Slag blocking preventing type wall-attached air device based on air staged combustion

A technology of air classification and wall-adhering wind, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of high-temperature corrosion, high-temperature corrosion of the wall-mounted air vents, and difficult to block slag, so as to improve the atmosphere and solve the problem of easy slag blocking. , the effect of reducing NOx

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] Taking the opposite combustion boiler as an example, see Figure 4 , the pulverized coal burner 8 is arranged on the front wall 9 and the rear wall 10 of the boiler, the pulverized coal airflow is opposed to combustion, and the middle area of the water wall 5 on the left side wall 6 and the right side wall 7 of the boiler is subjected to the pulverized coal flow of the pulverized coal burner Erosion, resulting in a strong reducing atmosphere at the wall of the water wall 5 in this area, and the problem of high temperature corrosion is serious.

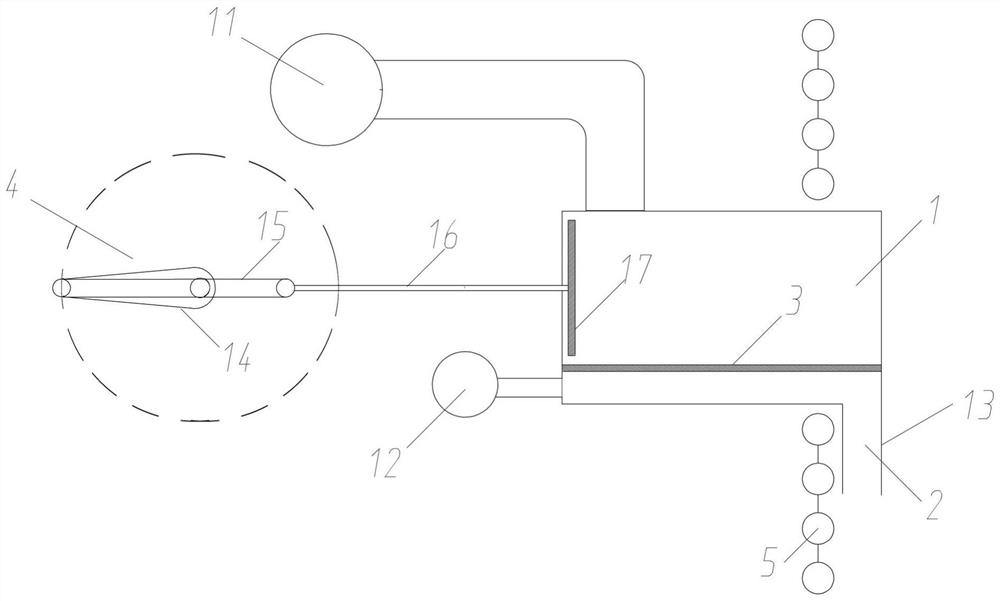

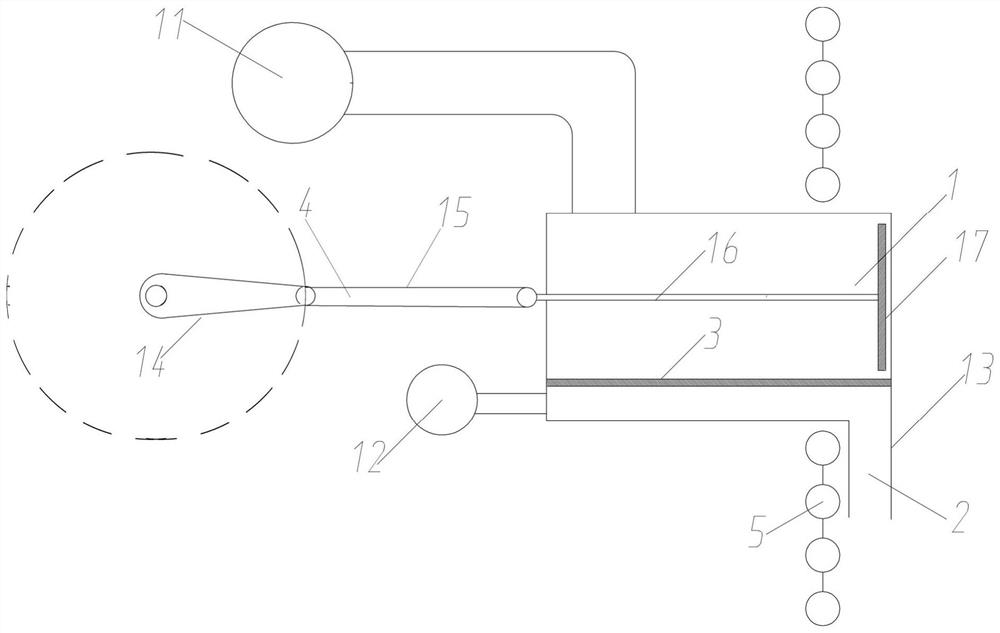

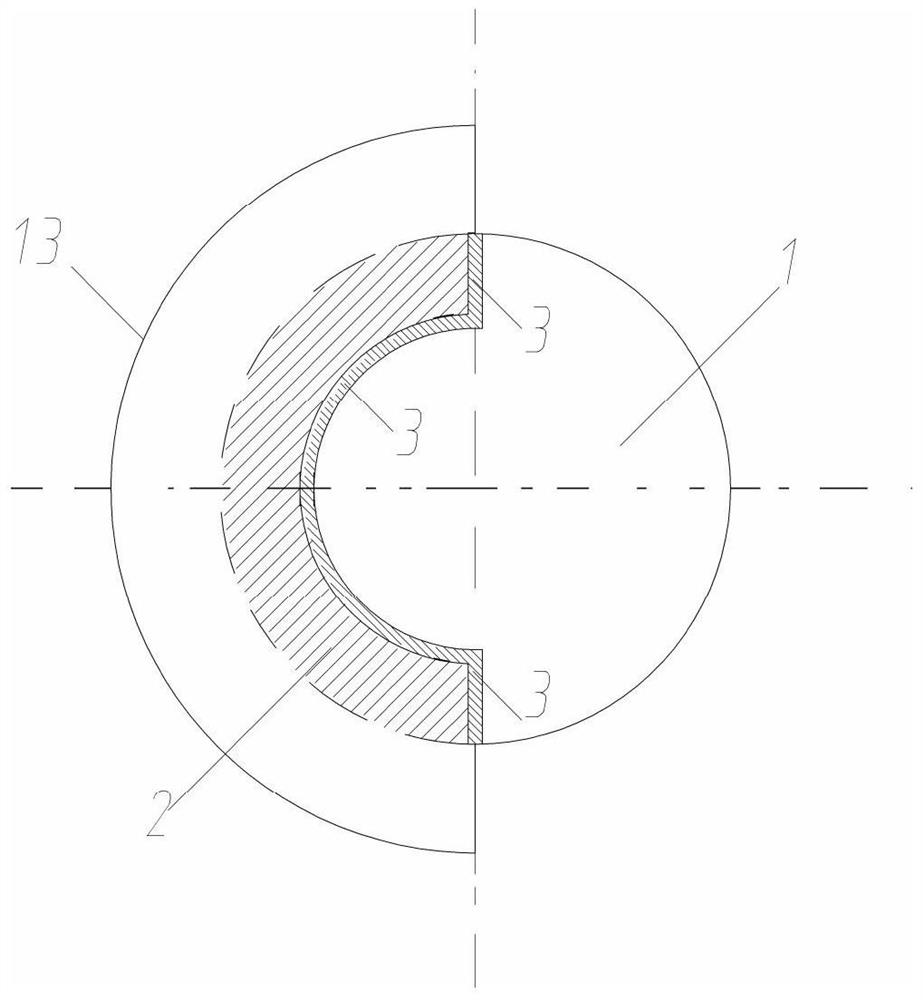

[0029] The present invention is arranged on the left side wall 6 and the right side wall 7 of the boiler, and includes a jet air spout 1 and a protective air spout 2 . The jet air nozzle 1 faces the jet flow direction of the pulverized coal burner 8, and the injection direction of the jet air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com