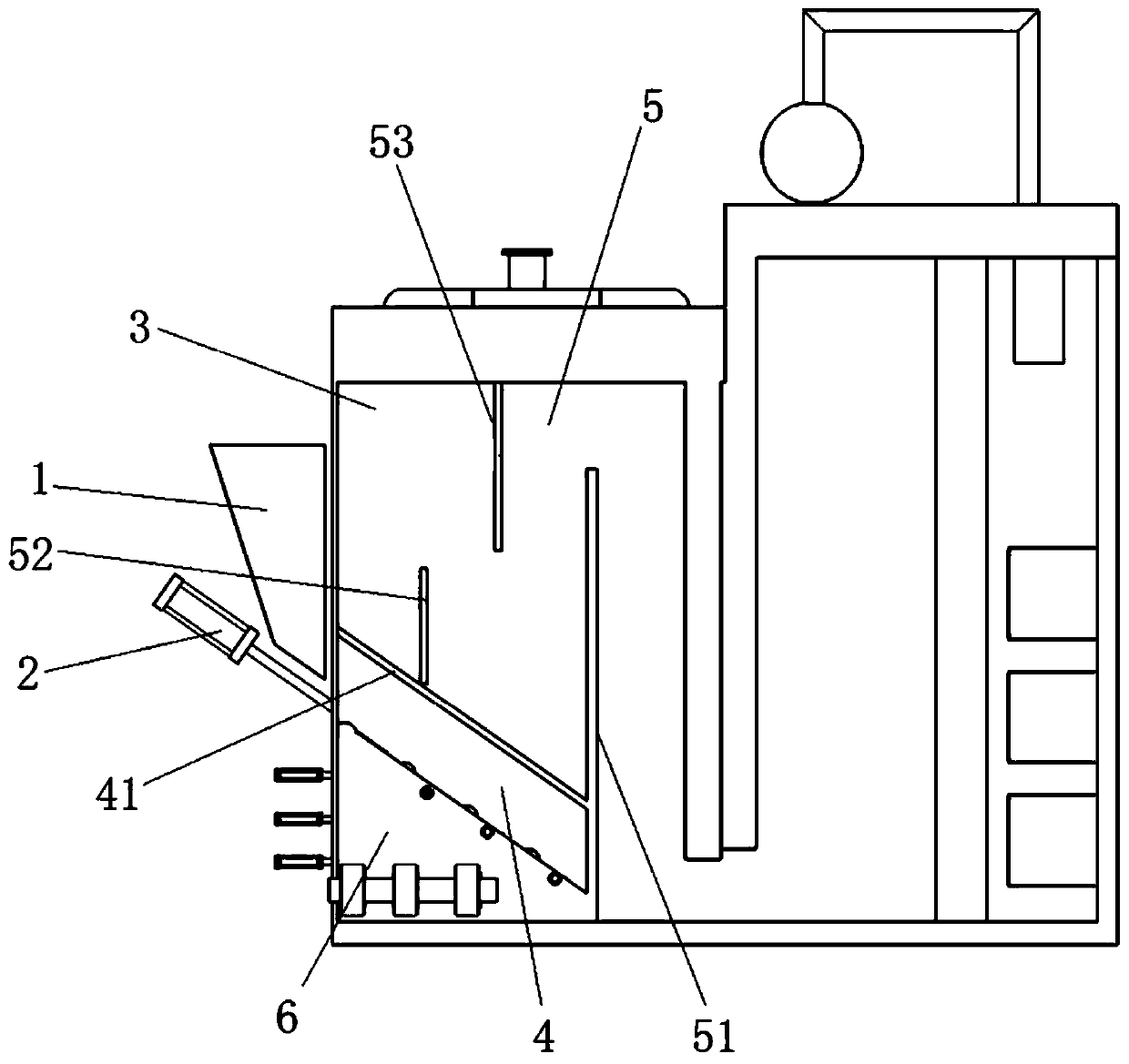

Biomass briquette gasified combustion normal pressure hot-water boiler

PendingCN107036283APrevent slaggingNot easy to slaggingSolid fuel combustionWater heatersWater pipeCombustion chamber

The invention discloses a biomass briquette gasified combustion normal pressure hot-water boiler, and belongs to the technical field of biomass briquette boilers. The problems existing in an existing biomass briquette boiler are solved. The biomass briquette gasified combustion normal pressure hot-water boiler comprises a burner, a gas combustion chamber and a flue. The burner comprises a gasification combustion chamber. The bottom of the gasification combustion chamber is provided with a fire grate and primary air openings. A gas nozzle is arranged at the side, far away from a feeding inlet, of a gas collecting area, and a secondary air opening is formed in the gas nozzle. The gas combustion chamber is arranged in front of the gas nozzle. A reciprocating grate is adopted in the fire grate. A separating wall perpendicular to the fire grate direction is arranged inside the gasification combustion chamber, and air holes are formed in the upper side of the separating wall. Rotational flow blades are arranged in the secondary air opening. Threaded smoke tubes are arranged inside the flue, and a normal pressure water tank is arranged outside the threaded smoke tubes. Heat exchange water pipes are arranged inside the normal pressure water tank and located above the threaded smoke tubes. The biomass briquette gasified combustion normal pressure hot-water boiler is used for biomass briquette gasified combustion heat supply.

Owner:HAILUN LIMIN ENERGY SAVING BOILER MFG

Slag blocking preventing type wall-attached air device based on air staged combustion

PendingCN112283736AAchieve staged combustionIncrease the atmosphereBlast-producing apparatusCasings/liningsSlagEngineering

The invention relates to a slag blocking preventing type wall-attached air device based on air staged combustion. The slag blocking preventing type wall-attached air device comprises a wall-attached air nozzle consisting of a jet flow air nozzle and a protective air nozzle; the jet flow air nozzle faces the air flow jet direction of a pulverized coal combustor, and the protective air nozzle is arranged back to the air flow jet direction of the pulverized coal combustor; the jet flow air nozzle and the protective air nozzle are separated by a partition plate; and a coke poking device is arranged in the jet flow air nozzle and can push coke slag adhered to the jet flow air nozzle into a hearth. According to the slag blocking preventing type wall-attached air device, air staged combustion isrealized, and NOx generated by combustion is reduced advantageously; protective air forms an air film at the wall-attached position of a water-cooled wall, and the atmosphere at the wall-attached position of the water-cooled wall is improved. Under the action of jet flow air and protective air, the problem of high-temperature corrosion of the boiler water-cooled wall can be solved. Meanwhile, slagbonding or burning loss of the nozzle due to the fact that coke slag particles adhere to the wall-attached air nozzle in the combustion process can be prevented.

Owner:XIAN THERMAL POWER RES INST CO LTD

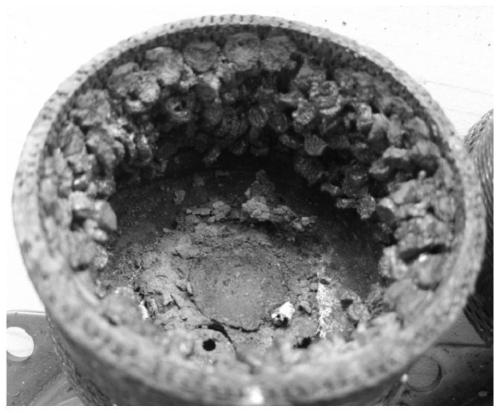

Gas generator

ActiveCN111548242AReduce output slopeAvoid Shock and FailurePedestrian/occupant safety arrangementExplosive working-up apparatusPhysicsChemistry

The invention relates to and provides a gas generator; staged combustion is achieved by changing the structure and layout of a filter and the formula and type of a gas production chemical, so that thefiltering efficiency of the filter is improved, the initial output slope of the gas generator is reduced, and the gas generator is small in size, light in weight and reliable in work. In addition, the formula of the gas generating agent composition is designed; zirconate, silicate or a mixture of zirconate and silicate is used as a slag-forming agent; by matching with other components, tablets can be condensed and agglomerated in a filter screen after being combusted, the form of the tablets before combustion is well kept, the tablets are completely prevented from melting and splashing to burn a gas bag after combustion, and slagging during combustion of the gas generating agent composition is improved by at least 50%.

