Patents

Literature

50results about How to "Reduce particle concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method For Completing Injection Wells

InactiveUS20040014606A1Reducing surface storage capacity requirementEliminate needCleaning apparatusFluid removalEngineeringWater well

This invention proposes a method for completing an interval of an open-hole injection wellbore penetrating a subterranean formation, said wellbore being communicating with the formation by way of an interface that comprises at least a filter cake invaded zone comprising bridging materials and other embedded solid materials, said method comprising the steps of injecting a clean-up fluid and contacting it with the filtercake for a period of time sufficient to loose some of the other solids embedded in the filter cake; removing the loosened solids by a high-rate displacement fluid comprising suspending additives; and then injecting a dissolving fluid comprising a diverter and an effective amount of a salt or acid capable of dissolving the bridging material.

Owner:SCHLUMBERGER TECH CORP

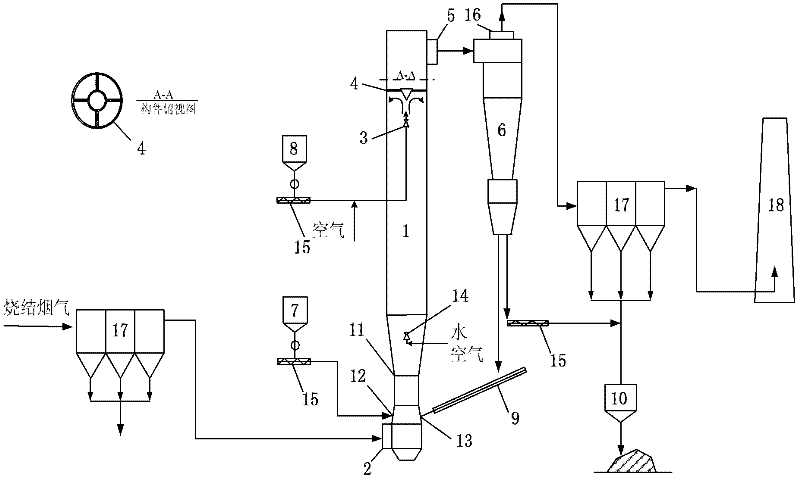

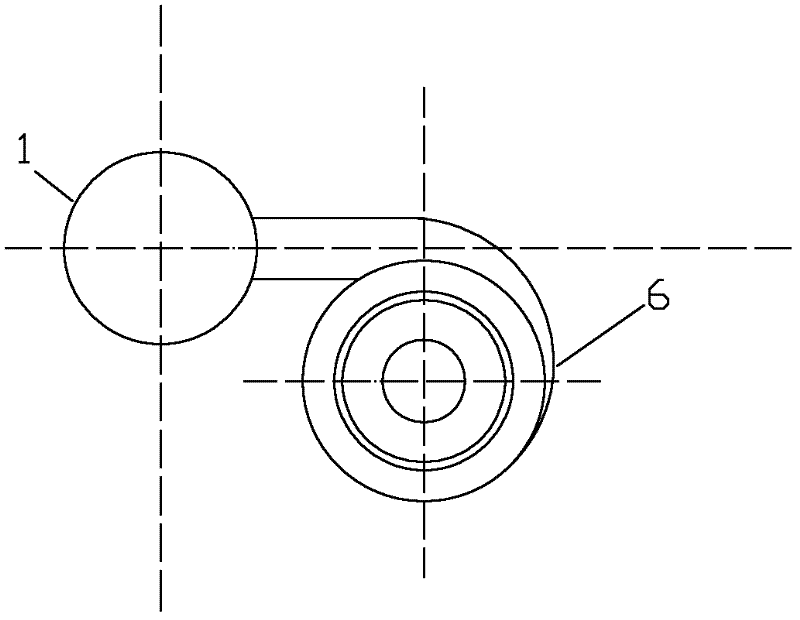

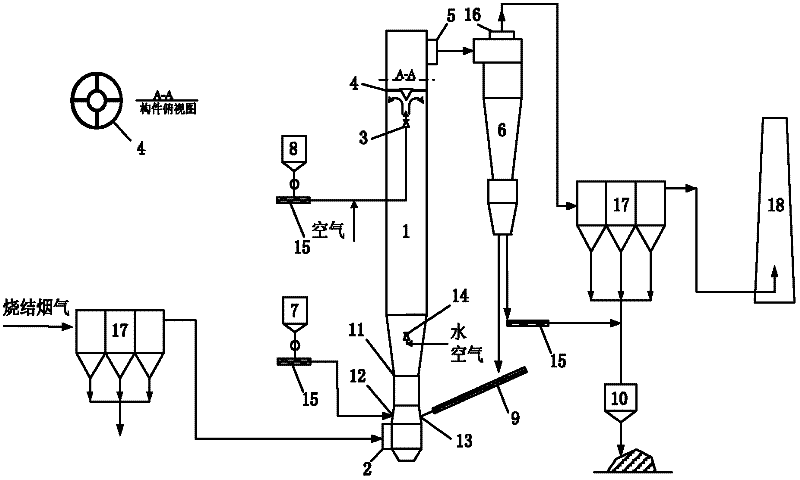

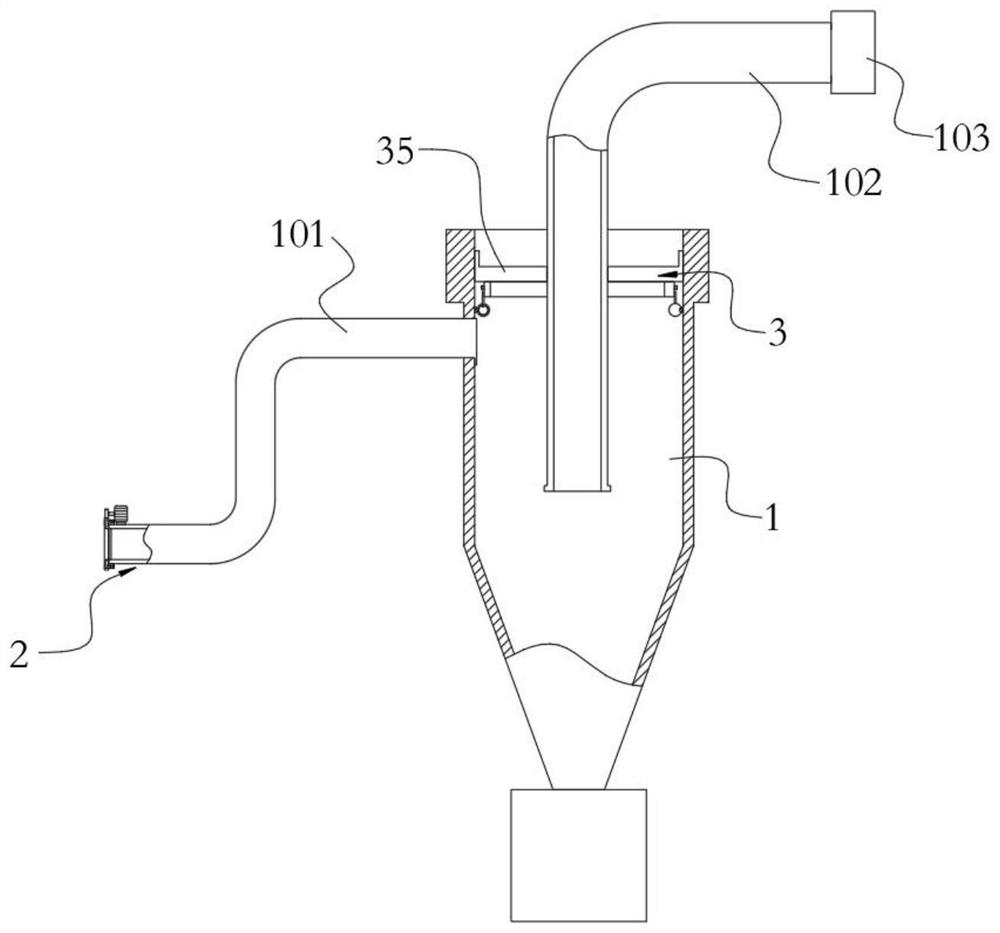

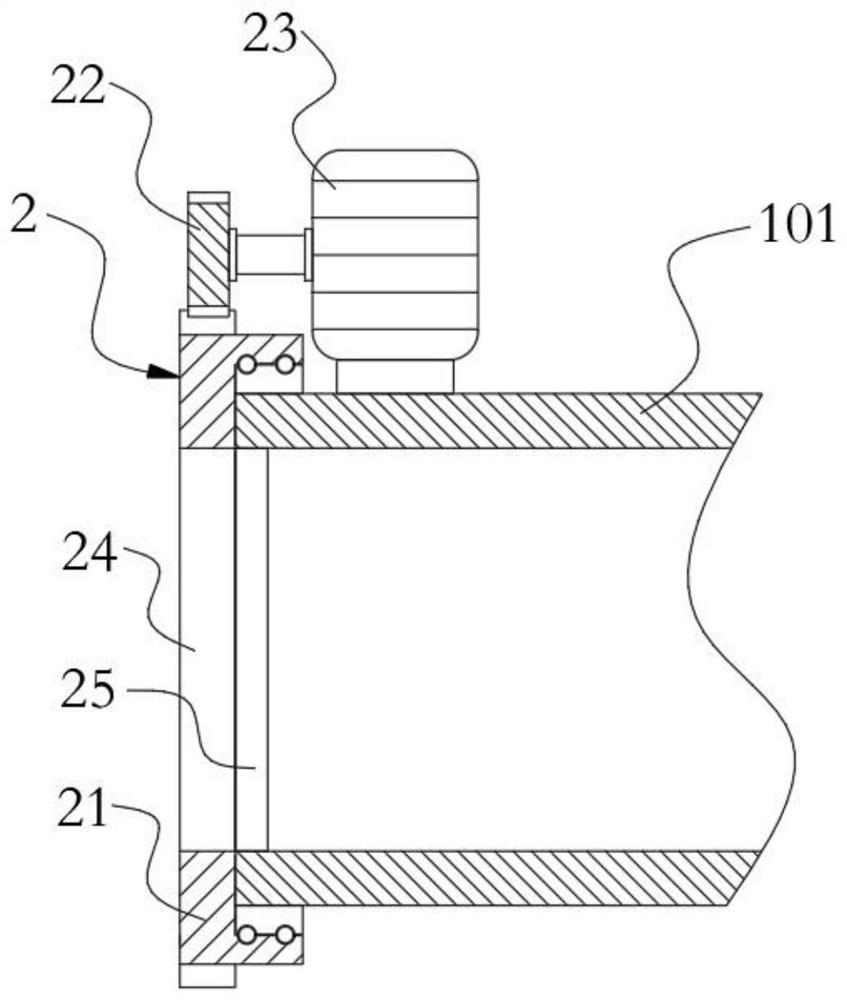

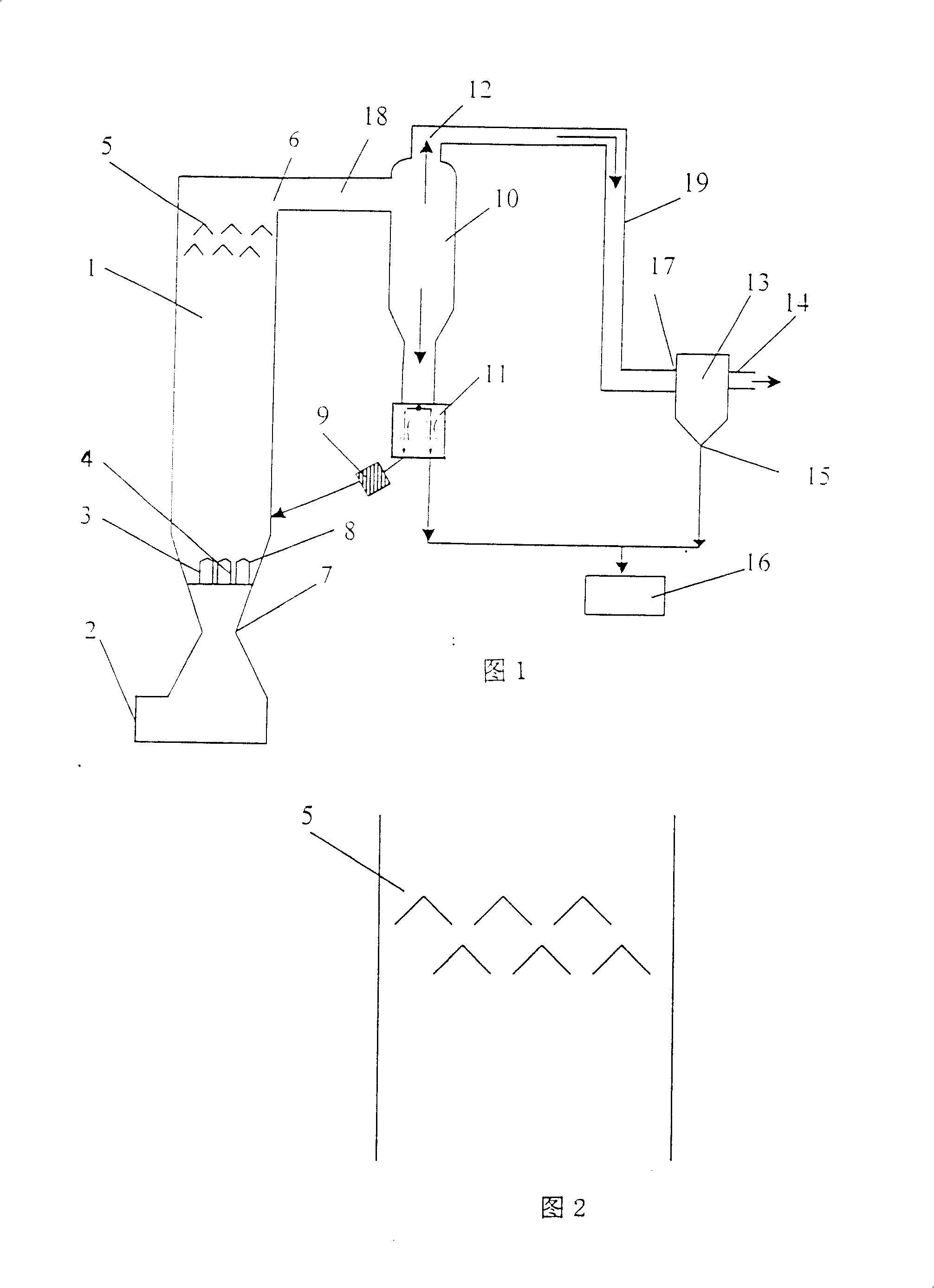

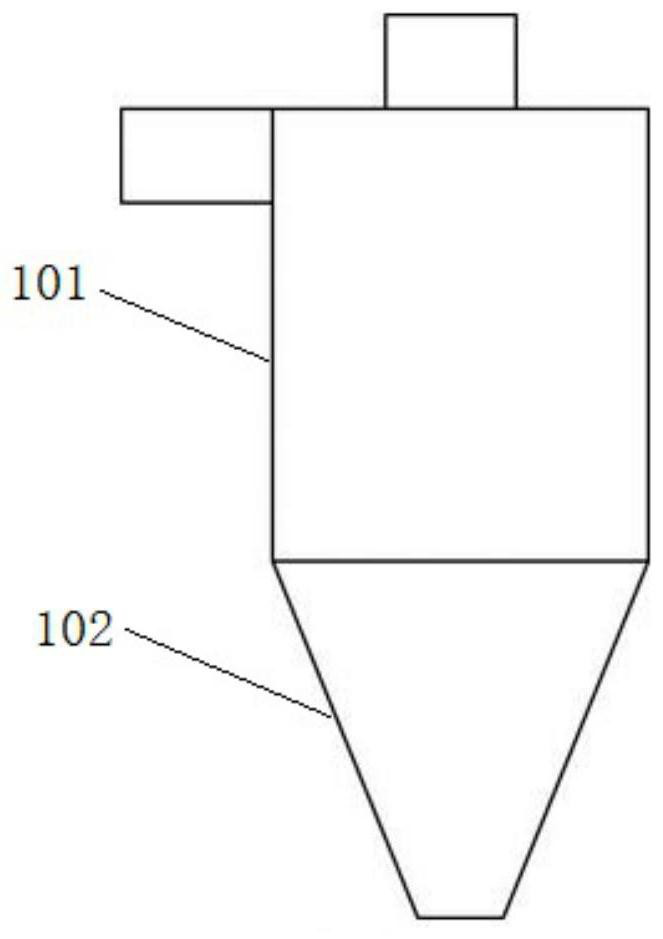

Device and method for removing sulfur dioxide and dioxin from sintering flue gas

The invention relates to a device and a method for removing sulfur dioxide and dioxin from sintering flue gas. The lower part of an absorption tower of the device has a Venturi structure; a Venturi shrinkage section is provided with a desulfurizing agent inlet and a circulating ash inlet; a Venturi expansion section is provided with a water spray nozzle; the upper middle part of the absorption tower is provided with an active carbon / coke nozzle and a conical component is arranged opposite to the nozzle; the upper part; the upper part of the absorption tower is provided with a flue gas outlet which is connected with a radially arranged cyclone separator; a hoper at the lower end of the cyclone separator is provided with two outlets, one outlet is connected with an ash bin, and the other outlet is connected with a circulating ash inlet through a spiral return device; a gas outlet on the top of the cyclone separator is communicated with an inlet of a deduster; and a gas outlet of the deduster is connected with a chimney. The sintering flue gas containing SO2 and dioxin enters the absorption tower through the Venturi, and is mixed with slaked lime Ca(OH)2, atomized water and active carbon / coke, which are sprayed in the absorption tower, the Ca(OH)2 absorbs the SO2 under the action of the atomized water and the active carbon / coke absorbs the dioxin to cooperatively remove the two pollutants.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

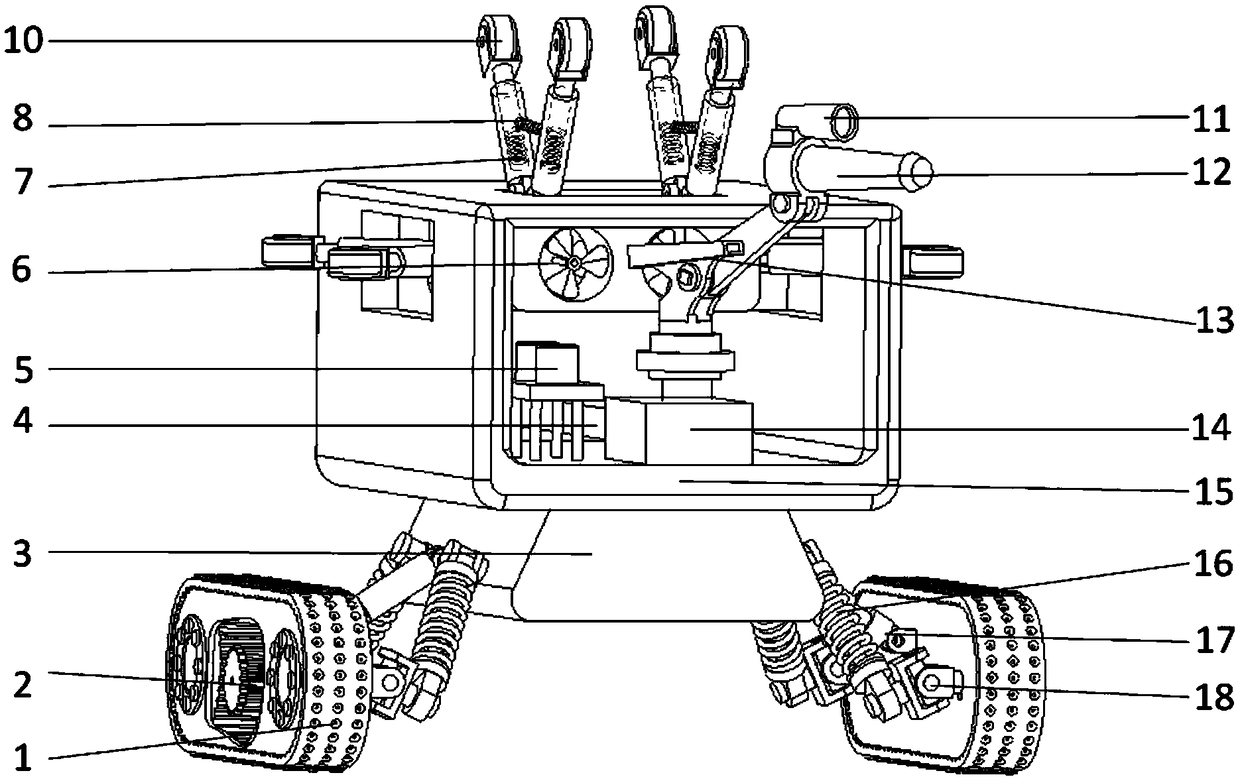

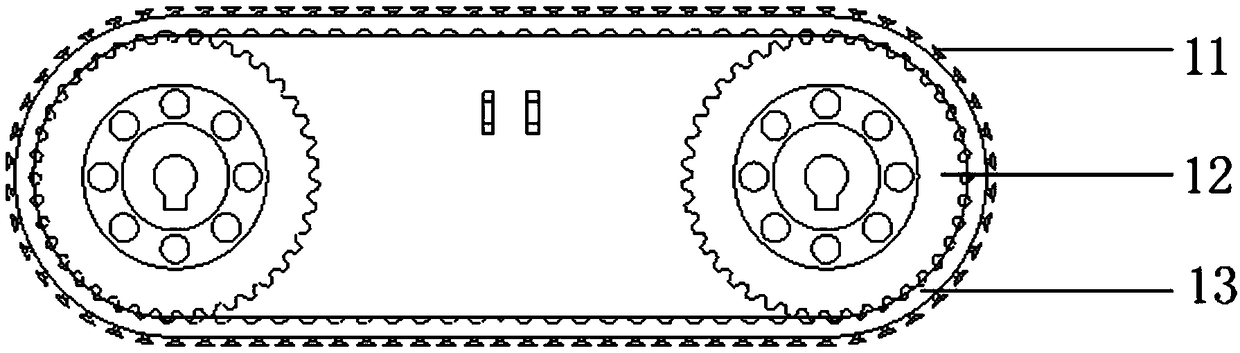

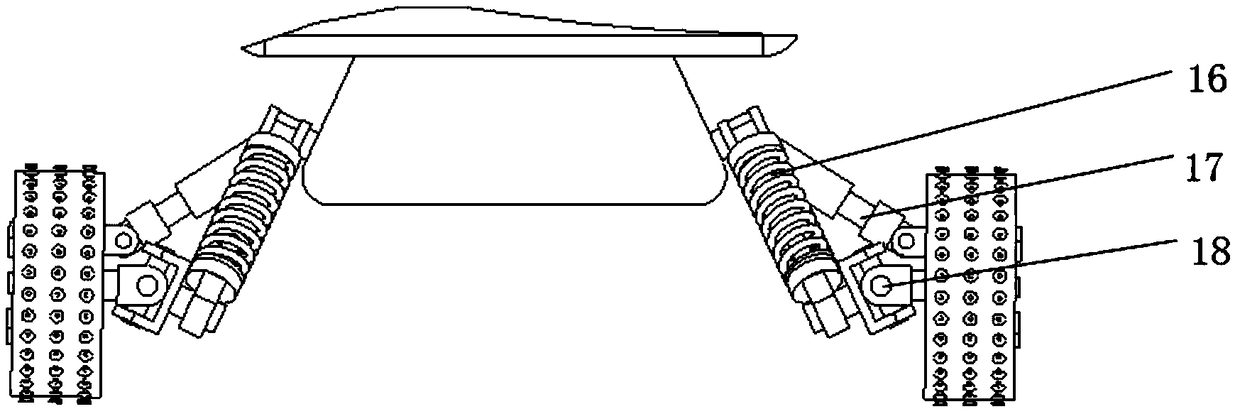

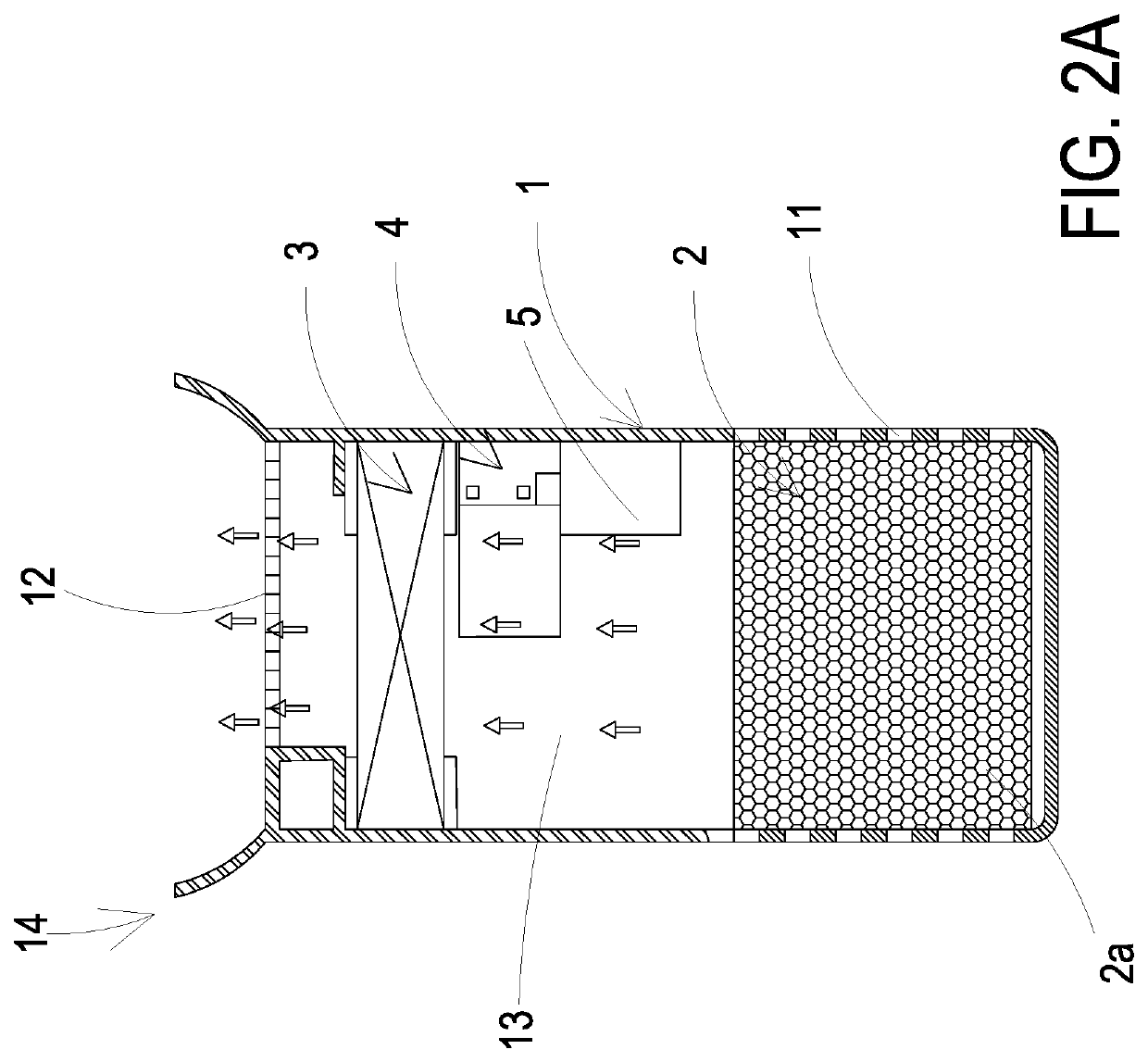

Pipeline robot

ActiveCN108692133ASimple structureReduce shock absorptionManipulatorPigs/molesControl systemMulti degree of freedom

The invention relates to a pipeline robot which comprises a supporting mechanism, a walking mechanism connected with the supporting mechanism, anti-collision mechanisms, an operating mechanism and anouter connecting mechanism. The supporting mechanism comprises a supporting base and a bearing vehicle body, the bearing vehicle body is of an inner hollow structure with an opening in the side face,and the supporting base is located under the bearing vehicle body. The walking mechanism is connected with the supporting base through a self-adapting mechanism. The anti-collision mechanisms are arranged on the top and the two sides of the bearing vehicle body. The operating mechanism comprises a mechanical arm with multi-degree of freedom and an end executor, the first end of the mechanical armwith the multi-degree of freedom is fixed into the bearing vehicle body, and the second end of the mechanical arm of the multi-degree of freedom is connected with the end executor. The outer connecting mechanism comprises a material cable conveying device and a control system, the material cable conveying device is arranged in the bearing vehicle body and is connected with the outer portion of a pipeline, and the control system is used for controlling all the mechanisms to operate. The pipeline robot is wide in application range and adapts to operation environments of pipelines in various shapes.

