Patents

Literature

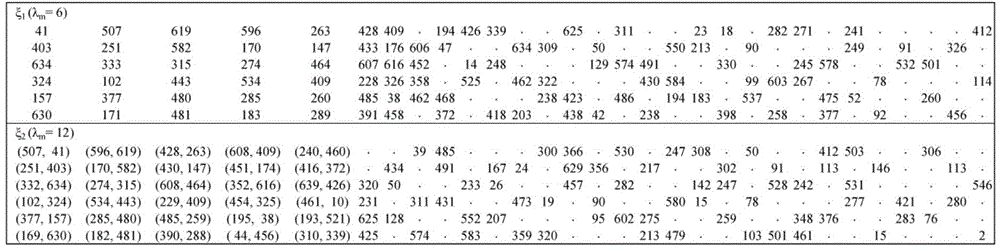

208 results about "Dual cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dual cycle is the combination of both diesel cycle and otto cycle. The efficiency of dual cycle is more than diesel cycle but less than otto cycle. In heat addition process first there will be constant volume for some time and then constant pressure till the end of heat addition process. 1.1k views · View 5 Upvoters.

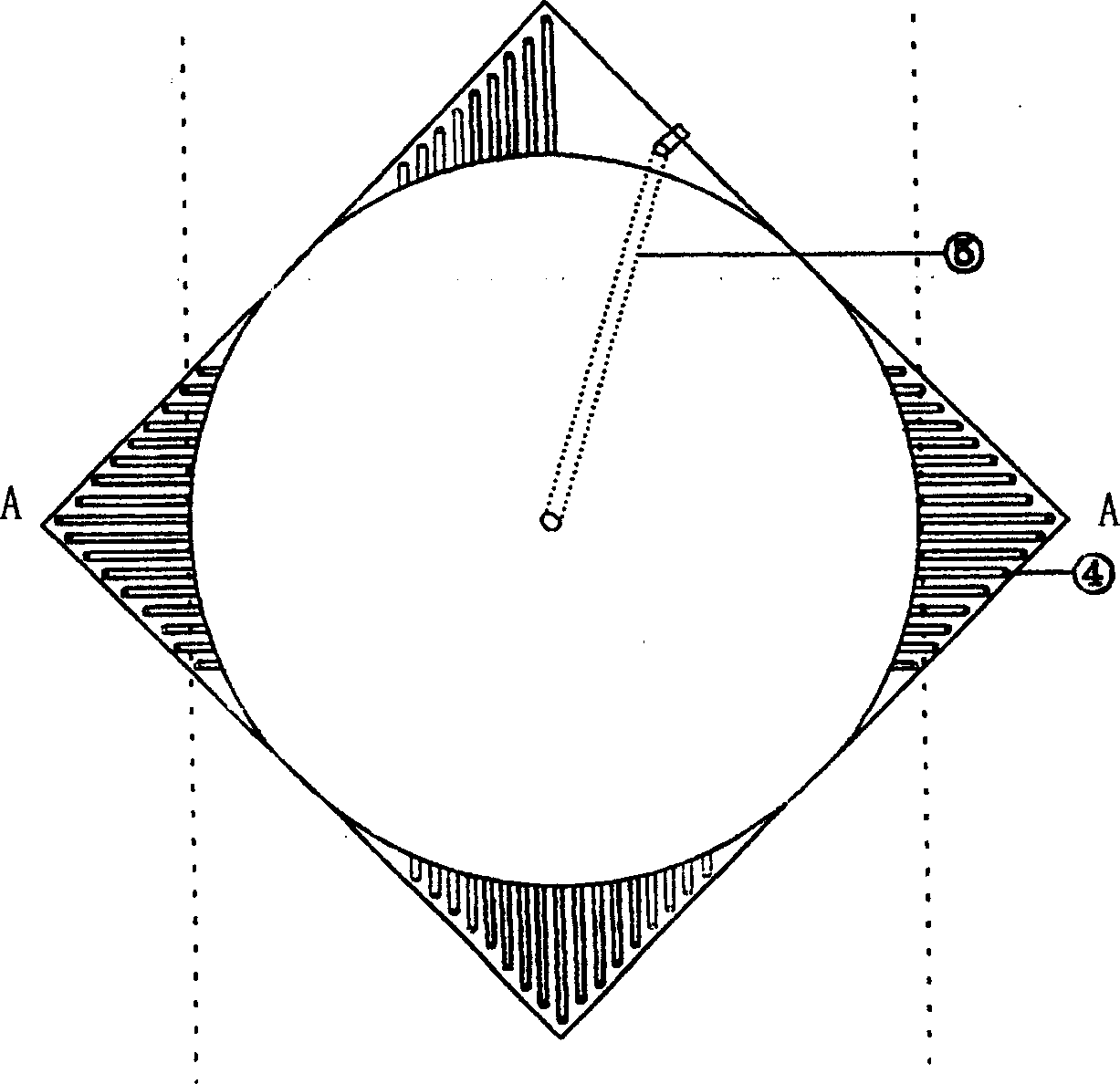

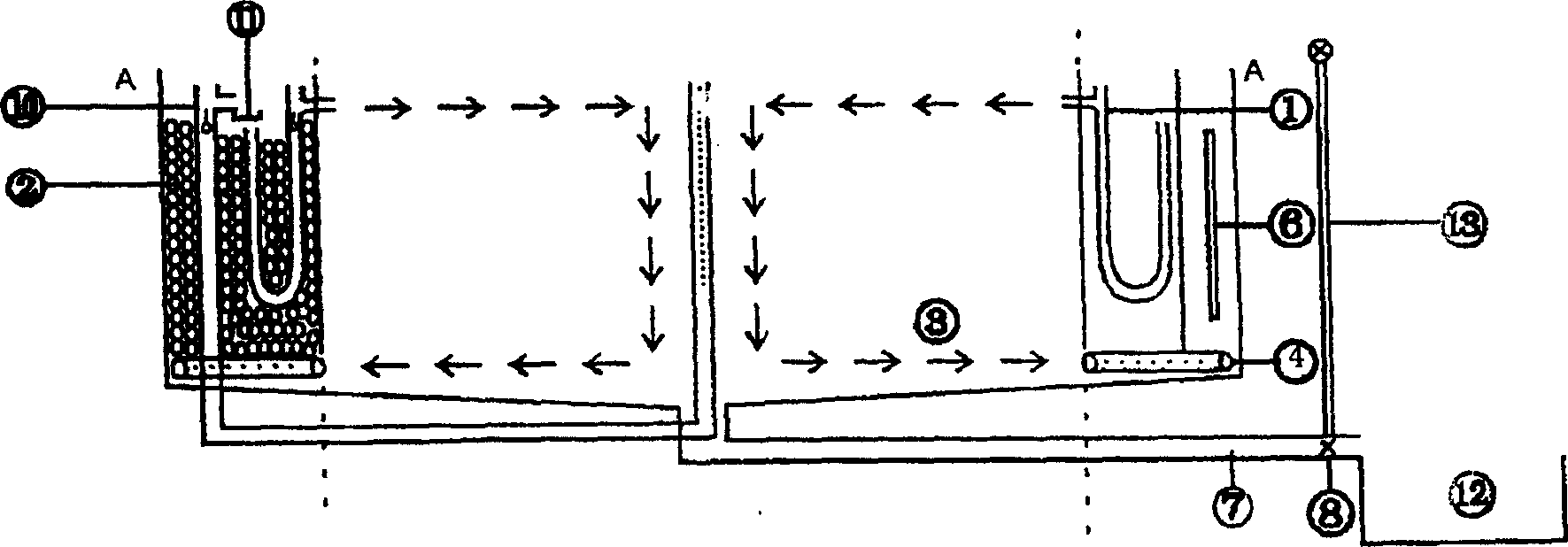

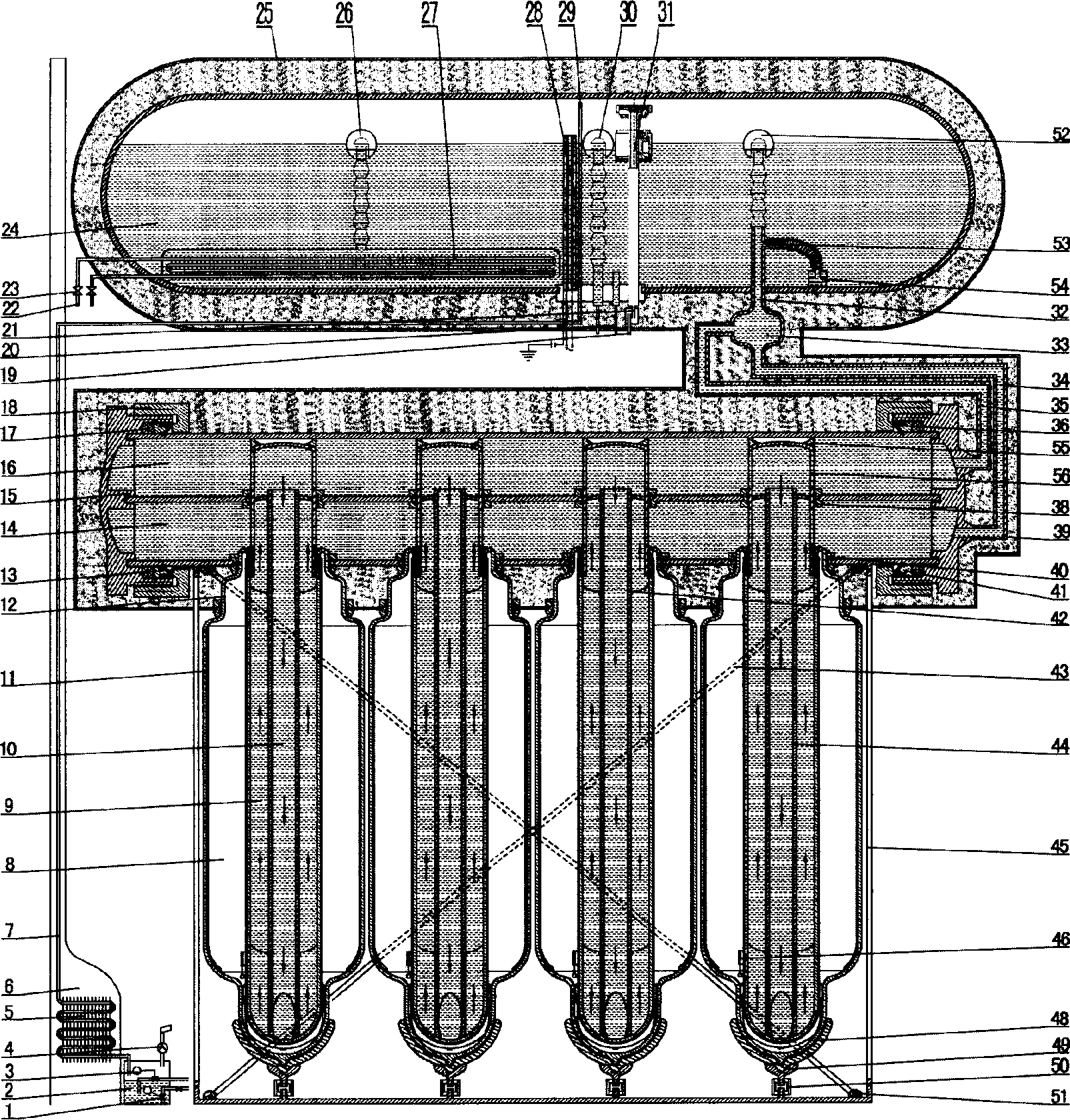

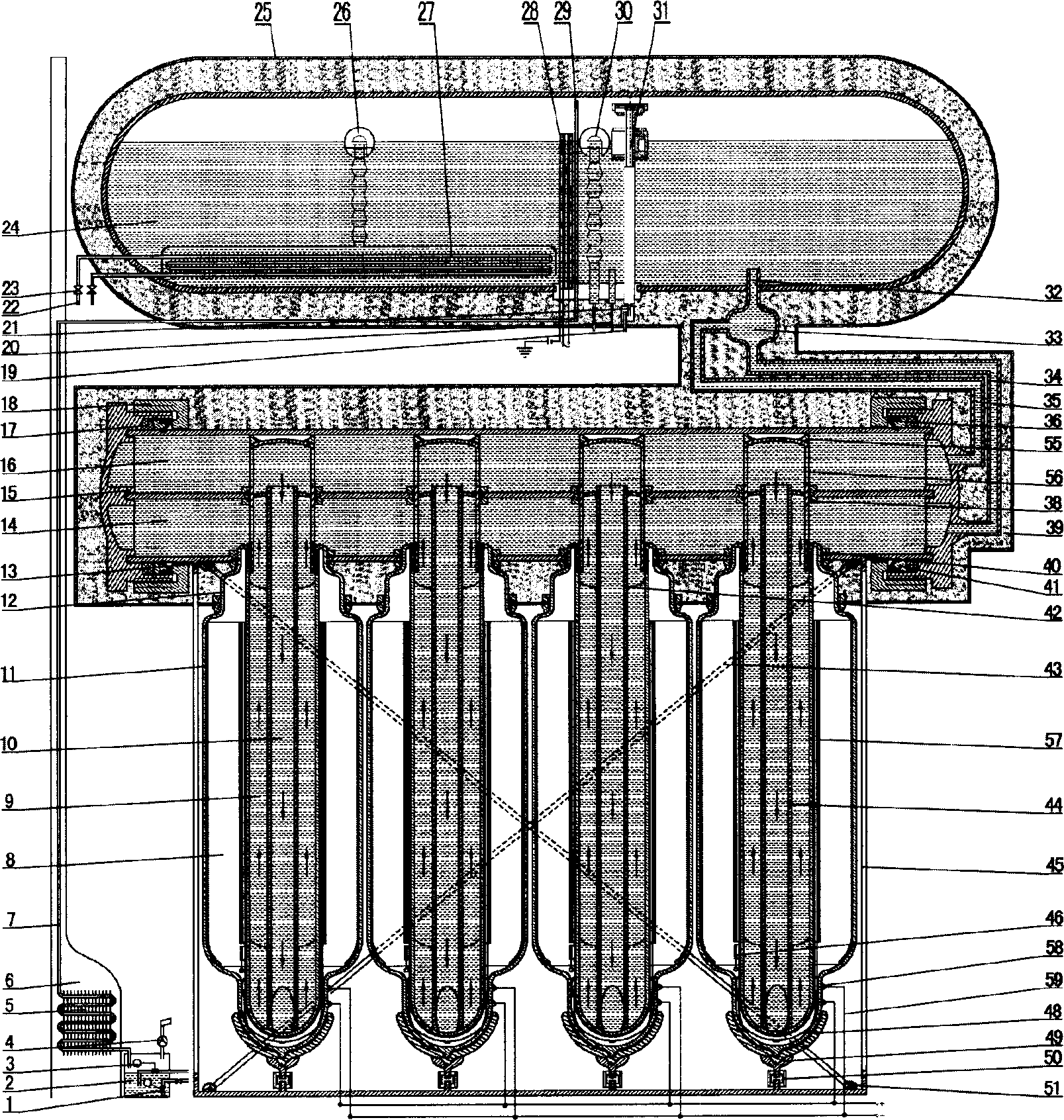

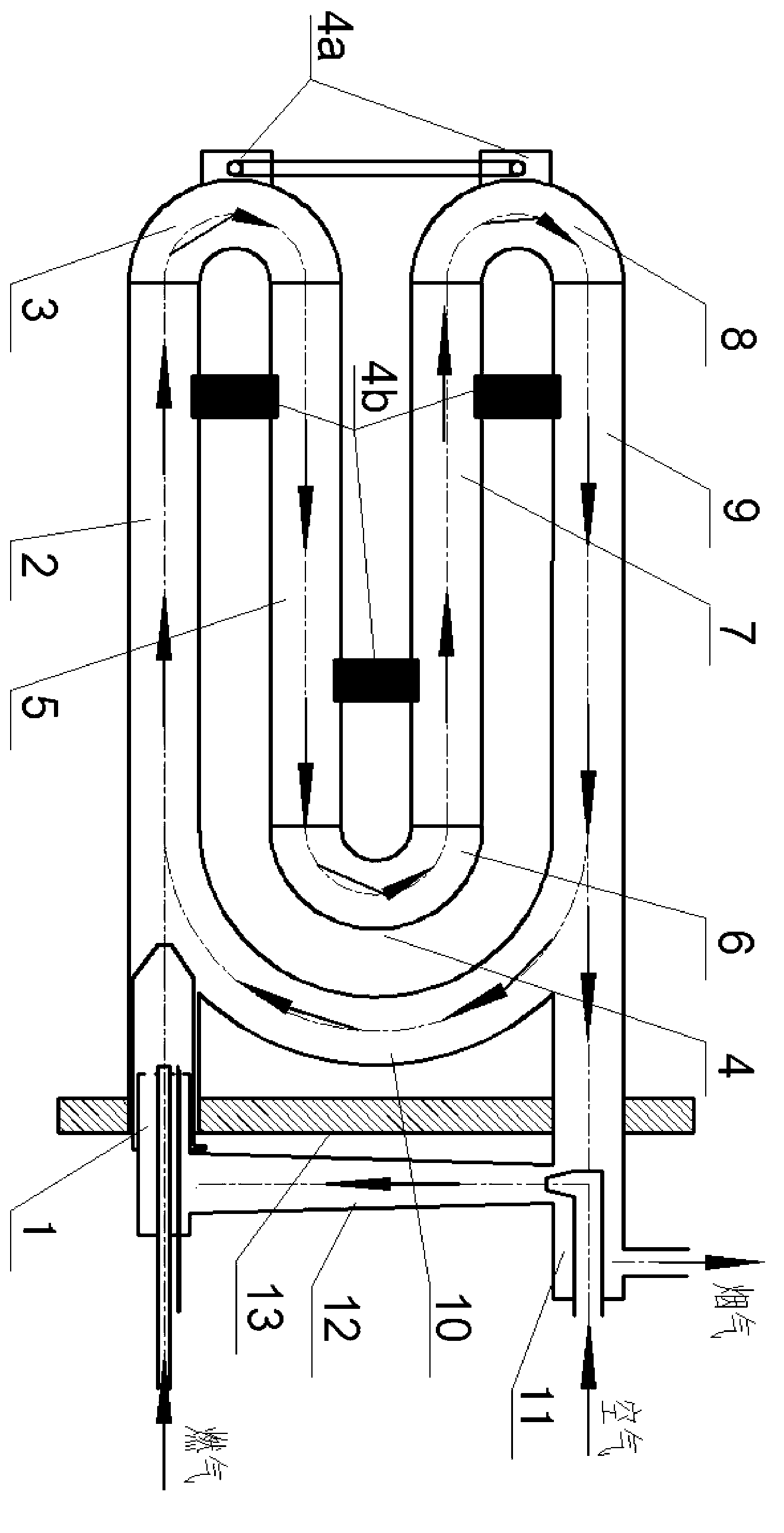

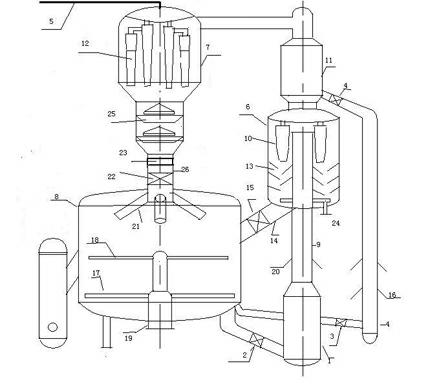