Owner:HUBEI HANGPENG CHEM POWER TECH

Biomass particle fuel gasification combustion normal-pressure water boiler

PendingCN108692456ABurn fullySafe and reliableSolid fuel combustionWater heatersFuel gasificationProcess engineering

The invention discloses a biomass particle fuel gasification combustion normal-pressure water boiler. The biomass particle fuel gasification combustion normal-pressure water boiler comprises a boilerbody, a spiral feeding device, a fire grate and a flue. A feeding port of the boiler body is connected with a discharging port of the spiral feeding device. The fire grate is arranged at the bottom ofthe boiler body. The flue is arranged at the upper portion of the boiler body. The biomass particle fuel gasification combustion energy-saving and environment-friendly normal-pressure water boiler which adopts biomass particles as fuel, and is efficient, capable of saving energy, low in pollution, capable of achieving zero emission, safe and environment-friendly is disclosed and provided.

Owner:HAILUN LIMIN ENERGY SAVING BOILER MFG

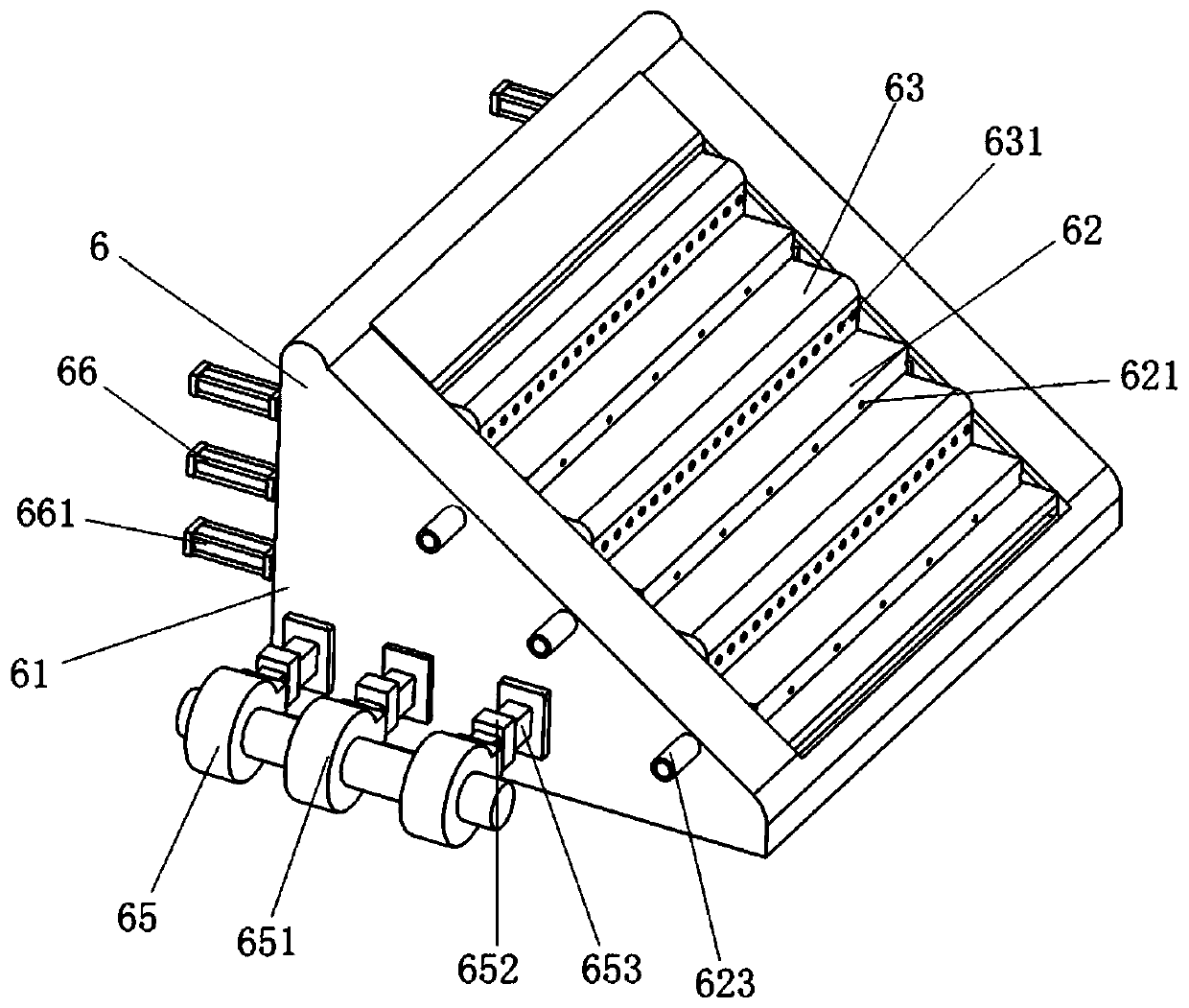

Continuously operated biomass forming fuel gasification combustor

PendingCN107036075APrevent slaggingNot easy to slaggingSolid fuel combustionNon-combustible gases/liquids supplyCombustion chamberEnvironmental geology

The invention discloses a continuously operated biomass forming fuel gasification combustor, belongs to the technical field of combustion of biomass forming fuels, and solves the problems in a traditional biomass forming fuel combustor. The continuously operated biomass forming fuel gasification combustor comprises a combustor body; the combustor body comprises a gasification combustion chamber; a feed port is formed in one side of the gasification combustion chamber; a fire grate and a primary wind port are arranged at the bottom of the gasification combustion chamber; a gas gathering area is arranged above the gasification combustion chamber; a gas nozzle is arranged on one side, farther from the feed port, of the gas gathering area; a secondary wind port is formed in the gas nozzle; the fire grate adopts a reciprocating fire grate; a tempering prevention wall is arranged in the upper side edge position of the feed port in the gasification combustion chamber; an isolation wall perpendicular to the fire grate is arranged in the gasification combustion chamber for dividing the gasification combustion chamber into two areas; an air hole is formed in the upper side of the isolation wall; and cyclone blades are arranged in the secondary wind port. The continuously operated biomass forming fuel gasification combustor is applied to gasification combustion of the biomass forming fuels.