Owner:YANSHAN UNIV

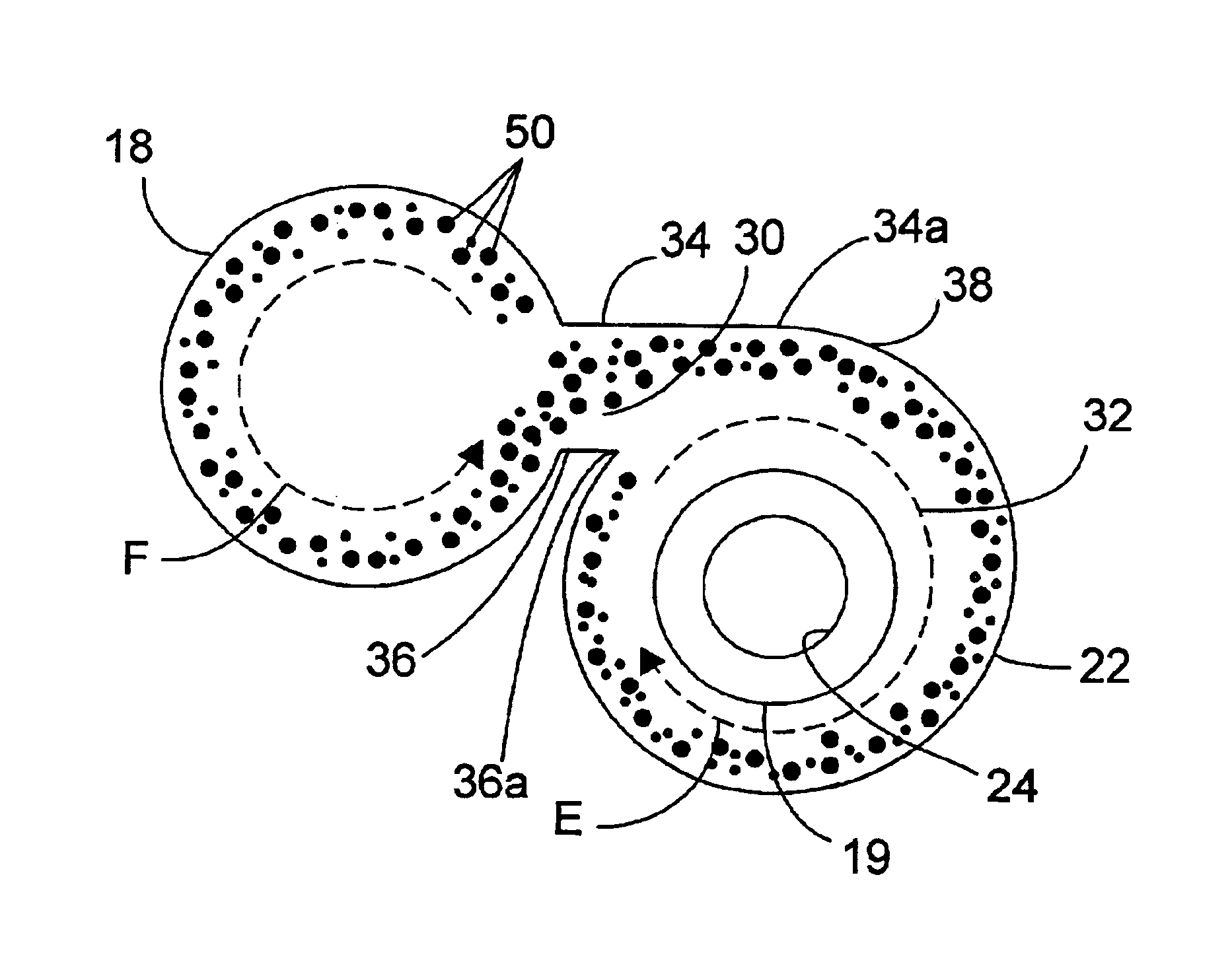

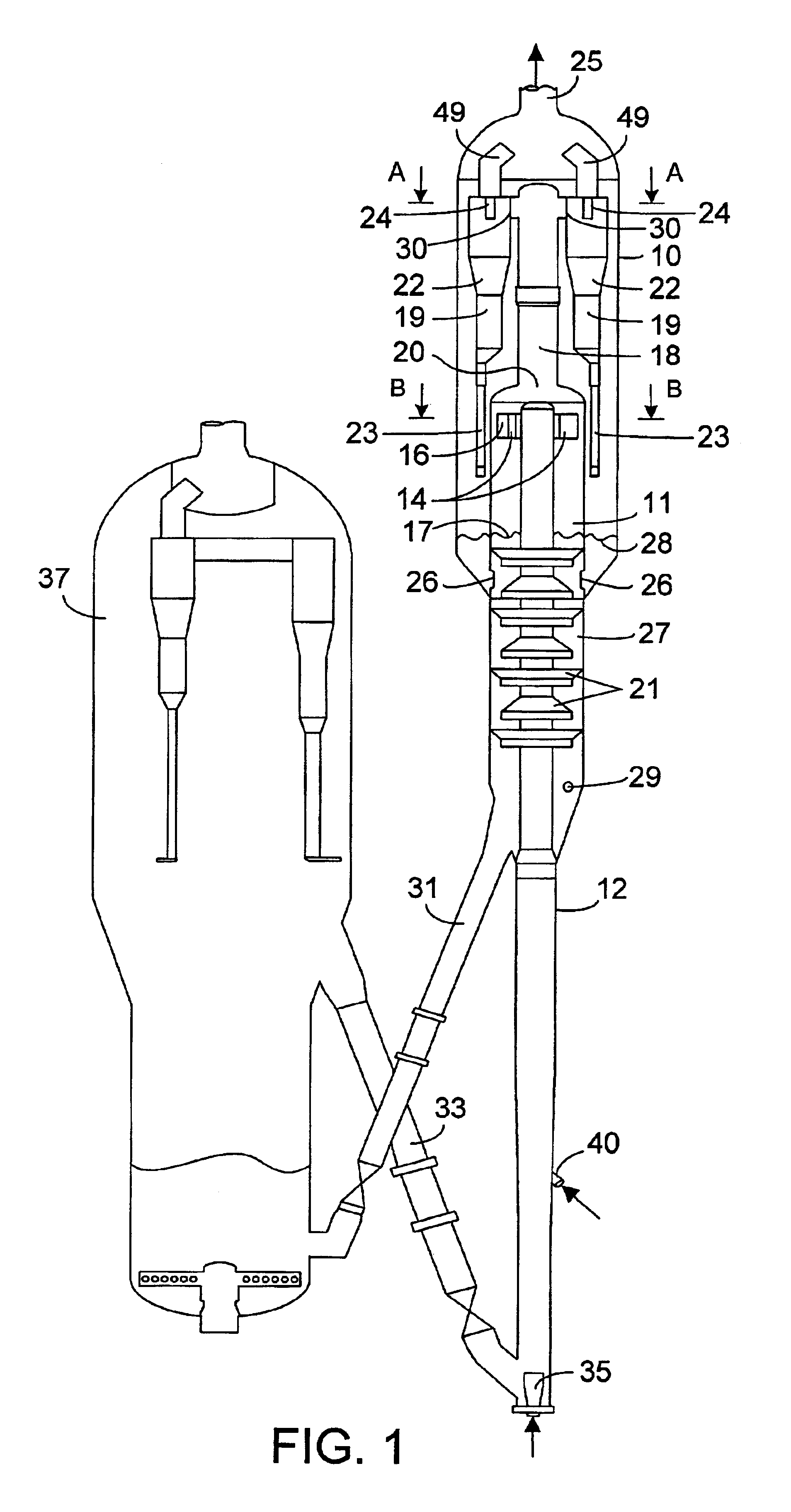

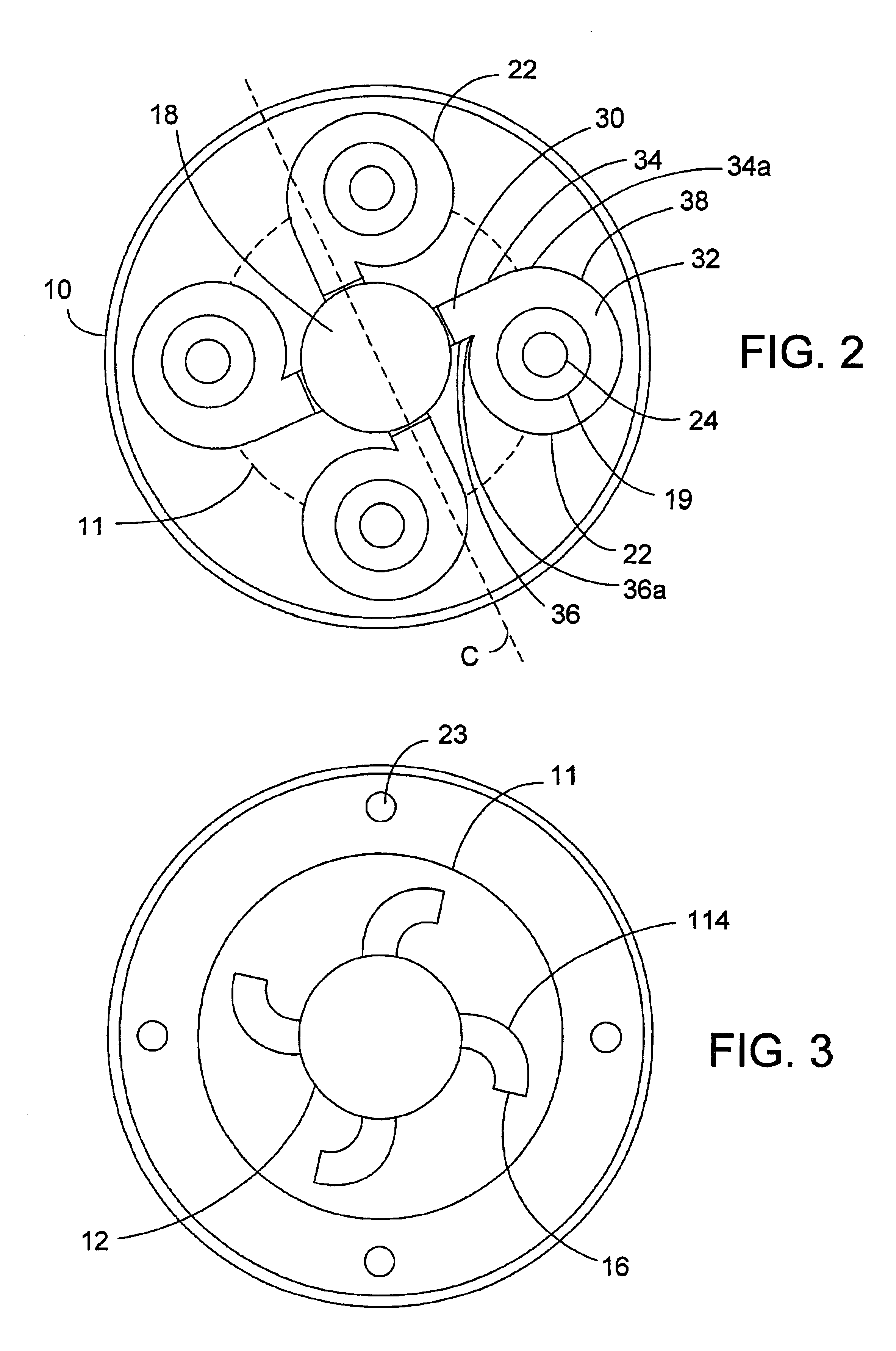

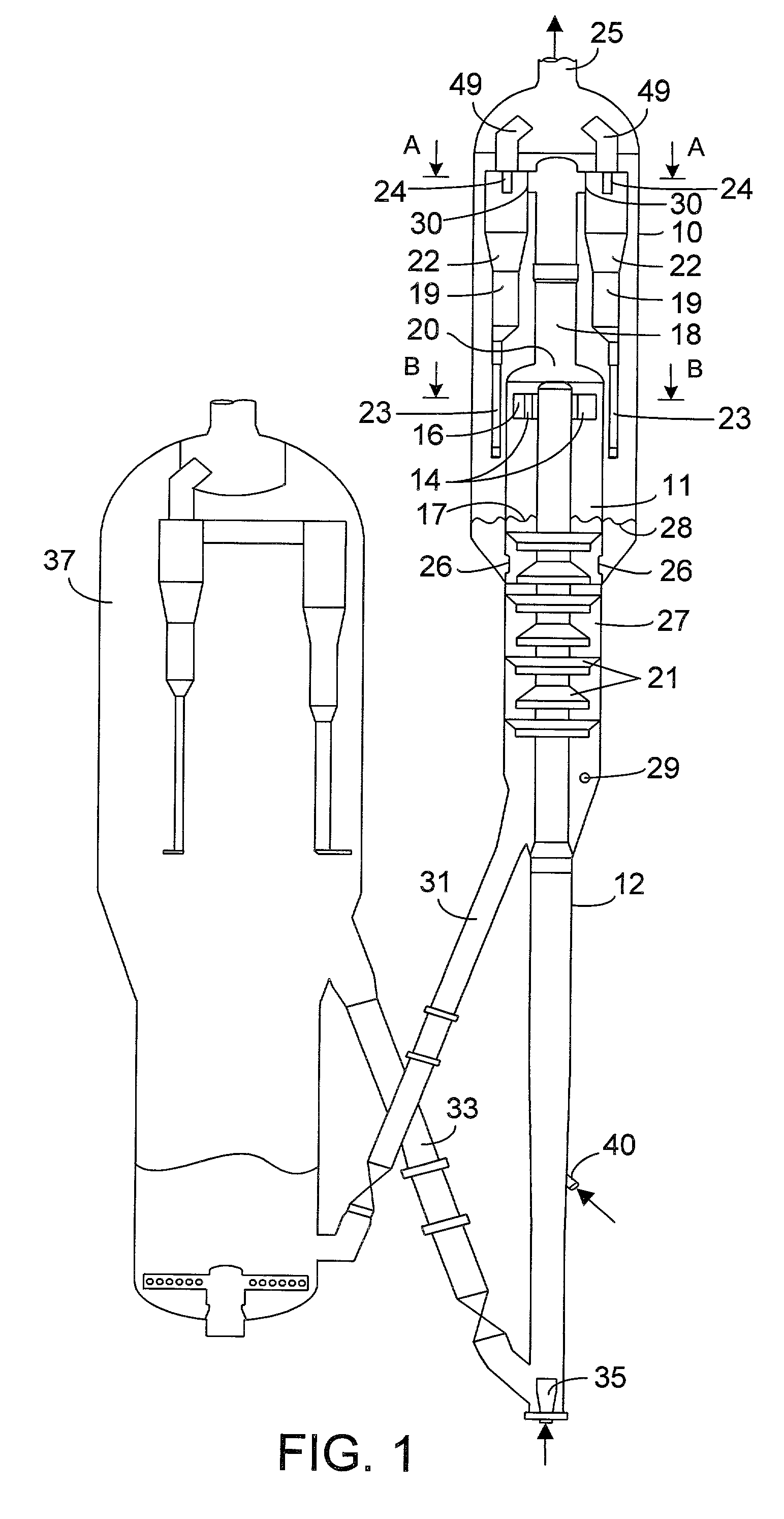

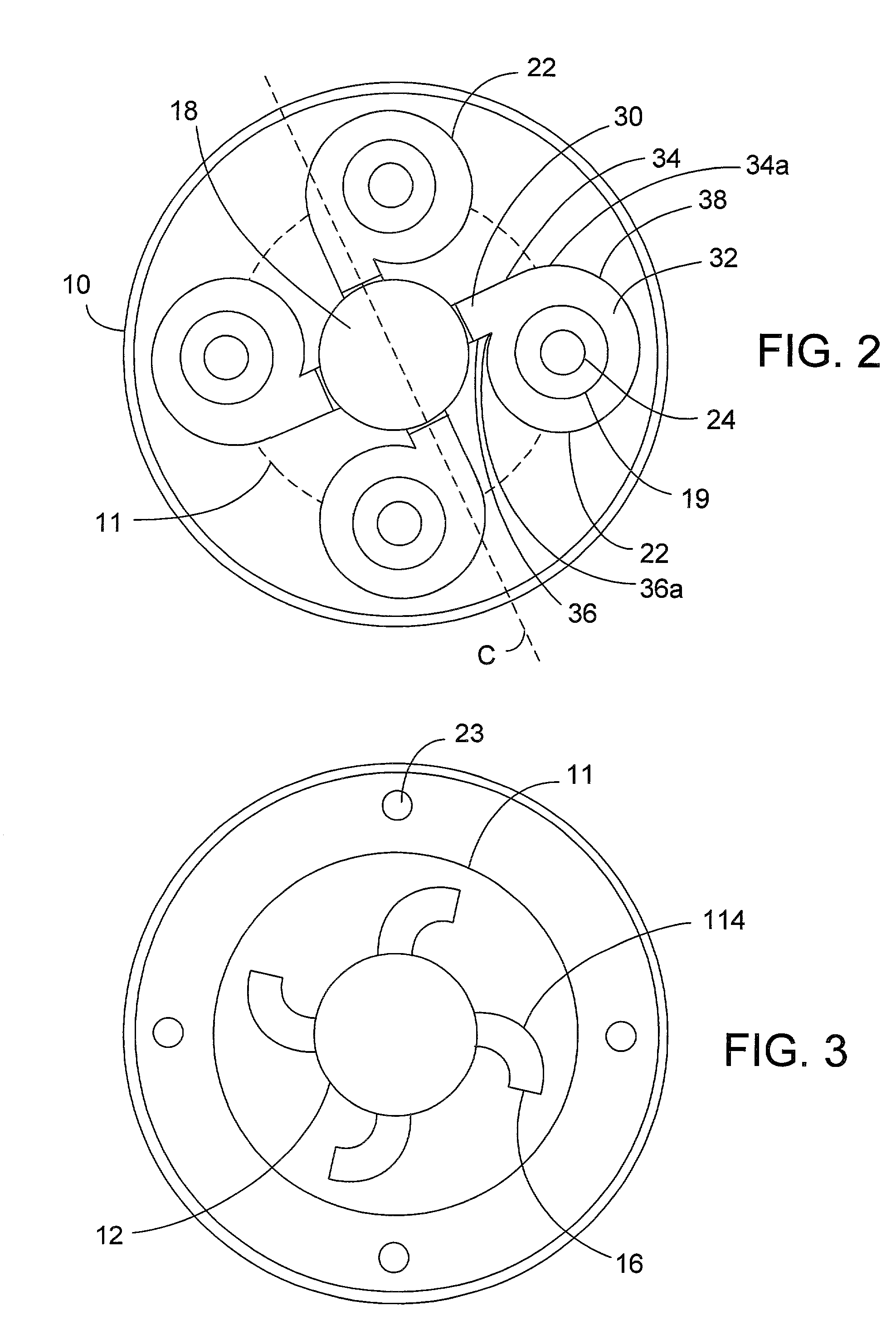

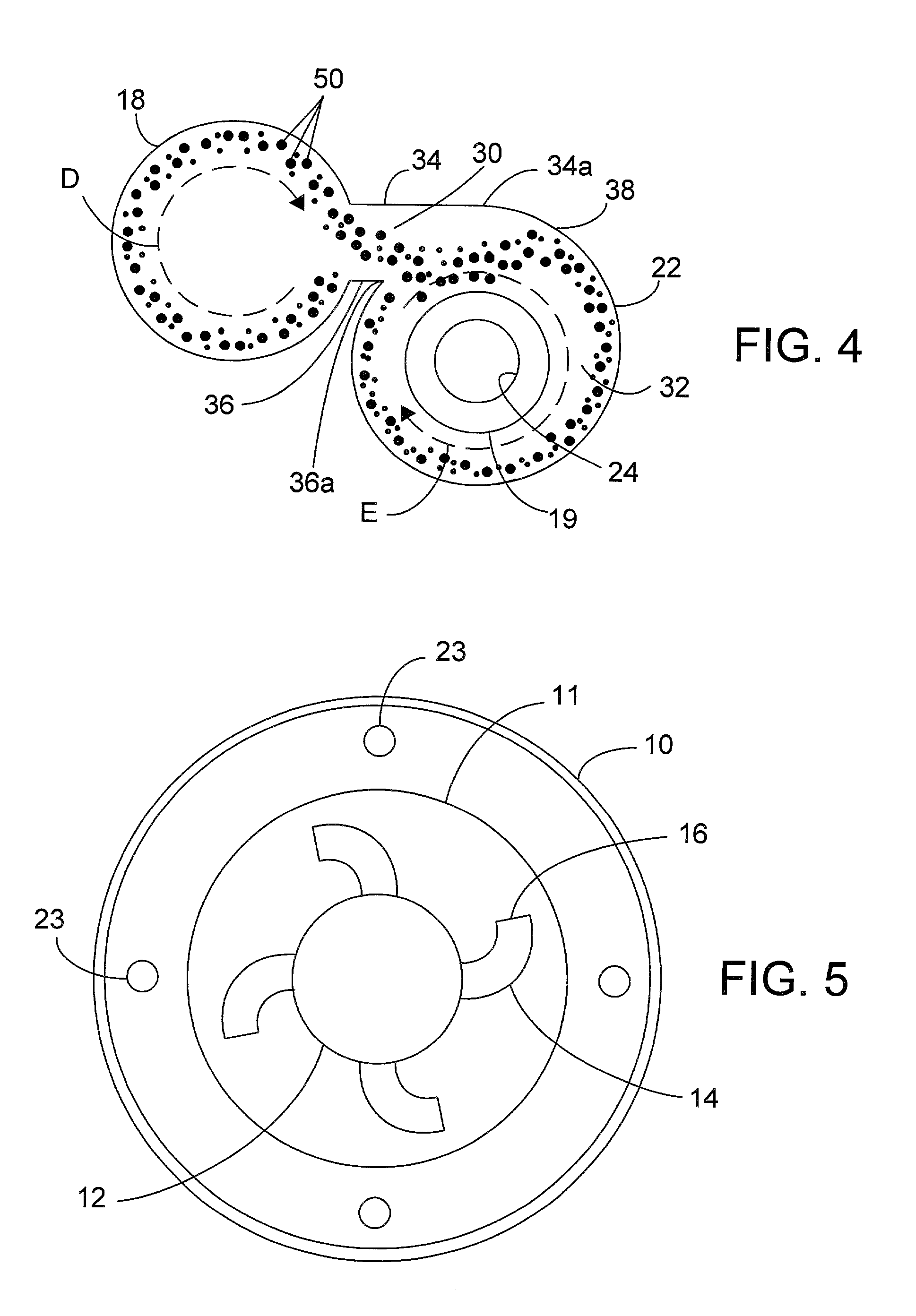

Separation process and apparatus

InactiveUS6841133B2Easy to separateMinimum separationCatalytic crackingDispersed particle separationCycloneEngineering

An apparatus and process is disclosed for the separation of solids from gases in a mixture which is most particularly applicable to an FCC apparatus. The mixture of solids and gases are passed through a conduit and exit through a swirl arm that imparts a swirl motion having a first annular direction to centripetally separate the heavier solids from the lighter gases. The mixture then enters a cyclone which has a curved outer wall and imparts a second swirling angular direction to the mixture. The second angular direction is counter to the first angular direction. The apparatus and method assures that a greater proportion of the mixture entering the cyclone is incorporated into the vortex to further enhance separation between the solids and gases.