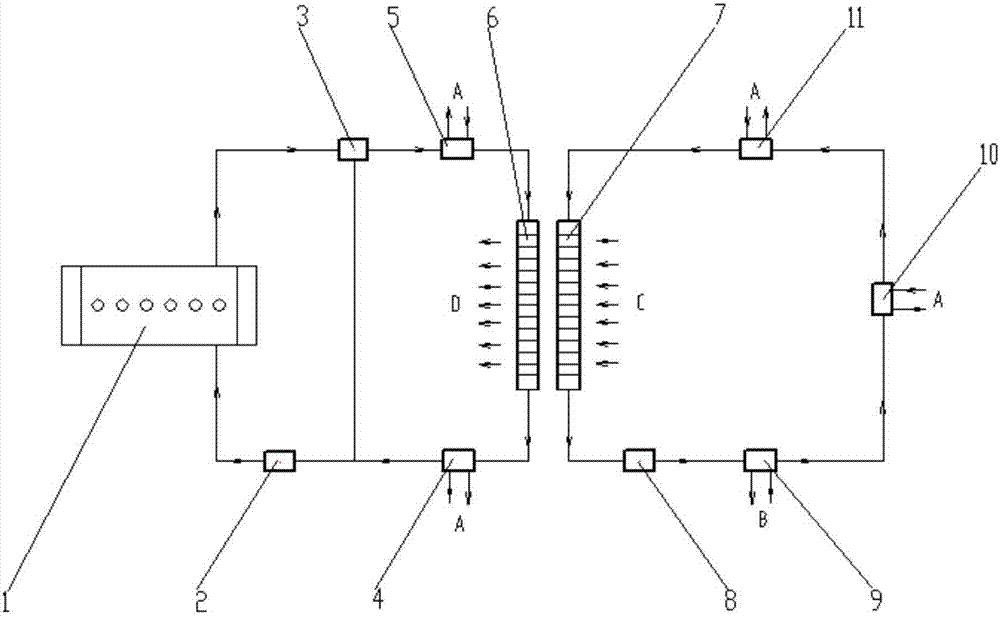

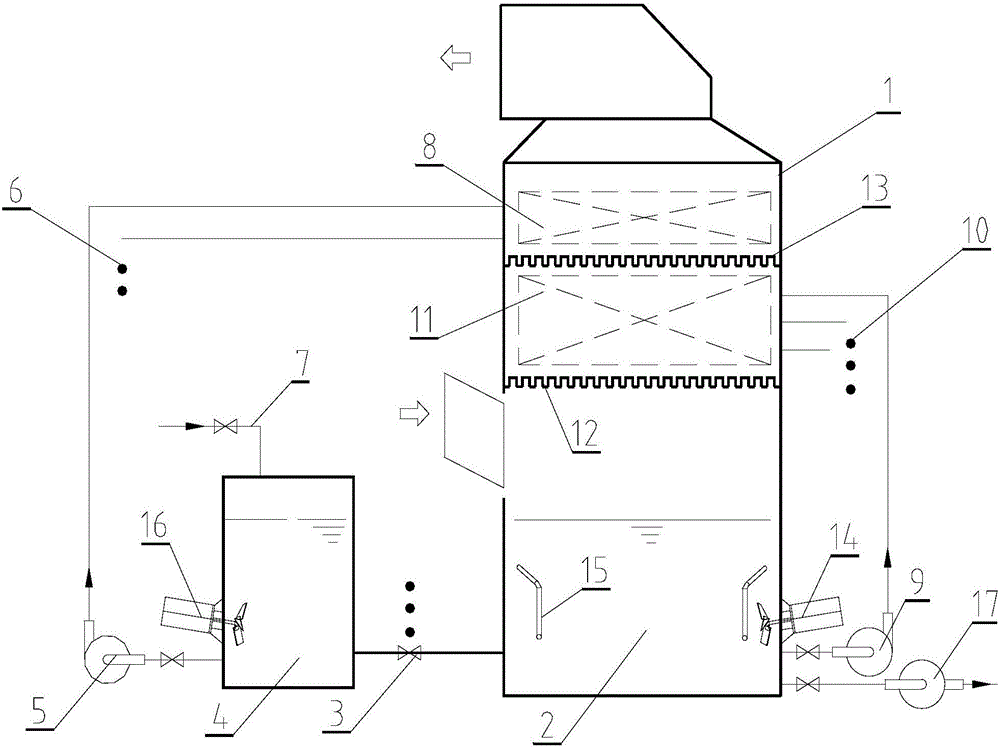

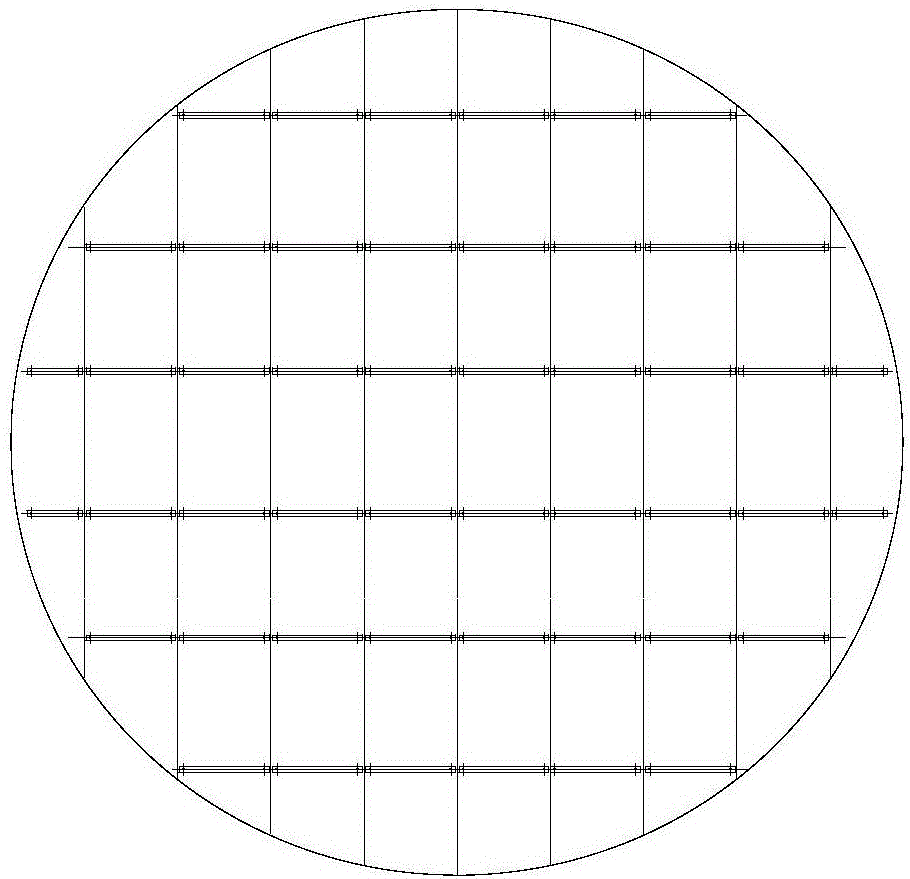

Ecological energy-saving level dual-cycle water treatment system for industrialized fish culture

InactiveCN1806537AIncrease productionImprove qualityPisciculture and aquariaEnergy based wastewater treatmentConstructed wetlandBiological filter