Owner:HAILUN LIMIN ENERGY SAVING BOILER MFG

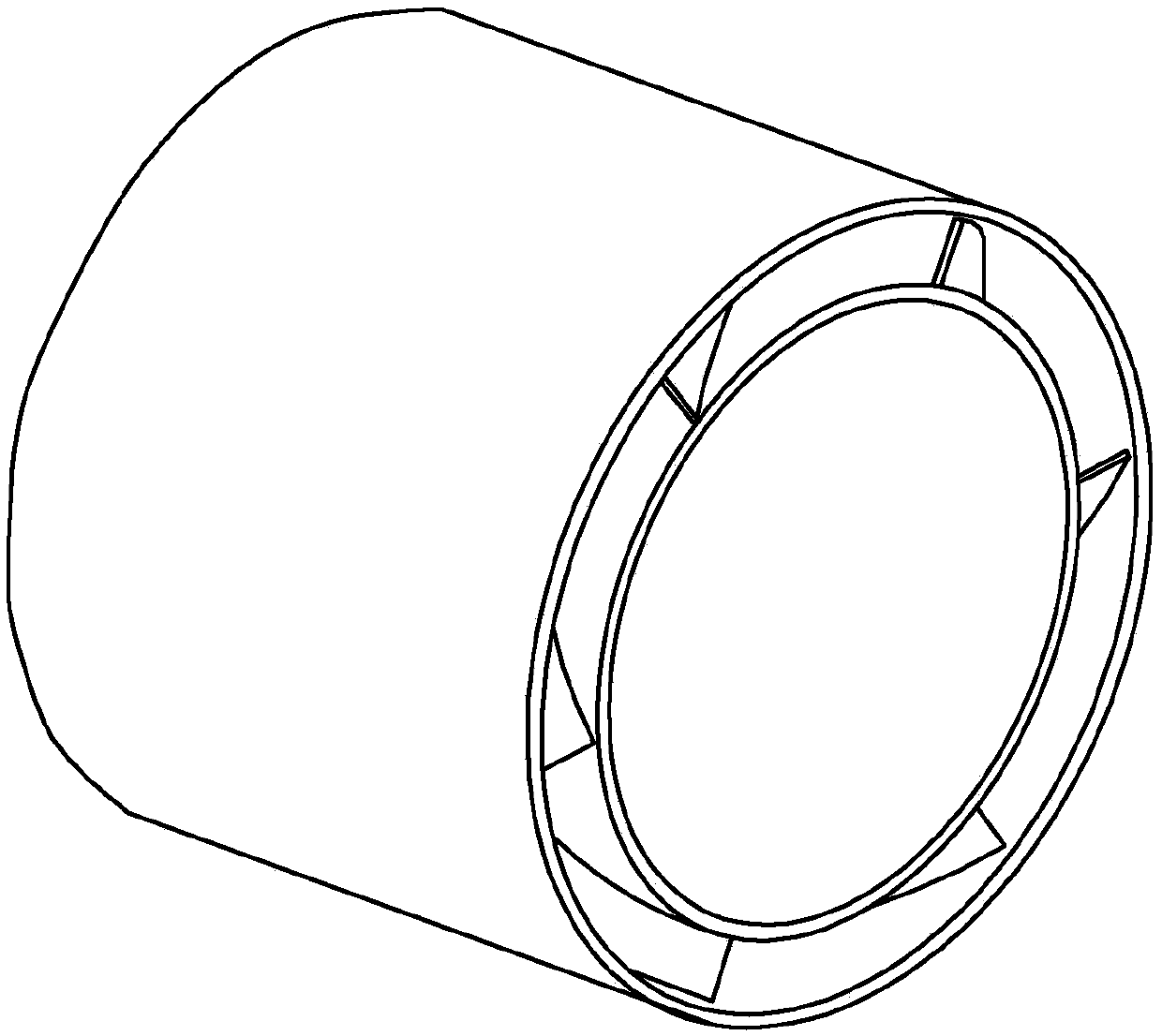

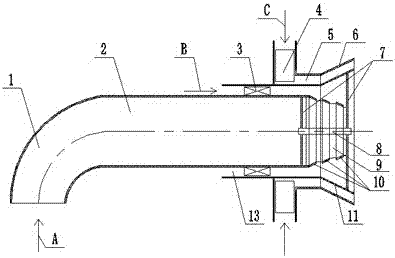

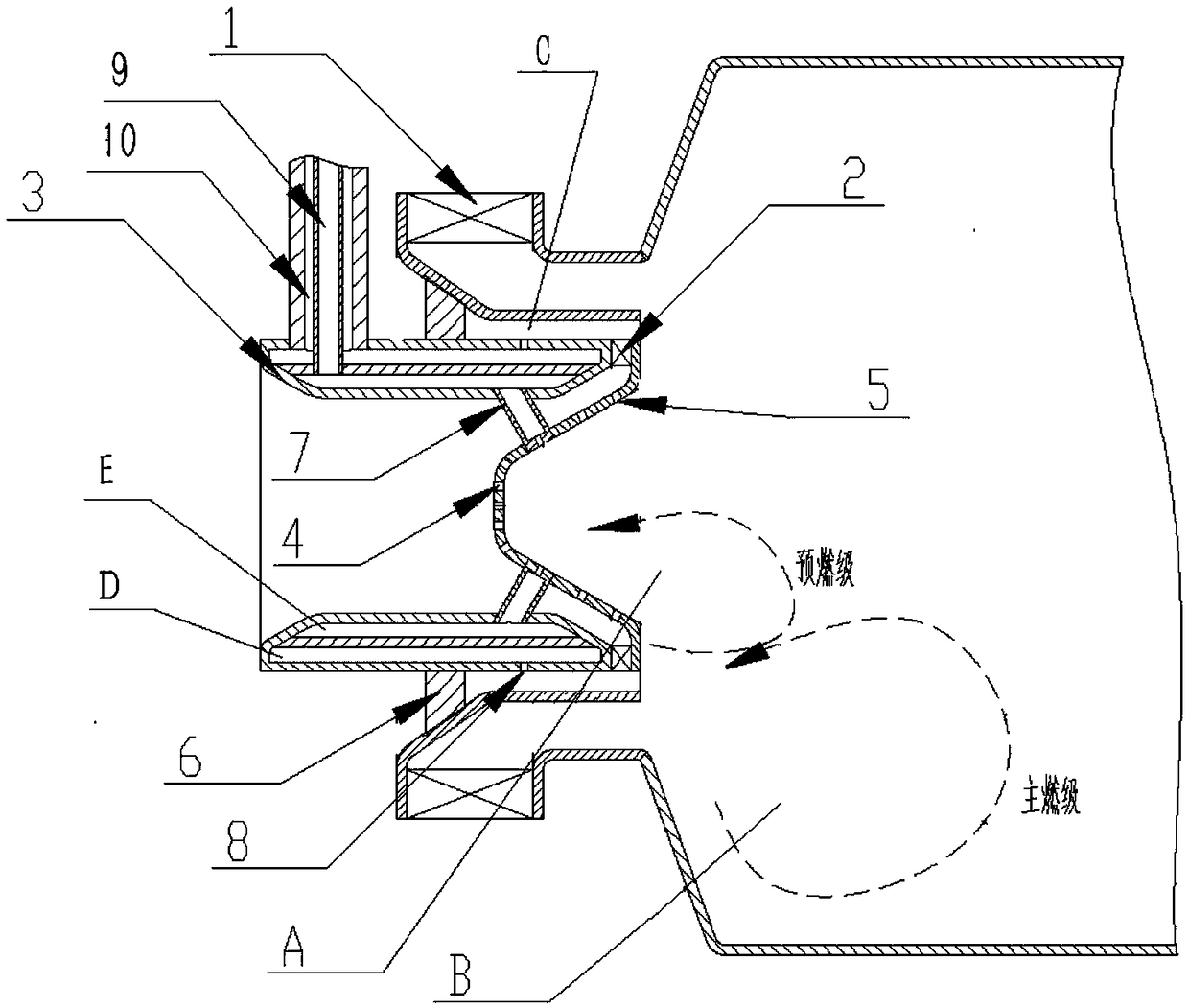

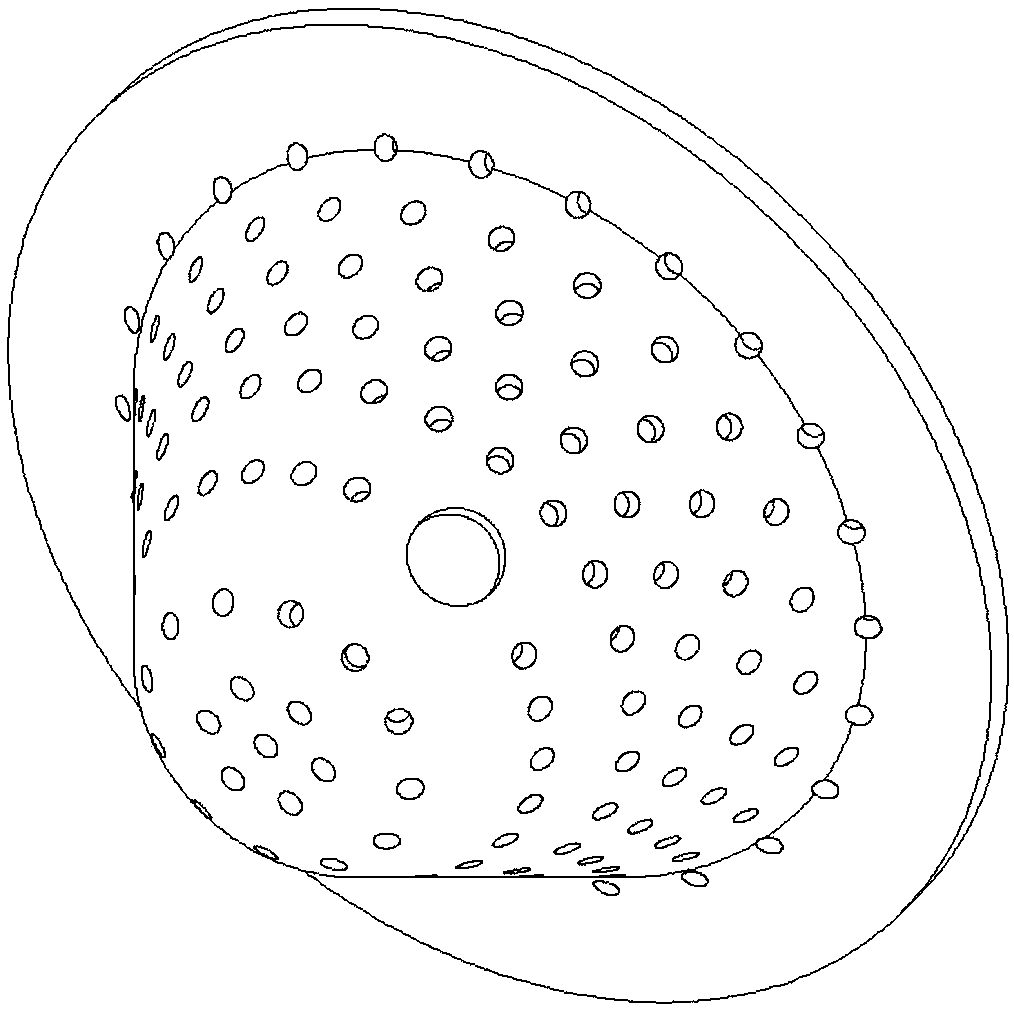

Standing vortex cavity rotational flow atomization device for head of flame tube

ActiveCN109282307ASimple structureAchieve staged combustionContinuous combustion chamberCombustion chamberInlet channel

The invention relates to the field of main combustion chamber design of an aero-engine, in particular to a standing vortex cavity rotational flow atomization device for a head of a flame tube. The standing vortex cavity rotational flow atomization device comprises an outer swirler, a nozzle shell body, a supporting rod, a standing vortex cavity, an inner swirler, a main oil pipe, an auxiliary oilpipe and a fuel pipe, wherein the nozzle shell body comprises an outer cylinder, a middle cylinder body and an inner cylinder, a main nozzle is formed in the wall surface of the outer cylinder, a cooling through hole is formed in the wall surface of the standing vortex cavity, a middle air flow channel is formed between the outer cylinder and the outer swirler, a main oil cavity is formed betweenthe outer cylinder and the middle cylinder body, an auxiliary oil cavity is formed between the middle cylinder body and the inner cylinder, and an air inlet channel is formed between the inner cylinder and the standing vortex cavity. The device has the advantages that the structure is simple, staged combustion of an main combustion chamber of the aero-engine, and the defects in the prior art are solved.