Owner:UOP LLC

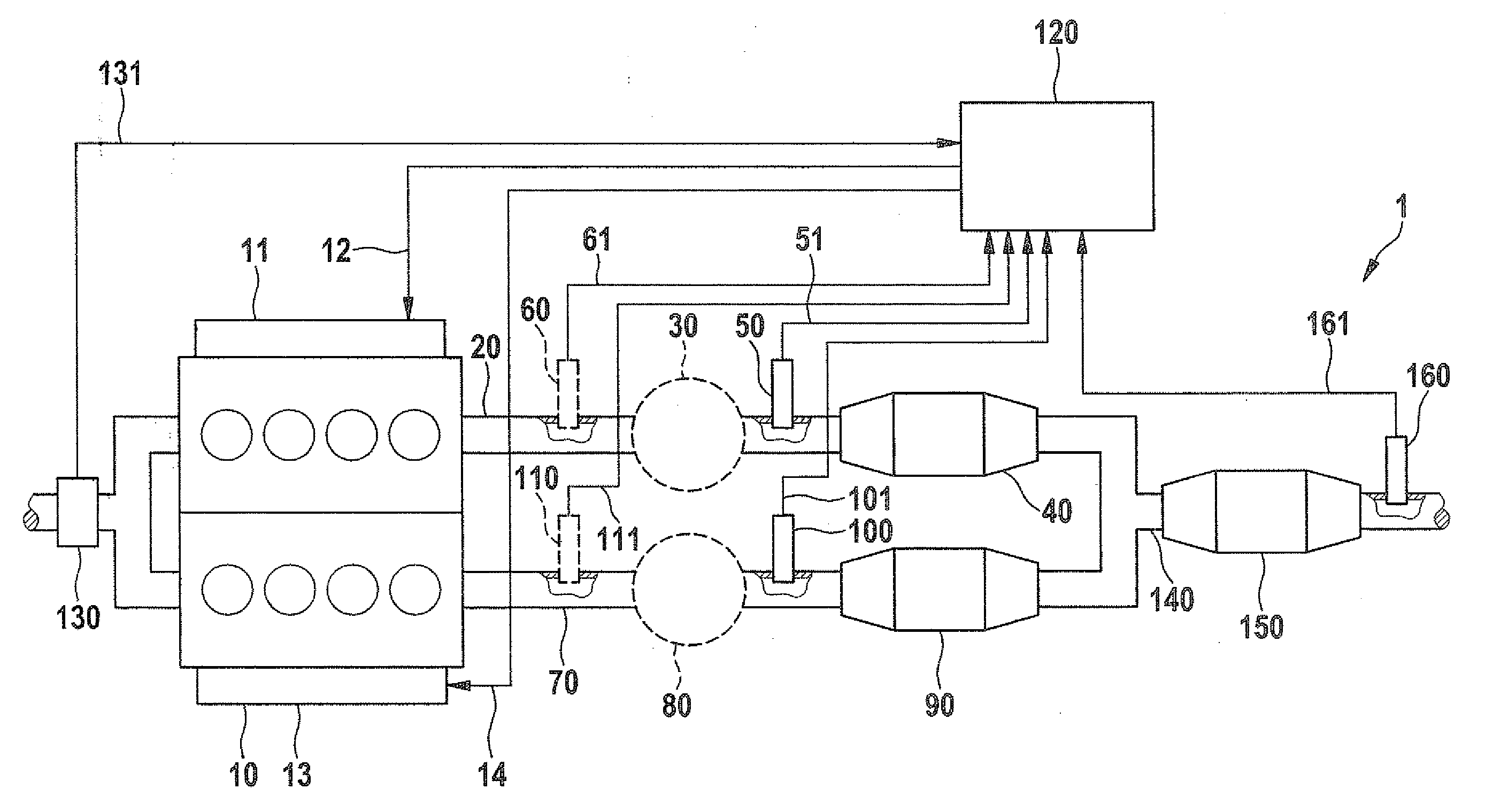

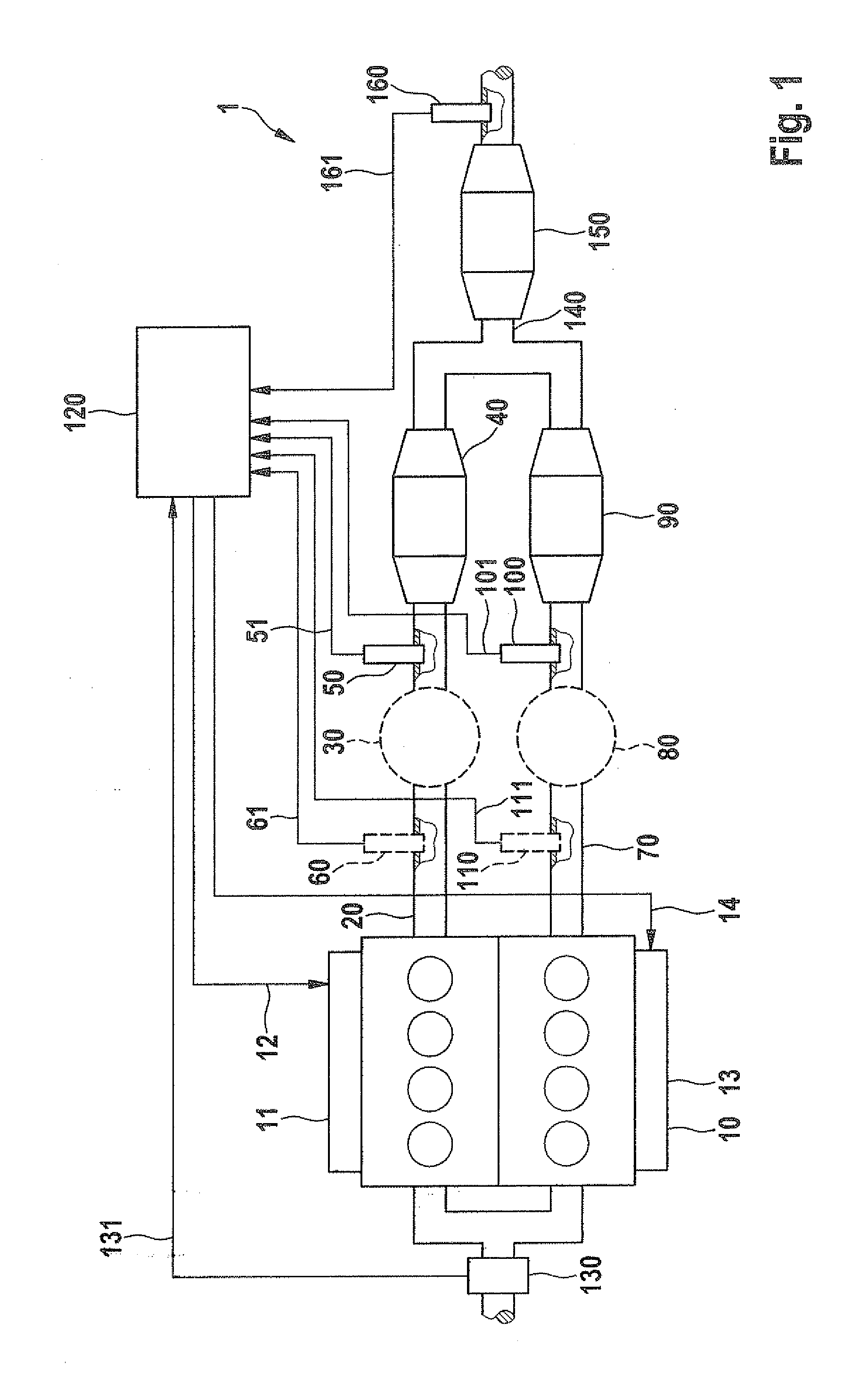

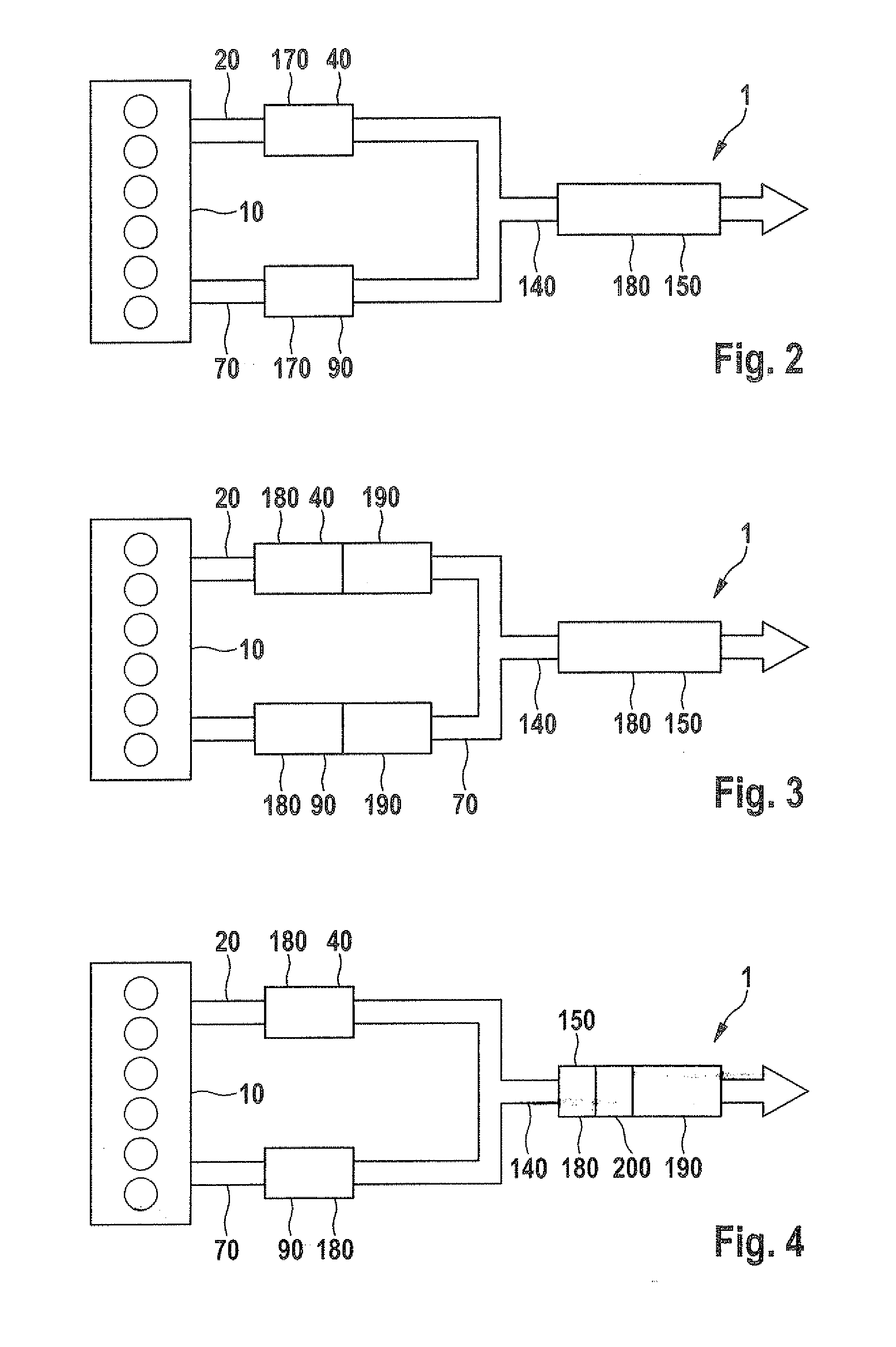

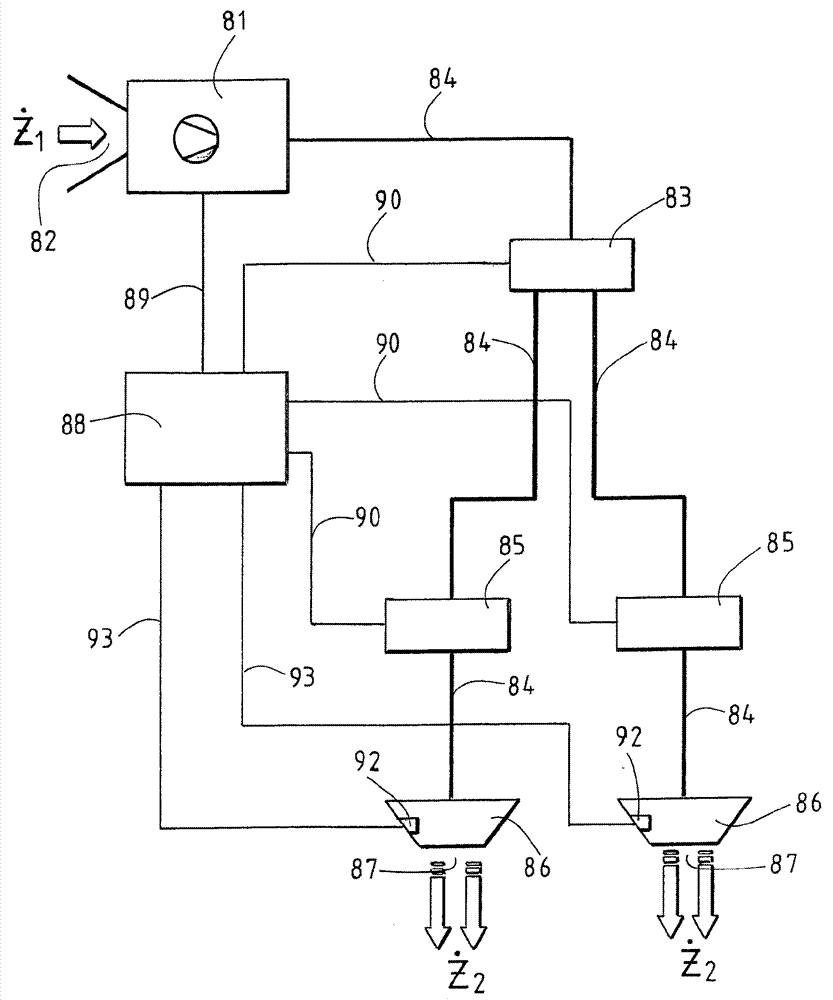

Method and device for regenerating a particle filter in a y-exhaust gas system

InactiveUS20120260631A1Reduce particle concentrationEasy to modifyElectrical controlInternal combustion piston enginesSoot particlesLambda

A method and device for regenerating an exhaust gas aftertreatment component for filtering soot particles in an engine having a first cylinder group, exhaust gases being guided through an exhaust gas channel and whose fuel / air mixture ratio is set via a fuel metering system, activated via a control unit, by a control loop for setting a lambda value using a signal of a first exhaust gas sensor, in the exhaust gas flow direction upstream from a catalytic converter, having at least another cylinder group, exhaust gases being guided through another exhaust gas channel and whose fuel / air mixture ratio is set via another fuel metering system by another control loop for setting another lambda value based on the signal of another exhaust gas sensor, in the exhaust gas flow direction upstream from a catalytic converter, the separate channels joined together downstream to form a shared channel, having a shared catalytic converter.

Owner:ROBERT BOSCH GMBH

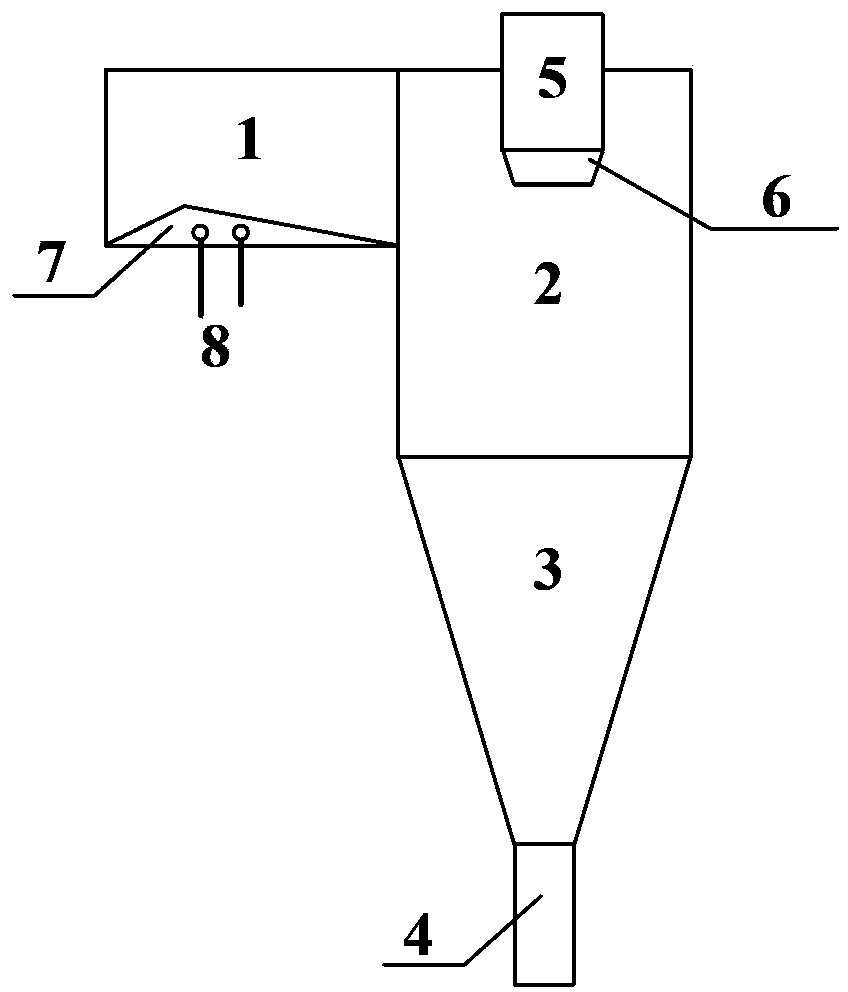

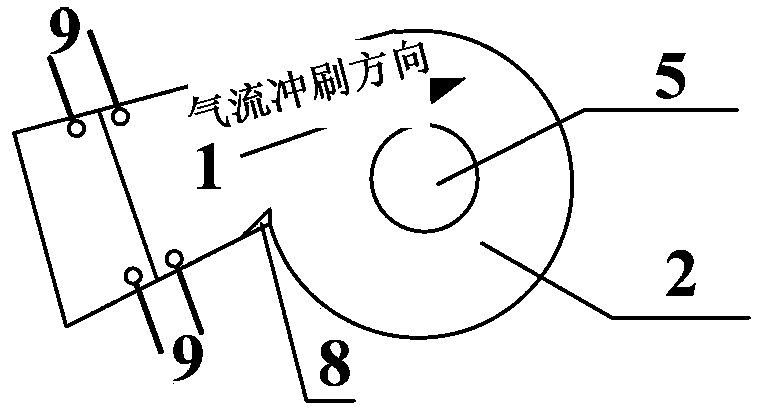

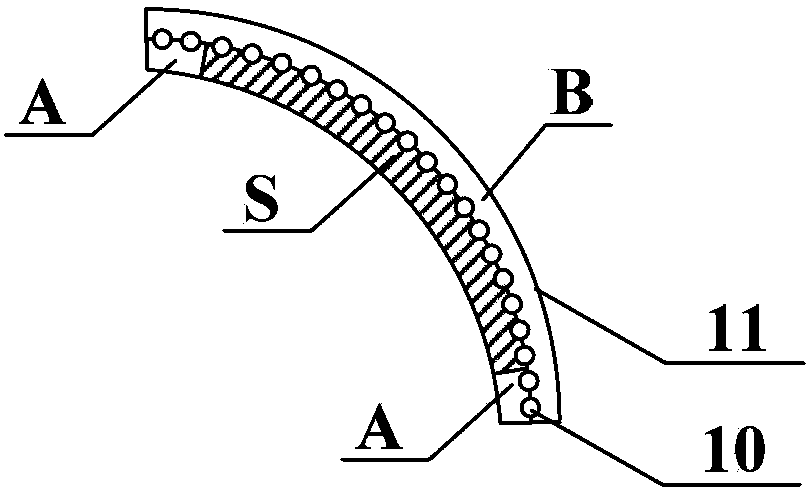

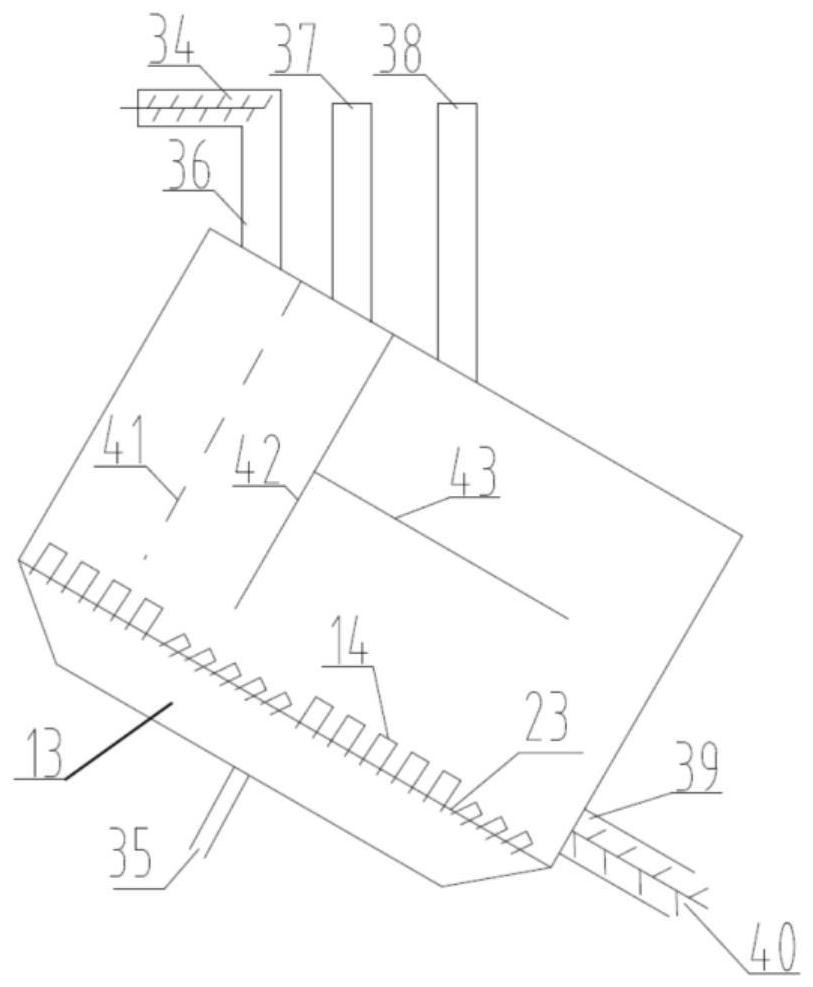

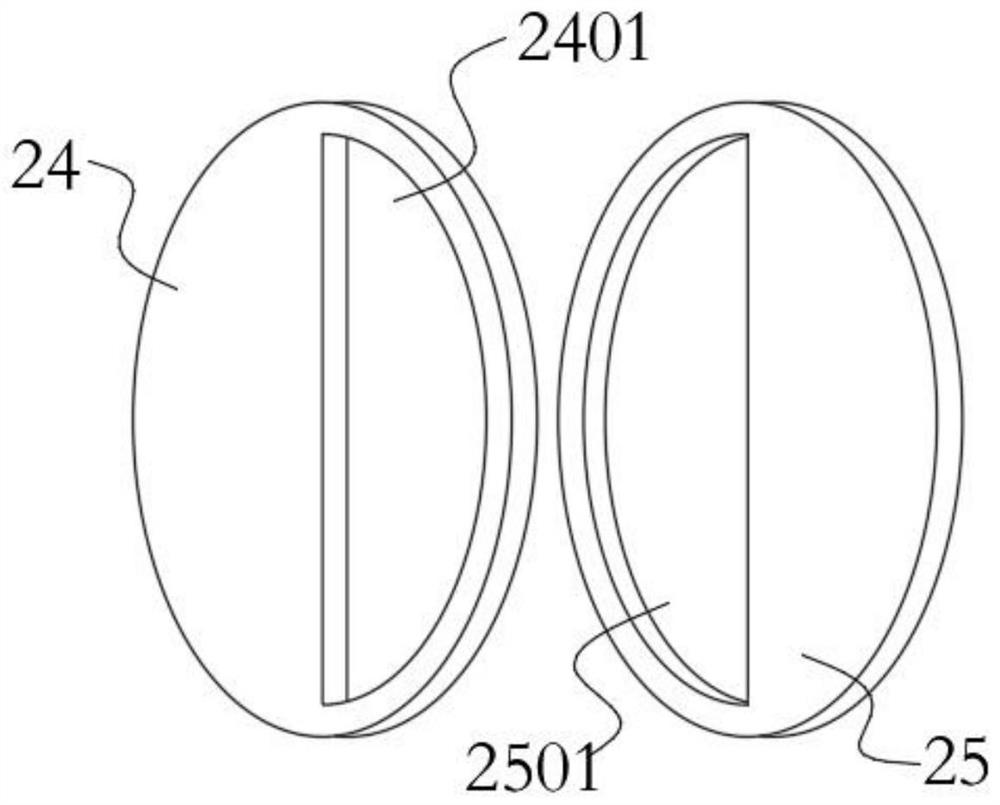

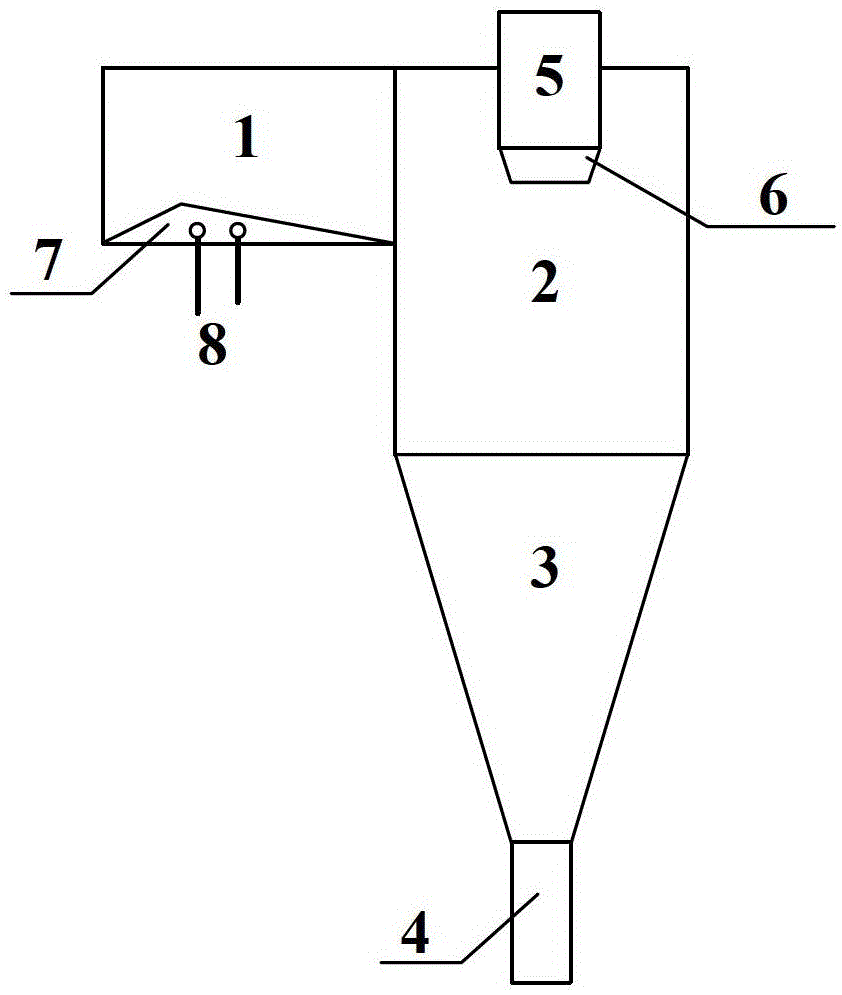

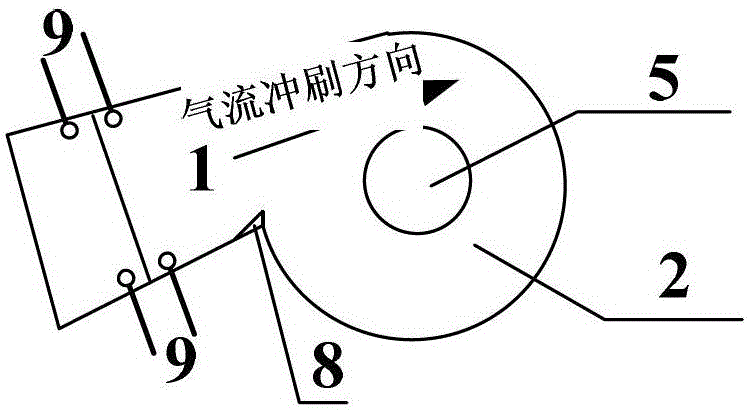

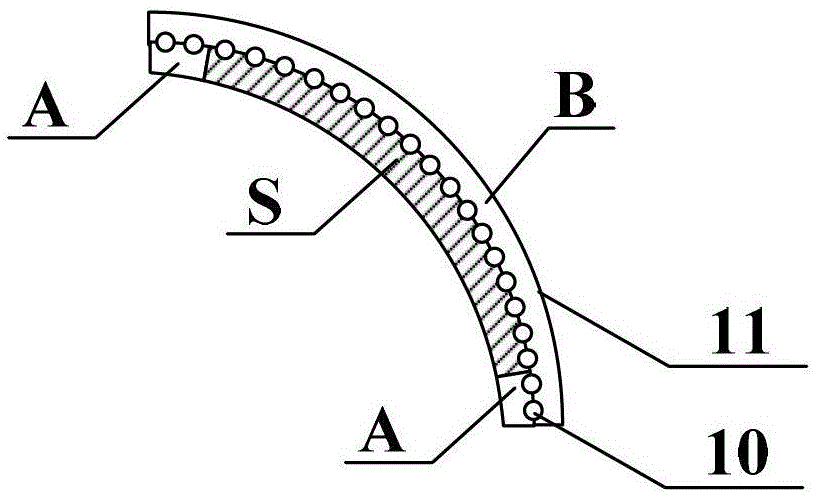

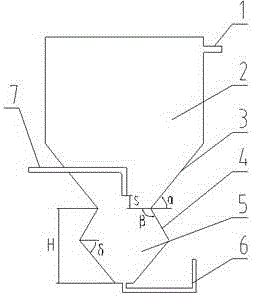

Cyclone separator with wear-resistant target section and guiding device for circulating fluidized bed boiler

ActiveCN103398375AIncreased flow velocityIncrease flow rateFluidized bed combustionApparatus for fluidised bed combustionRefractory wearCyclone

A cyclone separator with a wear-resisting target section and a guiding device for a circulating fluidized bed boiler. The cyclone separator comprises a separator inlet flue, a separator barrel body connected with an outlet of the separator inlet flue, a separator cone and a separator standpipe, which are successively connected below the separator cylinder body, and a separator central cylinder inserted into the upper part of the separator barrel body. The lower part of the separator central cylinder is provided with a central cylinder necking; the separator inlet flue is a tapered inlet flue, which is provided inside with a smoke guiding boss, and a smoke diversion part at the outlet; the smoke guiding boss and the smoke diversion part are covered with a high-strength refractory wear-resistant material layer; and one or a plurality of soot blowing mouths are arranged surrounding the smoke guiding boss. Optimization on the flow field in the cyclone separator reduces the direct impact of airflow and wear on the refractory wear-resistant material in the target section, and can improve the continuous operation cycle of the circulating fluidized bed boiler.

Owner:HUANENG CLEAN ENERGY RES INST

Automatic fuel adjustment system and method of multi-fuel fired boiler

InactiveCN103486607AImprove securityPrevent explosion accidentsFuel supply regulationAutomatic controlAutomotive engineering

The invention discloses an automatic fuel adjustment system of a multi-fuel fired boiler, and belongs to the technical field of automatic control. The automatic fuel adjustment system solves the problems that in the prior art, due to the lower pressure of the coal gas of a pipeline, coal gas blasting is easily caused in an existing fuel adjustment system, quality of automatic fuel adjustment is poor, and the heat loss is large. The system comprises an automatic control module, a detection module and a valve module, wherein the automatic control module judges the burning state of the boiler according to the difference value between the overheating steam pressure measuring value detected by the detection module and the preset boiler overheating steam pressure setting value and transmits a corresponding command to the valve module, the detection module is used for detecting various parameters of boiler burning and transmitting the corresponding parameters to the automatic control module, the valve module receives the command from the automatic control module, adjusts fuel of a corresponding fuel layer, and can manually adjust valves in the modules, and the automatic control module is respectively connected with the detection module and the valve module. The invention further provides an automatic fuel adjustment method of the multi-fuel fired boiler. The automatic fuel adjustment system and method of the multi-fuel fired boiler are suitable for fuel adjustment of the multi-fuel fired boiler.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Separation process and apparatus

InactiveUS20030029774A1Easy to separateMinimum separationCatalytic crackingLayered productsCycloneEngineering

An apparatus and process is disclosed for the separation of solids from gases in a mixture which is most particularly applicable to an FCC apparatus. The mixture of solids and gases are passed through a conduit and exit through a swirl arm that imparts a swirl motion having a first annular direction to centripetally separate the heavier solids from the lighter gases. The mixture then enters a cyclone which has a curved outer wall and imparts a second swirling angular direction to the mixture. The second angular direction is counter to the first angular direction. The apparatus and method assures that a greater proportion of the mixture entering the cyclone is incorporated into the vortex to further enhance separation between the solids and gases.

