Arrangement method of catalytic cracking tetra-cyclone separator

A cyclone separator, catalytic cracking technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problem of insufficient utilization of the sedimentation separation function in the dilute phase space, increase the working load of the quadruple cyclone, and the concentration of particles at the entrance of the quadruple cyclone advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

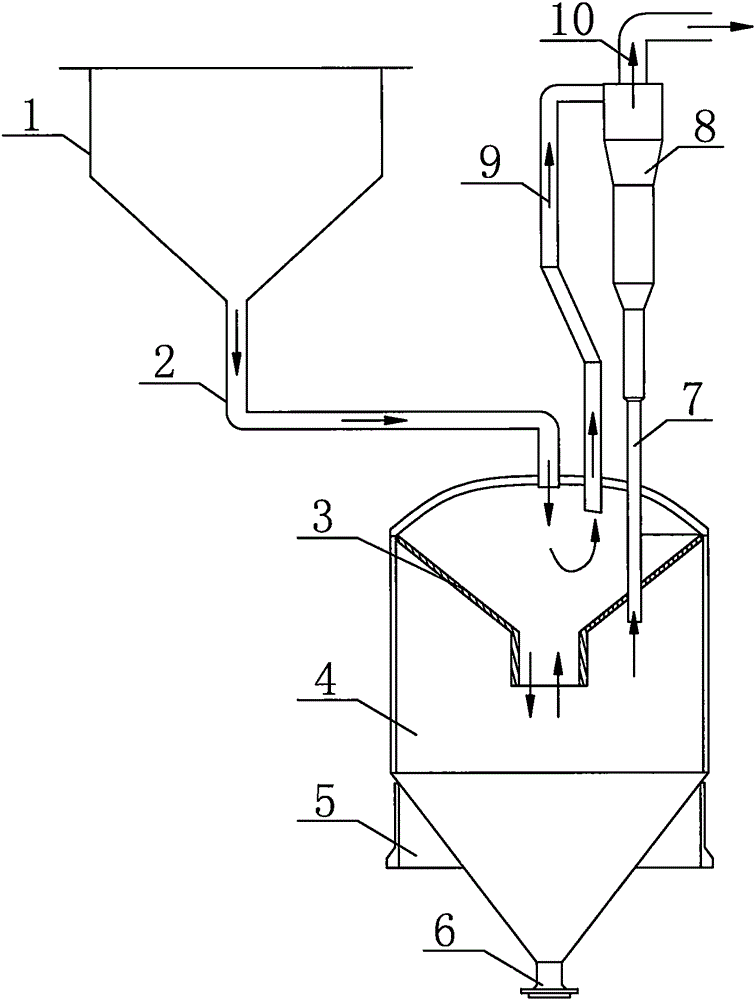

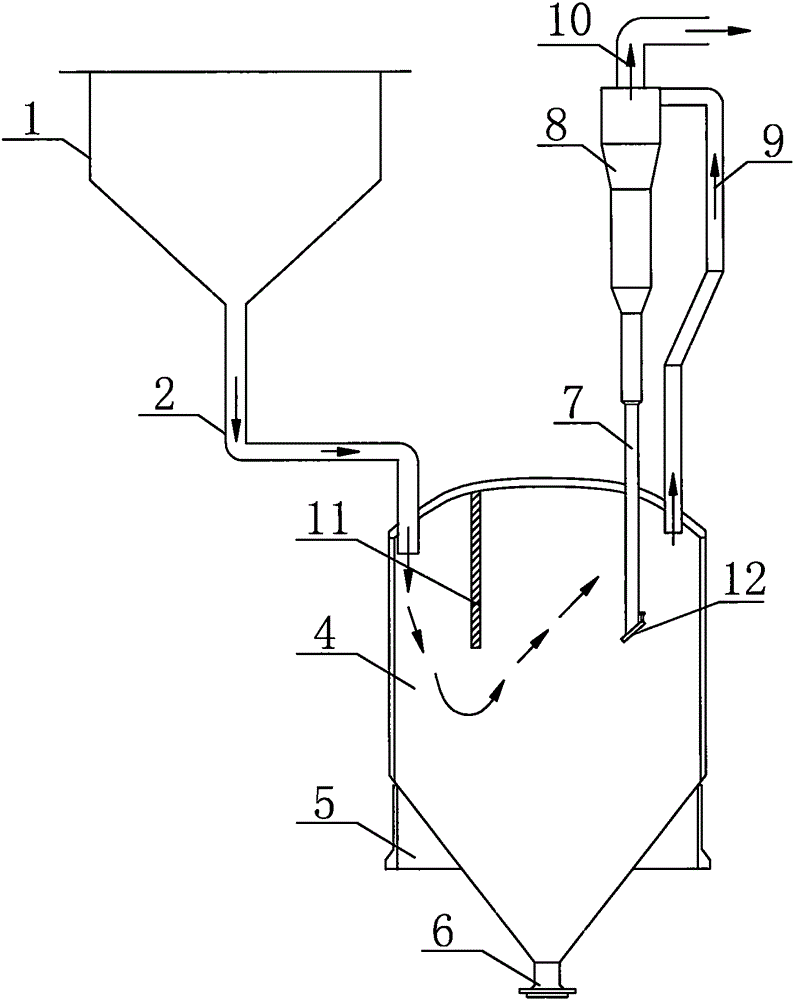

[0020] figure 2 A typical structure type of the novel four-spin system proposed by the present invention is given, and figure 1 The difference of the traditional four-rotation system shown is that in this structure, the conical baffle (3) inside the storage tank (4) of the traditional four-rotation system is removed, and the upper part of the storage tank (4) is set up A vertical partition (11). Here, with the storage tank (4) top, the space on the left side of the vertical partition (11) is defined as an inertial separation zone; with the storage tank (4) top, the space on the right side of the vertical partition (11) is defined as Sedimentation separation zone. The outlet of the three-rotation discharge pipe (2) is arranged on the side farther away from the vertical partition (1) and close to the wall of the storage tank (4). Due to the high air velocity in the three-rotation discharge pipe (2), after entering the inertial separation space on the left, due to the sudden ...

Embodiment 2

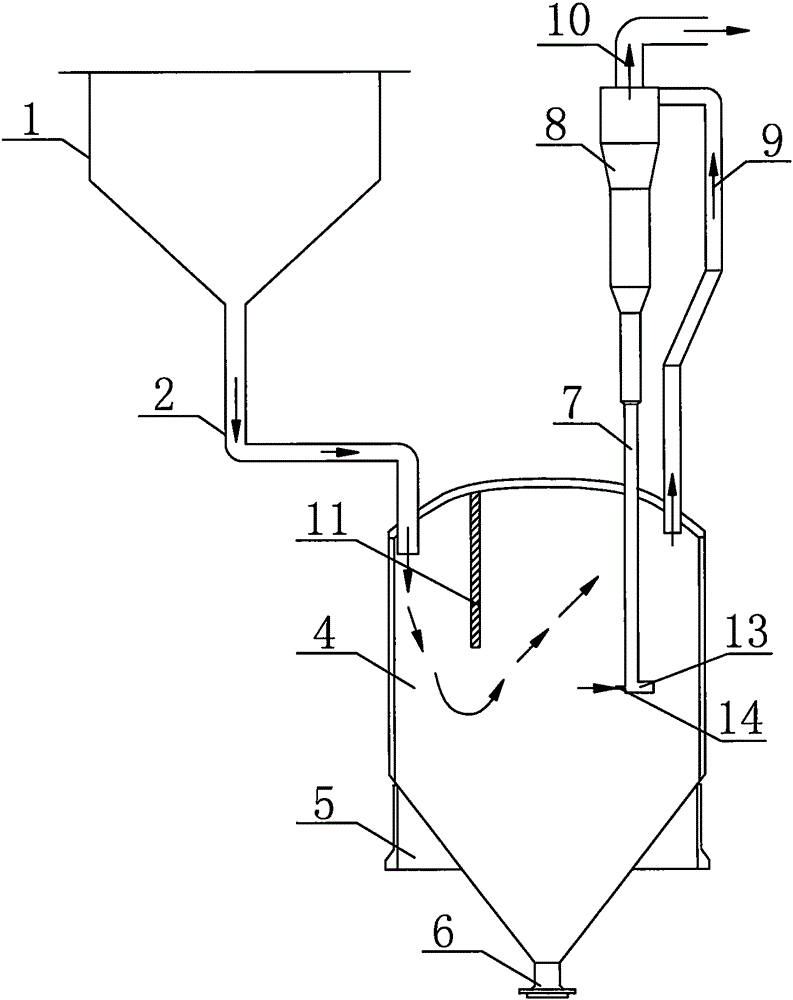

