Inspection of rod-shaped articles from the tobacco processing industry

A processing industry and product technology, applied in the field of rod-shaped products, especially in the field of filter cigarettes, can solve the problems of interference optical control, consumption, wrong evaluation, etc., and achieve the effects of reducing pollution, improving quality, and reducing the density of interference particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

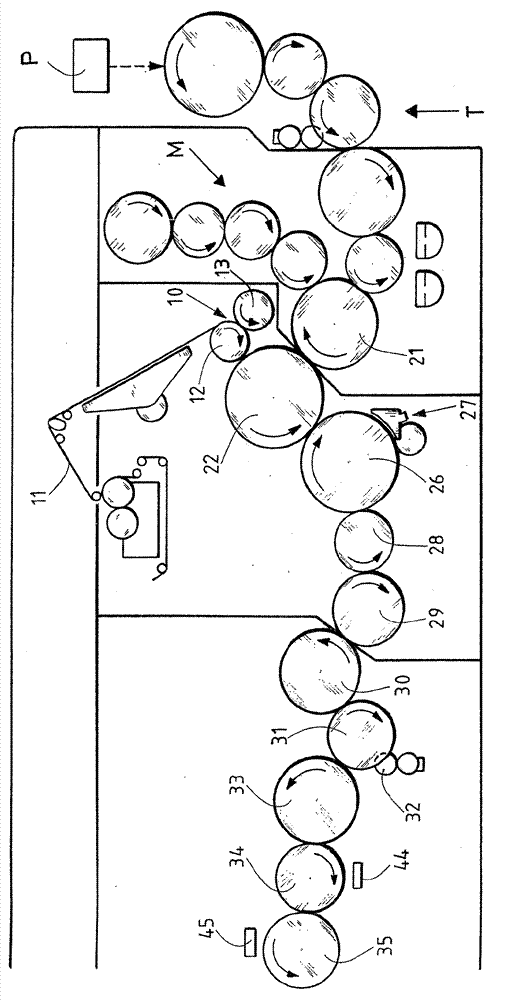

[0042] In FIG. 1 a filter tipping machine is partially shown in a front view, wherein the filter tipping machine receives double-use-length cigarettes from a schematically shown cigarette rod maker P via a drum device T for transporting cigarettes. branch. Cigarette rod making machines are known under the name "PROTOS" of the applicant of this patent.

[0043] The double-use-length cigarettes are cut and longitudinally divided on their transport path to the alignment drum 21 . On the alignment drum 21, double-length filter rods are transported through another drum device M, the filter rods being respectively inserted between two longitudinally spaced cigarettes. As a result, a group of cigarette-filter rod-cigarette groups arranged one after the other in the transverse axis is formed on the arrangement drum 21 . The aligned product groups are transferred by the alignment drum 21 to the transport drum 22 .

[0044] The coated paper strips 11 that have been glued and conveyed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com