Owner:UOP LLC

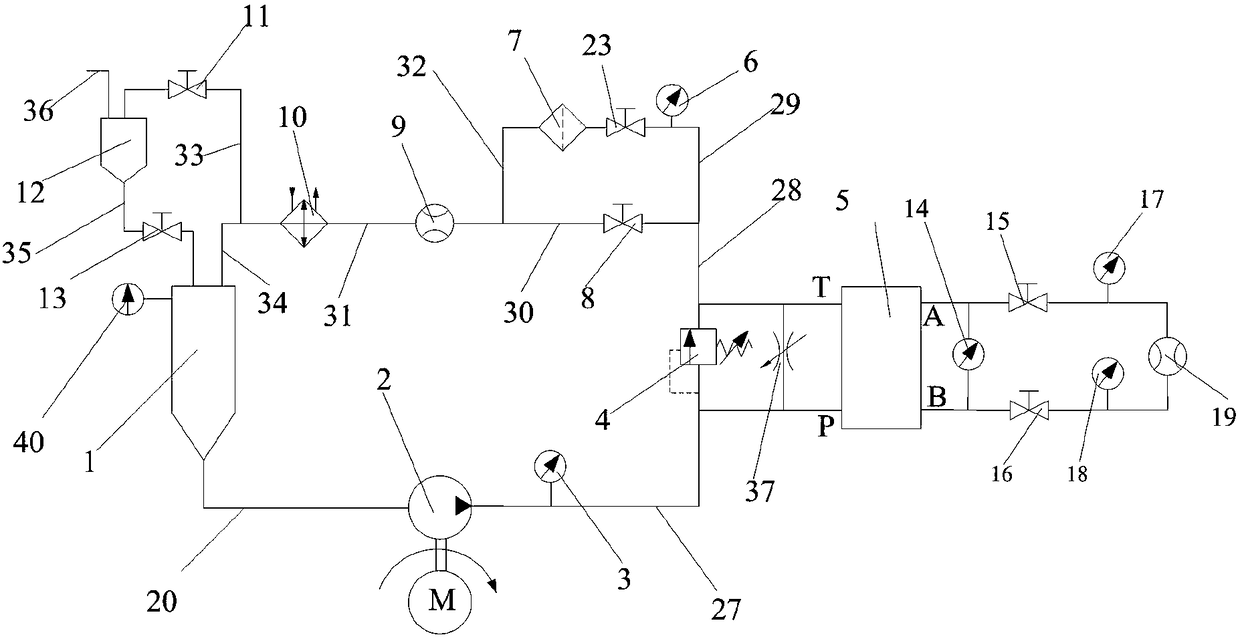

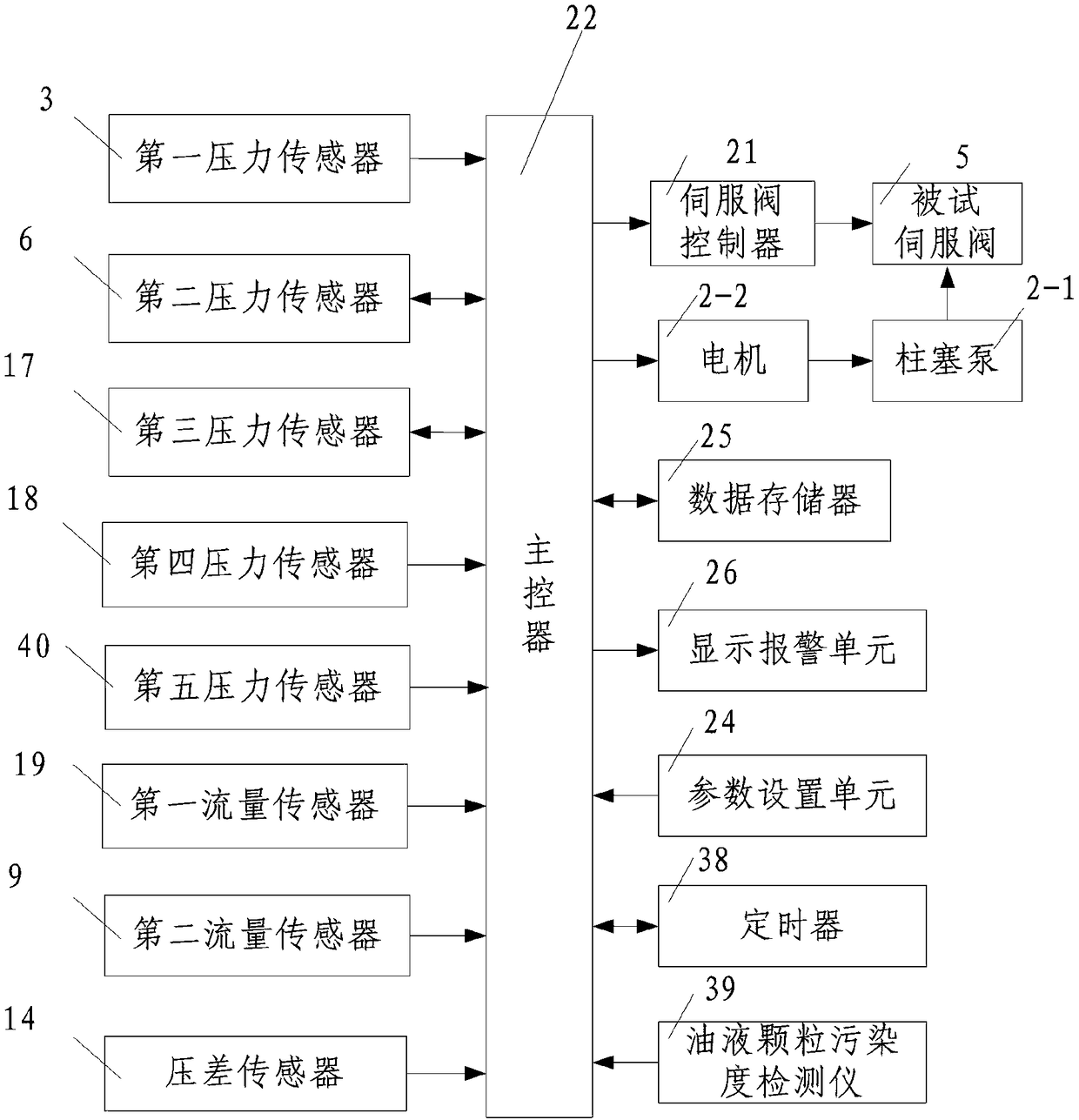

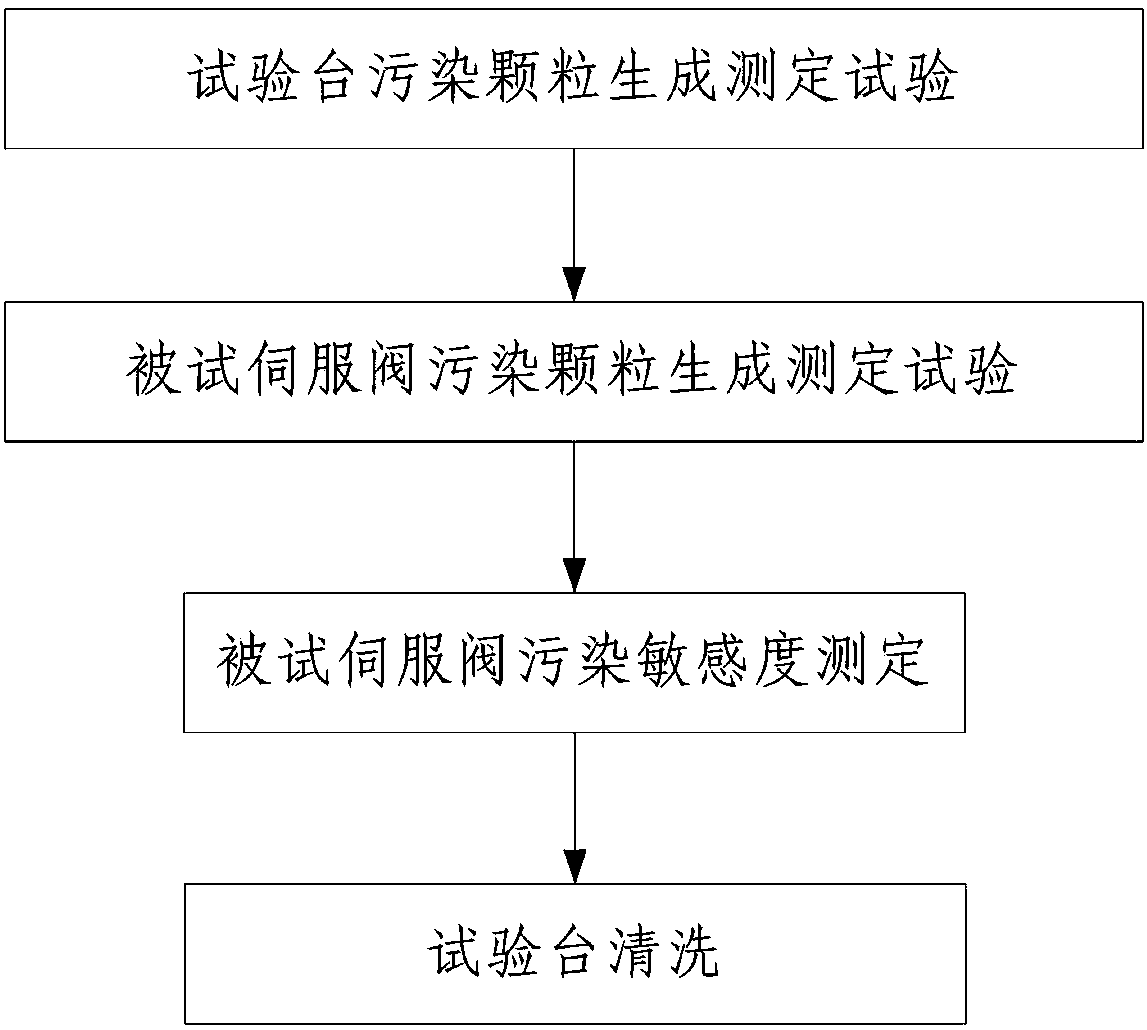

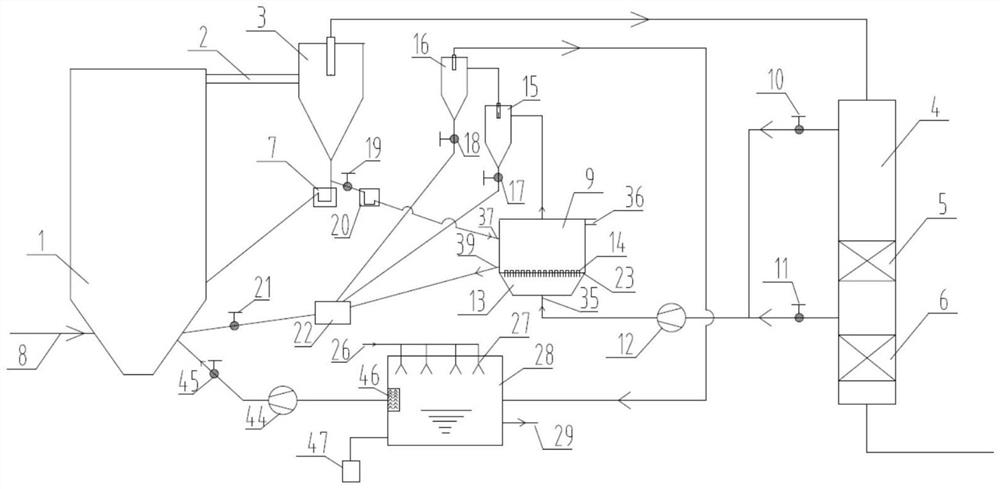

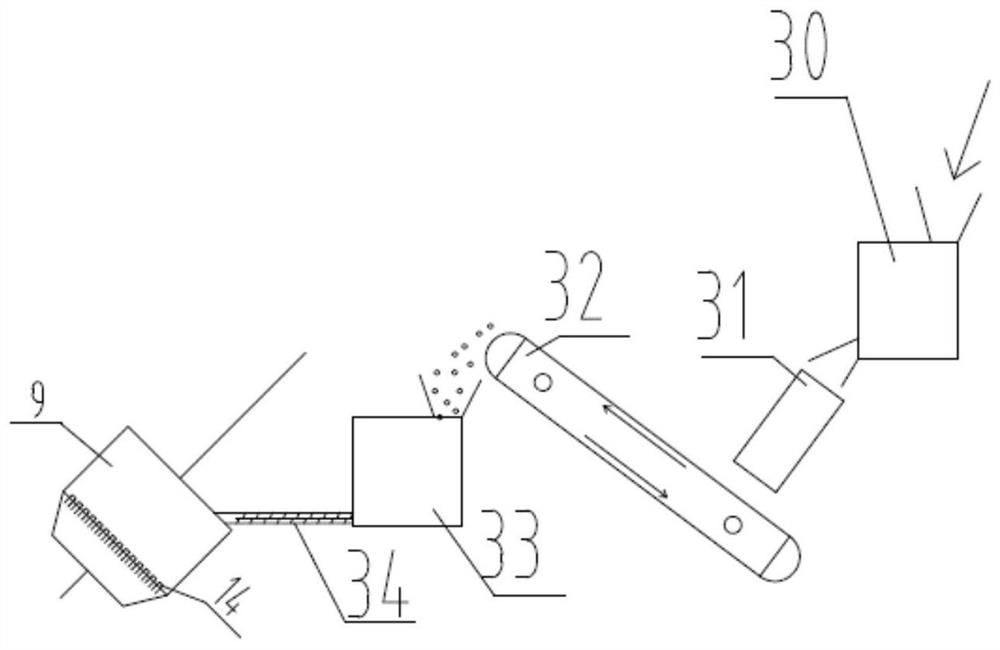

Testing device and testing method for servo valve pollution sensitivity measurement

ActiveCN108169091ASimple structureReasonable designParticle suspension analysisMeasurement testControl theory

The invention discloses a testing device and a testing method for servo valve pollution sensitivity measurement. The testing device comprises a monitoring device and a test bench for mounting a testedservo valve, wherein the test bench comprises an oil supply device for supplying oil to the tested servo valve, a cleaning filter for filtering hydraulic oil at an oil returning port of the tested servo valve, and a dust solution tank for collecting the hydraulic oil at the oil returning port of the tested servo valve and accommodating a dust solution. The testing method comprises the following steps: 1, performing a test bench pollution particle generation measurement test; 2, performing a tested servo valve pollution particle generation measurement test; 3, performing tested servo valve pollution sensitivity measurement; 4, cleaning the test bench. The testing device is reasonable in design, easy and convenient to use and operate and good in using effect; measurement of servo valve pollution sensitivity can be easily, conveniently and quickly completed; the testing precision is relatively high.

Owner:陕西东方长安航空科技有限公司

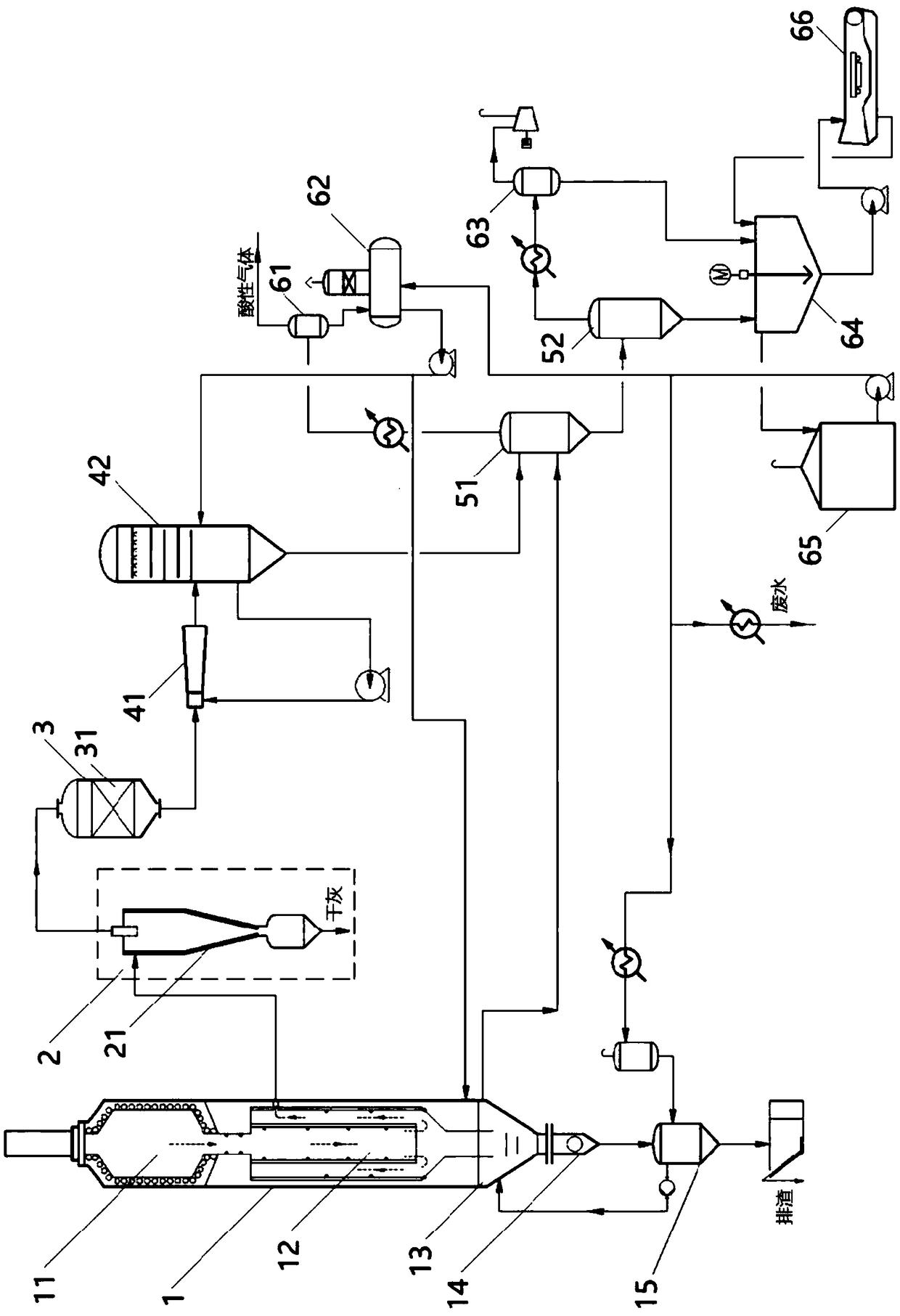

Waste fan blade pyrolysis recovery system and working method thereof

ActiveCN113046107AIndependent and flexible structureHarmlessProductsReagentsFan bladeCirculating fluidized bed boiler

The invention discloses a waste fan blade pyrolysis recovery system and a working method thereof, and belongs to the technical field of resource recovery. The waste fan blade pyrolysis recovery system comprises a crushing system, a circulating fluidized bed boiler system, a pyrolysis reactor, a material collecting and conveying device, a pyrolysis gas-solid separation system and a cracking oil separation system. According to the invention, composite materials in waste blades can be effectively cracked, cracking oil generated by cracking can be recovering, cracking gas is pumped to a hearth to be effectively incinerated, heat value contained in the cracking gas is effectively utilized, pollutants generated in the combustion process can be discharged in a standard reaching mode by means of an environment-friendly device arranged in an original boiler system, and a pyrolysis reaction in a pyrolysis reactor under an anoxic atmosphere effectively avoids the potential problems of dioxin generation and emission, and the like caused by direct incineration of the waste leaves, so that harmless and resourceful treatment of the waste leaves is completely achieved; and before the comprehensive recycling technology of the blade material is mature and utilized on a large scale, the influence of the waste blade on the environment and the like can be effectively solved, and good environmental protection benefits and economic benefits are generated.

Owner:HUANENG CLEAN ENERGY RES INST

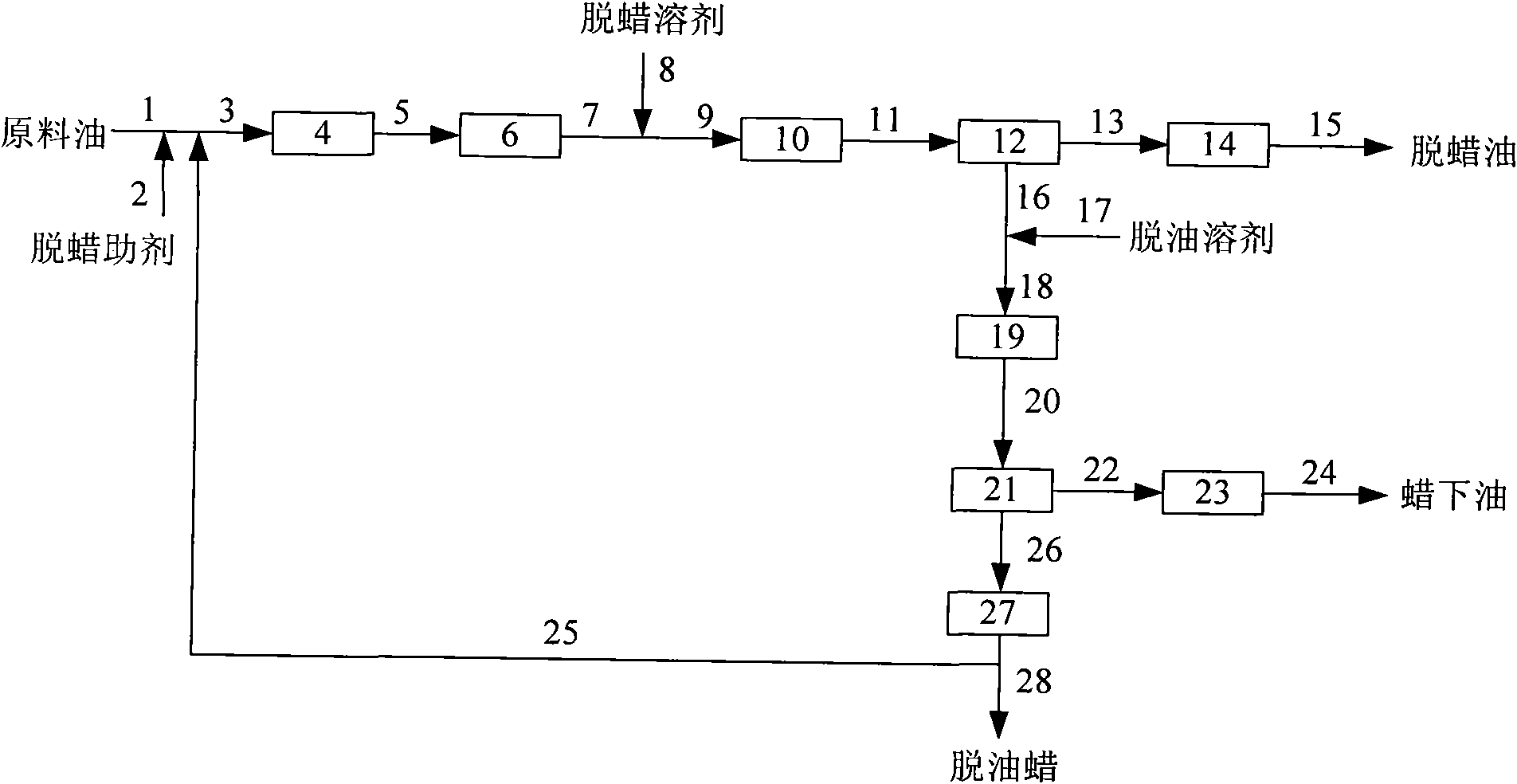

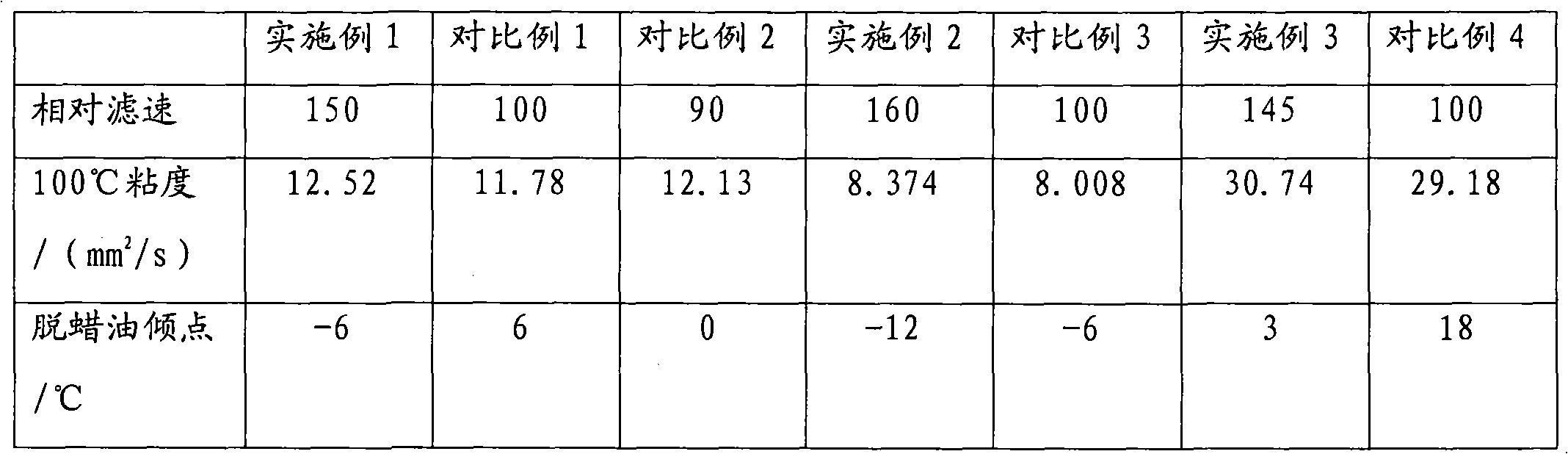

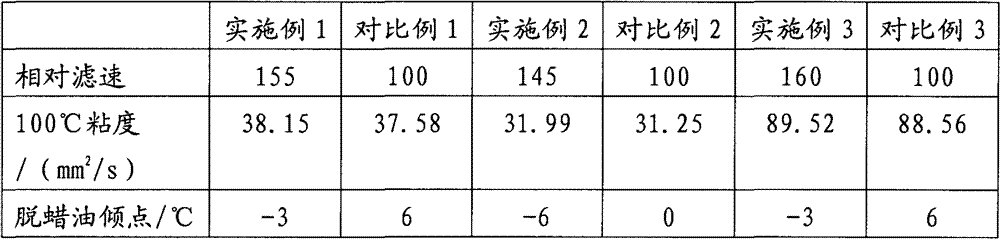

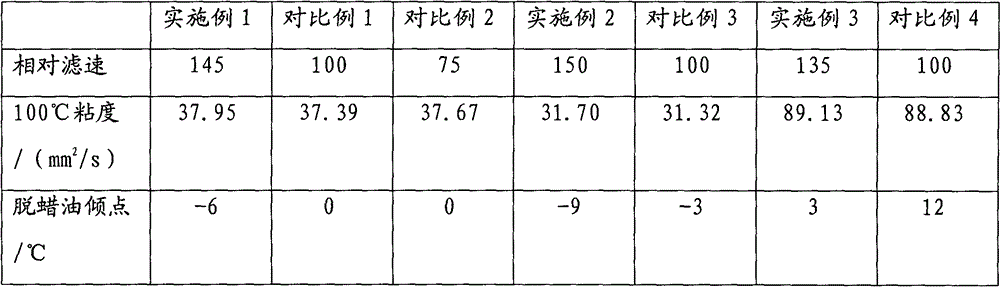

Solvent dewaxing method for low waxy hydrocarbon oil

ActiveCN102757821AReduce particle concentrationReduce filtration performancePetroleum wax recoveryWaxTemperature difference

The invention relates to a solvent dewaxing method for low waxy hydrocarbon oil. The method includes: mixing raw oil, dewaxing auxiliaries and dewaxing solvent, cooling the mixture to a filtering temperature, filtering to obtain filtrate and cerate, and removing the solvent from the filtrate to obtain dewaxed oil, wherein C17-C100 n-alkane mass content in the dewaxing auxiliaries is larger than or equal to 40%, and the mass ratio of the dewaxing auxiliaries to the raw oil ranges from 0.01:1 to 0.30:1. Compared with conventional solvent dewaxing techniques, the solvent dewaxing method has the advantage that the low waxy hydrocarbon oil can be dewaxed more effectively to lower dewaxing temperature difference and increase filtering speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

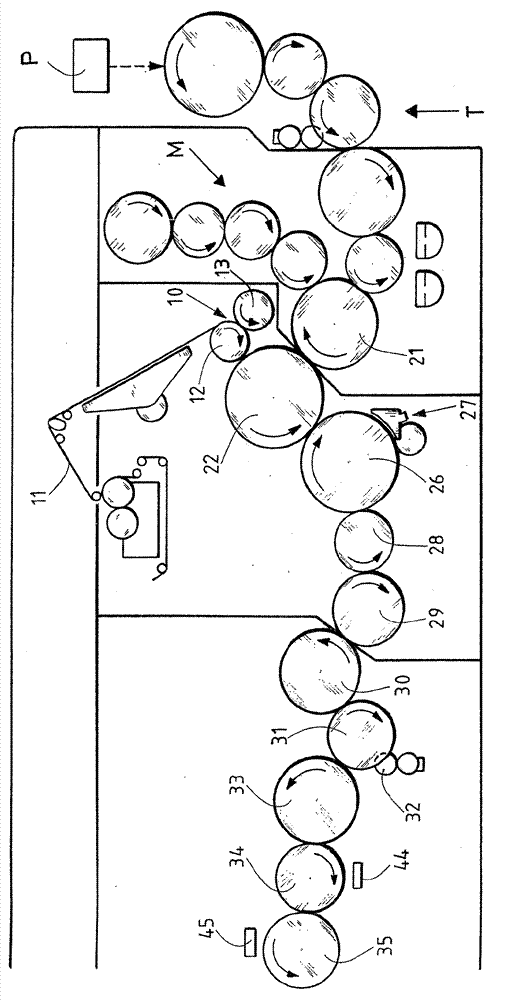

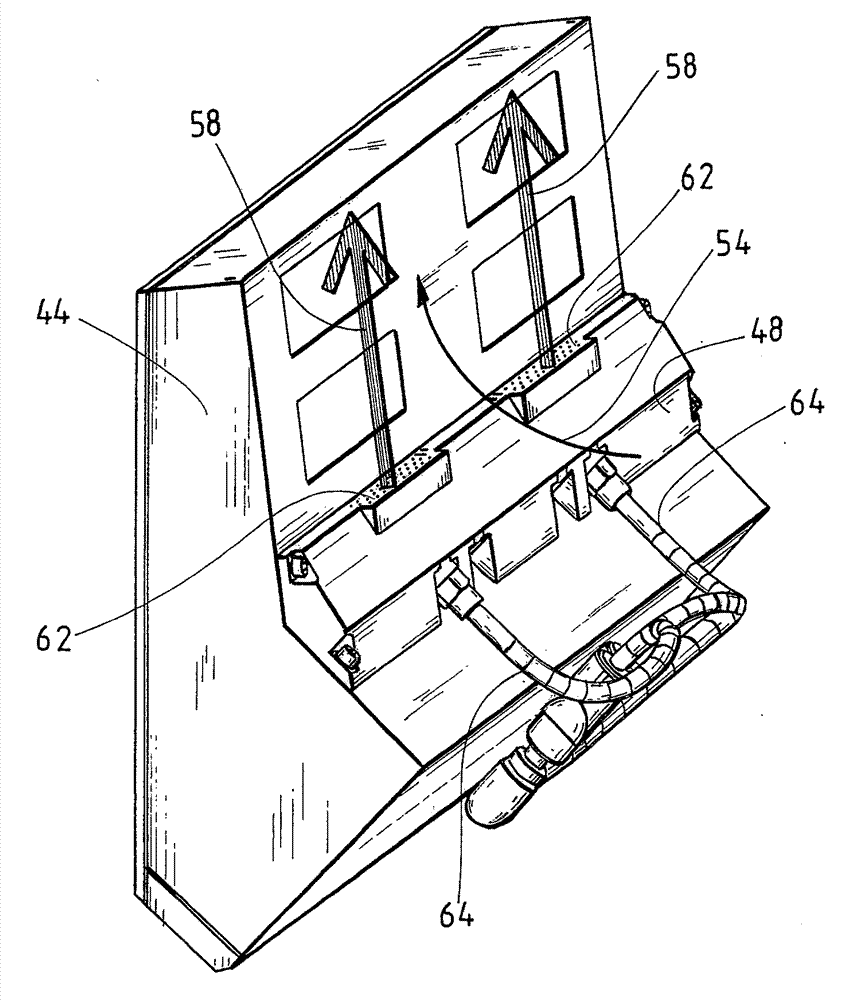

Inspection of rod-shaped articles from the tobacco processing industry

InactiveCN103202534AReduce pollutionQuality improvementCigarette manufactureMaterial analysis by optical meansHorizontal axisEngineering

The invention relates to an inspection of rod-shaped articles from the tobacco processing industry. According to a method of inspecting the rod-shaped articles, especially filter cigarettes, by using an inspection device, the articles are conveyed along a horizontal axis on test drums and inspected by the inspection device arranged on the test drums. The surrounding air and the tobacco crumbs, before or after entering test zones of testers, are accelerated and / or deflected by air curtains that are generated by air curtain generating units, where the generating units are preferably arranged at the testers and the test drums. The air curtains are formed or directed in the test zones or in a region of the test zones that are spaced or parallel to a surface of the test drums. The device for inspection of the articles, especially the filter cigarettes, comprises the test drums used for conveying the articles preferably for the horizontal conveying and an inspection apparatus arranged on the test drums and used for inspecting the articles conveyed on the test drums. The invention further relates to a machine, especially to a filter installation machine.

