Device and method for removing sulfur dioxide and dioxin from sintering flue gas

A technology of sintering flue gas and flue gas, which is applied in the field of flue gas purification, can solve the problems of system investment, high operating cost, complicated activated carbon/coke process, and easy spontaneous combustion of activated carbon/coke, and achieves small footprint, lightened burden, Effect of reducing particle concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

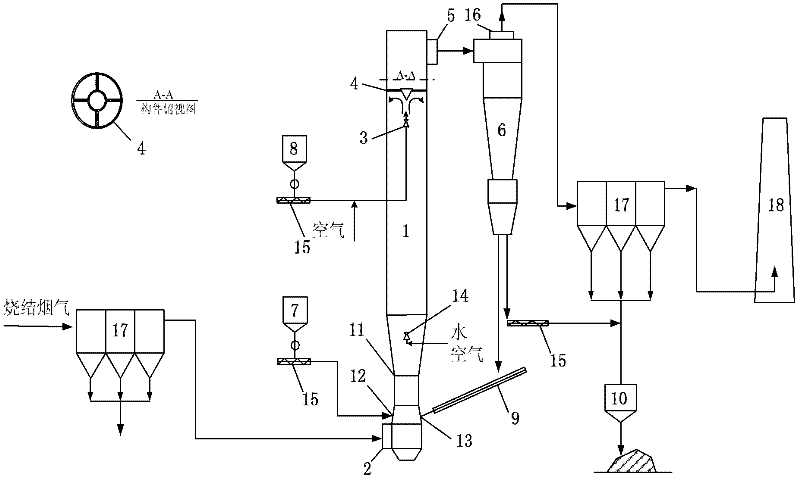

[0038] Further detailed description will be given below in conjunction with the accompanying drawings and specific embodiments.

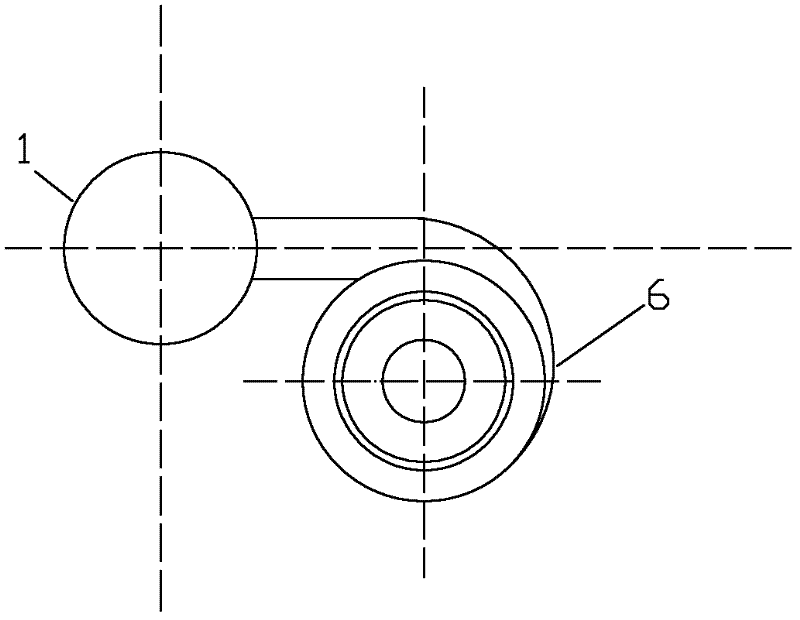

[0039] Such as figure 1 Shown, this figure is the sintering flue gas SO provided by the present invention 2 and dioxin removal device. Including a circulating fluidized bed absorption tower (1), a flue gas inlet (2) is provided at the bottom of the absorption tower (1), and an activated carbon / coke nozzle (3) is arranged in the upper part of the absorption tower (1), facing the activated carbon / coke nozzle (3) Conical member (4) is set, and the top of absorption tower (1) is provided with flue gas outlet (5), and flue gas outlet (5) is communicated with cyclone separator (6) by pipeline; It is characterized in that: also includes Desulfurizer bin (7), activated carbon / coke bin (8), screw feeder (9), ash bin (10); wherein the lower part of the circulating fluidized bed absorption tower (1) adopts a Venturi structure (11) , the Venturi structure (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com