Owner:AECC SHENYANG ENGINE RES INST

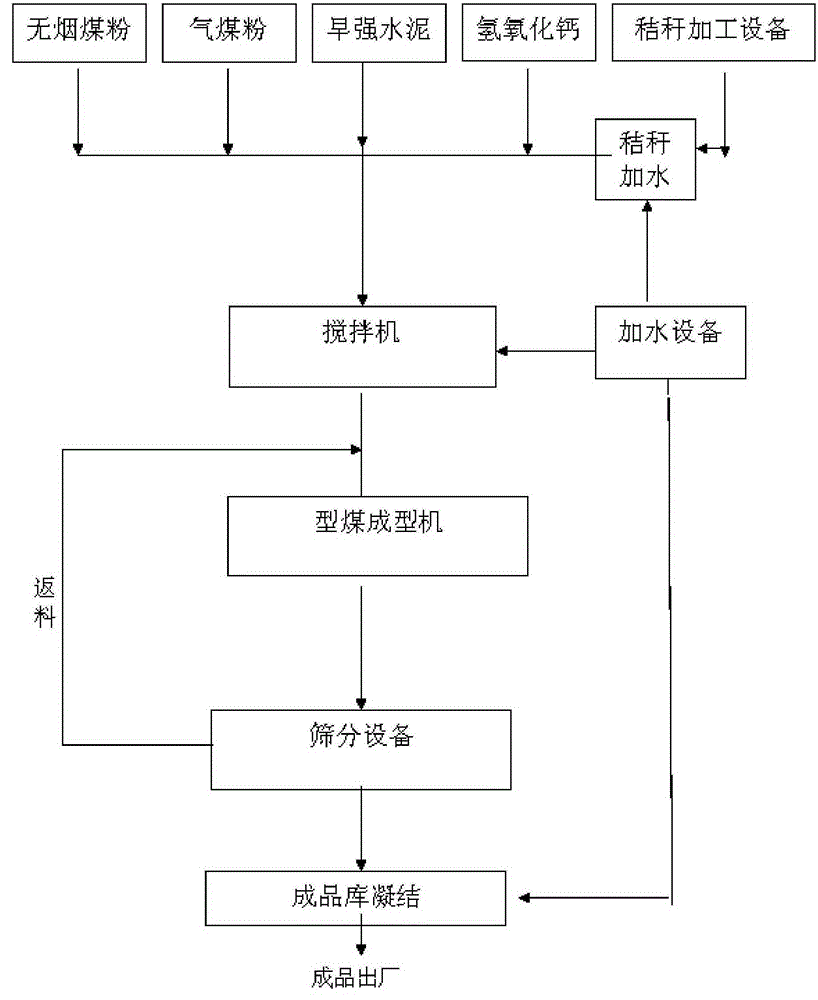

Anthracite composite fuel, composite coal and preparation method for composite coal

InactiveCN105112115AIncrease the calorific value of combustionLow ashSolid fuelsStaged combustionFiber

The invention provides an anthracite composite fuel, a composite coal and a preparation method for composite coal. The anthracite composite fuel is prepared from the following components in parts by weight: 53-60 parts of pulverized anthracite, 25-32 parts of gas pulverized coal, 2.5-3.5 parts of plant fiber, 4-6 parts of a binding agent, 1.5-2.5 parts of a desulfurization agent and 3-5 parts of water. The anthracite composite fuel provided by the invention comprises pulverized anthracite, gas pulverized coal and plant fiber, so that the content of ash generated after the combustion of the anthracite composite fuel is lower, the combustion heating value is larger; the compression strength is larger; the sulfur emission is lower; an excellent ecological benefit is provided; the anthracite composite fuel is smokeless and combustible, and can realize staged combustion. Experimental results show that the content of ash generated after the combustion of the composite coal prepared from the composite fuel is 13-18%, the combustion heating value is 6000-7000 kcal, the compression strength is 80-100 MPa, and the sulfur emission is 0.07-0.11%.