Owner:HAUNI MASCHINENBAU AG

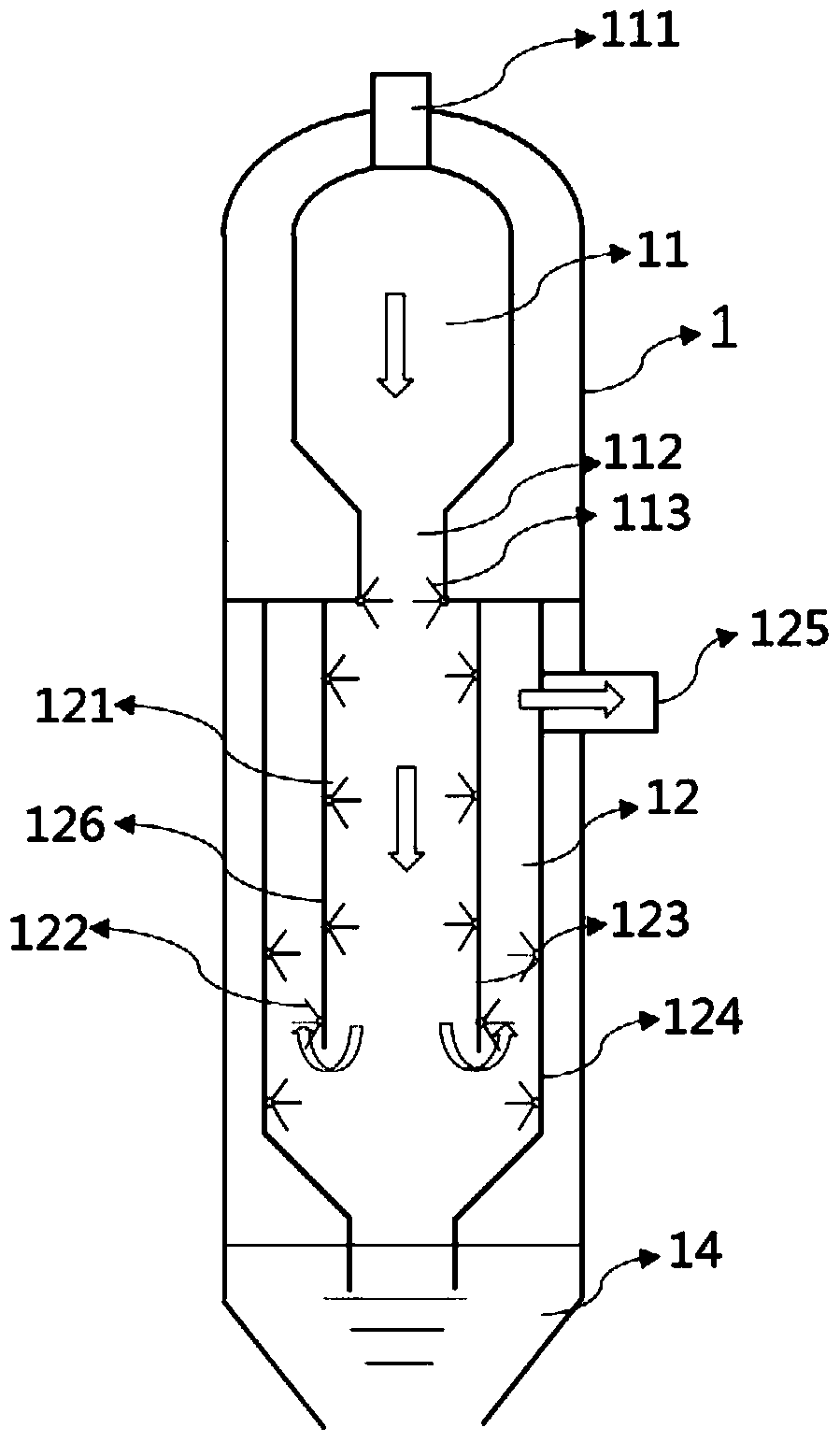

Gasification system and technology for efficient heat recovery

PendingCN108795500AImprove heat recoveryEnsure safetyChemical industryGasification processes detailsThermal energyDistillation

The invention provides a gasification system for efficient heat recovery. The system comprises a gasification furnace, gas-solid separation and ash cooling equipment, a convective heat exchange device, gas scrubbing equipment and a black water treatment system, wherein a spraying device is arranged on a heat transfer surface in a radiation heat transfer chamber of the gasification furnace, so as to form a lower temperature zone close to the heat transfer surface and a core high temperature zone on one side, far from the heat transfer surface, of the lower temperature zone; the gas-solid separation and ash cooling equipment is communicated with a synthesis gas outlet of the gasification furnace; the convective heat exchange is used for recycling sensible heat of synthesis gas and producingpower steam; the gas scrubbing equipment comprises a venturi scrubber and a scrubbing tower which are connected in series; the black water treatment system comprises a primary flash distillation device and a secondary flash distillation device. The invention further provides a gasification technology for efficient heat recovery. The scheme adopts a radiation heat exchange chamber adopting a borderland temperature control technology, not only guarantees the safety of a heat exchange tube, but also guarantee high heat recovery efficiency, higher yield of saturated steam and smaller equipment volume under high radiation intensity.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

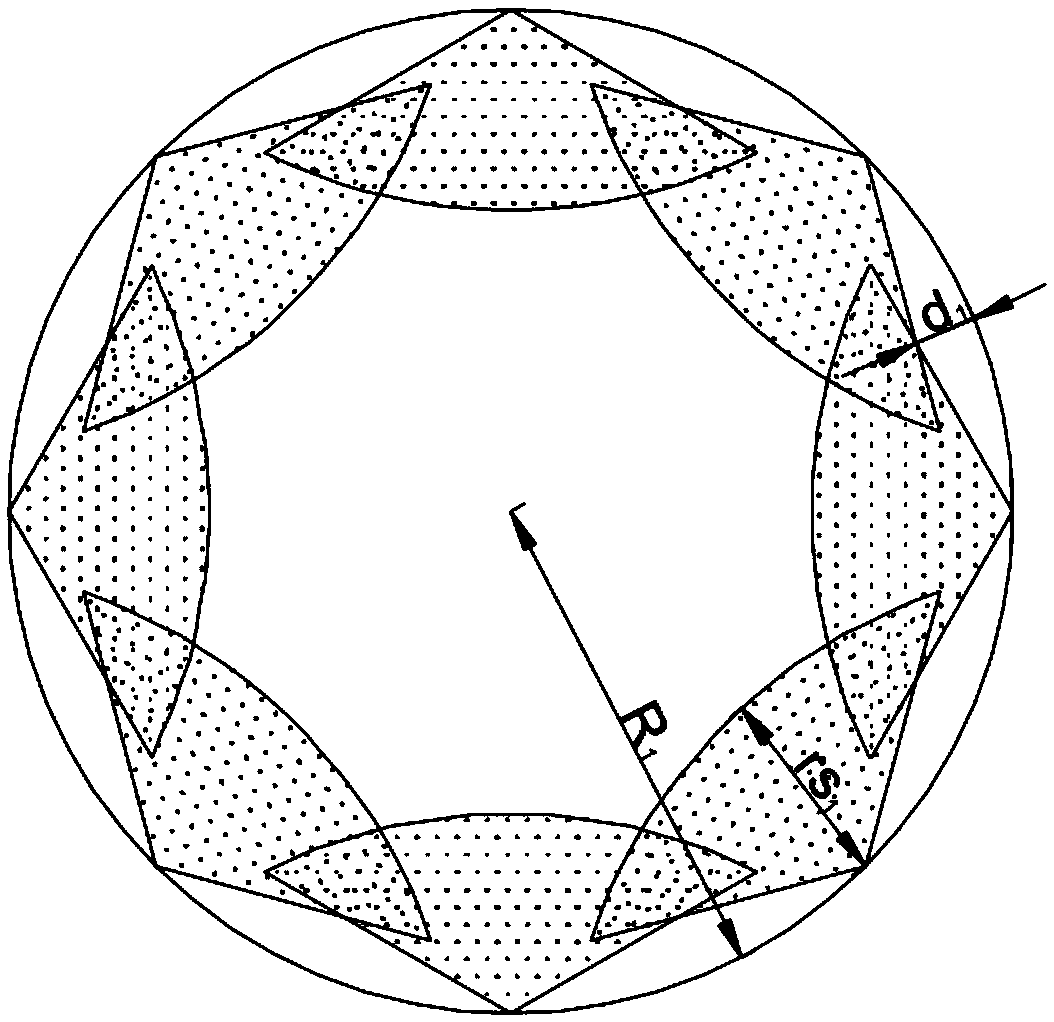

Arrangement method of catalytic cracking tetra-cyclone separator

InactiveCN106492570AExtended service lifeReduce particle concentrationCombination devicesCycloneFlue gas

The invention discloses an arrangement method of a catalytic cracking tetra-cyclone separator (referred to as a tetra-cyclone). The tetra-cyclone separator system mainly comprises a tertiary cyclone discharge pipe, a material storage tank, a tetra-cyclone gas inlet pipe and a tetra-cyclone. A dilute phase space at the upper part of the material storage tank is provided with a vertical partition plate. The vertical partition plate divides the dilute phase space of the material storage tank into an inertial separation zone and a sedimentation separation zone. Dust-containing flue gas in the tertiary cyclone discharge pipe is introduced from the top of the inertial separation zone, passes through the inertial separation zone and the sedimentation separation zone and then enters the tetra-cyclone through the tetra-cyclone gas inlet pipe at the top of the sedimentation separation zone. Gas subjected to dedusting in the tetra-cyclone enters a downstream critical nozzle. Solid particles separated by the tetra-cyclone enter a bottom material layer of the material storage tank along a dipleg. The inertial separation zone realizes gas and solid separation through difference of gas and solid particles. The sedimentation separation zone realizes gas-solid separation by a lower section gas velocity. Through the above two kinds of particle pre-separation measures, a particle concentration at the inlet of the tetra-cyclone and separation load are reduced. A gas-locking device is arranged at a tetra-cyclone dipleg particle outlet so that backflow of gas in the dipleg is prevented and smooth delivery of particles in the dipleg is guaranteed.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

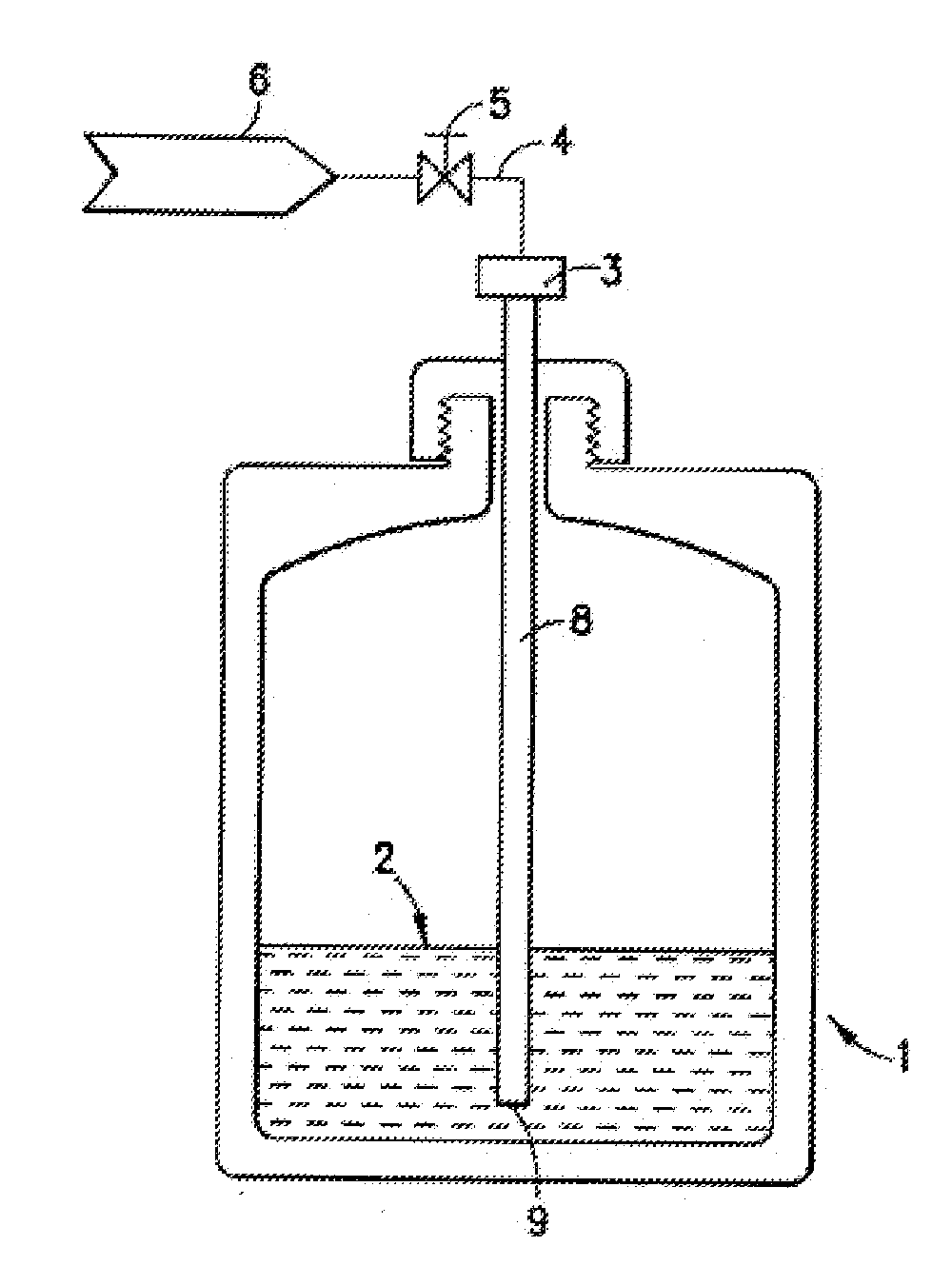

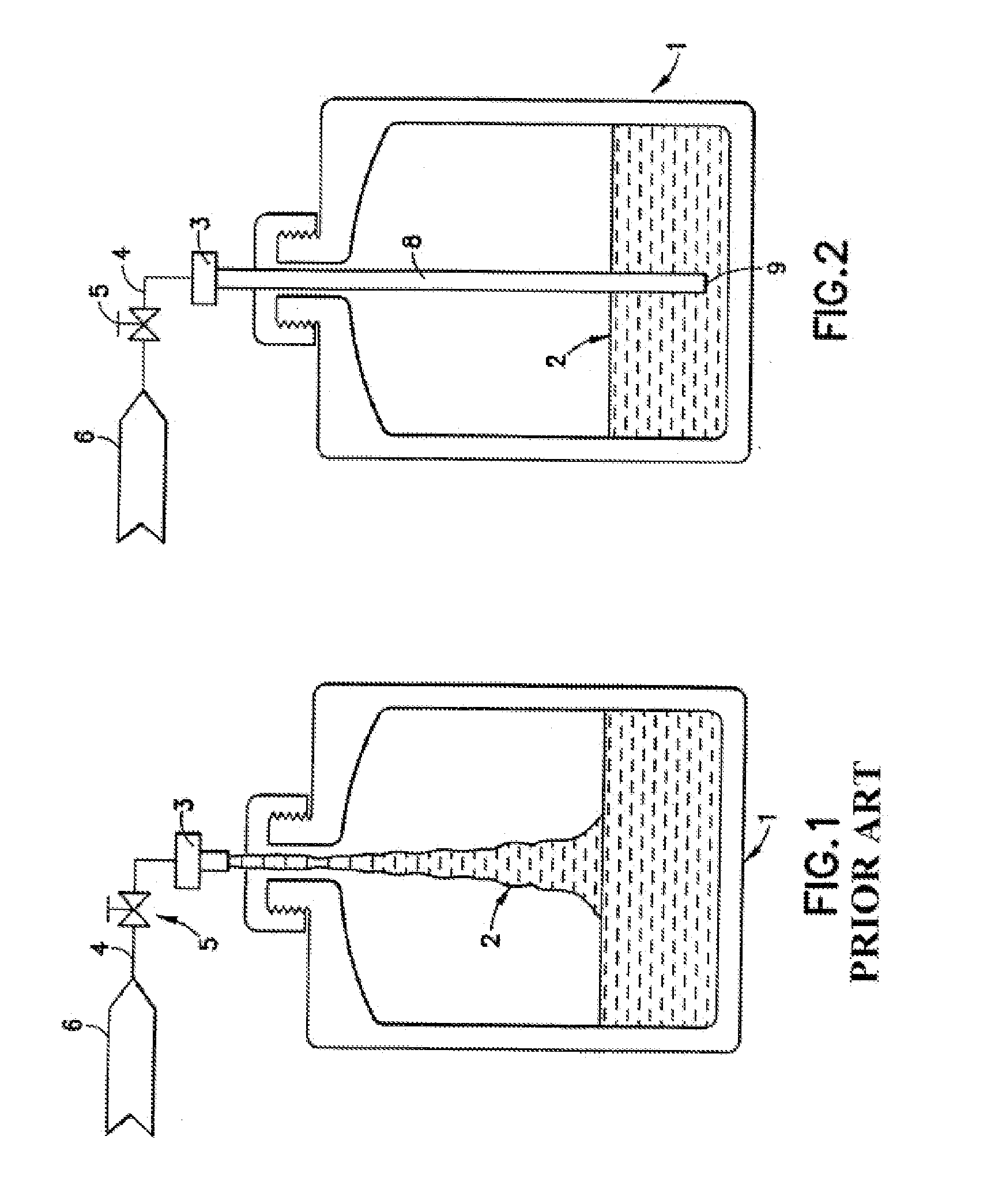

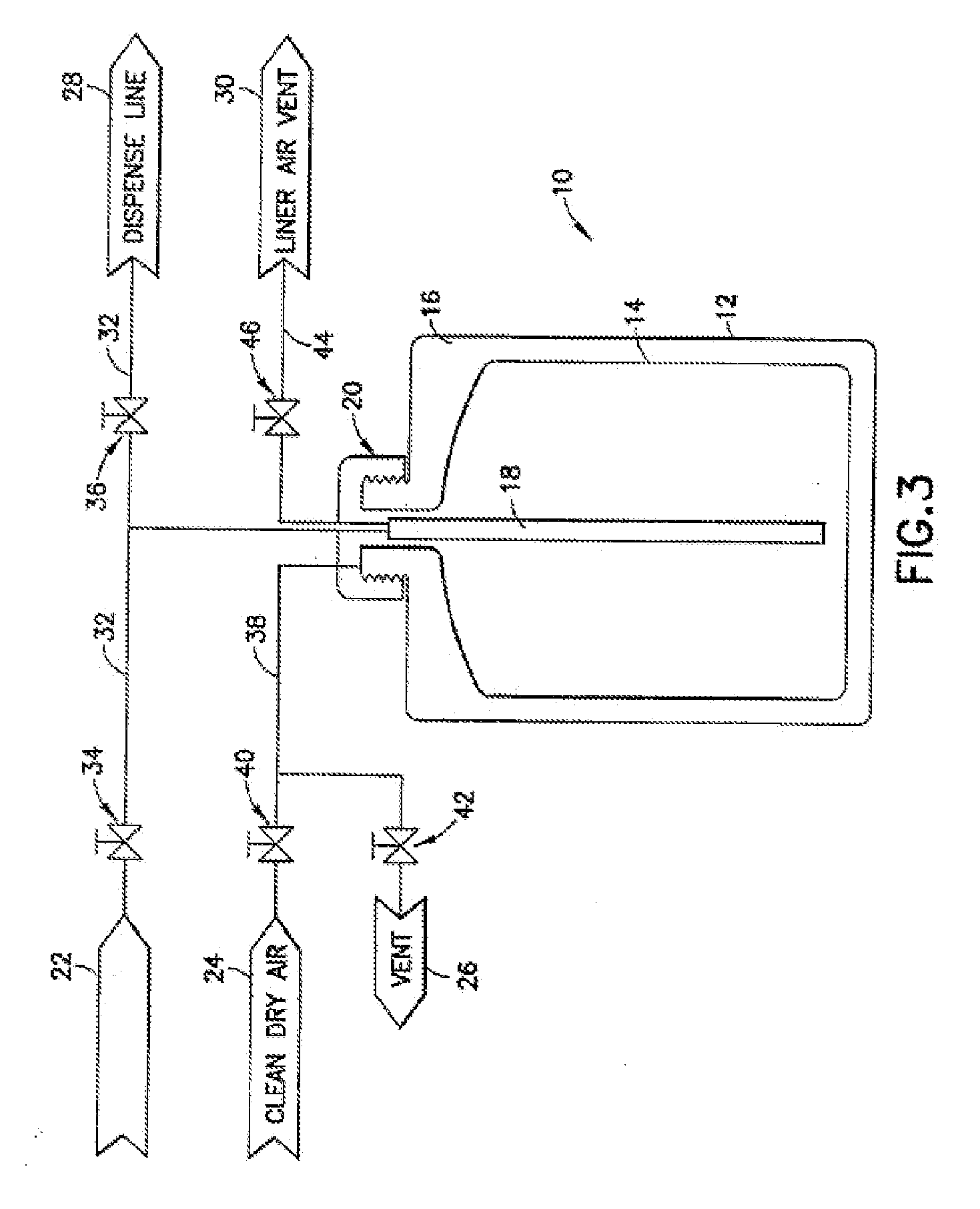

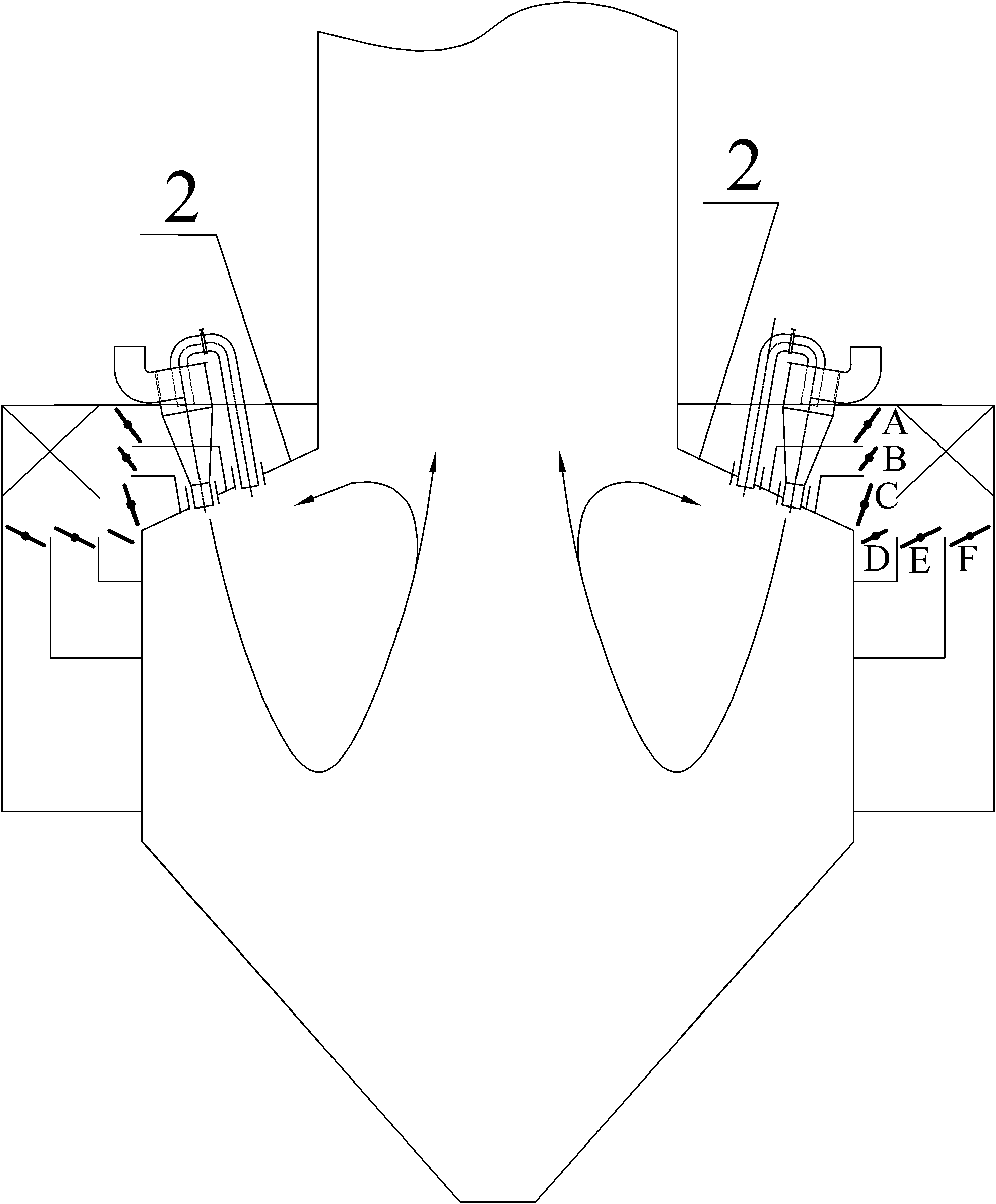

Apparatus and method for minimizing the generation of particles in ultrapure liquids

InactiveUS20070113923A1Quantity minimizationIncrease particle concentrationSpraying apparatusLiquid transferring devicesAir liquid interfaceEngineering

A system and method of reducing particle generation in packaging containers used to transport ultra pure liquids. Particle generation in the containers is reduced by reducing the air-liquid interface present during filling, transport, and dispensing of the liquid.

