Gravity concentration device

A technology of gravity concentration and secondary sedimentation, which is applied to the feeding/discharging device, separation method, and sedimentation separation of the settling tank. It can solve the problems of small sedimentation tank volume, affecting the sedimentation effect, and easy overflow of solid particles. Achieve rapid separation, reduce the concentration of particulate matter, and improve the effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

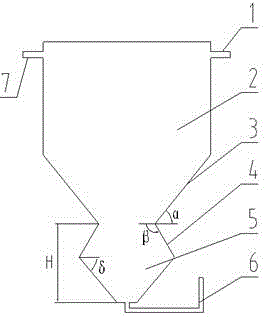

[0031] Such as figure 1 As shown, the gravity concentration device provided by the present invention includes a primary sedimentation zone 2, a secondary sedimentation tank 5, a water inlet pipe 7, an outlet pipe 1, and a mud discharge pipe 6, and a water inlet 7 is arranged on one side of the primary sedimentation zone 2. The other side is provided with a water outlet pipe 1, the lower part of the primary sedimentation area 2 is provided with a secondary sedimentation area 5, the bottom of the secondary sedimentation area 5 is provided with a mud discharge pipe 6, and the angle α between the lower side wall 3 of the primary sedimentation area and the horizontal plane is 45°, the angle β between the upper side wall 4 of the secondary precipitation zone and the horizontal plane is 135°, and the angle δ between the lower side wall of the secondary precipitation zone and the horizontal plane is 45°. The sewage enters the primary sedimentation zone 2 from the water inlet pipe 7, a...

Embodiment 2

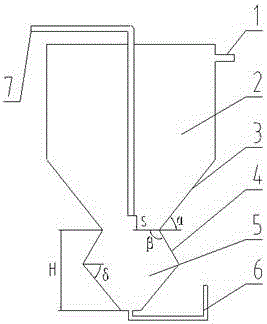

[0033] Such as figure 2 As shown, the gravity concentration device provided by the present invention includes a primary sedimentation area 2, a secondary sedimentation tank 5, an inlet pipe 7, an outlet pipe 1, and a mud discharge pipe 6, and sewage enters from the upper part of the primary sedimentation area 2 through the water inlet pipe 7. In the primary sedimentation zone 2, the outlet of the water inlet pipe 7 is vertically downward, the height H of the secondary sedimentation zone 5 is 1 m, the distance between the lower end of the water inlet pipe 7 and the top opening of the secondary sedimentation zone 5 is 0.2 m, and the sewage flows out into the The water pipe enters the secondary sedimentation zone 5 vertically downwards. Due to the action of inertial force, the particles and water are quickly separated, and the clear water flows upwards out of the secondary sedimentation zone 5. The top opening area is not larger than 1 / 2 of the maximum cross-sectional area of ...

Embodiment 3

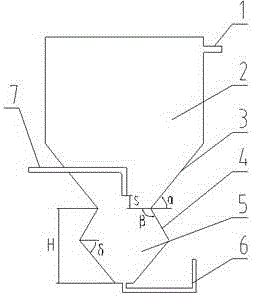

[0035] Such as image 3 As shown, the difference from Embodiment 2 is that the water inlet pipe enters from the side wall of the primary sedimentation zone 2. Compared with Embodiment 2, Embodiment 3 is easier to construct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com