[0023] image 3 Another typical structure type of the new four-spin system proposed by the present invention is given, which is generally the same as figure 2 The structure type shown is the same, the difference is that an L-shaped valve (13) is set at the bottom of the four-rotary material leg (7), which is a common non-mechanical material leg air lock mechanism. Similarly, other similar Non-mechanical dipleg air locks, such as V-valves, can also be used here. In order to ensure the normal operation of this type of non-mechanical valve, it is necessary to arrange a loosening air duct (14) on this type of non-mechanical valve, and to ensure the smooth discharge of particles and the normal air-locking function by inputting a continuous loosening air flow.

Embodiment 3

[0025] Figure 4 Another typical structure type of the new four-spin system proposed by the present invention is given, which is generally the same as image 3 The structural types shown are the same, the difference is that a layer of louver grille (15) is arranged at the bottom of the storage tank (4), and this layer of grille (15) is arranged on the highest possible material layer at the bottom of the storage tank (4). Above the position, 0.05-0.5m away from the surface of the highest possible material layer. Figure 5A partial cross-sectional schematic diagram of the louver grille (15) is given. It is precisely because of the function of its inclined blades (16) that it can perform the function of inertial separation of some particles without affecting the circulation of the gas, so as to further reduce the gas flow rate. The eluting entrainment effect on the separated solid particle material layer at the bottom of the storage tank (4). In addition to the louver grille (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com