Owner:KELLY WAYNE +1

W flame boiler for avoiding clinkering on water-cooled walls of wing walls and sidewalls by four-corner ventilation

ActiveCN101943400ASolve the problem of serious slaggingPrevent slaggingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelHearthCoal

The invention discloses a W flame boiler for avoiding clinkering on water-cooled walls of wing walls and sidewalls by four-corner ventilation and relates to the W flame boiler, solving the problem of severe clinkering on the wing walls and the sidewalls commonly existing in the current W flame boiler. The technical scheme is as follows: boiler arches close to the wing walls on the four corners of the W flame boiler are respectively provided with a group of nozzles, and each group consists of a far wing wall dense coal powder flow nozzle, a far wing wall thin coal powder flow nozzle, an oil secondary air nozzle, a first anti-clinkering air nozzle and a second anti-clinkering air nozzle; the far wing wall dense coal powder flow nozzle, the far wing wall thin coal powder flow nozzle, the first anti-clinkering air nozzle and the second anti-clinkering air nozzle are arranged on the boiler arches in a rectangular outline, the oil secondary air nozzle is arranged on the outside of the rectangular outline and is far from a hearth, the first anti-clinkering air nozzle and the second anti-clinkering air nozzle are arranged at one side close to the wing walls and the sidewalls, and the far wing wall dense coal powder flow nozzle is far from the hearth center. The W flame boiler can effectively reduce coal powder and ash particles which are impacted on the water-cooled walls of the wing walls and the sidewalls, thus avoiding clinkering on the wing walls and the sidewalls.

Owner:HARBIN INST OF TECH

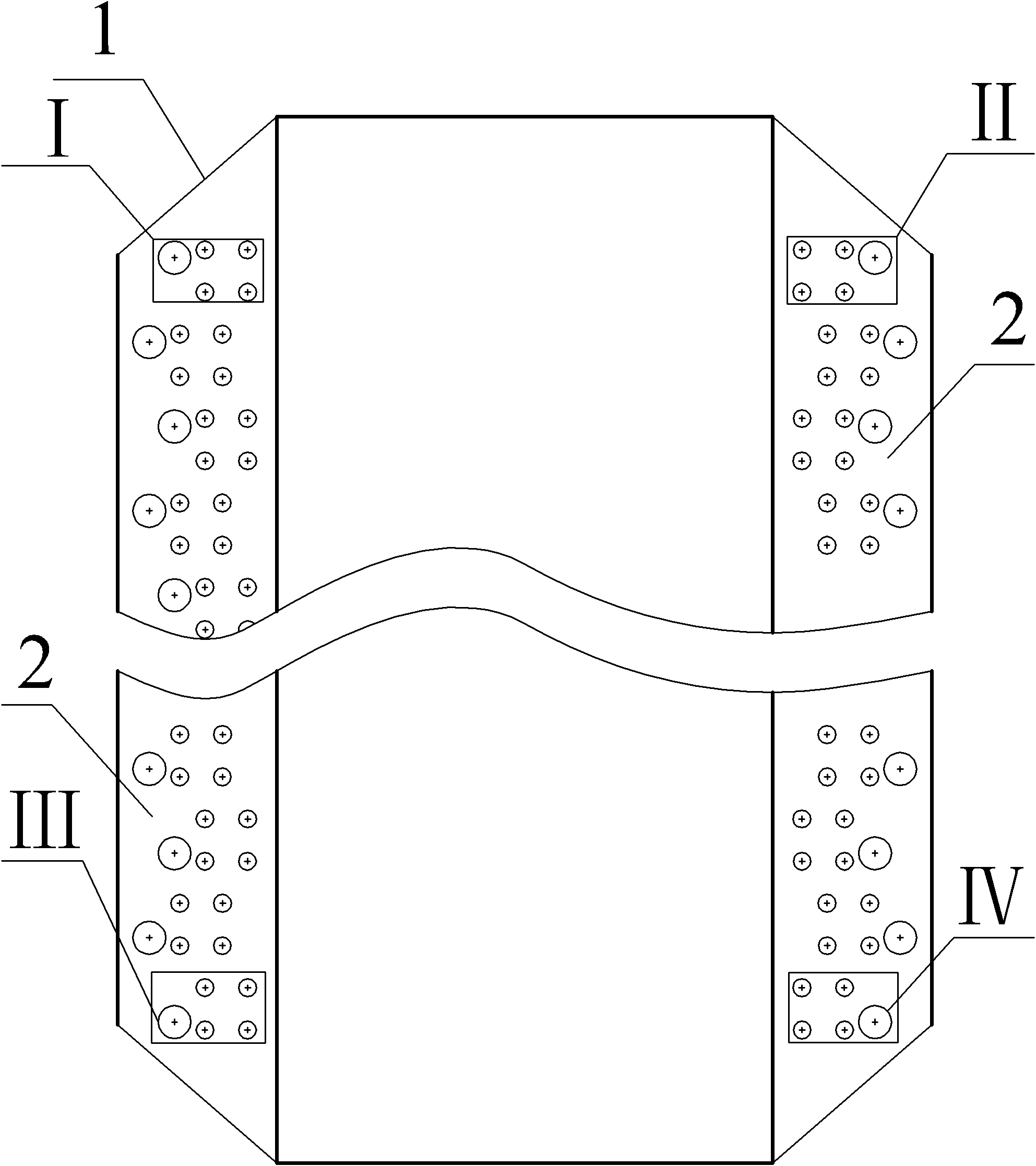

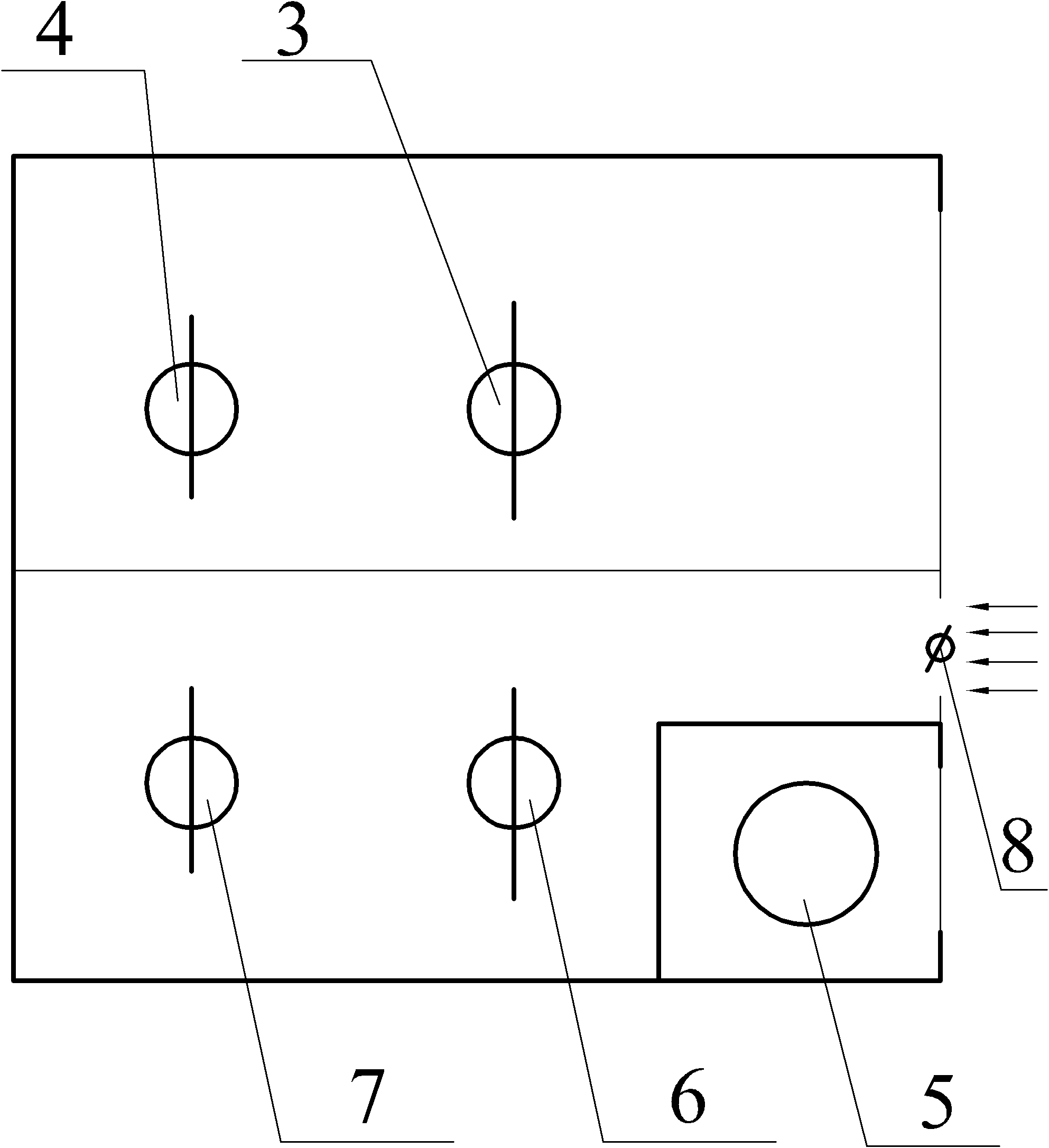

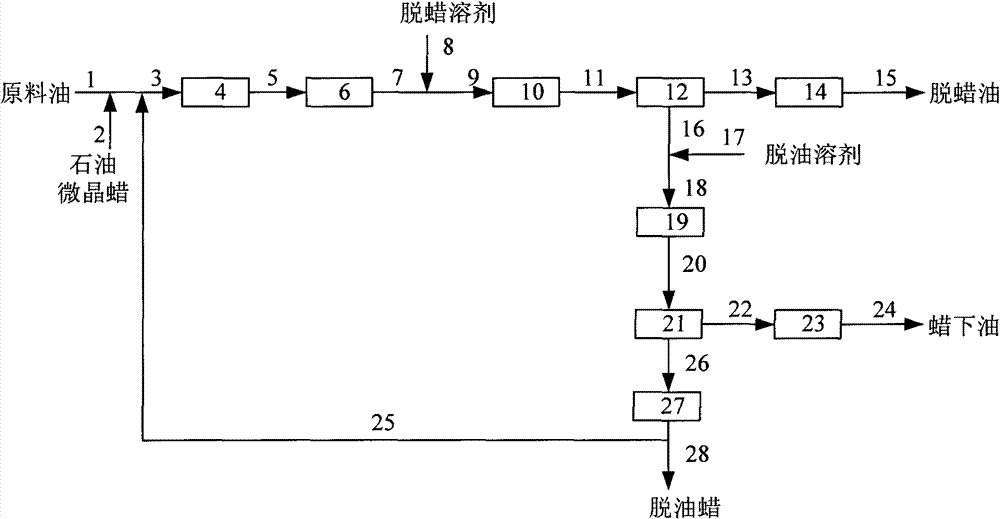

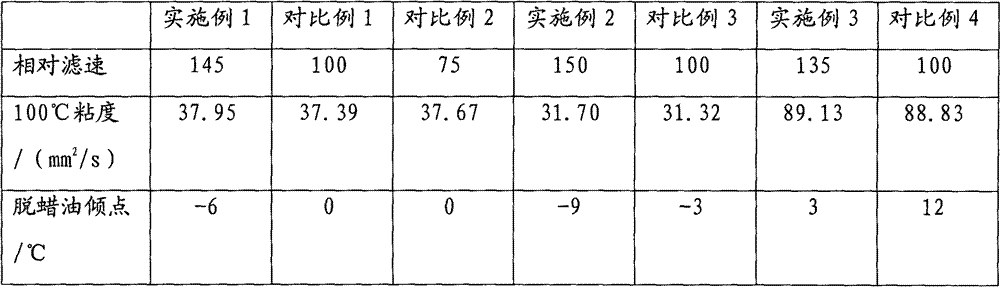

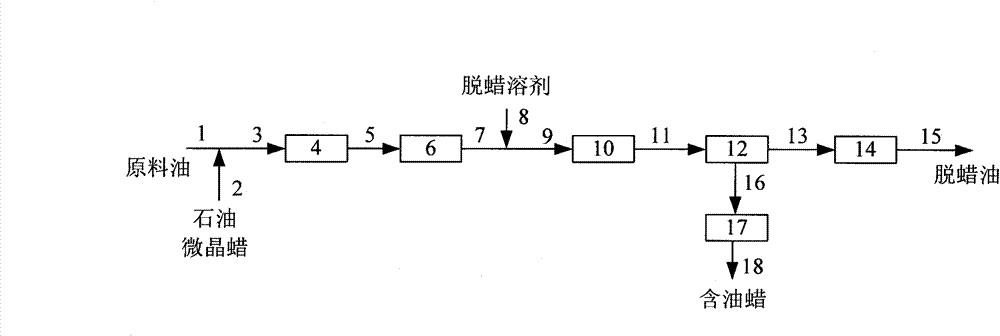

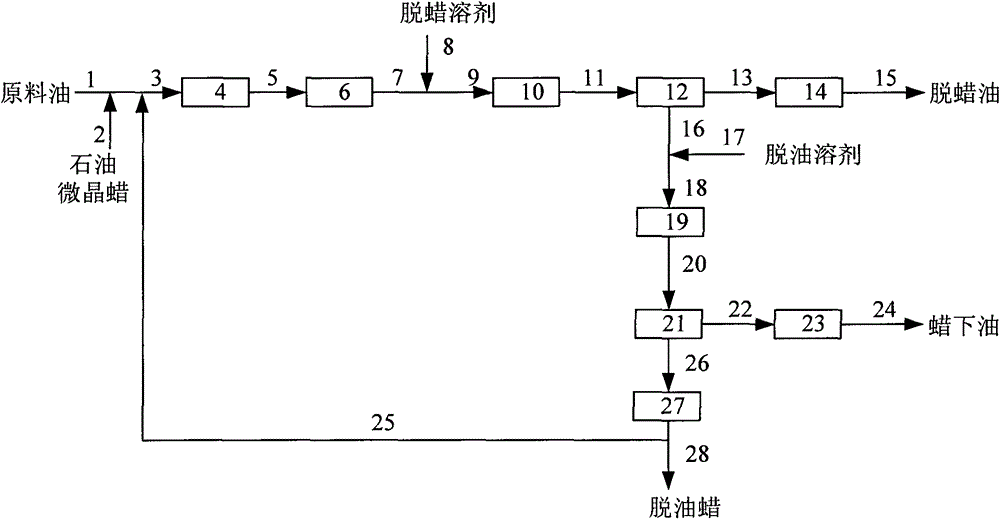

Solvent dewaxing method of low-wax content heavy hydrocarbon oil

ActiveCN102952572AIncrease the frequency of warm washingReduce dewaxing temperature differenceTreatment with plural serial refining stagesMineral wax recovery/refiningSolventChemistry

The invention relates to a solvent dewaxing method of low-wax content heavy hydrocarbon oil. The solvent dewaxing method comprises the following steps of mixing one or more raw material oil, petroleum microcrystalline wax and dewaxing solvents, cooling to a filtration temperature, filtering to obtain a dewaxed filtrate and dewaxed cerate, and removing the solvents in the dewaxed filtrate to obtain dewaxed oil, mixing the dewaxed cerate and a deoiling solvent, heating to a filtration temperature, and filtering to obtain a deoiled filtrate and deoiled cerate, wherein a petroleum microcrystalline wax droplet melting point is in a range of 67 to 92 DEG C and a mass ratio of the petroleum microcrystalline wax to the one or more raw material oil is in a range of (0.01: 1) to (0.25: 1). Compared with the conventional solvent dewaxing technology, the solvent dewaxing method provided by the invention can effectively remove wax in low-wax content heavy hydrocarbon oil, reduce a dewaxing temperature difference and improve a filtration speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

