Organic matter high temperature gasification low-oxygen fractional combustion method

A technology of graded combustion and organic matter, applied in the direction of combustion method, combustion chamber, controlled combustion, etc., can solve the problems of inability to control air content well, high boiler exhaust smoke loss, low boiler efficiency, etc., and achieve slag thermal ignition loss rate Low, complete volatilization and complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with specific embodiments.

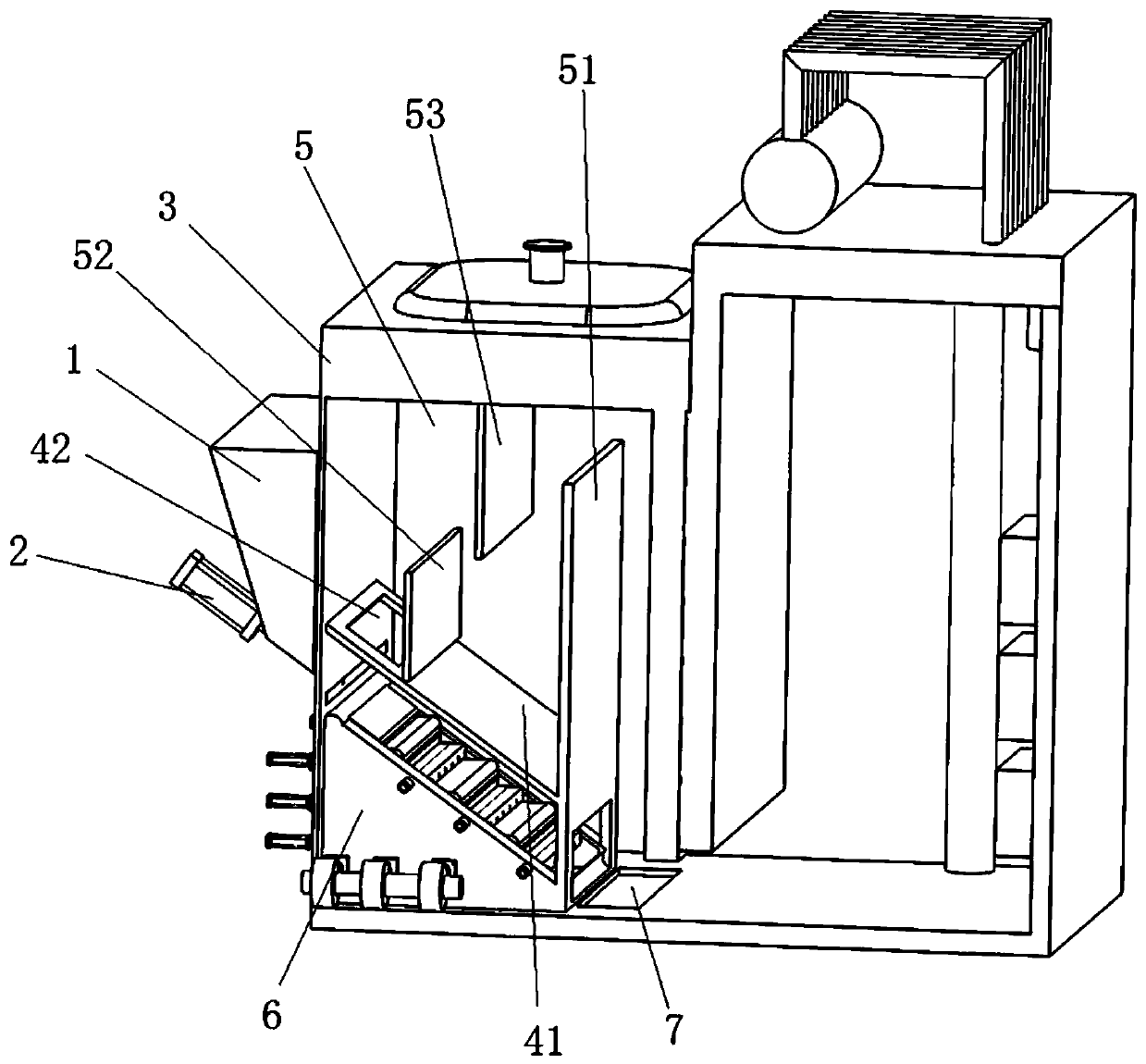

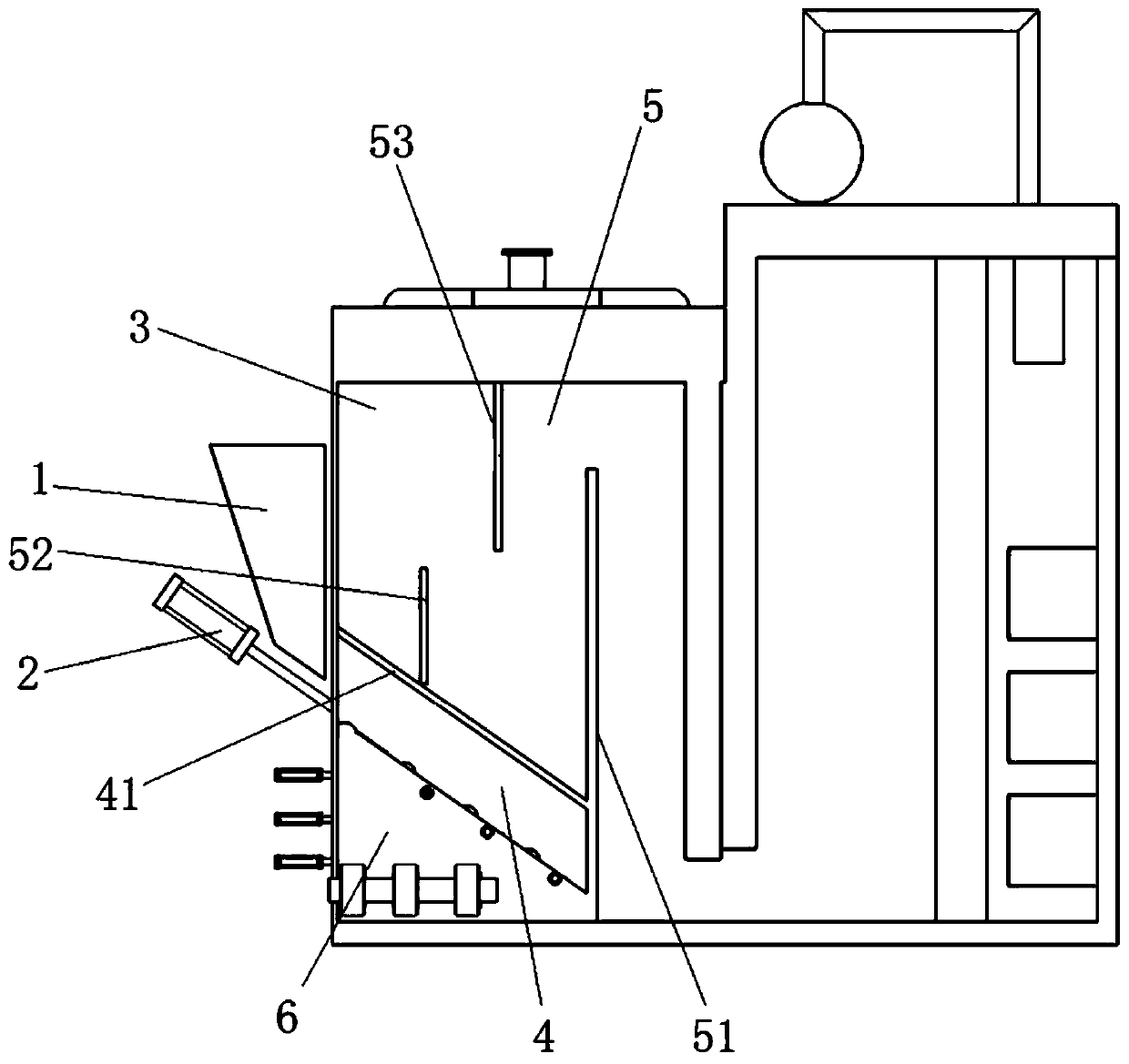

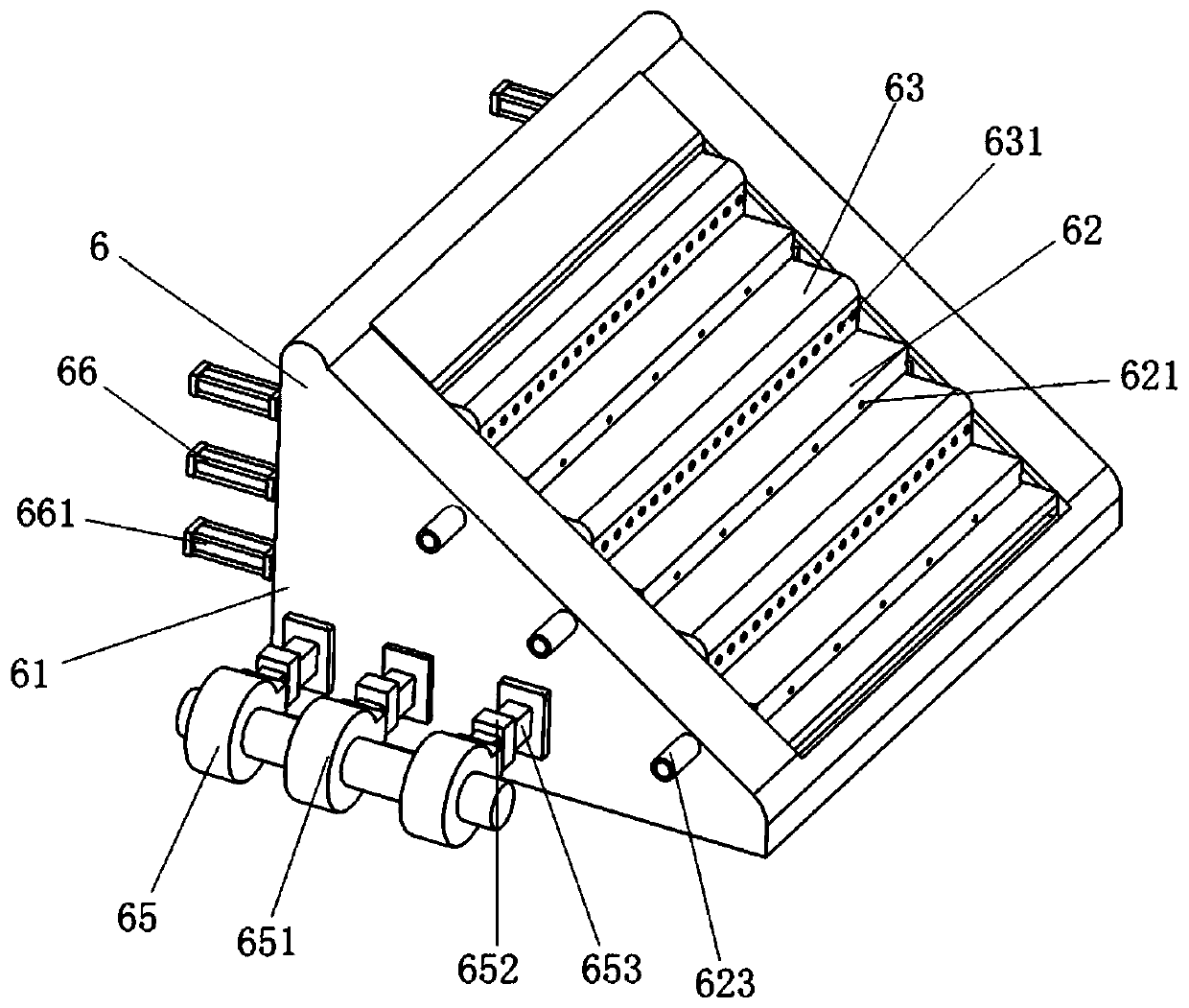

[0044] A high-temperature gasification low-oxygen staged combustion device for organic matter, combined with Figures 1 to 8 As shown, it includes a combustion furnace 3 and a PLC controller. The front end of the combustion furnace 3 is provided with a blanking mechanism 1 and a material pushing mechanism 2, and the controlled end of the pushing mechanism 2 is connected to the output end of the PLC controller. The interior of the combustion furnace 3 is set as a furnace, and the bottom of the furnace is set as a stepped reciprocating grate 6, and the top of the stepped reciprocating grate 6 is arranged obliquely. The stepped reciprocating grate 6 can reduce the temperature of the grate and prevent the grate from burning out . The pushing direction of the material pushing mechanism 2 is the same as the top inclination direction of the stepped reciprocating fire gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com