Apparatus and method for minimizing the generation of particles in ultrapure liquids

a technology of ultrapure liquids and particle generation, applied in the direction of liquid transfer devices, liquid handling, packaging goods types, etc., can solve the problems of product deficient or even useless for its intended purpose, and achieve the effect of reducing particle generation, less particle generation, and reducing particle concentration in liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

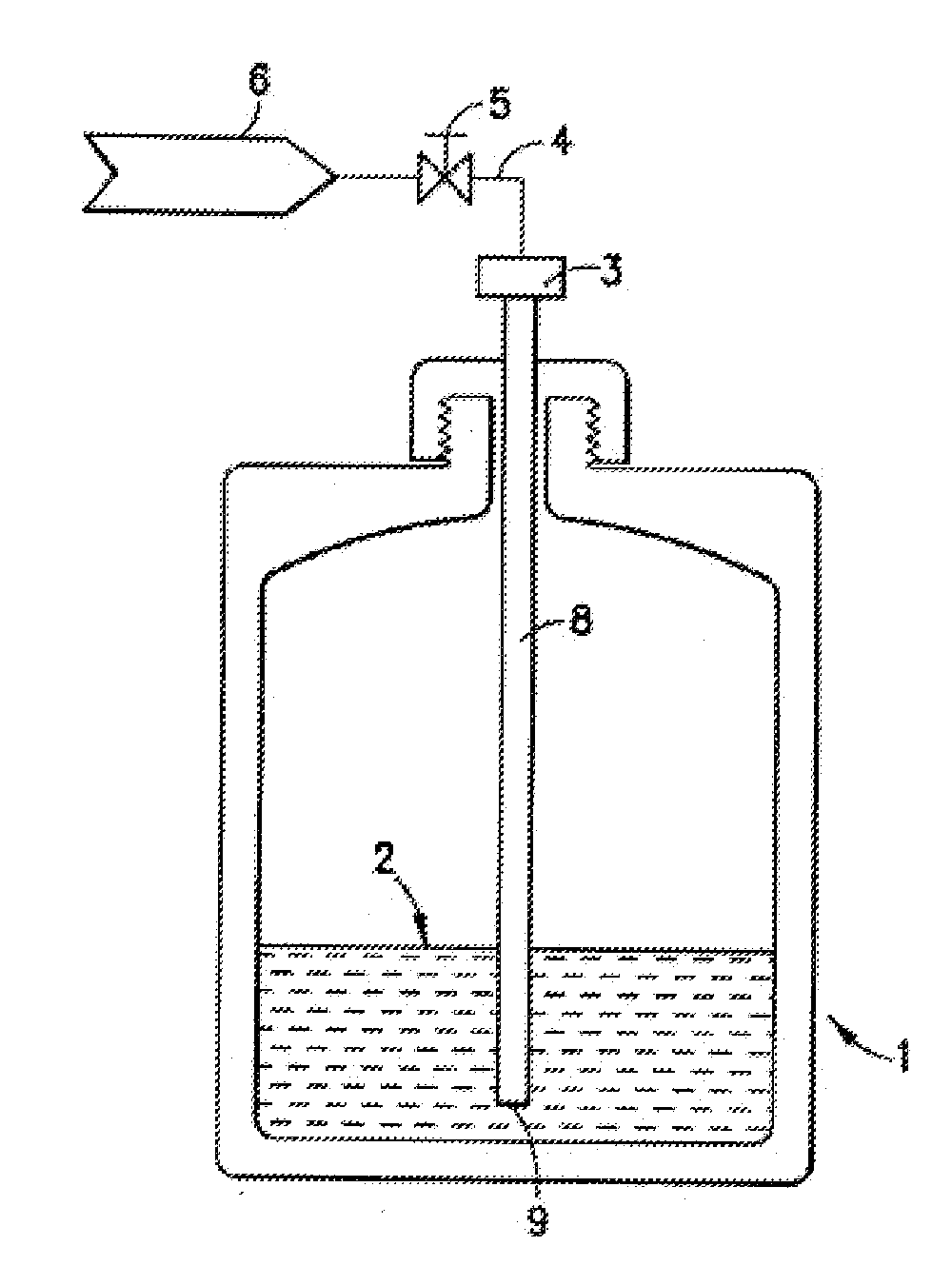