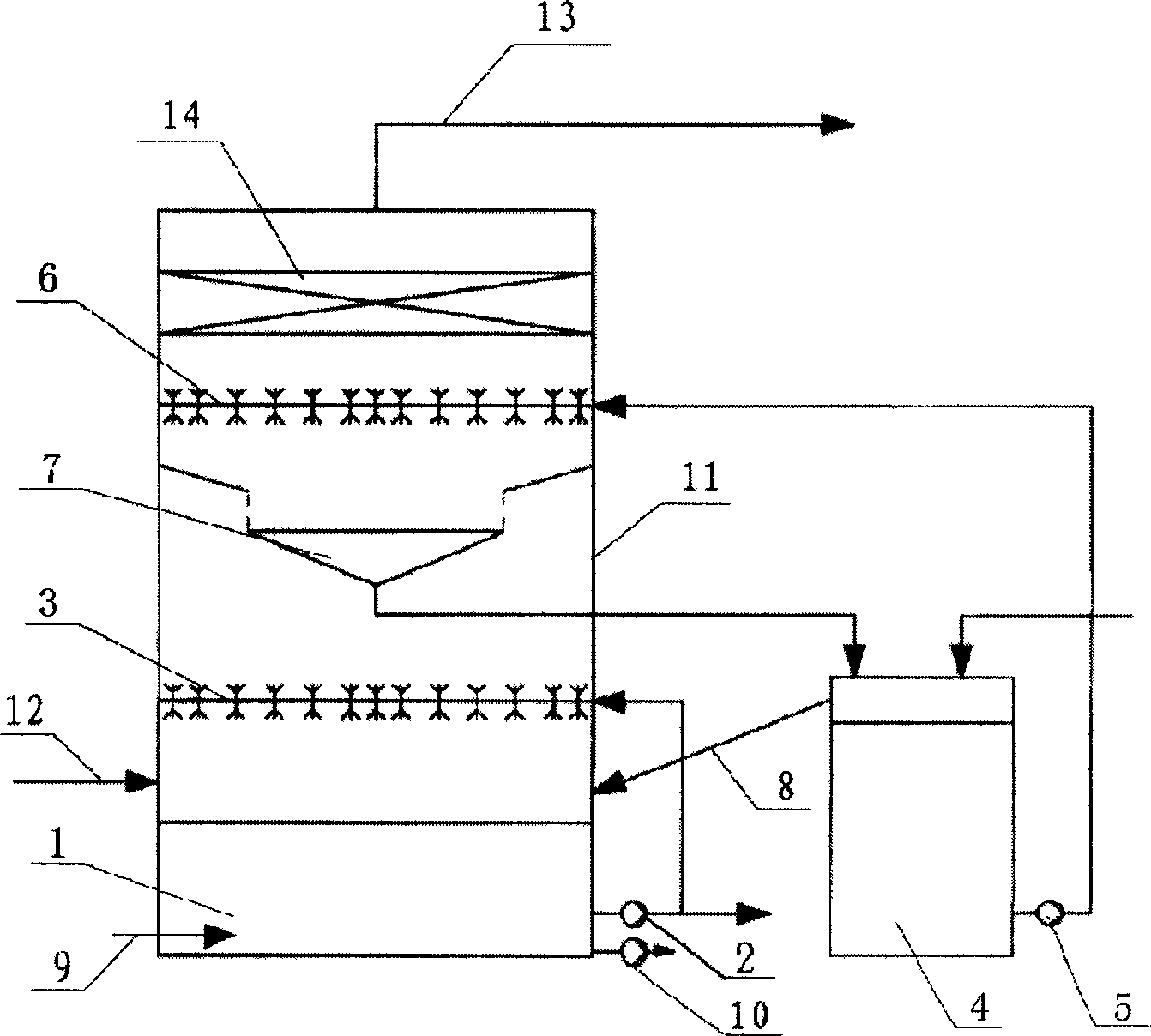

The invention belongs to protective fishery field, which in detail relates to two-cycle water treating system for industrialized fish culturing, with main characteristics being: internal recycle pool structure of various shape taking square outside and round inside as representation, cultivating fish in circular pool, the quadrangle outside pool is biological filter; water and pollution discharging pipe are equipped in bottom of pool; the mating outside circular system comprises drainage ditch, out biological filter and artificial wet land, feed ditch, pollution collecting tank; special air raising pump of U shape, high effective aeration, water raising cycle; the artificial wet land and out biological filter are combined together, depositing, filtering, adsorption, bacteria degradation, adsorption by aquatic plant and animal and cleaning water body high effectively; constructing open water inlet and outlet pitch which also used as biological filter by using fish pond to realize omni-bearing restore of cultivating wastewater. The invention is characterized by less equipment investment, low energy consumption, safe and reliable operation, convenient management and maintenance, outstanding ecological, economical and social benefit, low production cost and increased quantity and quality.