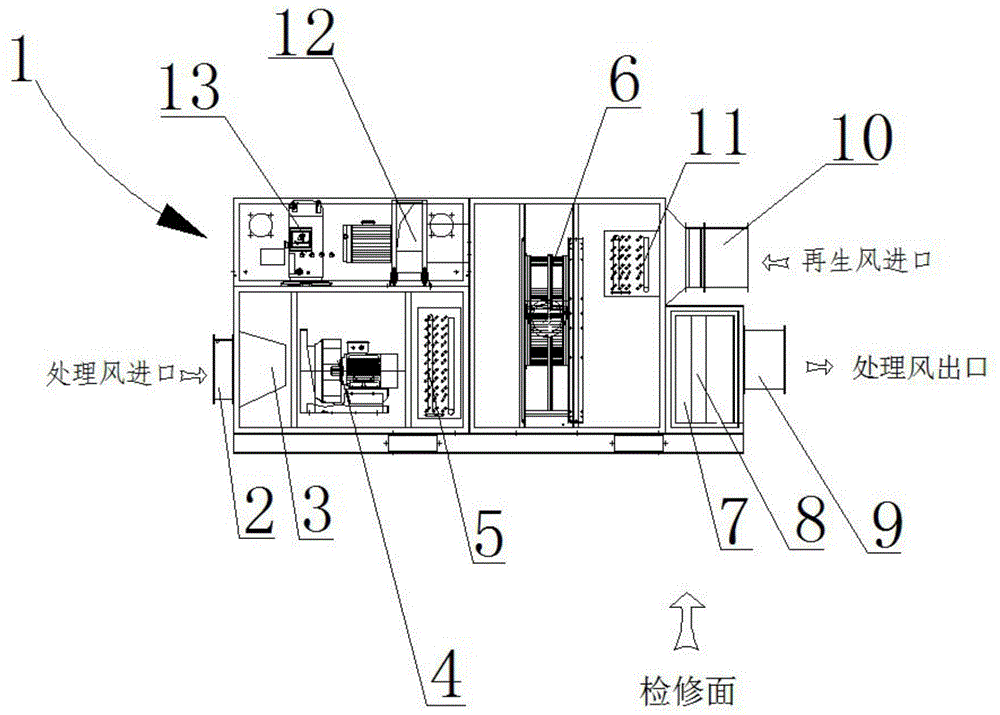

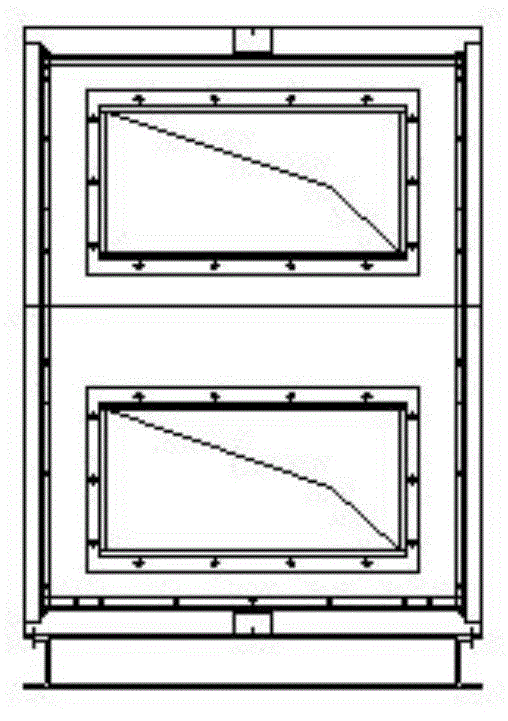

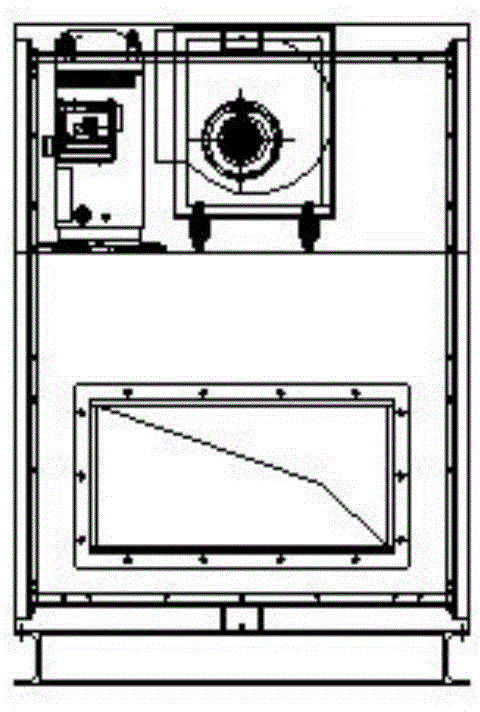

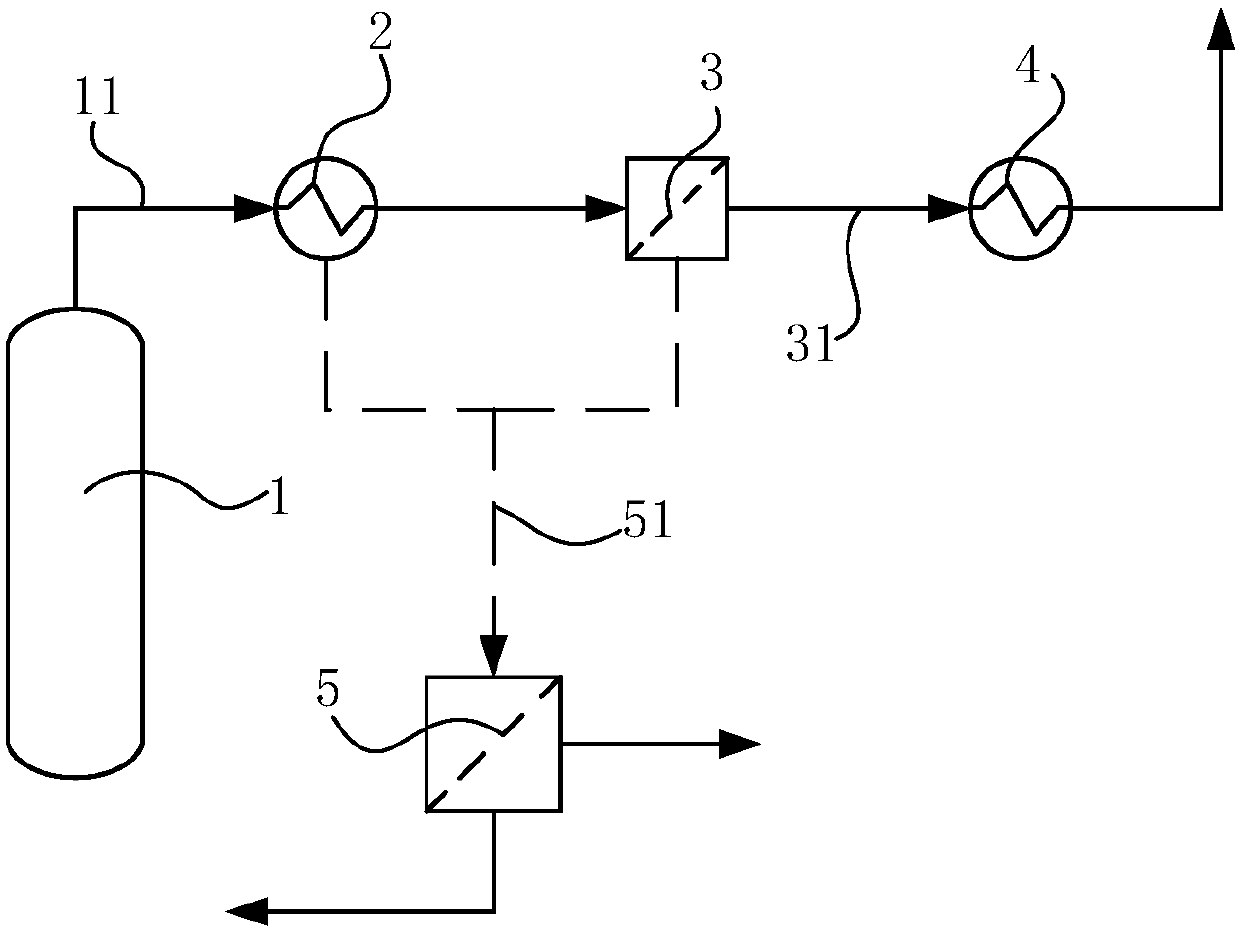

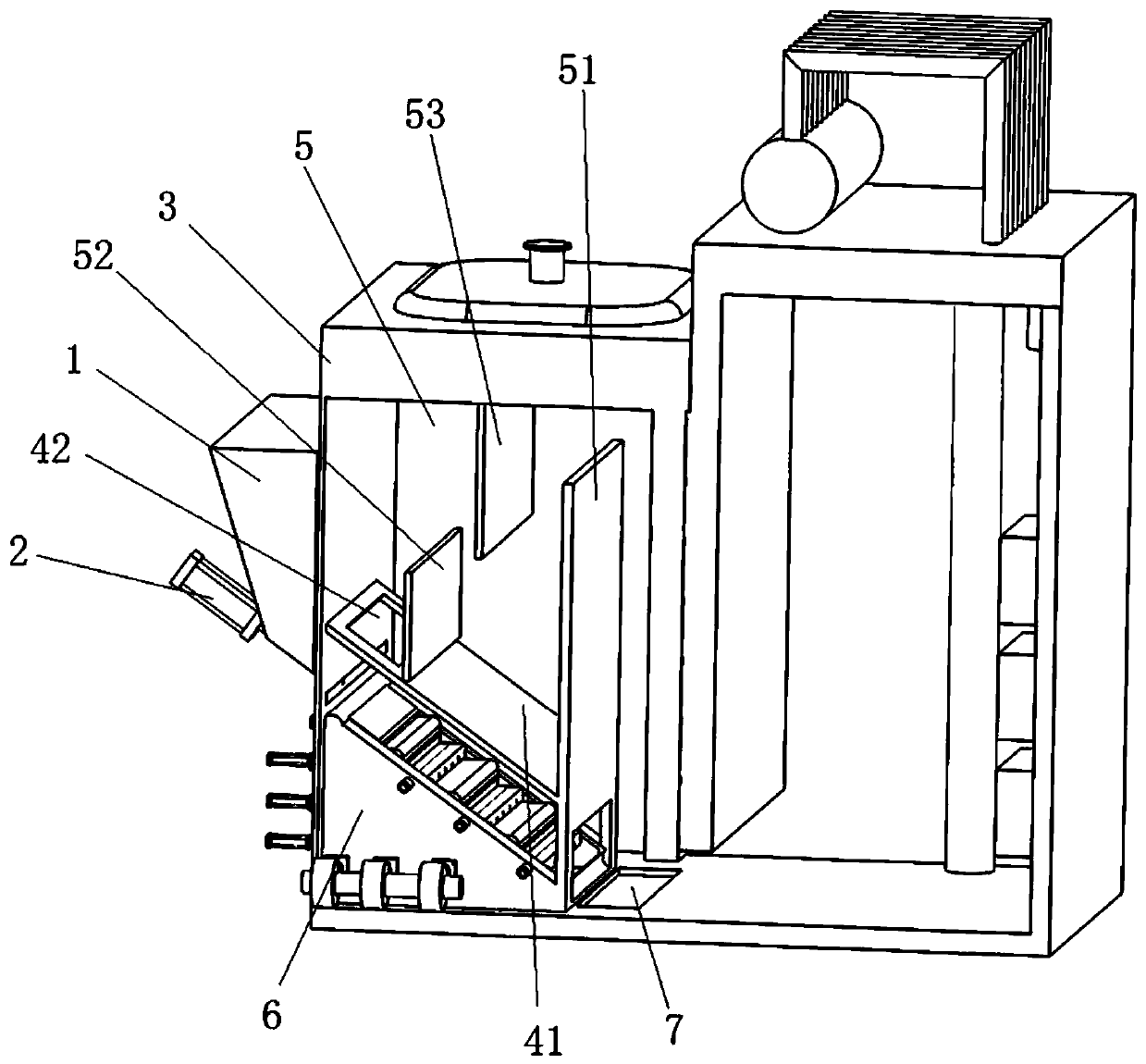

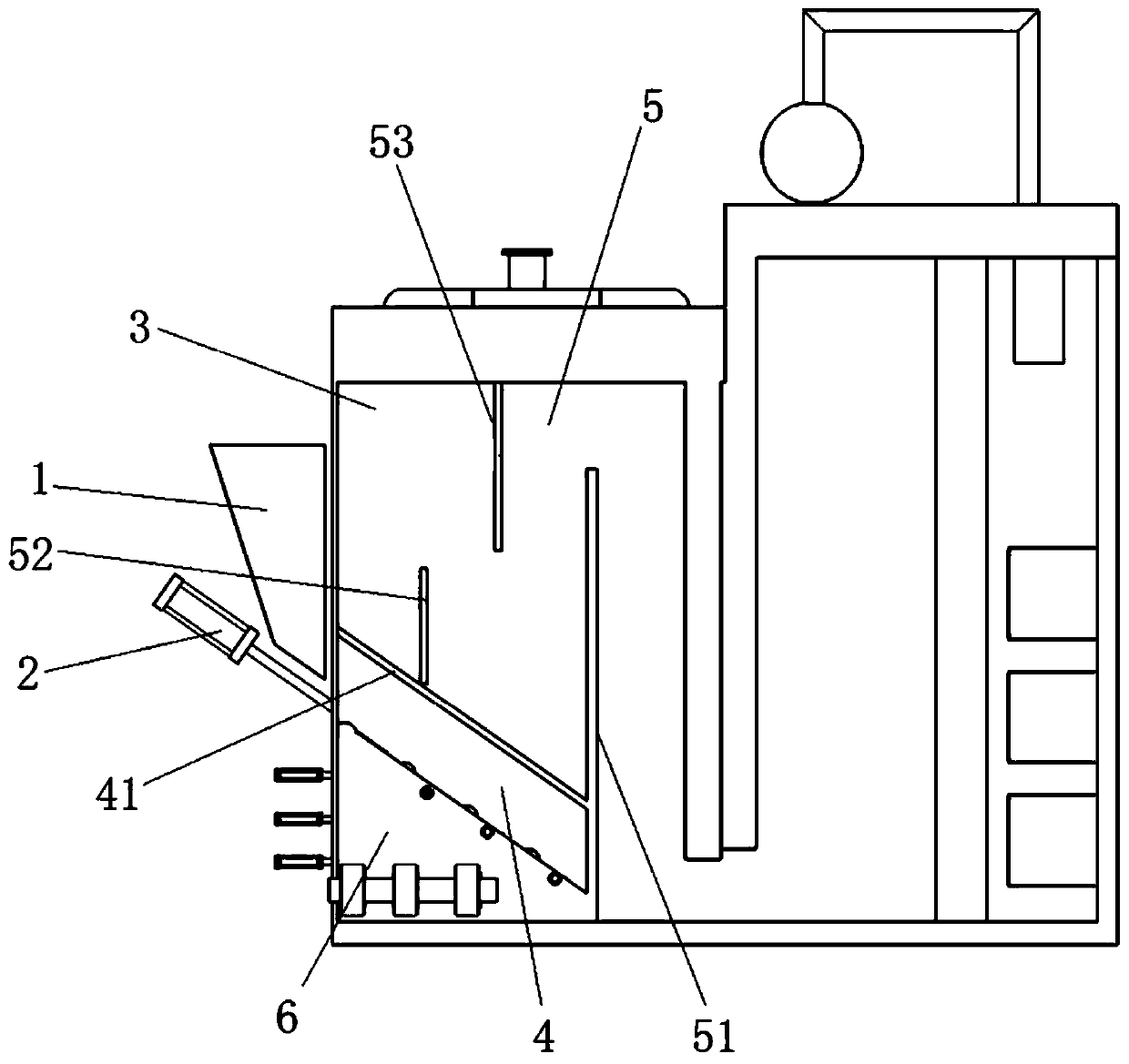

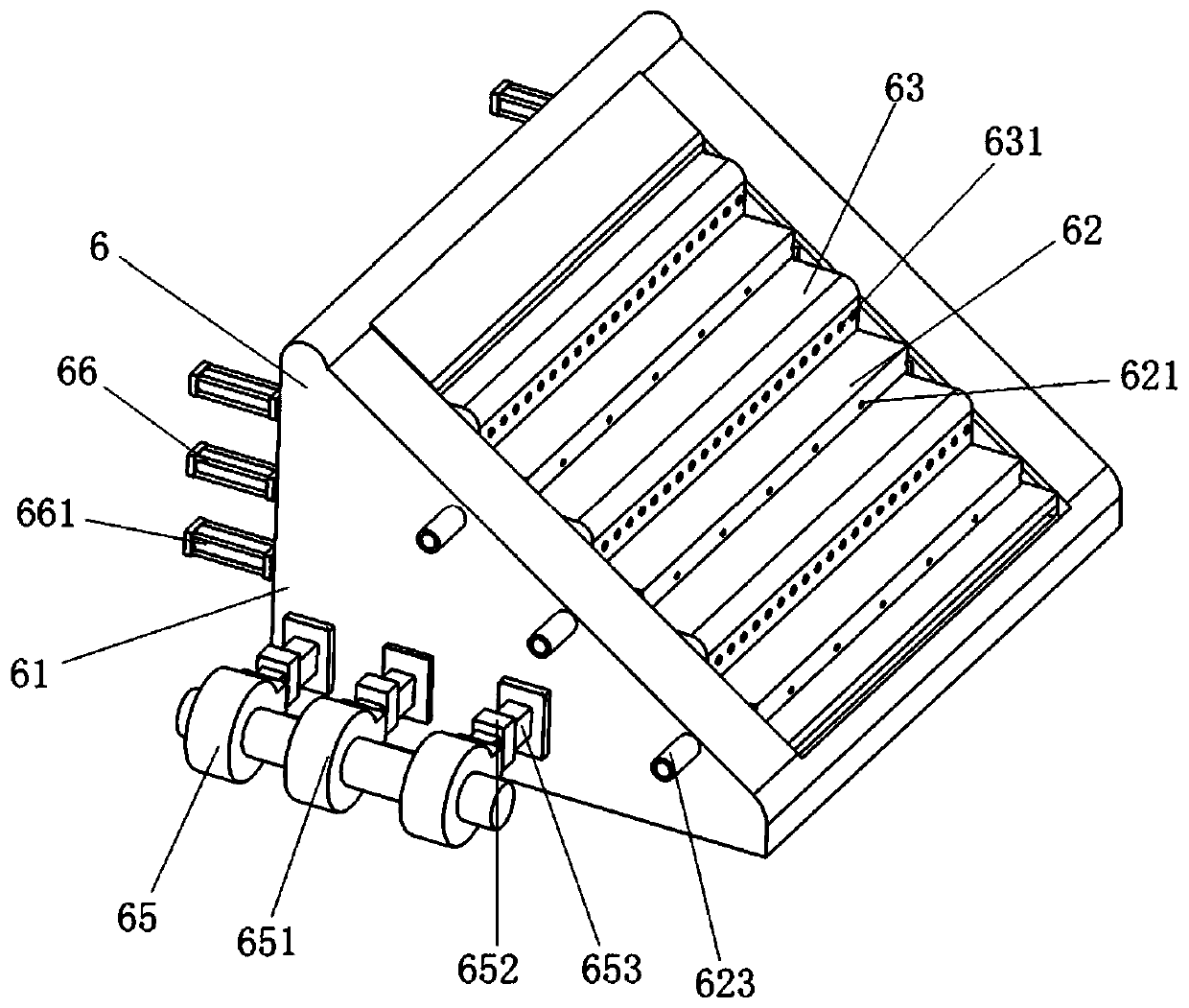

Fresh air purifying and dehumidifying all-in-one machine

InactiveCN104374017AReduce pollutionReduce concentrationMechanical apparatusLighting and heating apparatusFresh airMicroparticle

The invention discloses a fresh air purifying and dehumidifying all-in-one machine which comprises a machine body (1). The machine body comprises a processing air inlet and a processing air outlet, wherein a plate type primary filter (2) and a pocket type medium efficiency filter (3) are arranged at the processing air inlet in sequence, the outlet end of the pocket type medium efficiency filter is connected with an air feeder (4), a refrigerating evaporator (5) and a silica gel adsorption rotating wheel (6), and a high-efficiency filter (7), an active carbon adsorption filter (8) and an air valve (9) are arranged at the processing air outlet in sequence. The machine body is further provided with a regenerated air inlet which is provided with an air valve (10), a heat recycling condenser (11), a regeneration heating fan (12) and a compressor (13) in sequence. The fresh air purifying and dehumidifying all-in-one machine has the advantages that the air pollution degree in a room can be lowered, the PM2.5 particle concentration can be lowered, and the air with microparticles, second-hand smoking, peculiar smells and the like can be purified. Meanwhile, the humidity in the room can be controlled, mould and the musty smell can be prevented from being generated in the room, and the comfortable humidity for human bodies can be ensured.

Owner:钹特环保科技(上海)有限公司

Recovery system and method for desulfurizing agent in desulfurized gas of catalytic-cracking regeneration waste gas

ActiveCN107837681ALower dew pointReduce water vapor contentGas treatmentDispersed particle separationWater vaporProduct gas

The invention relates to a recovery system and method for a desulfurizing agent in a desulfurized gas of a catalytic-cracking regeneration waste gas. The recovery system comprises a desulfurizing tower, a condensing heat exchanger, a mechanical separation purifier, a heating heat exchanger and a filter, wherein a gas outlet of the desulfurizing tower is communicated with a gas inlet of the mechanical separation purifier through a first pipeline; the condensing heat exchanger is mounted in the first pipeline; the heating heat exchanger is mounted in a gas exhaust pipeline of the mechanical separation purifier; the condensing heat exchanger and the mechanical separation purifier are communicated with the filter respectively through second pipelines. The recovery system can be used for effectively decreasing the dew point of an outlet gas from the desulfurizing tower, is used for decreasing water vapor content and the particle concentrations of entrained desulfurizing agent and catalyst in the outlet gas, can be used for recovering most of the desulfurizing agent, and is used for decreasing the discharge loss of the desulfurizing agent, decreasing a running cost and meanwhile reducingenvironment pollution; through arranging the heating heat exchanger, an exhausted gas can be prevented from entering an environment of which temperature is lower than the temperature of the gas so that a liquid drop can be still immediately condensed and the formation of a rime fog is prevented.

Owner:BEIJING CREDITCONGRUITY ENERGY TECH CO LTD

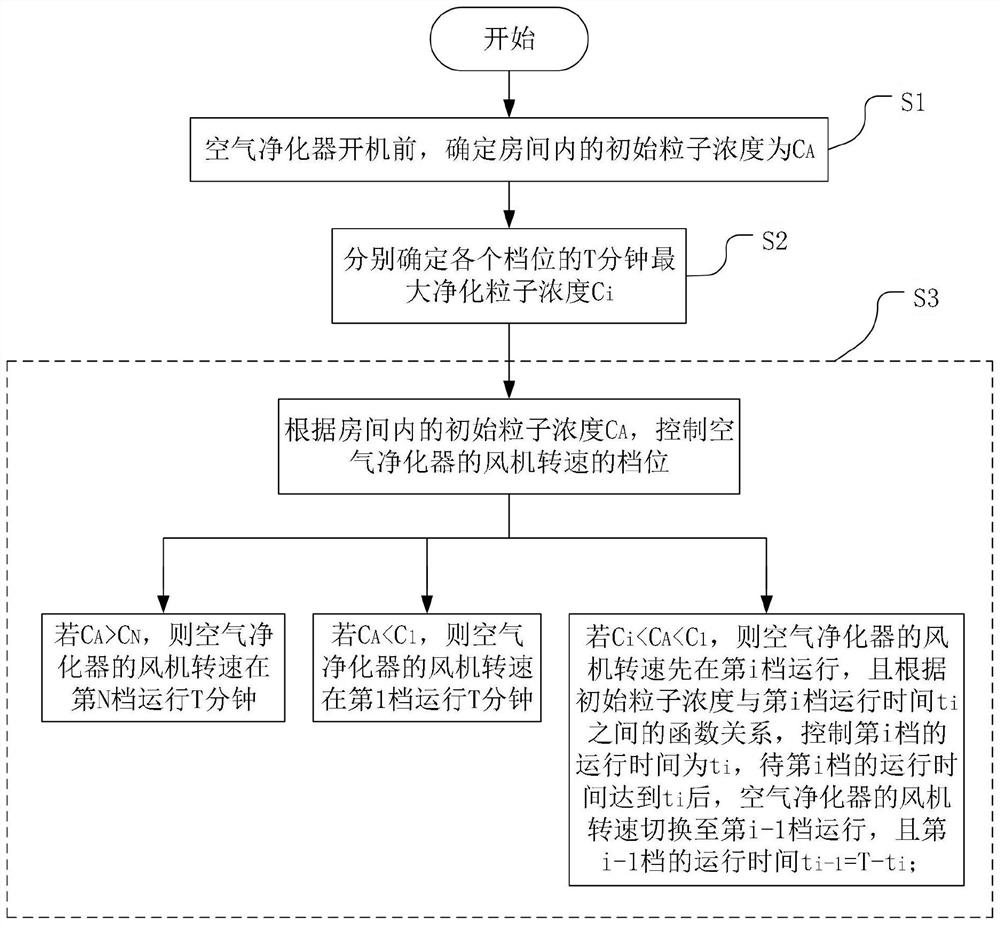

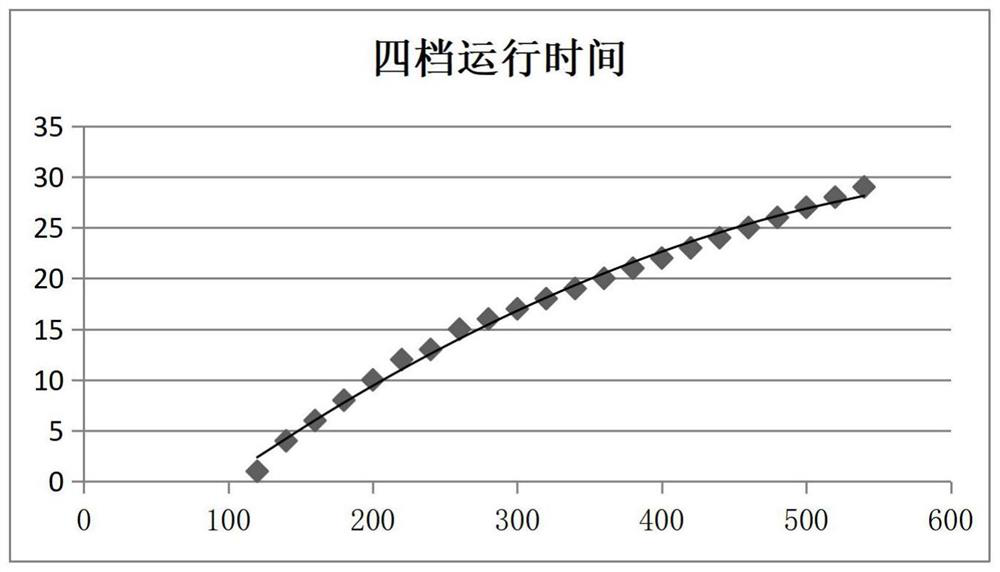

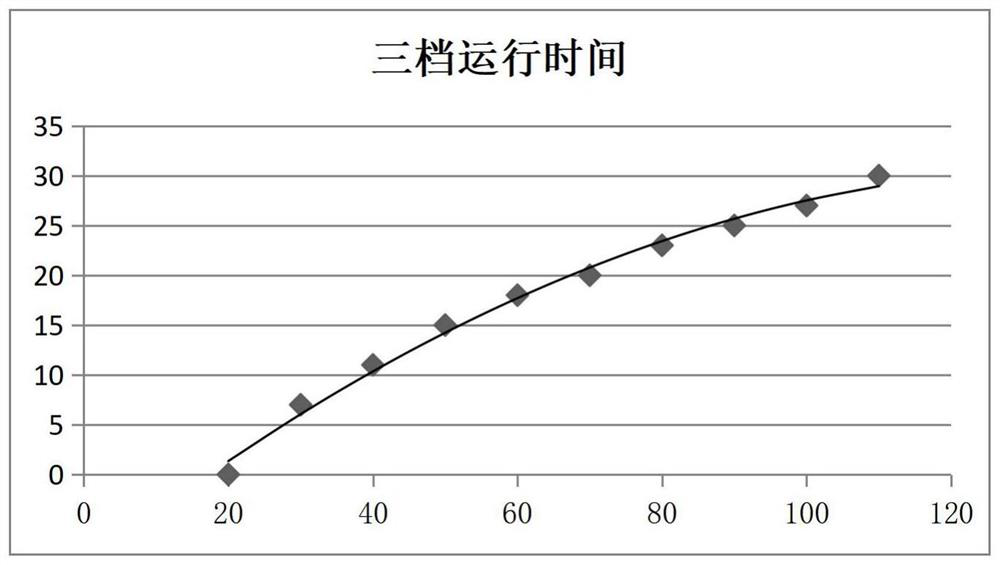

Rotating speed control method for air purifier

ActiveCN114440385AReduce particle concentrationParticle concentration has no effectMechanical apparatusLighting and heating apparatusAir purifiersEngineering

The invention discloses a rotating speed control method for an air purifier, which comprises the following steps: before the air purifier is started, determining the initial particle concentration CA in a room; the T-minute maximum purification particle concentration Ci of each gear is determined; according to the initial particle concentration CA in the room, the gear of the rotating speed of a fan of the air purifier is controlled; if CAgt; if CN, the air purifier operates at the Nth gear for T minutes; if so; c1, the air purifier runs for T minutes at the first gear; if Cigt; c < gt >; if the initial particle concentration CA is equal to Ci-1, the air purifier firstly runs for ti minutes at the ith gear according to the function relation between the initial particle concentration CA and the running time ti of the ith gear, and after the running time of the ith gear reaches ti, the rotating speed of a fan of the air purifier is switched to the i-1 gear to run for T-ti minutes. Based on the initial particle concentration, the gear and the operation time of the air purifier are controlled, so that it is guaranteed that the concentration of surrounding particles is rapidly reduced without influence on the air purifier, and the purification effect is better.

Owner:HEFEI GENERAL MACHINERY RES INST +1

Solvent dewaxing method of low-wax content heavy hydrocarbon oil

ActiveCN102952571AReduce particle concentrationReduce filtration performanceTreatment with plural serial refining stagesMineral wax recovery/refiningMicrocrystalline waxFiltration

The invention relates to a solvent dewaxing method of low-wax content heavy hydrocarbon oil. The solvent dewaxing method comprises the following steps of mixing one or more raw material oil, petroleum microcrystalline wax and dewaxing solvents, cooling to a filtration temperature, filtering to obtain a filtrate and cerate, and removing the solvents in the filtrate to obtain dewaxed oil, wherein a petroleum microcrystalline wax droplet melting point is in a range of 67 to 92 DEG C and a mass ratio of the petroleum microcrystalline wax to the one or more raw material oil is in a range of (0.01: 1) to (0.25: 1). The solvent dewaxing method provided by the invention can effectively remove wax in low-wax content heavy hydrocarbon oil, reduce a dewaxing temperature difference and improve a filtration speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermal desorption cyclone spraying dust settling system capable of automatically and quickly monitoring, regulating and controlling

InactiveCN113304899AReduce trafficReduce particle concentrationVortex flow apparatusUsing liquid separation agentSpray towerGas concentration

The invention discloses a thermal desorption cyclone spraying dust settling system capable of automatically and rapidly monitoring, regulating and controlling. The system comprises a spraying tower, a gas inlet pipe and a gas outlet pipe are respectively arranged in the spraying tower, and the end part of the gas inlet pipe is provided with a gas inlet regulating device for controlling waste gas flow; a spraying device is mounted at the top of the spraying tower; the spraying device comprises a spraying cavity fixedly mounted at the top of the spraying tower, the top of the spraying cavity is communicated with a water inlet pipe, the bottom of the spraying cavity is connected with a movable ring through a sealing bearing, the bottom of the movable ring is connected with an end cover through a sealing bearing, and the end cover is fixedly connected with the inner wall of the spraying tower; and a plurality of groups of spraying holes are formed in the end cover in a central symmetry manner. A tail gas concentration detection module transmits data to a controller, a program is set in the controller, when the tail gas concentration data value is too large and exceeds the set range, a PLC drives a servo motor and an air cylinder, the servo motor drives a gear to rotate, a movable plate rotates along with the servo motor, an outer through hole and an inner through hole are staggered, and the flow in the gas inlet pipe is reduced.

Owner:安徽省通源环境节能股份有限公司

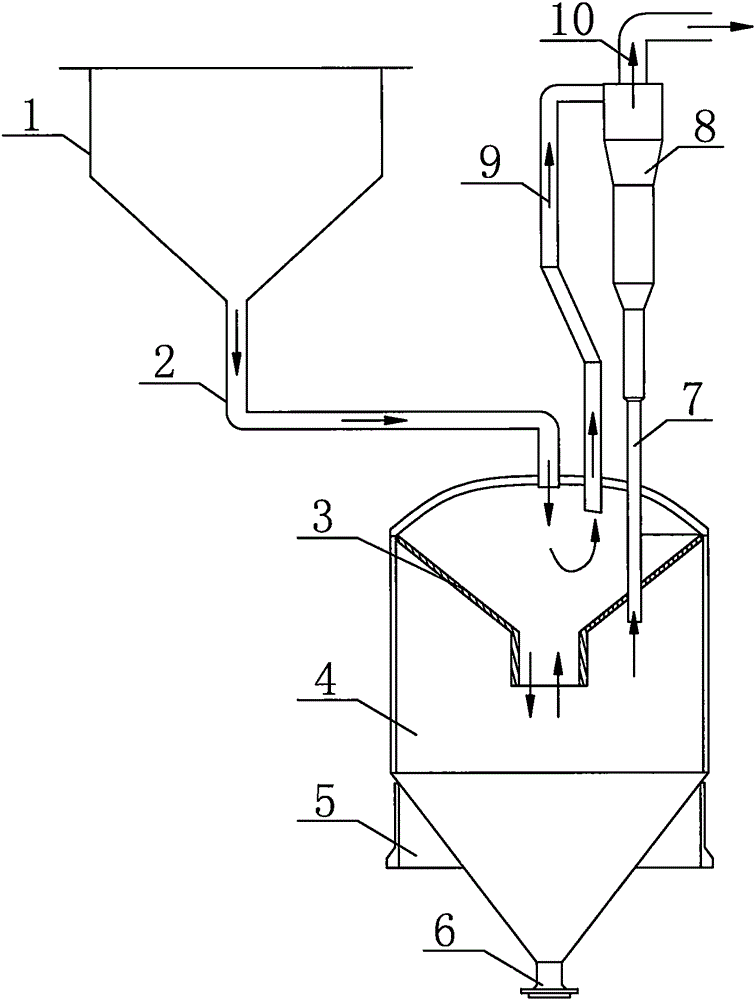

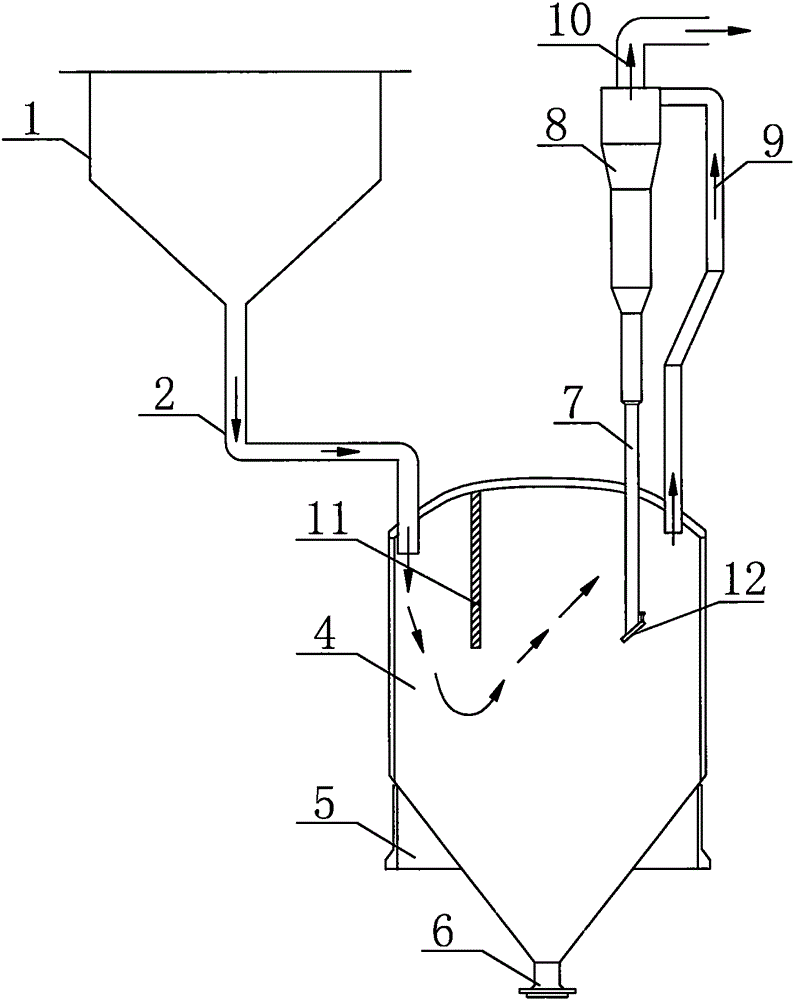

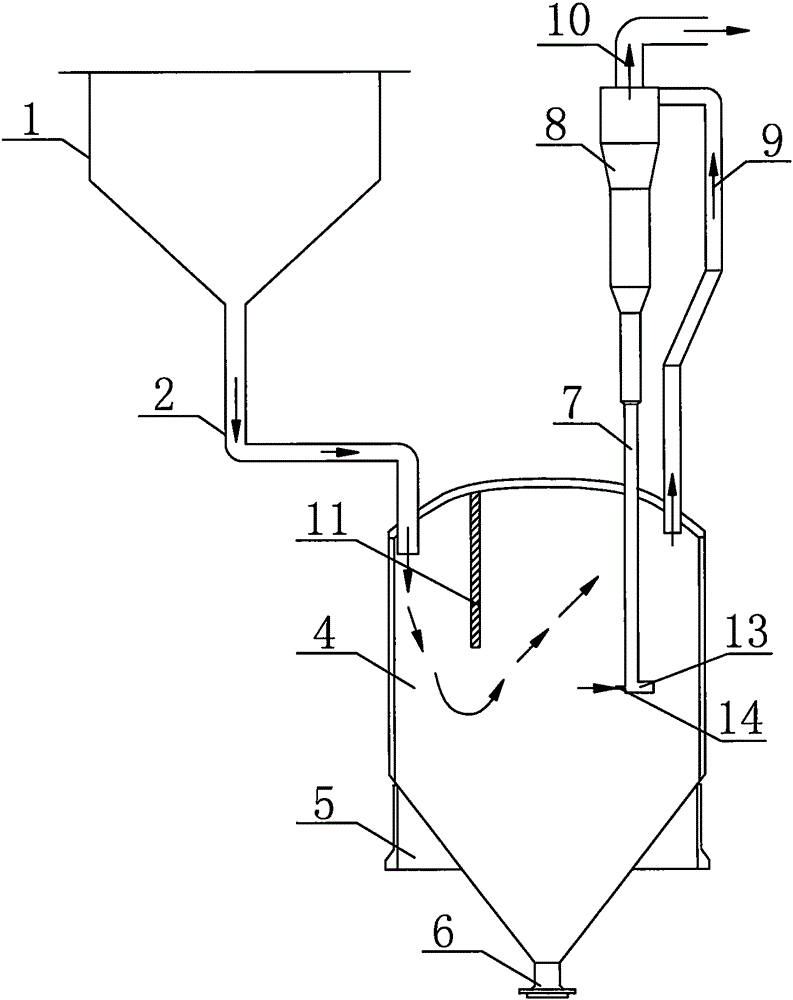

Dried type outside and inside dual circulation fluidized bed desulfurizing device and desulfurizing method thereof

InactiveCN100434146CSimple structureSmall footprintDispersed particle separationCycloneFluidized bed

The invention relates to a dry inner-outer dual cycle fluidized bed desulphurization device and a method. The device comprises a flue gas intake mounted at the bottom of the inner cycle fluidized bed reaction tower, a desulfurizer nozzle, a diector nozzle and an air nozzle mounted at the bottom of inner wall; a cyclone is mounted between passing conduit for connecting the flue gas outlet and the dust collector conduit, the solid outlet of the cyclone is connect to a separating tank, of which the outlet on the top is connected to the inlet of the dust collector via the transport conduit, the cleanout door at the bottom of the dust collector is connected to the ash cellar, and the clear gas outlet of the dust collector is connected to the chimney. The flue gas with SO2 enter from the bottom of the thionizer, at the same time, powdery desulfurizer, air and water are sprayed form the bottom of the thionizer respectively, and they moves upwards together in the thionizer, when the SO2 reacts with desulfurizer to deprive the SO2 in the flue gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

