Pipeline robot

A pipe robot and shock absorber technology, which is applied in the field of robots, can solve the problems of being unable to adapt to rectangular pipe shapes, unable to adapt to continuous normal work, and decreased walking stability, etc., to achieve strong functional expansion, compact structure, and smooth walking sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

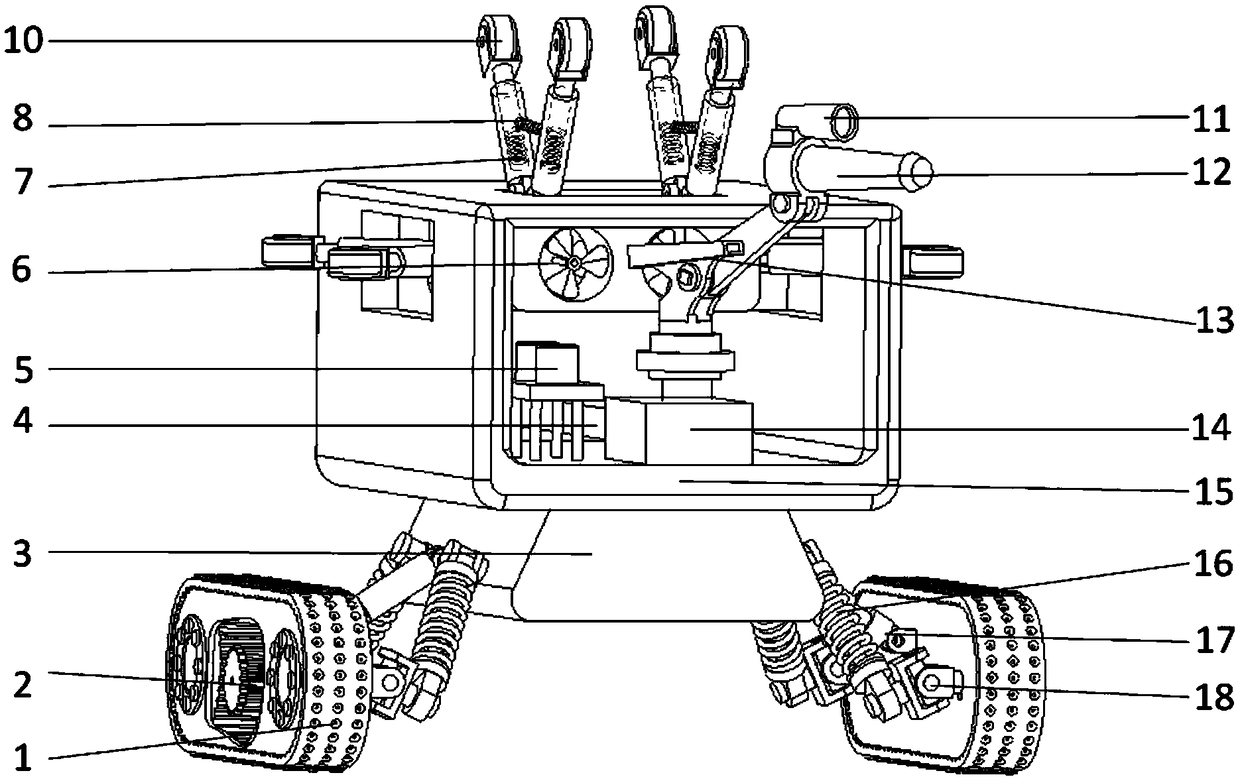

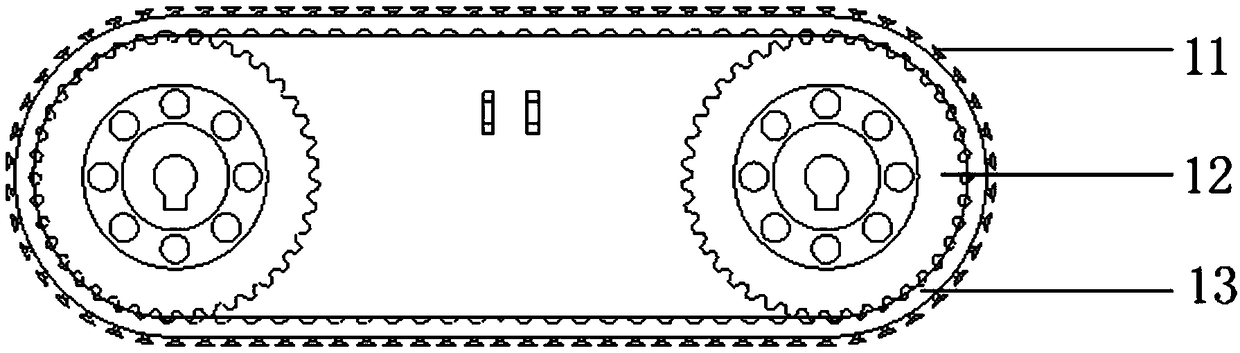

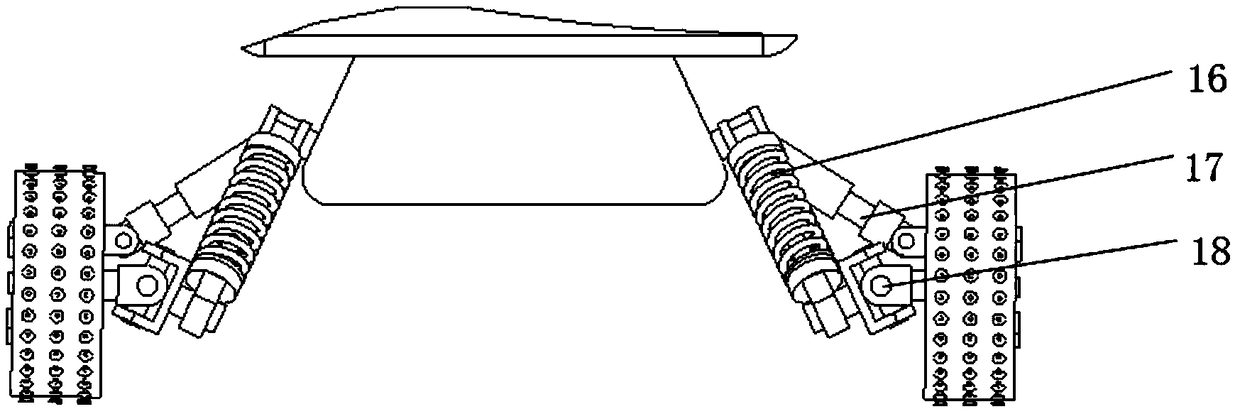

[0031] Such as figure 1 As shown, a pipeline robot includes a support mechanism, a walking mechanism, an adaptive mechanism, an anti-collision mechanism, an operating mechanism, a safety auxiliary mechanism, an information collection mechanism, an external connection mechanism and a positioning mechanism,

[0032] The support mechanism includes a support base 3 and a load-bearing vehicle body 15. The load-bearing vehicle body 15 is an internal hollow structure with side openings. The load-bearing vehicle body 15 is used to carry necessary equipment. , the opening of the carrying car bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com