Owner:宜都天峡特种渔业有限公司

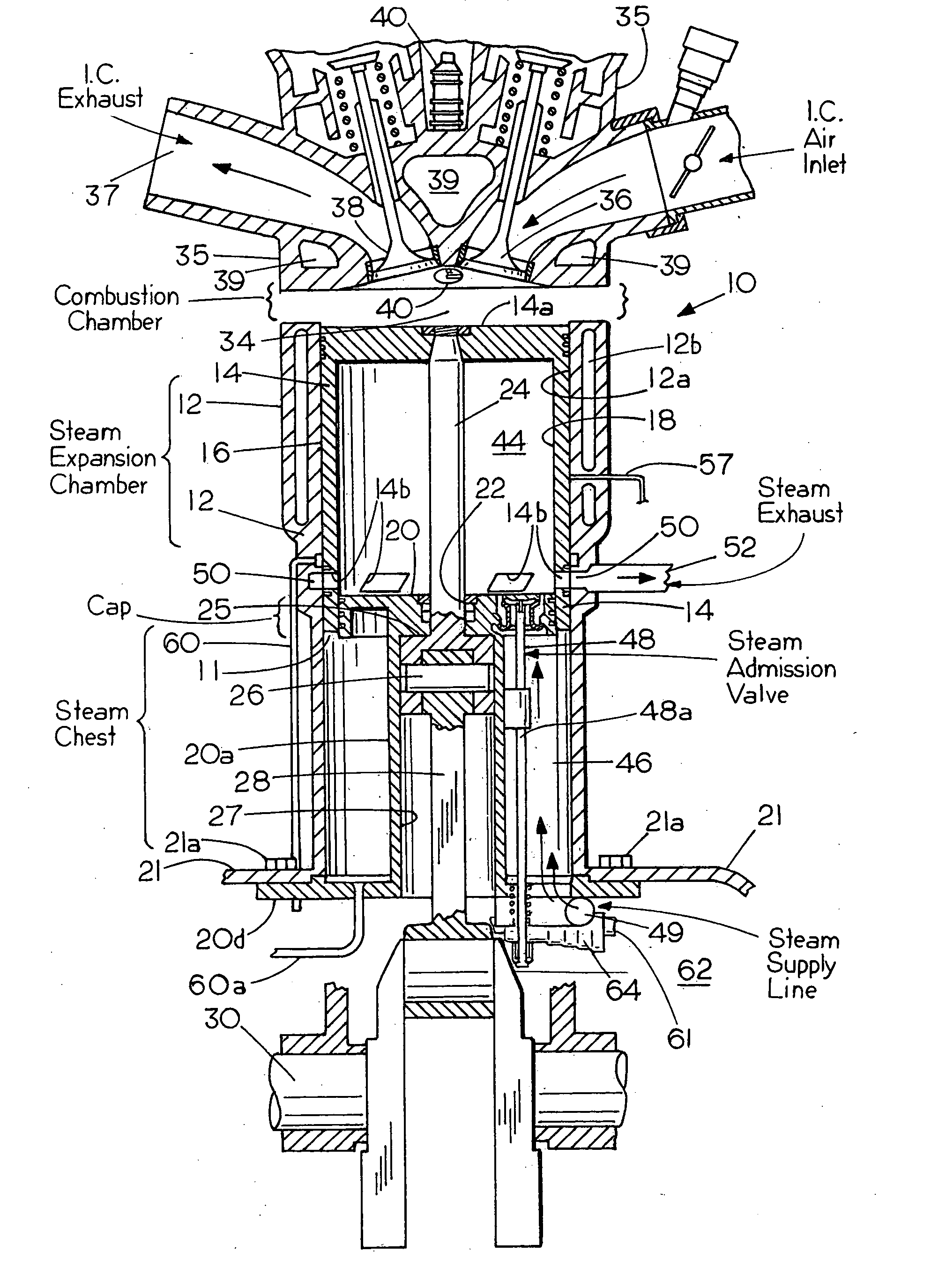

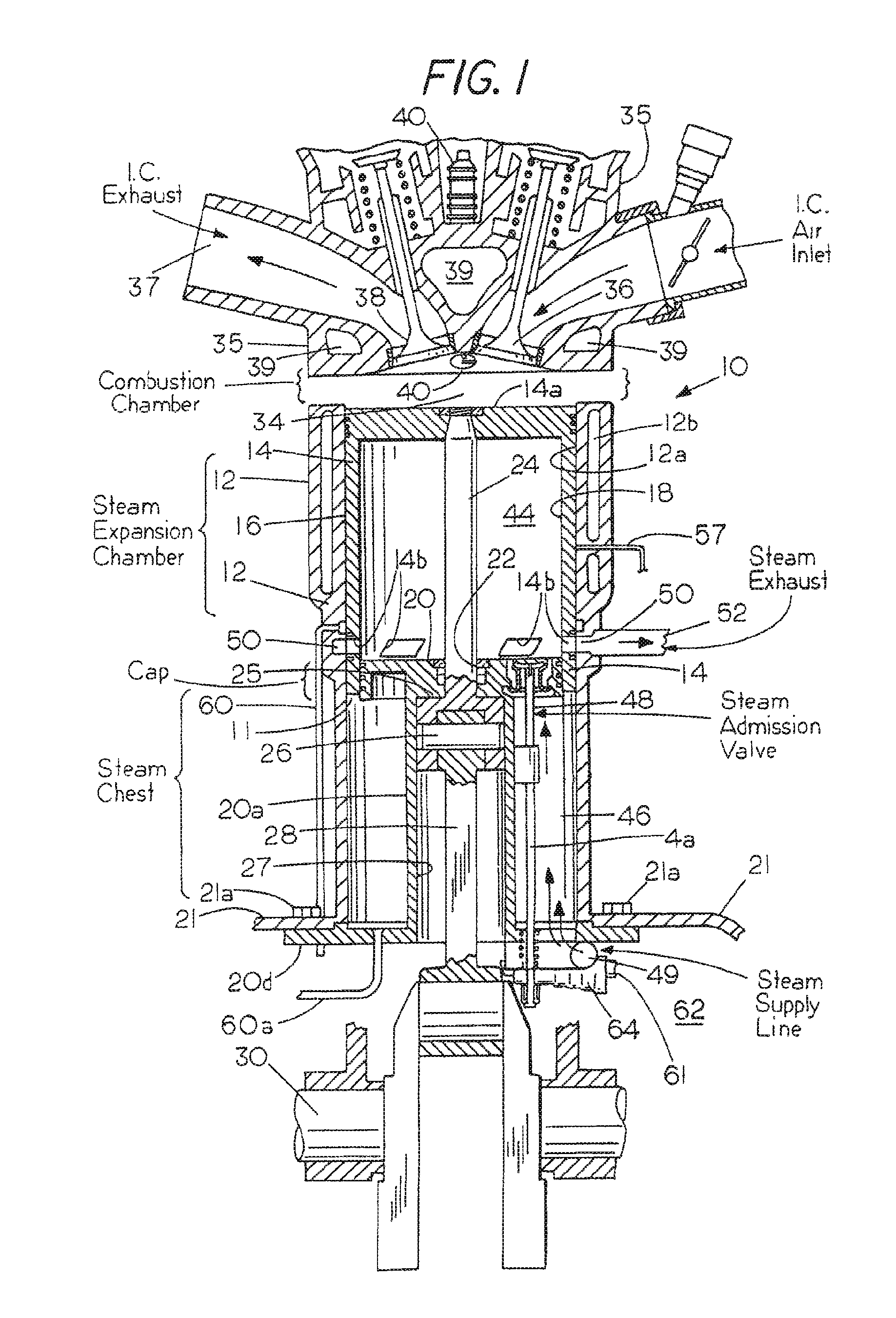

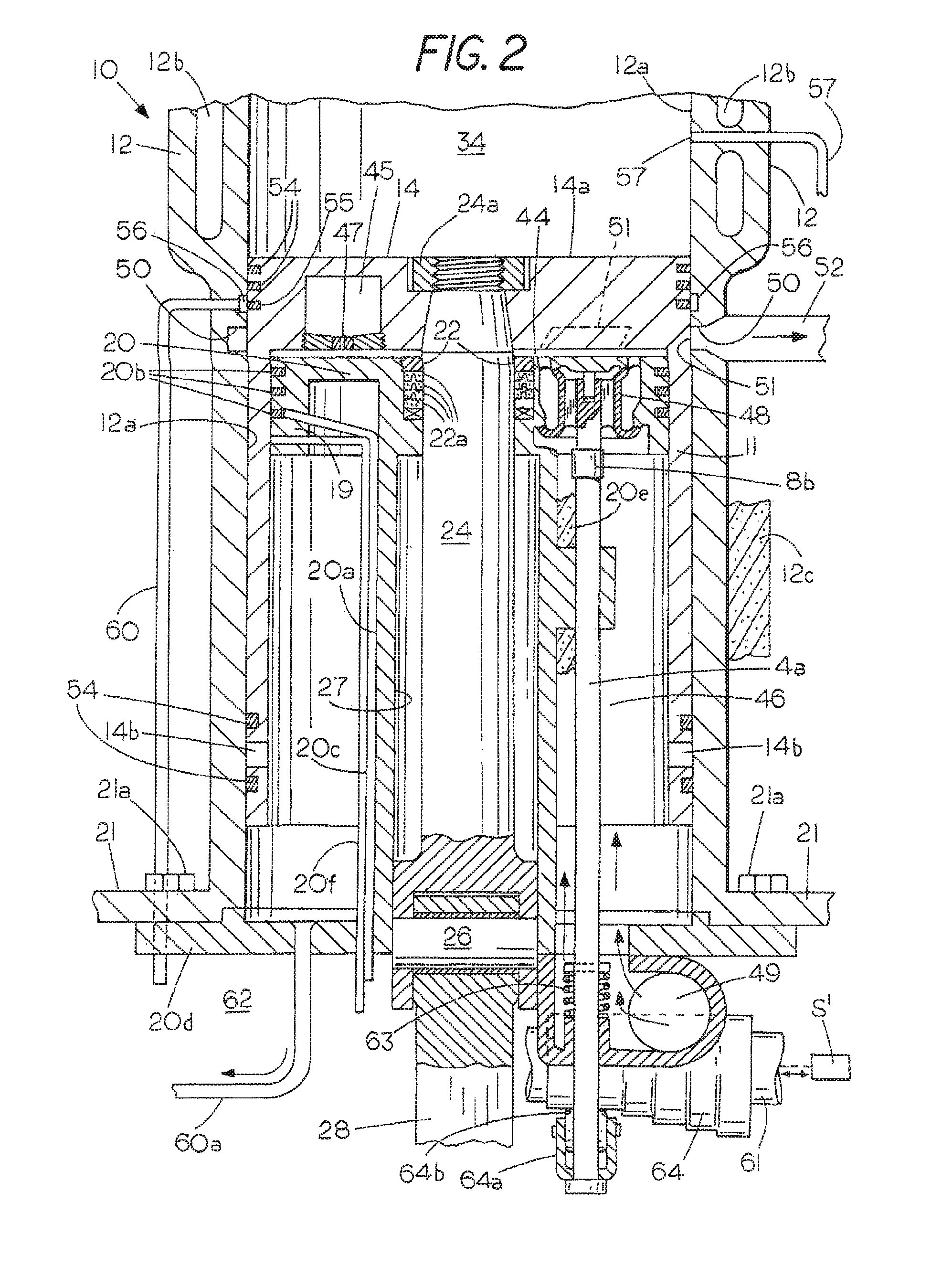

