Testing device and testing method for servo valve pollution sensitivity measurement

A pollution sensitivity and test device technology, which is applied in the field of servo valve pollution sensitivity measurement test device, can solve the problems of hydraulic oil deviation, no consideration of the influence of pollution particles, and inconvenient test operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

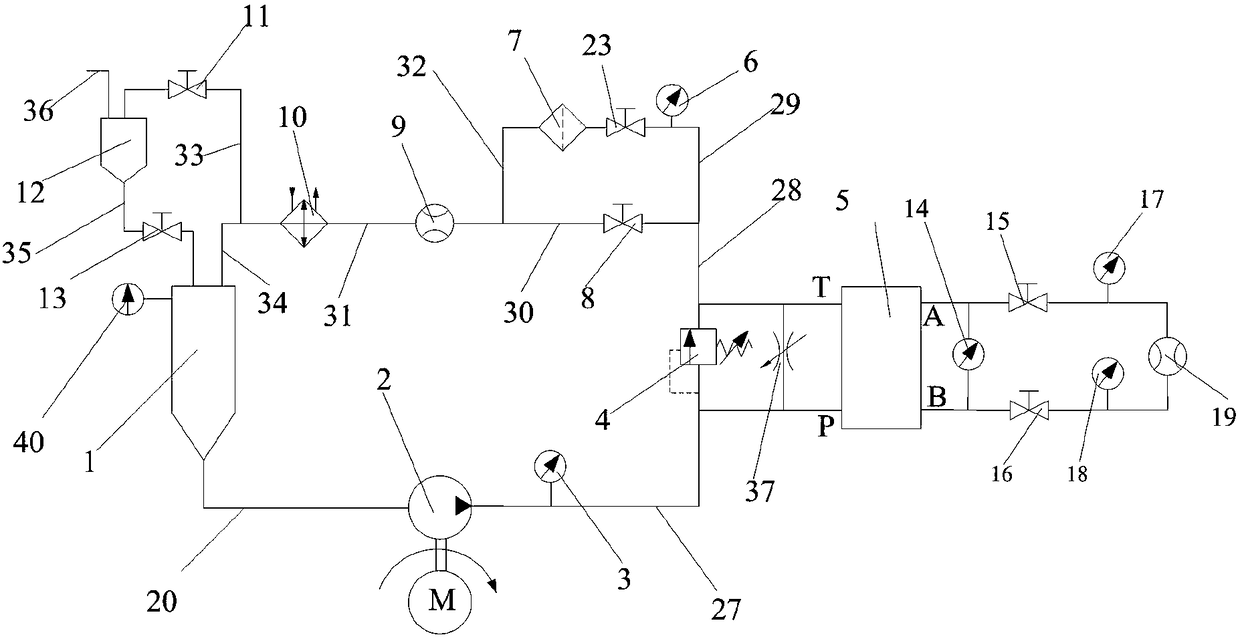

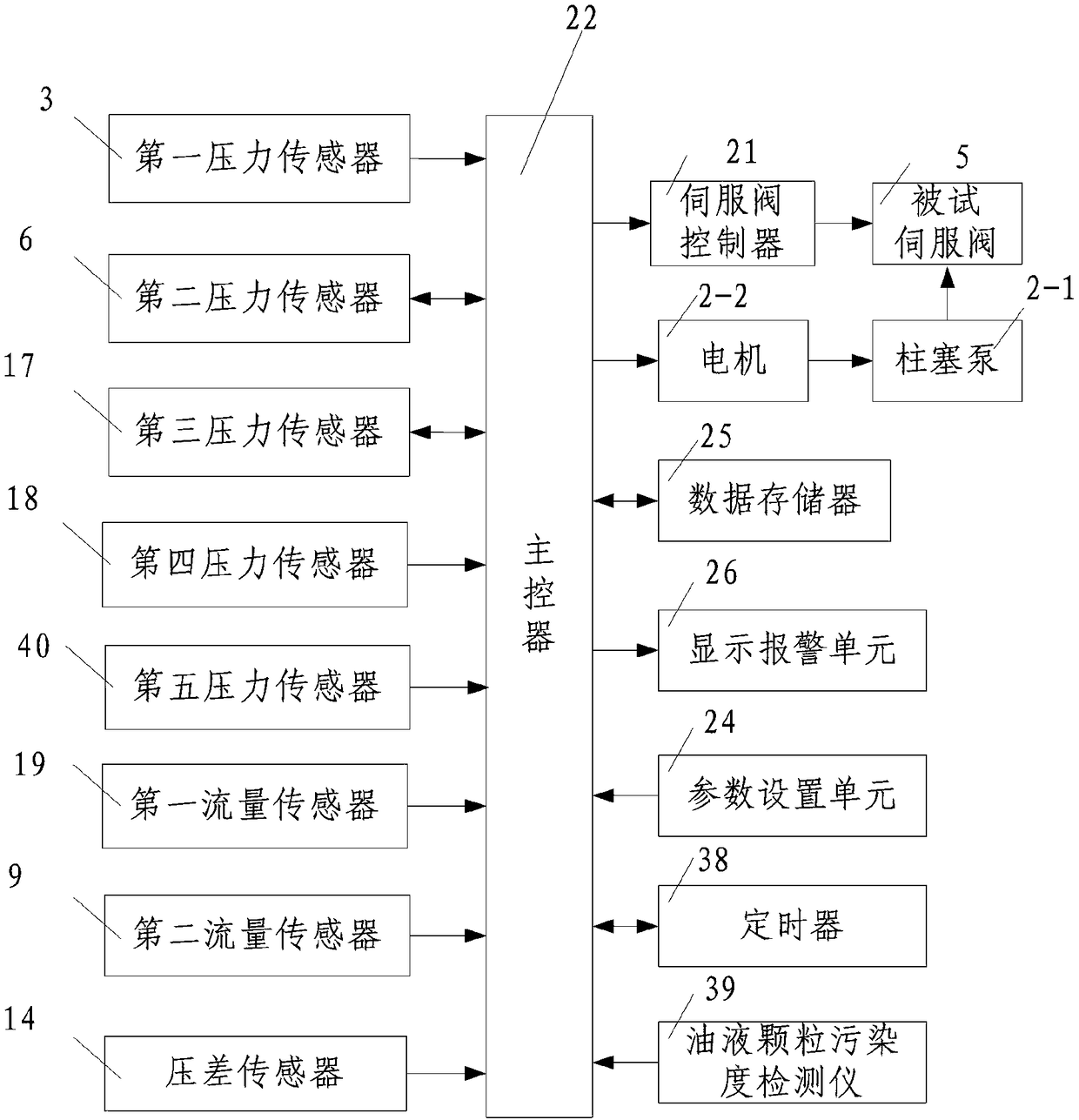

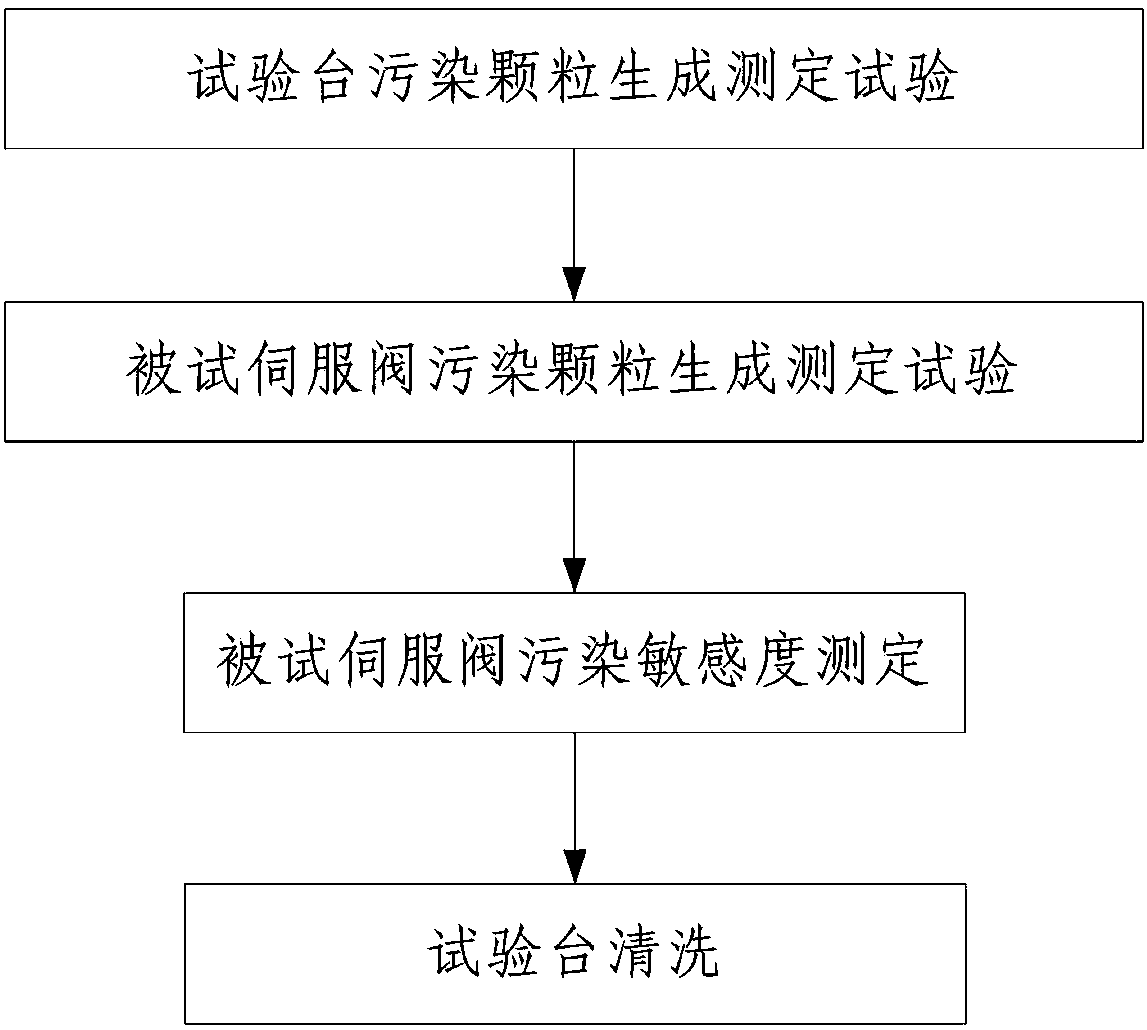

[0082] Such as figure 1 and figure 2 As shown, the present invention includes a monitoring device and a test bench for the installation of the servo valve 5 to be tested. The cleaning filter 7 for filtering oil and the dust solution tank 12 for holding the dust solution, the oil supply device includes the oil tank 1 and the drive mechanism 2 connected with the oil tank 1 and supplying oil to the servo valve 5 under test, the drive mechanism 2 It includes a plunger pump 2-1 and a motor 2-2 that drives the action of the plunger pump 2-1, the oil inlet of the plunger pump 2-1 is connected to the oil tank 1, and the oil outlet of the plunger pump 2-1 The port is divided into three routes, one route is connected with the inlet of the safety valve 4, the other route is connected with the inlet of the manual throttle valve 37, and the third route is connected with the oil inlet port of the tested servo valve 5; the return port of the tested servo valve 5 The oil port, the outlet o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com