Owner:BAISHAN YITONG ECONOMY & TRADE CO LTD

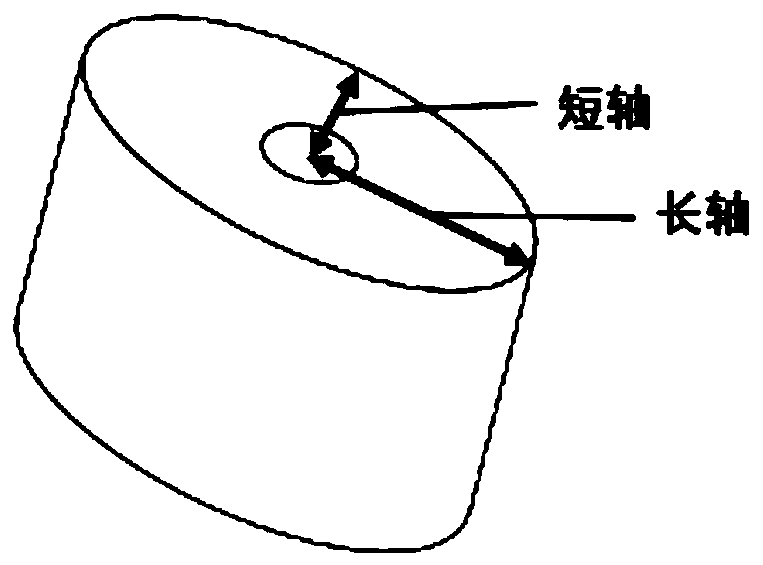

Pyrotechnic gas generator for airbag

PendingCN111516633AAchieve staged combustionReduce output slopePedestrian/occupant safety arrangementAirbagControl theory

The invention relates to the technical field of gas generators and relates to a pyrotechnic gas generator for an airbag. A filter adopts a design mode with the same height as an upper shell; a lower shell is of a double-cup-body structure; the lower shell is provided with a first cup body and a second cup body; the filter is arranged in the first cup body; the upper shell is connected to an opening of the first cup body of the lower shell; an igniter base is arranged on the bottom surface of the lower shell; an igniter is arranged in the igniter base; an ignition shell is connected to the igniter base; the ignition shell is provided with at least one ignition hole; and a mesoporous columnar gas production initiation power sheet of which the major axis radius-to-minor axis radius ratio is larger than 1 is arranged in a gas production initiation power chamber. Compared with the prior art, the pyrotechnic gas generator improves the filter efficiency of the filter and meanwhile, reduces the output slope of the initial pressure of the pyrotechnic gas generator.