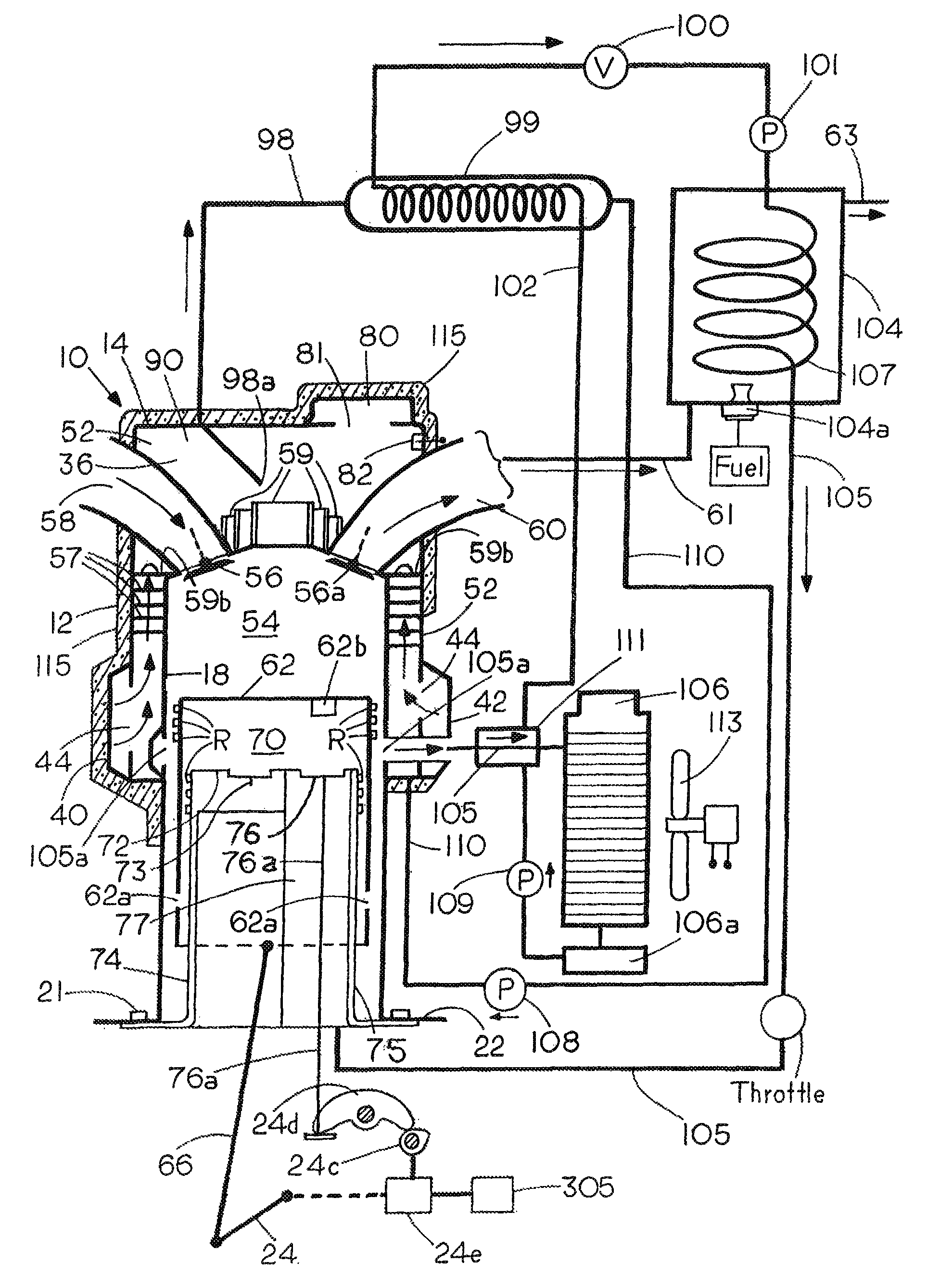

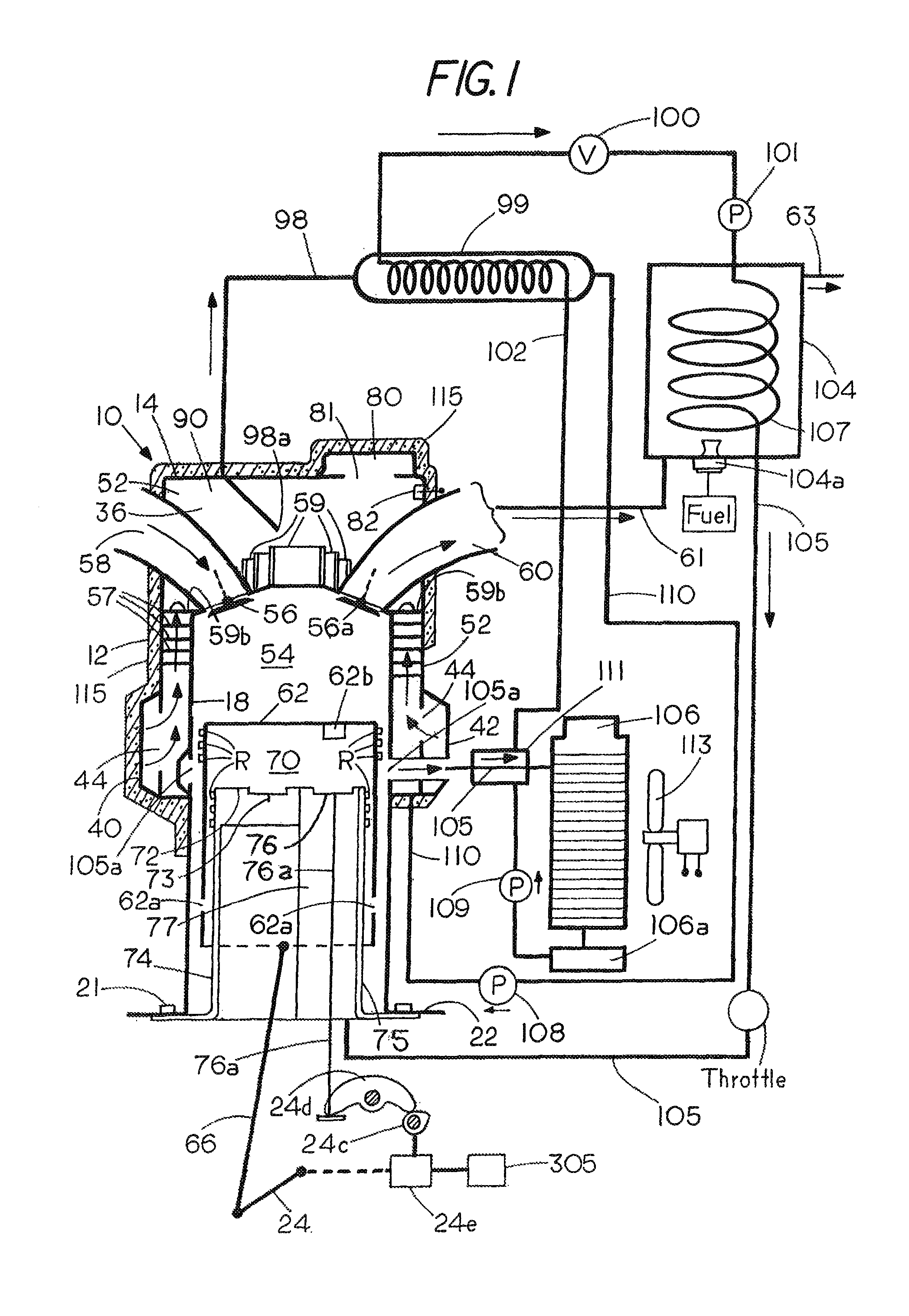

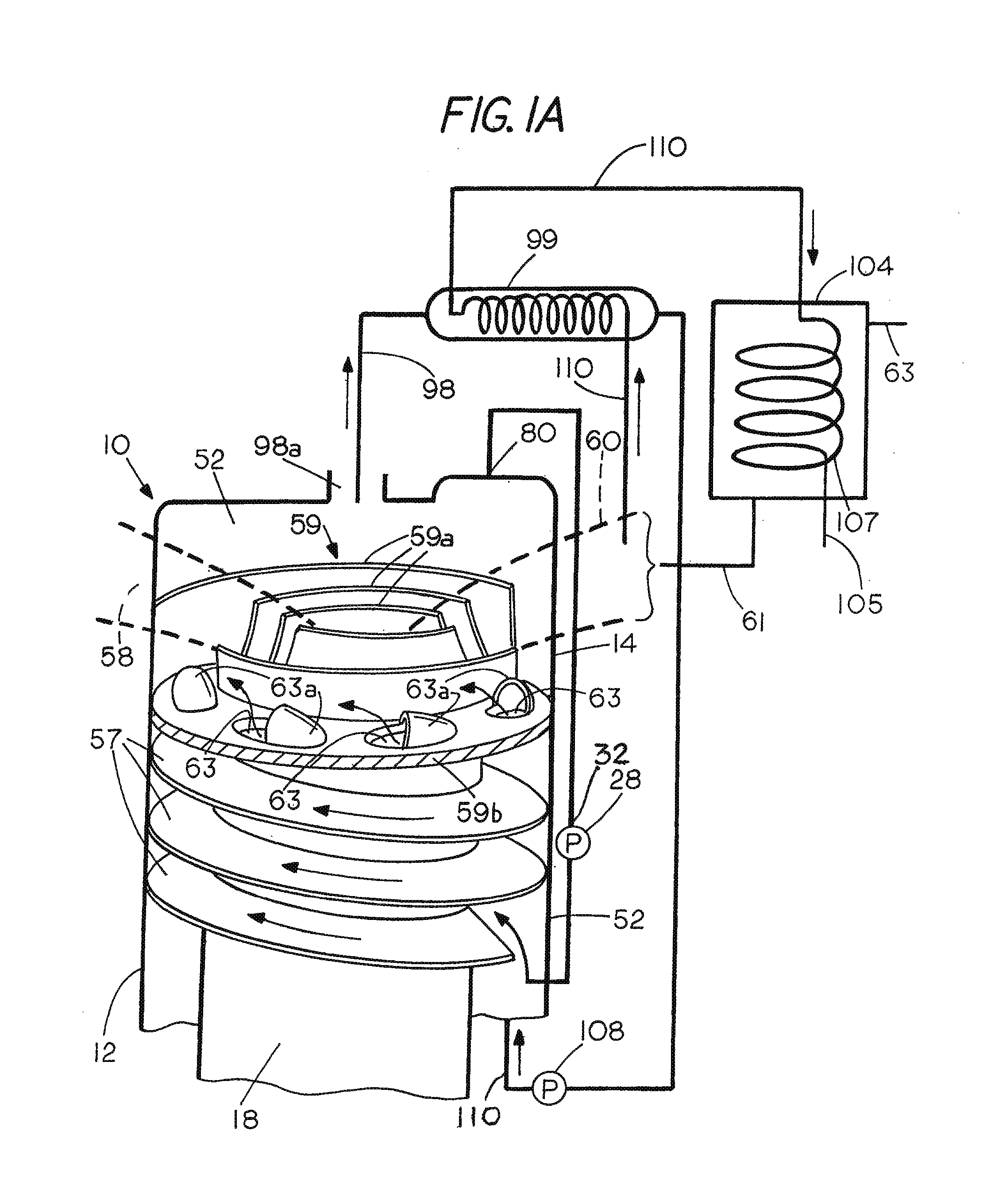