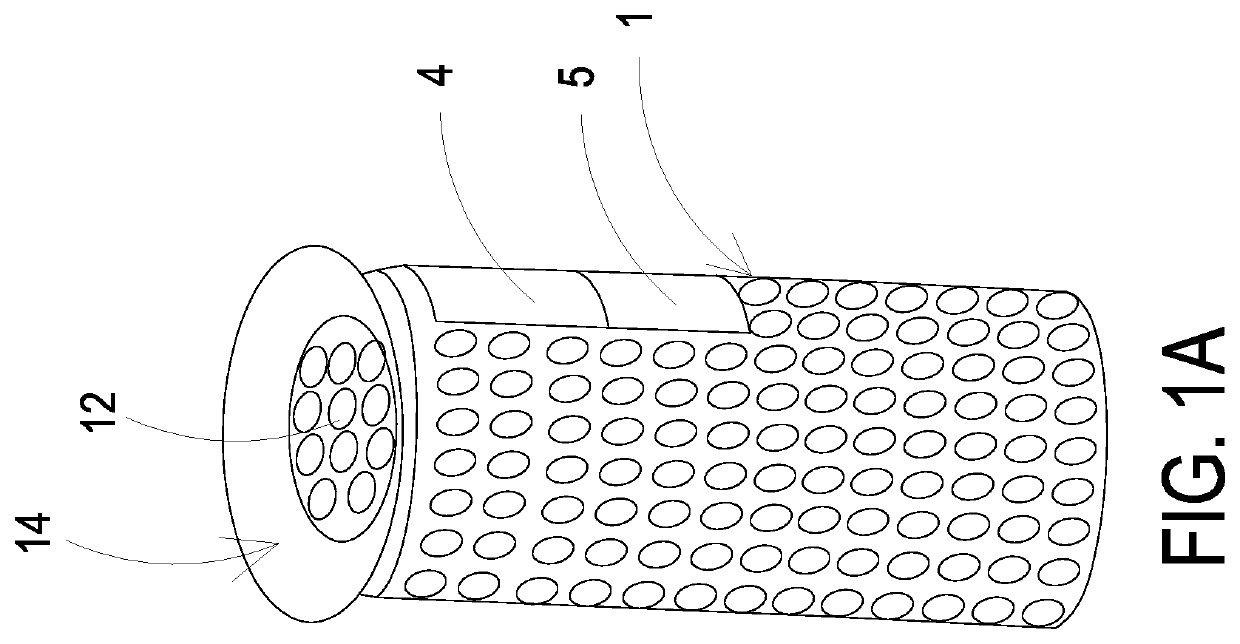

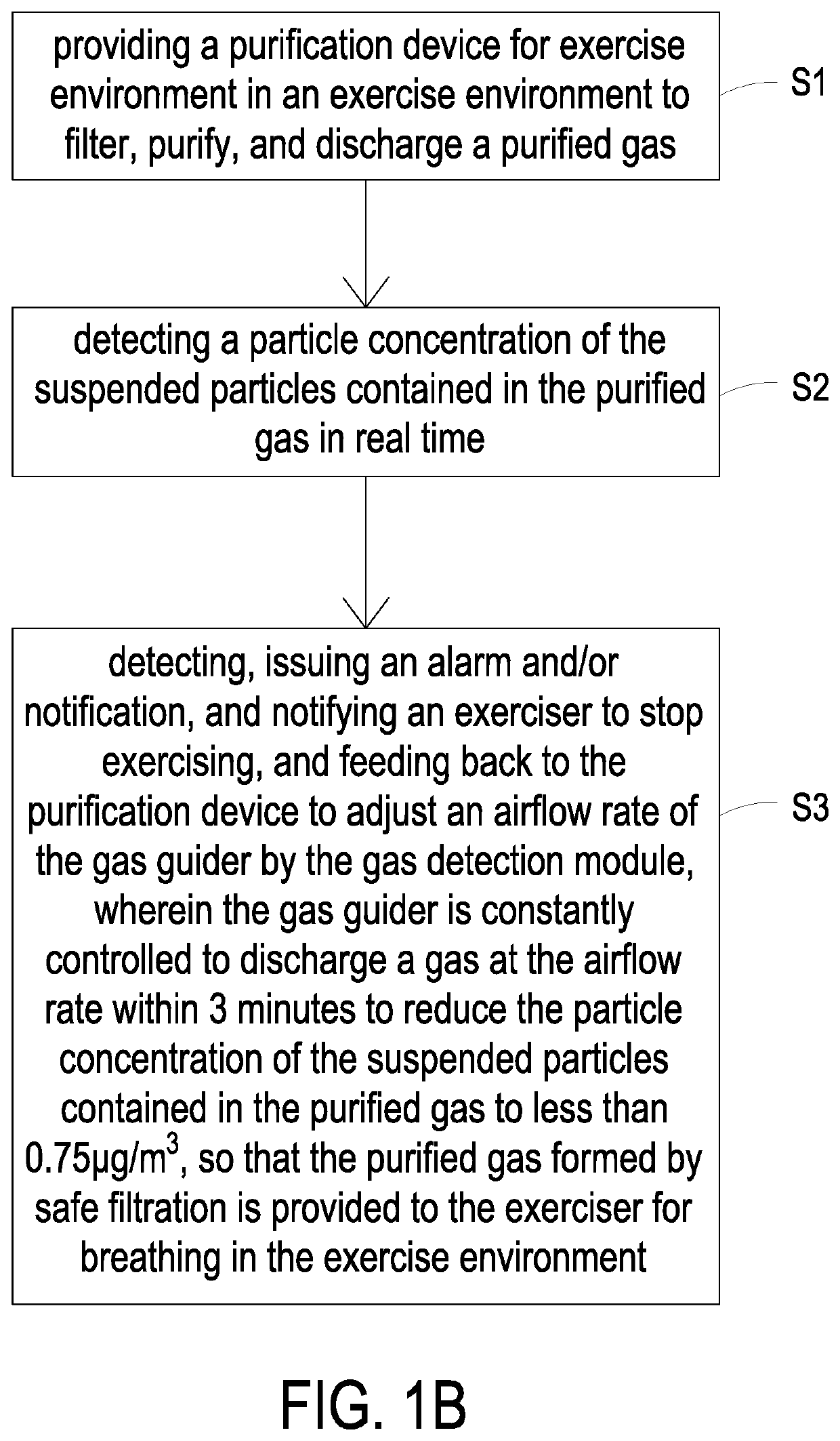

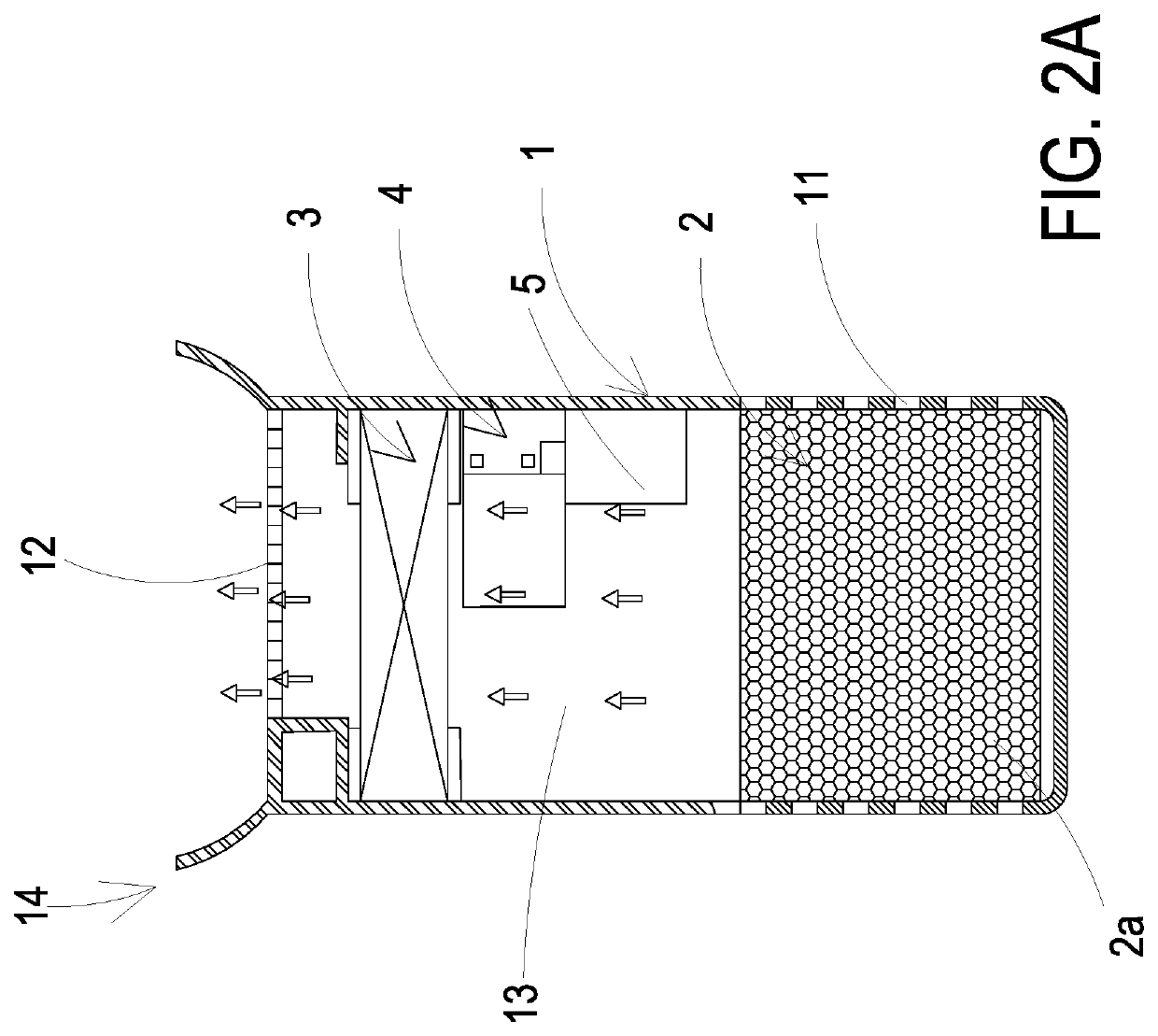

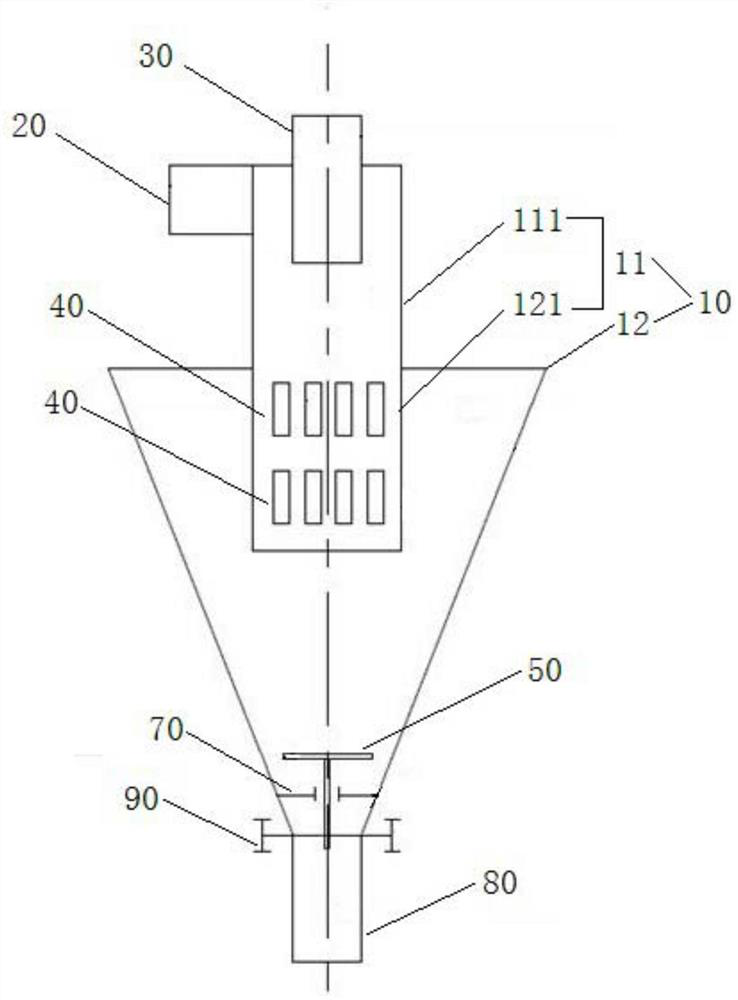

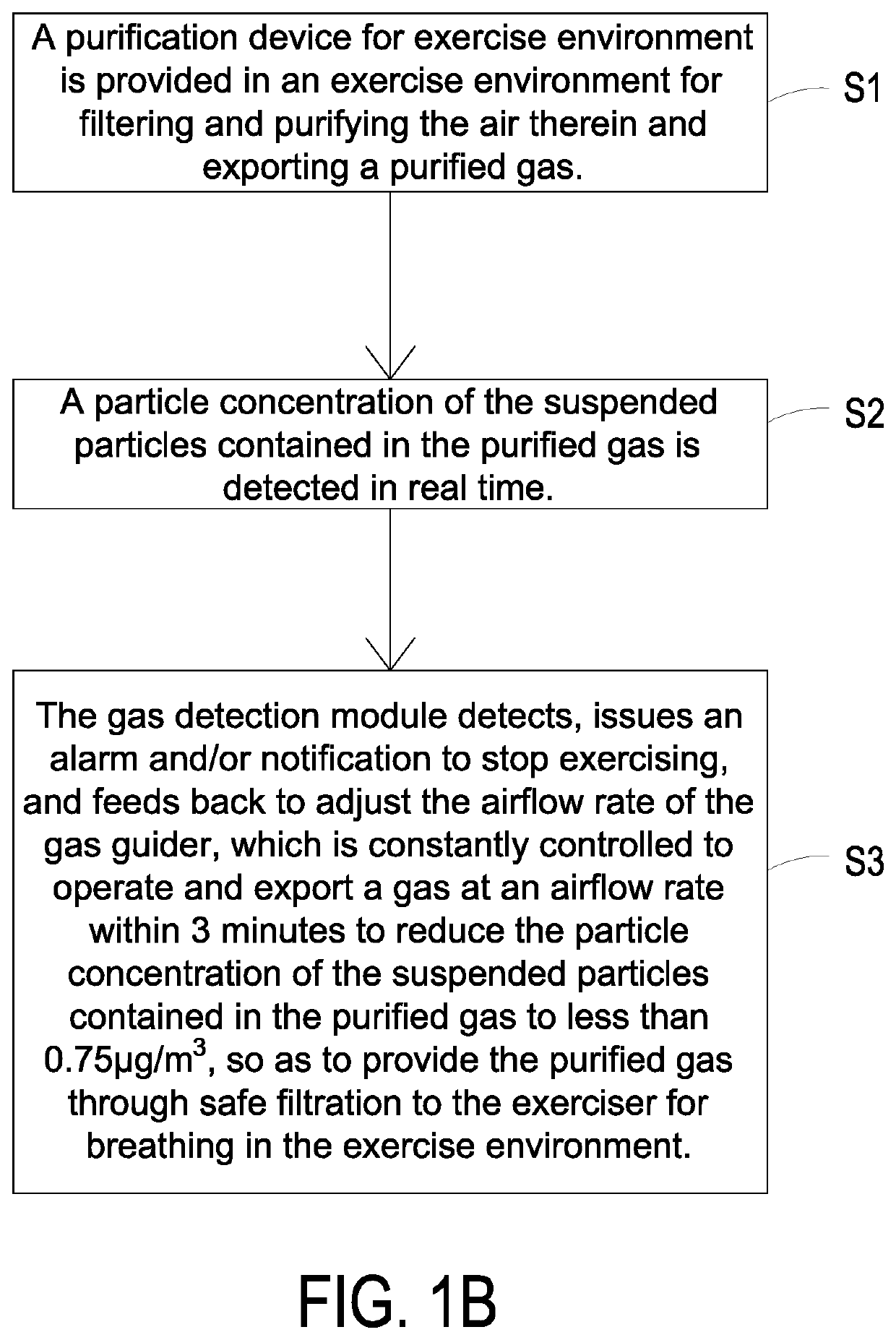

Gas purifying and processing method for exercise environment

PendingUS20220057092A1Improve air qualitySafely filtrated for the exerciserMechanical apparatusDispersed particle filtrationPhysicsProcess engineering

A gas purifying and processing method for exercise environment is provided and includes steps: (a) providing a purification device for exercise environment in an exercise environment, wherein the purification device for exercise environment includes a main body, a purification unit, a gas guider and a gas detection module; (b) detecting a particle concentration of the suspended particles contained in the purified gas in real time by the gas detection module; and (c) detecting, issuing an alarm and / or notification, and notifying an exerciser to stop exercising, and feeding back to the purification device to adjust an airflow rate of the gas guider by the gas detection module, wherein the gas guider discharge a gas at the airflow rate within 3 minutes to reduce the particle concentration of the suspended particles to less than 0.75 μg / m3, wherein the airflow rate is at least 800 ft3 / min, and the main body maintains a breathing distance ranged from 60 cm to 200 cm.

Owner:MICROJET TECH

Organic matter high temperature gasification low-oxygen fractional combustion method

ActiveCN110848737AReduce bring inAchieve staged combustionFuel supply regulationTravelling grateCombustion chamberData set

The invention discloses an organic matter high temperature gasification low-oxygen fractional combustion method. The organic matter high temperature gasification low-oxygen fractional combustion method specifically comprises the following steps that a pushing mechanism pushes fuel into a ladder reciprocating type fire grate; furnace starting is carried out; air is blown through an air blowing mechanism, and hot air after gasification enters a gasification chamber; the ladder reciprocating type fire grate carries out intermittent falling; a monitoring system a monitors the gasification chamber;the gasified hot air in the gasification chamber enters a high-temperature heat insulation low-oxygen combustion chamber, and high-temperature flue gas is discharged into a heat exchange system through a flue gas circulation channel to be subjected to heat exchange; a monitoring system b carries out monitoring; and a PLC forms a data set according to the monitoring information of the monitoring system a and the monitoring system b, the data set is compared with inner set data value, and whether the gas producing amount of the gasification chamber needs to be controlled or not is judged. Through real-time monitoring of temperature of different combustion segments, the opening degree of air adjusting valves of the air chambers can be controlled, precise air supply is achieved, the fire grate combustion efficiency is improved, bringing in of invalid air is reduced, and the hot losses are reduced.

Owner:河北约翰节能设备科技有限公司

Cyclone separator and solid-gas separation system

ActiveCN113457859AHigh Tangential and Radial VelocitiesImprove efficiencyReversed direction vortexHuman health protectionGas separationEngineering

The invention relates to a cyclone separator and a solid-gas separation system. The cyclone separator comprises a separator body, an air inlet pipe and an exhaust pipe, wherein the separator body comprises a straight cylinder part and a conical cylinder part which are connected, the diameter of the straight cylinder part is smaller than that of the large end of the conical cylinder part, one end of the straight cylinder part extends into the conical cylinder part, the exhaust pipe is arranged at the upper end of the straight cylinder part, the air inlet pipe is tangentially connected to the upper part of the straight cylinder part and located above the air inlet end of the exhaust pipe in the axial direction of the separator body, and the part, located in the conical cylinder part, of the straight cylinder part is provided with a flow guiding grid structure. The cyclone separator has relatively high gas-solid separation efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

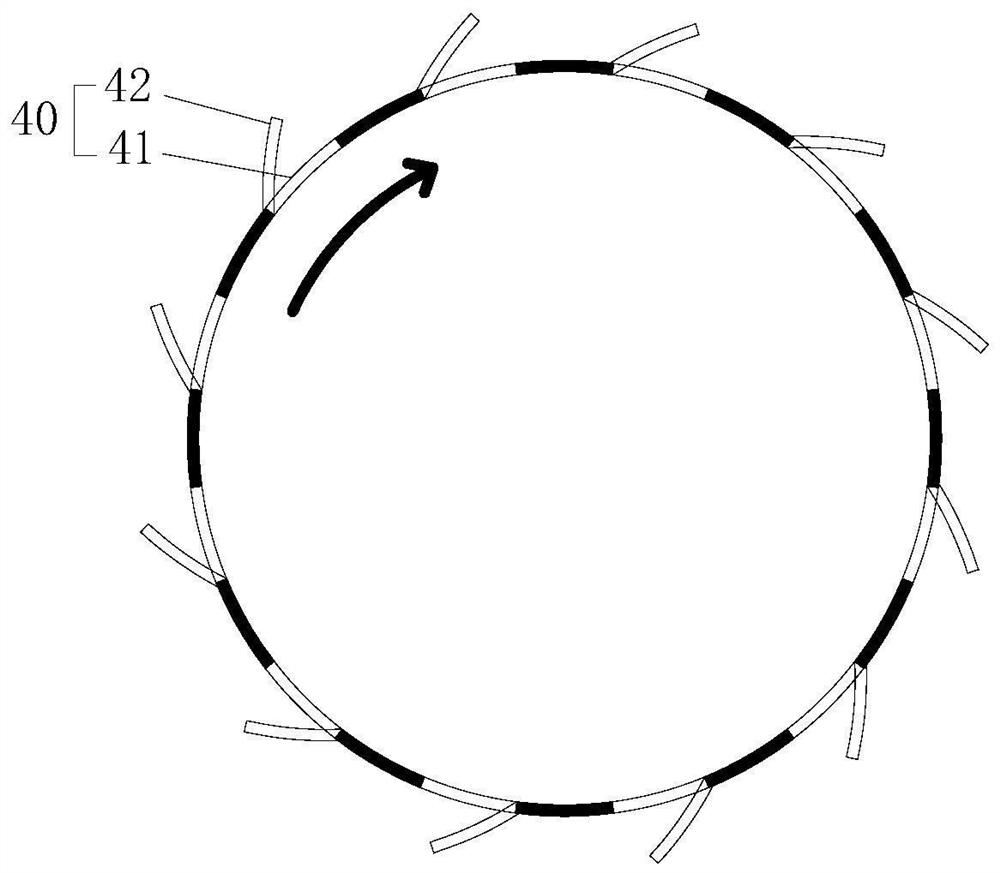

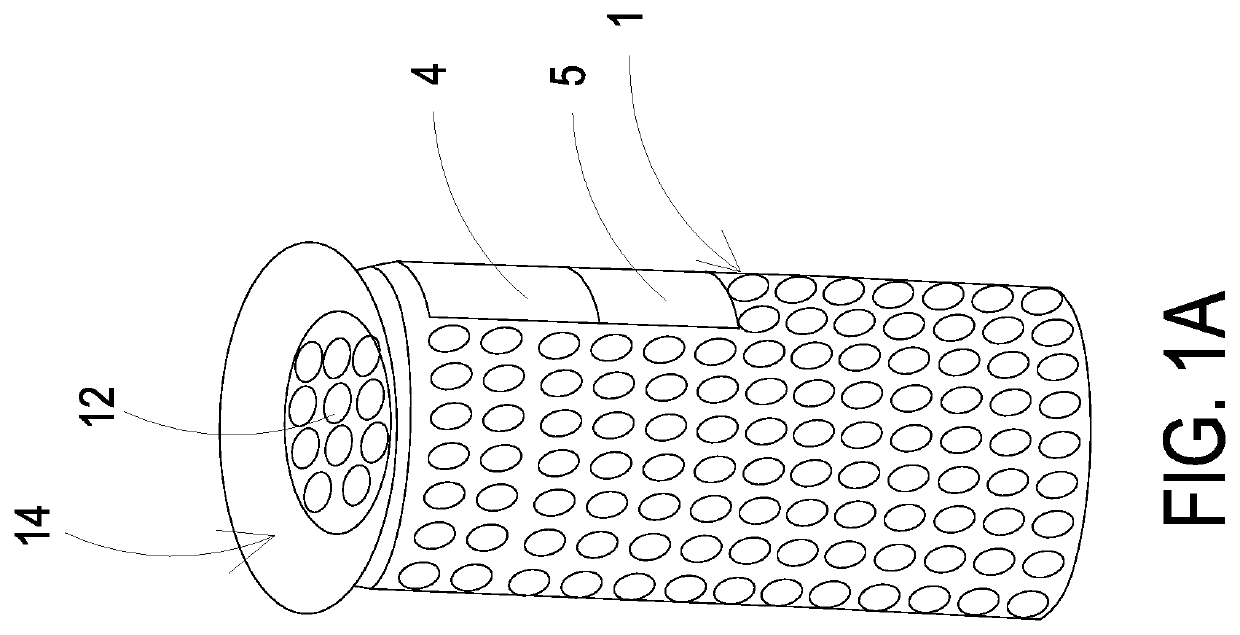

Purification device for exercise environment

PendingUS20220057091A1Improve air qualitySafely filtratedGas treatmentMechanical apparatusSuspended particlesProcess engineering

A purification device for exercise environment is provided and includes a main body, a purification unit, a gas guider and a gas detection module. The purification unit, the gas guider and the gas detection module are disposed in the main body to guide the gas outside the main body through the purification unit for filtering and purifying the gas, and discharge a purified gas. The gas detection module detects particle concentration of suspended particles contained in the purified gas. The gas guider is controlled to operate and export the gas at an airflow rate within 3 minutes. The particle concentration of the suspended particles contained in the purified gas, which is filtered by the purification unit, is reduced to and less than 0.75 μg / m3. Consequently, the purified gas is filtered, and an exerciser in an exercise environment can breathe with safety.

Owner:MICROJET TECH

Solvent dewaxing method of low-wax content heavy hydrocarbon oil

ActiveCN102952572BReduce particle concentrationReduce filtration performanceTreatment with plural serial refining stagesMineral wax recovery/refiningMicrocrystalline waxFiltration

The invention relates to a solvent dewaxing method of low-wax content heavy hydrocarbon oil. The solvent dewaxing method comprises the following steps of mixing one or more raw material oil, petroleum microcrystalline wax and dewaxing solvents, cooling to a filtration temperature, filtering to obtain a dewaxed filtrate and dewaxed cerate, and removing the solvents in the dewaxed filtrate to obtain dewaxed oil, mixing the dewaxed cerate and a deoiling solvent, heating to a filtration temperature, and filtering to obtain a deoiled filtrate and deoiled cerate, wherein a petroleum microcrystalline wax droplet melting point is in a range of 67 to 92 DEG C and a mass ratio of the petroleum microcrystalline wax to the one or more raw material oil is in a range of (0.01: 1) to (0.25: 1). Compared with the conventional solvent dewaxing technology, the solvent dewaxing method provided by the invention can effectively remove wax in low-wax content heavy hydrocarbon oil, reduce a dewaxing temperature difference and improve a filtration speed.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cyclone Separator for Circulating Fluidized Bed Boiler with Wear-Resistant Target Area and Guide

ActiveCN103398375BIncreased flow velocityIncrease flow rateFluidized bed combustionApparatus for fluidised bed combustionCycloneRefractory wear

A cyclone separator with a wear-resisting target section and a guiding device for a circulating fluidized bed boiler. The cyclone separator comprises a separator inlet flue, a separator barrel body connected with an outlet of the separator inlet flue, a separator cone and a separator standpipe, which are successively connected below the separator cylinder body, and a separator central cylinder inserted into the upper part of the separator barrel body. The lower part of the separator central cylinder is provided with a central cylinder necking; the separator inlet flue is a tapered inlet flue, which is provided inside with a smoke guiding boss, and a smoke diversion part at the outlet; the smoke guiding boss and the smoke diversion part are covered with a high-strength refractory wear-resistant material layer; and one or a plurality of soot blowing mouths are arranged surrounding the smoke guiding boss. Optimization on the flow field in the cyclone separator reduces the direct impact of airflow and wear on the refractory wear-resistant material in the target section, and can improve the continuous operation cycle of the circulating fluidized bed boiler.

Owner:HUANENG CLEAN ENERGY RES INST

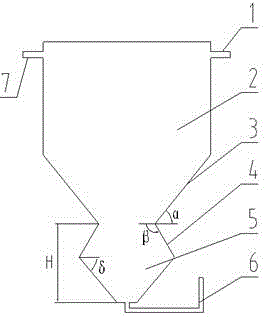

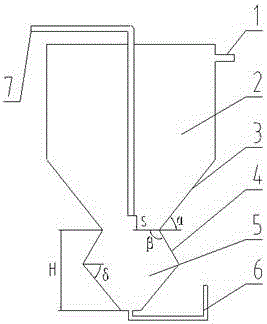

Gravity concentration device

ActiveCN106110719AEliminate the effects ofImprove settlement efficiencySettling tanks feed/dischargeSedimentation settling tanksSludgeSolid particle

The invention discloses a gravity concentration device which comprises a primary settling area, a secondary settling area and a water inlet pipe, wherein an included angle alpha between the lower side wall of the primary settling area and the horizontal plane is more than 0 degree and less than or equal to 90 degrees; the top of the secondary settling area is connected with the bottom of the primary settling area; an included angle beta between the upper side wall of the secondary settling area and the horizontal plane is more than 90 degrees; a mud pipe 6 is arranged at the bottom of the secondary settling area; the area of the top opening of the secondary settling area is not larger than 1 / 2 of the maximum sectional area of the primary settling area; and an included angle delta between the lower side wall of the secondary settling area and the horizontal plane is more than 0 degree and less than 180 degrees. According to the device disclosed by the invention, the influence of vortex in the primary settling area on a flow field in the secondary settling area can be eliminated, vortex formed in the secondary settling area is effectively avoided, and the settling efficiency of solid particles is improved; and moreover, the sludge does not overflow out of the secondary settling area, and the system operation is stable.

Owner:卓宇轩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com