Owner:HUBEI HANGPENG CHEM POWER TECH

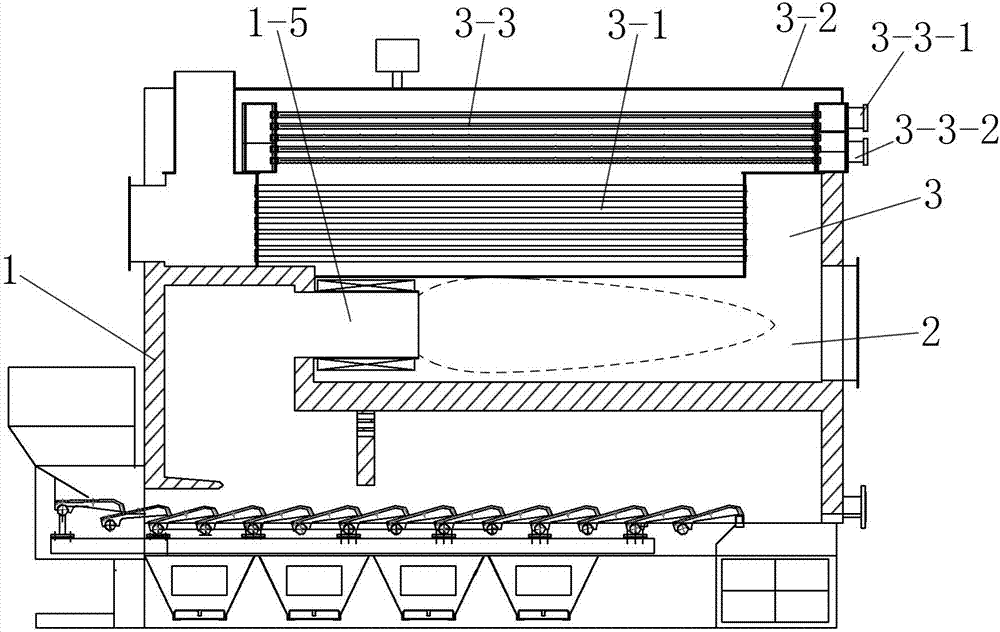

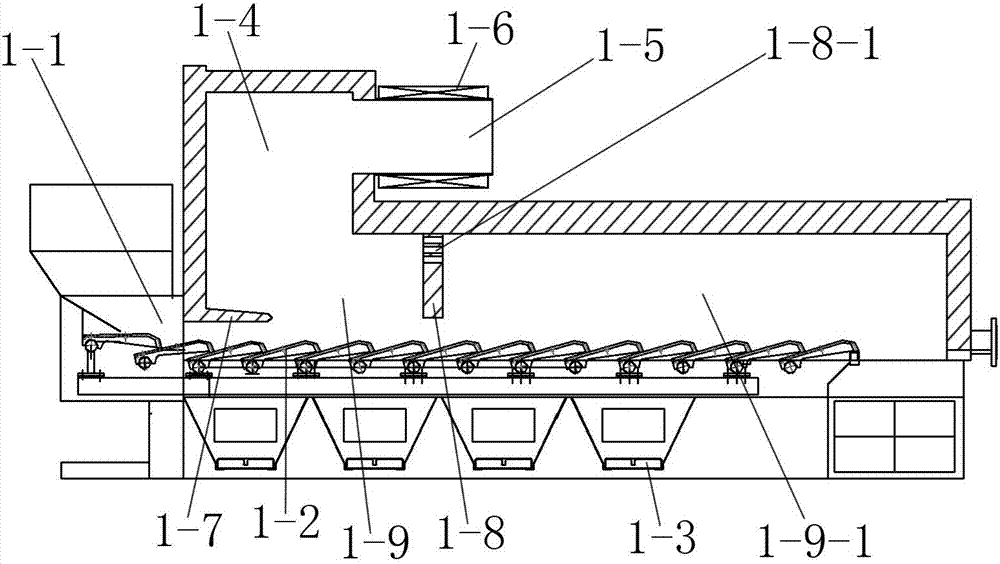

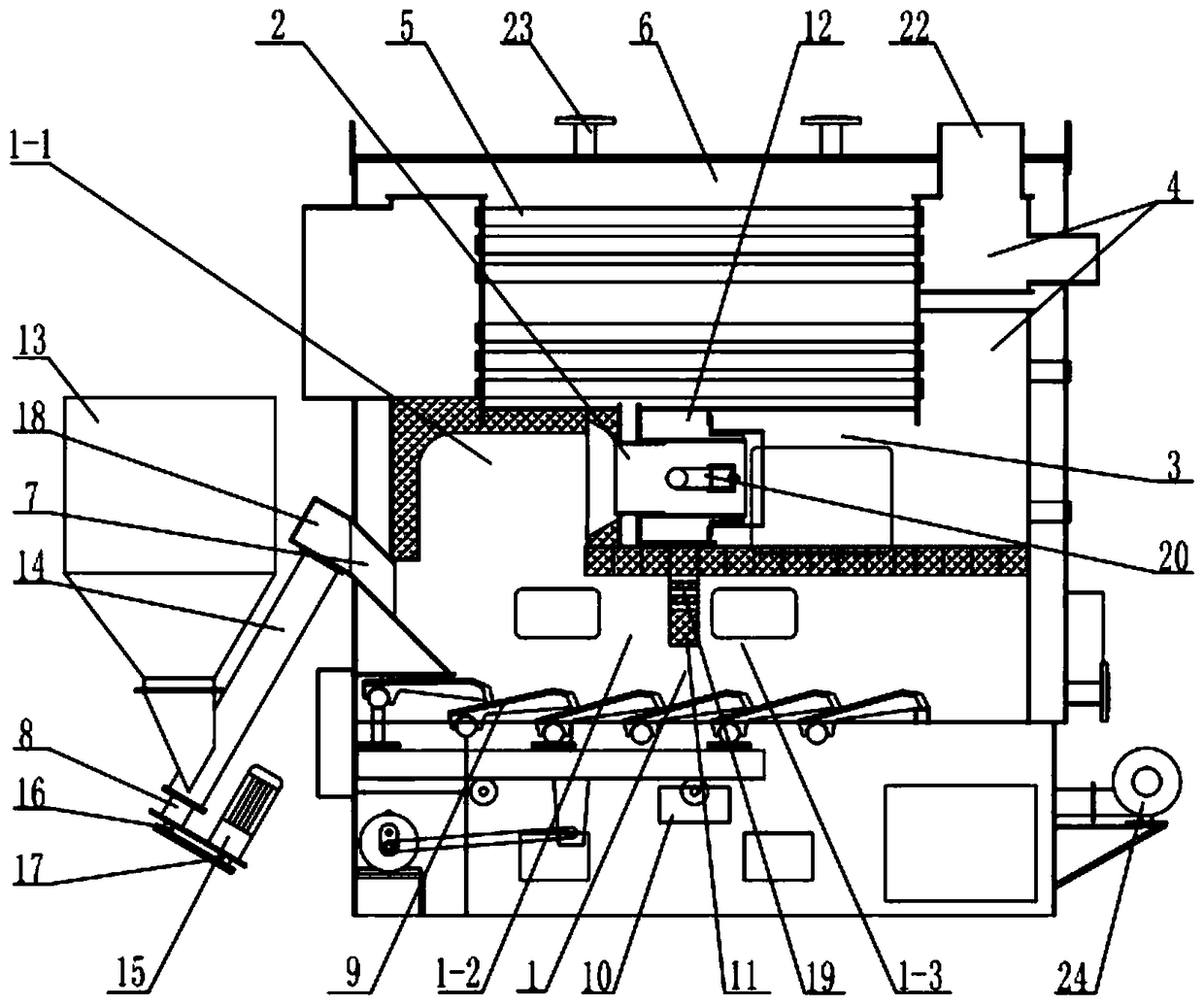

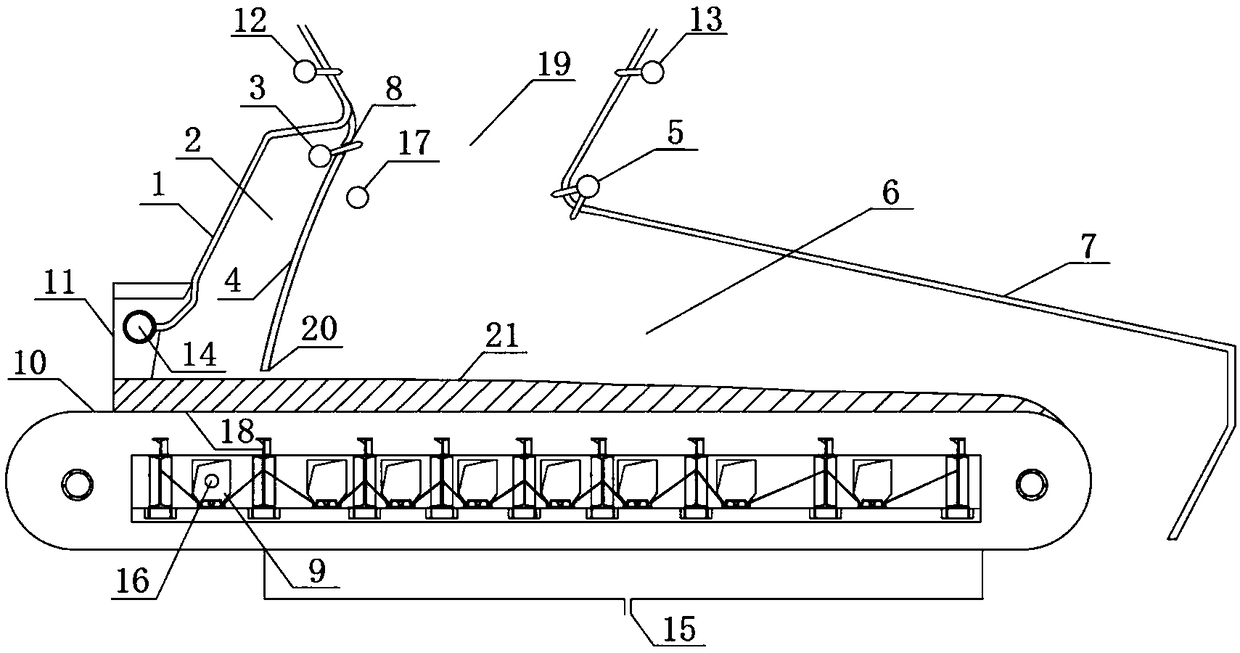

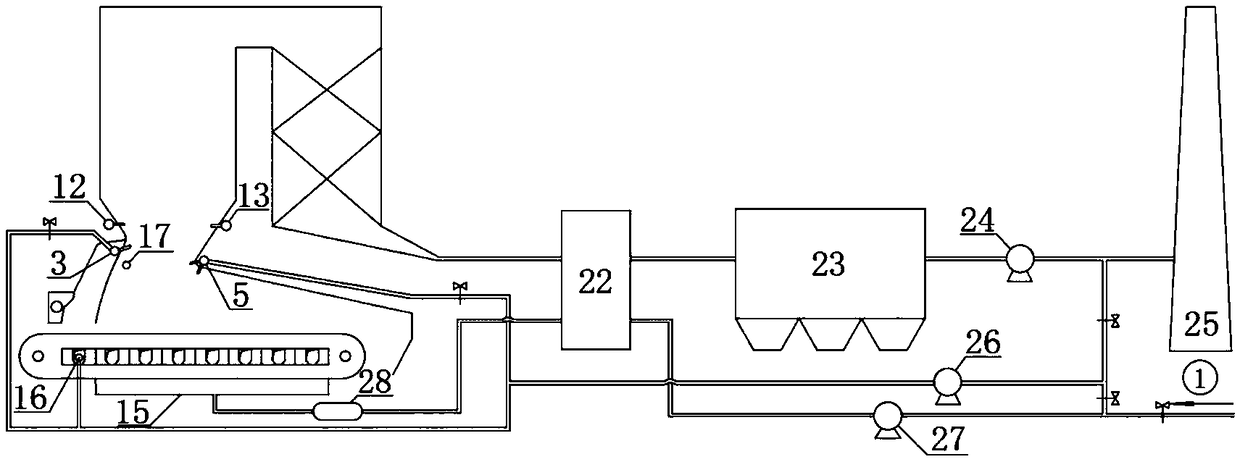

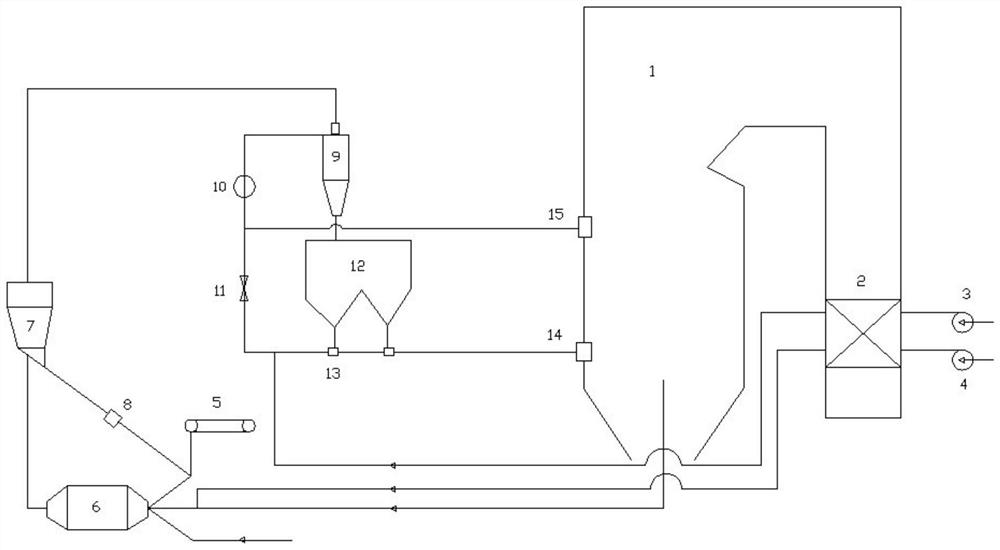

Layer-burning boiler for achieving fuel-air-smoke three-stage low-nitrogen burning and system thereof

PendingCN109297014AEnsure complete burnoutReduce outputSolid fuel combustionCombustion apparatusGas solidCombustion chamber

The invention discloses a layer-burning boiler for achieving fuel-air-smoke three-stage low-nitrogen burning and a system of the layer-burning boiler for achieving fuel-air-smoke three-stage low-nitrogen burning. The boiler comprises a front arch, a rear arch corresponding to the front arch, a hearth, a throat, a burning chamber and a conveying belt below the hearth, wherein the hearth, throat andthe burning chamber are sequentially formed through the front arch and the rear arch from bottom to top, and complete burning of volatile components can be ensured. In the system, some recycling smoke from an outlet of a smoke extraction fan and a certain amount of water vapor produced by a steam generator are doped in primary air fed into other air bins except for a volatile component air bin, the oxygen content of primary air introduced into a fire grate can be reduced through recycling smoke, the water steam and hot coke are subjected to a water-gas reaction on the fire grate to generate CO and H2, partial gas-solid reaction is converted into gas phase reaction, and on the other hand, CO can increase the thickness of a reduction layer above a coal layer, and NOx generated by coal layerburning is effectively reduced; and on the condition of no large auxiliary machine equipment is added, generation of NOx can be actively reduced, and the dual purposes of energy saving and emission reduction are achieved.

Owner:XI AN JIAOTONG UNIV

Staged air supply low-nitrogen gas boiler