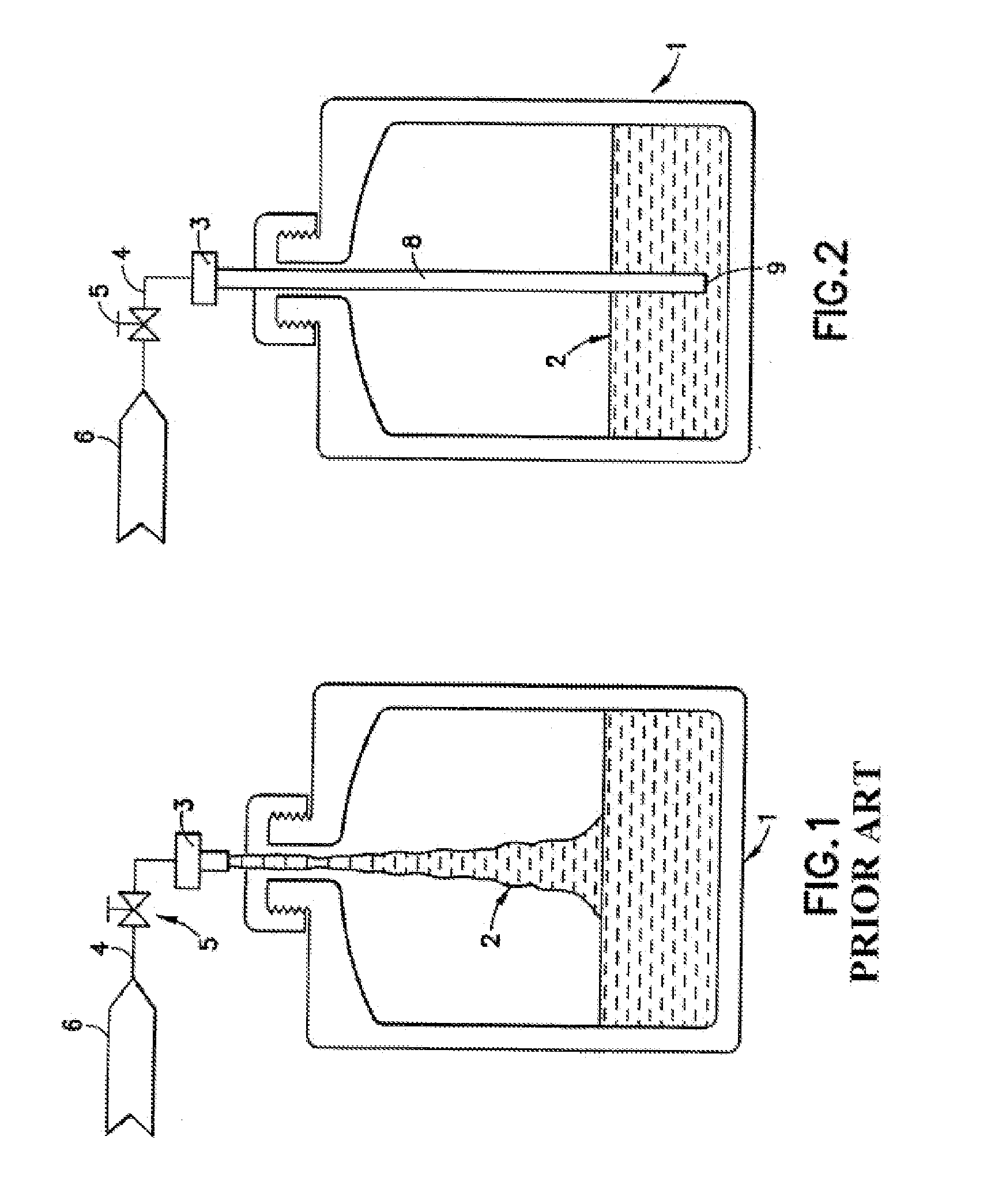

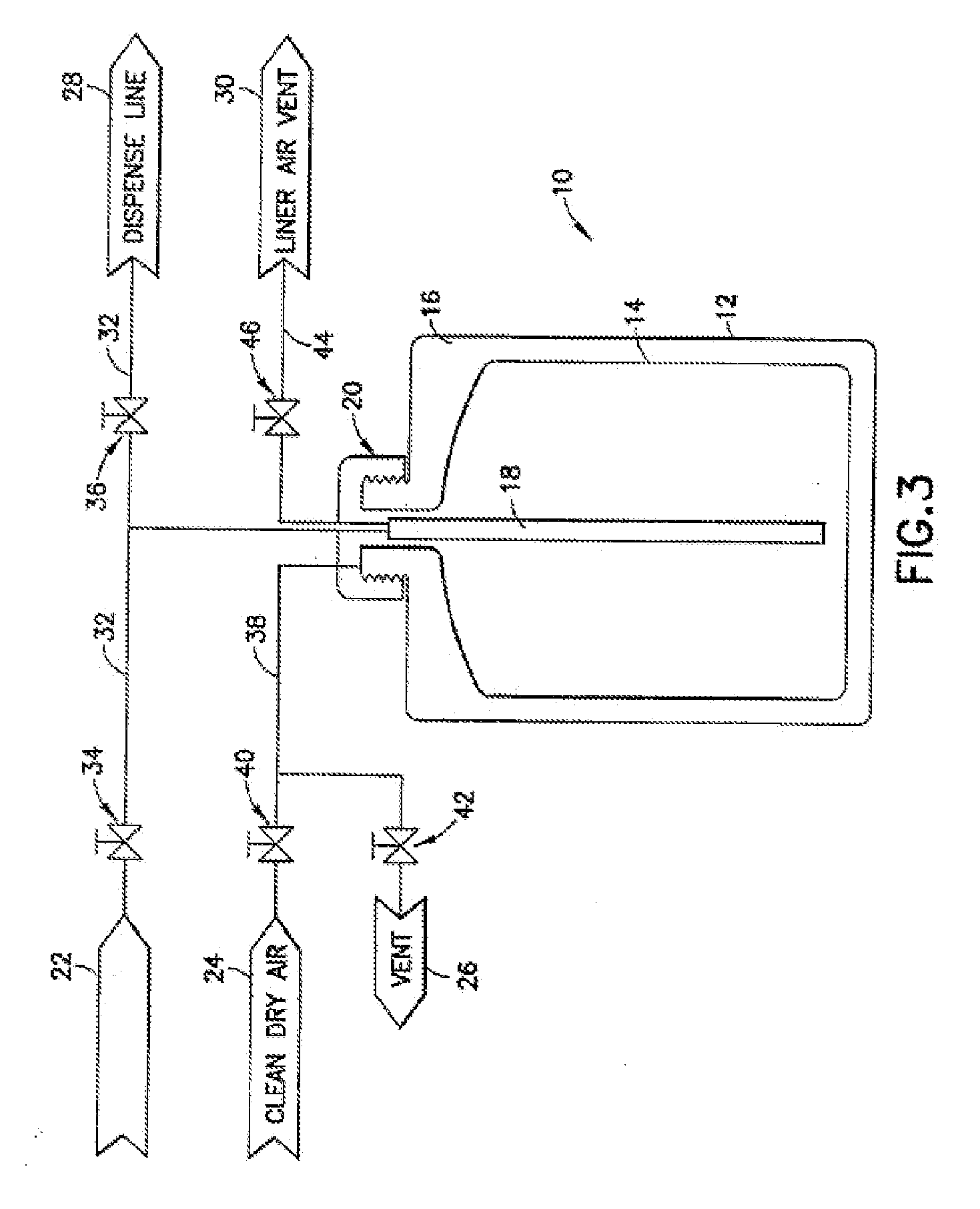

[0134] From the same lot of Oxide Slurry OS-70KL material (ATMI Materials Lifecycle Solutions, Danbury, Conn.) several different sample vials were made up, containing the OS-70KL material, to simulate behavior of the liquid in a bag in a drum container of the type generally shown and described herein and in U.S. patent application Publication No. US2003 / 0004608 A1 and U.S. Pat. No. 6,698,619, incorporated herein by reference in their entirety, with varying headspace in the interior volume of the liner.

[0135] The sample vials were made up with the following differing headspace levels: 0%, 2%, 5% and 10%. Each of the sample vials was vigorously shaken for one minute by hand, and the liquid in the vial was then subjected to analysis in an Accusizer 780 Single Particle Optical Sizer, a size range particle counter commercially available from Sci-Tec Inc. (Santa Barbara, Calif.), which obtains particle counts in particle size ranges that can then be “binned” algorithmically into broad pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com