Staged air supply low-nitrogen gas boiler

A gas-fired boiler and air duct technology, applied in the field of gas-fired boilers, can solve the problems of expensive equipment, reduced boiler thermal efficiency, increased boiler manufacturing cost, etc., to achieve the effects of reducing NOx generation, reducing initial investment, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

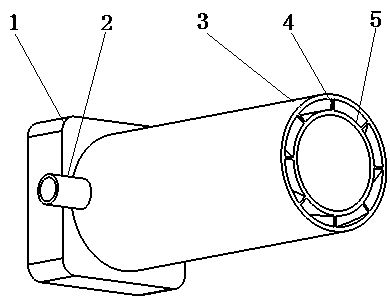

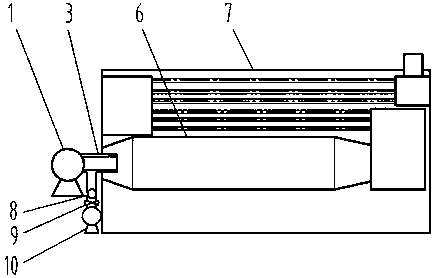

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] The assembly process of the graded air supply low-nitrogen gas boiler: After the boiler body is assembled, first weld the secondary air pipe and the front end of the secondary air sleeve, and then weld the baffles to the secondary air sleeve in equal parts by spot welding. The inner wall of the sleeve, and then put the secondary air sleeve and the baffle into the burner air duct, keep the concentricity and spot weld the baffle and the outer wall of the air duct; weld the burner and the secondary air sleeve into one The cylinder passes through the installation hole of the front panel of the furnace body, so that the combustion head of the burner is placed at the front end of the furnace, and the burner and the front panel of the boiler body are fixed with bolts; the flow meter and the solenoid valve are installed on the secondary air pipe successively, and then C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com