PendingCN108488830ASimple structureReduce upfront investmentNon-combustible gases/liquids supplyCombustorBoiler furnace

The invention discloses a staged air supply low-nitrogen gas boiler. The boiler comprise a combustor, a secondary air system, a boiler furnace and a boiler body, wherein the secondary air system comprises a secondary air sleeve, baffle pieces, a secondary air pipe, a secondary fan, an electromagnetic valve and a flowmeter, and the staged air supply low-nitrogen gas boiler is characterized in thatthe combustor is located at the front end of the boiler body, the length of the secondary air sleeve is equal to the length of the air pipe of the combustor, the secondary air sleeve is fixed on the outer side of the air pipe through the baffle pieces, and the baffle pieces are in a spiral line shape; the left end of the secondary air sleeve is sealed and closed, and the lower portion of the secondary air sleeve is connected with the secondary air pipe, and the right end of the secondary air sleeve and the air pipe of the combustor both penetrate through the front panel of the boiler body andare inserted into the boiler furnace; the electromagnetic valve and the flowmeter are installed on the secondary air pipe, and the lower end of the secondary air pipe is connected with the secondary fan below. During operation, secondary air is blown into the secondary air pipe by the secondary fan, and then enters the boiler furnace at a certain angle through the secondary air sleeve and passes through the baffle pieces, and the secondary air and the primary air blown by the combustor are mixed in different areas, staged combustion is formed in the boiler furnace, so that the combustion temperature can be reduced, and the Nox generation amount can be reduced.

Owner:ZHENGZHOU UNIV

Grading catalytic combustion device capable of coupling strong and weak heat release

Owner:CHONGQING UNIV

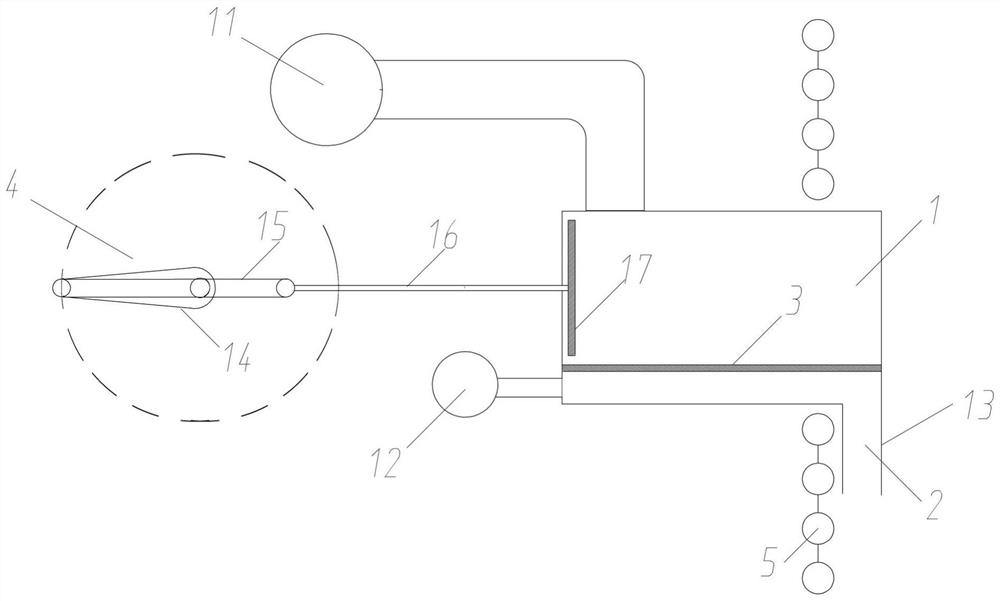

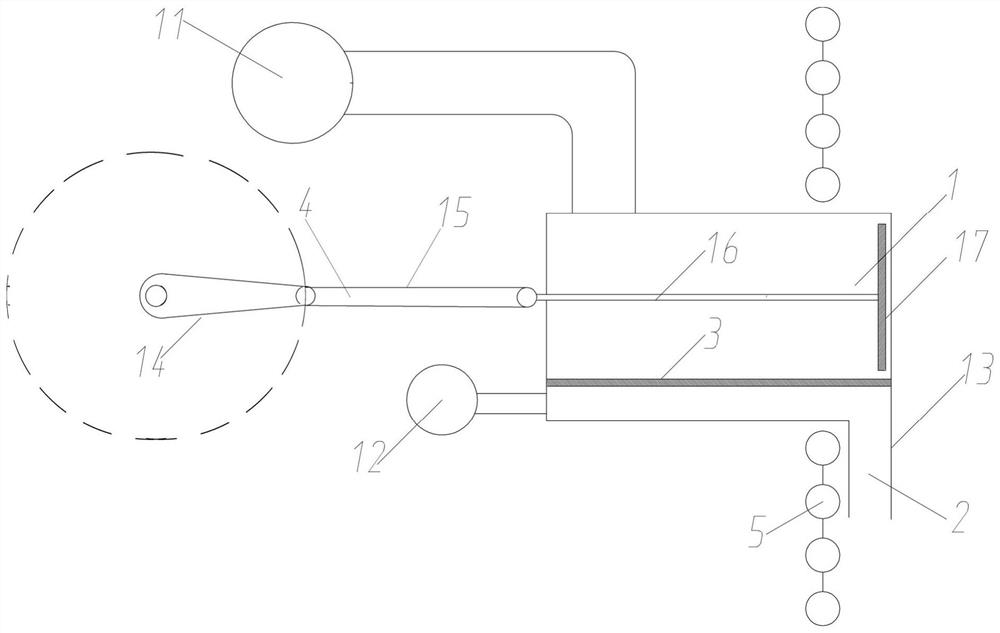

Organic matter high temperature gasification low-oxygen fractional combustion method

ActiveCN110848737AReduce bring inAchieve staged combustionFuel supply regulationTravelling grateCombustion chamberData set

The invention discloses an organic matter high temperature gasification low-oxygen fractional combustion method. The organic matter high temperature gasification low-oxygen fractional combustion method specifically comprises the following steps that a pushing mechanism pushes fuel into a ladder reciprocating type fire grate; furnace starting is carried out; air is blown through an air blowing mechanism, and hot air after gasification enters a gasification chamber; the ladder reciprocating type fire grate carries out intermittent falling; a monitoring system a monitors the gasification chamber;the gasified hot air in the gasification chamber enters a high-temperature heat insulation low-oxygen combustion chamber, and high-temperature flue gas is discharged into a heat exchange system through a flue gas circulation channel to be subjected to heat exchange; a monitoring system b carries out monitoring; and a PLC forms a data set according to the monitoring information of the monitoring system a and the monitoring system b, the data set is compared with inner set data value, and whether the gas producing amount of the gasification chamber needs to be controlled or not is judged. Through real-time monitoring of temperature of different combustion segments, the opening degree of air adjusting valves of the air chambers can be controlled, precise air supply is achieved, the fire grate combustion efficiency is improved, bringing in of invalid air is reduced, and the hot losses are reduced.

Owner:河北约翰节能设备科技有限公司

Process for generating power by coupling intermediate storage type pulverizing system with sludge drying incineration

InactiveCN112050243AKeep dryEmission reductionSludge treatment by de-watering/drying/thickeningIndirect carbon-dioxide mitigationBoiler furnaceSludge

The invention discloses a process for generating power by coupling an intermediate storage type coal pulverizing system with sludge drying incineration. The process utilizes the intermediate storage type coal pulverizing system, the intermediate storage type coal pulverizing system comprises a furnace smoke suction pipe and a steel ball coal mill, the steel ball coal mill uses sludge conveyed by apumping system, the furnace smoke suction pipe is used for sucking hot smoke at the bottom of a boiler hearth and sending the hot smoke into the steel ball coal mill for pre-drying of the sludge. According to the process, with addition of the furnace smoke suction pipe, the hot smoke at the bottom of the hearth is sucked to enter the steel ball coal mill, so that the drying capacity of the coal pulverizing system is improved, sludge can be fully dried by the hot smoke, moisture-carrying exhaust gas finally enters the hearth through a tertiary air nozzle, staged combustion is achieved, and NOxemission is reduced; and the hot smoke sucked by the furnace smoke suction pipe can form inert atmosphere in the coal pulverizing system, therefore, the adaptability of the coal pulverizing system tovolatile components mixed with the sludge is improved, and the explosion-proof risk is reduced.

Owner:XIAN THERMAL POWER RES INST CO LTD

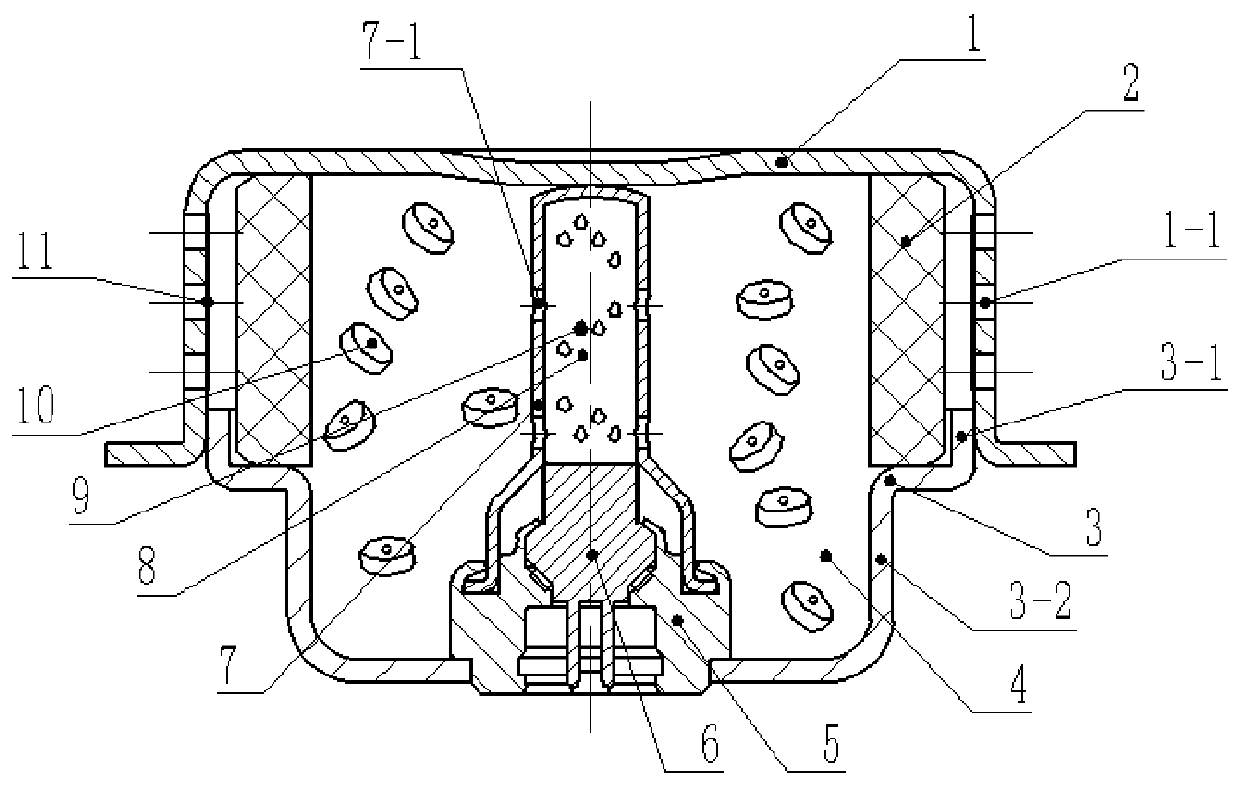

Rotational flow atomization device and aviation engine main combustion chamber with same

InactiveCN108061310AAchieve staged combustionImprove combustion stabilityContinuous combustion chamberAviationCombustion chamber

The invention discloses a rotational flow atomization device and an aviation engine main combustion chamber with the same. The rotational flow atomization device comprises an inner rotational flow device, an outer rotational flow device, valves, supporting plates, springs and nozzle shells. The inner rotational flow device, the outer rotational flow device and the supporting plates are connected with the nozzle shells; sliding rail grooves, main jet openings and auxiliary jet openings are formed in the nozzle shells; the valves are embedded into the sliding rail grooves in the inner sides of the nozzle shells to constitute sliding pairs; through holes are formed in the valves; bosses are arranged on the supporting plates; the springs are located between the valves and the supporting platesand positioned through the bosses on the supporting plates; and through holes are formed in the bosses and are opposite to the through holes in the valves. According to the rotational flow atomization device, fractional combustion in the main combustion chamber is simply achieved, a plurality of oil circuits do not need to be arranged, the oil circuit cooling difficulty is reduced, the structurecomplexity is reduced, and meanwhile the design requirement for an oil pump is reduced.

Owner:AECC SHENYANG ENGINE RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com