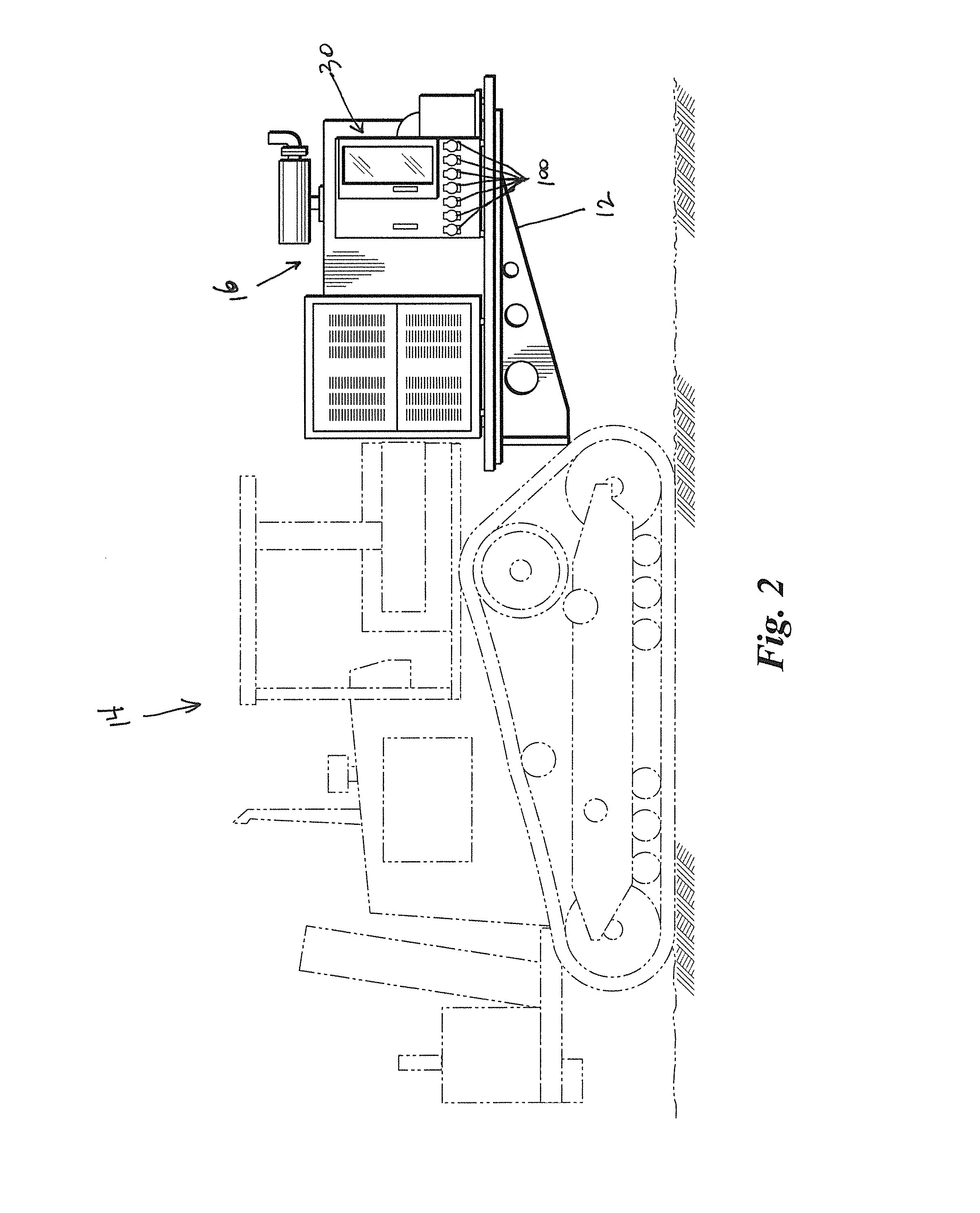

High efficiency dual cycle internal combustion engine with steam power recovered from waste heat

ActiveUS20090205338A1Operation efficiency can be improvedImprove efficiencyInternal combustion piston enginesSteam useCombustion chamberExhaust valve

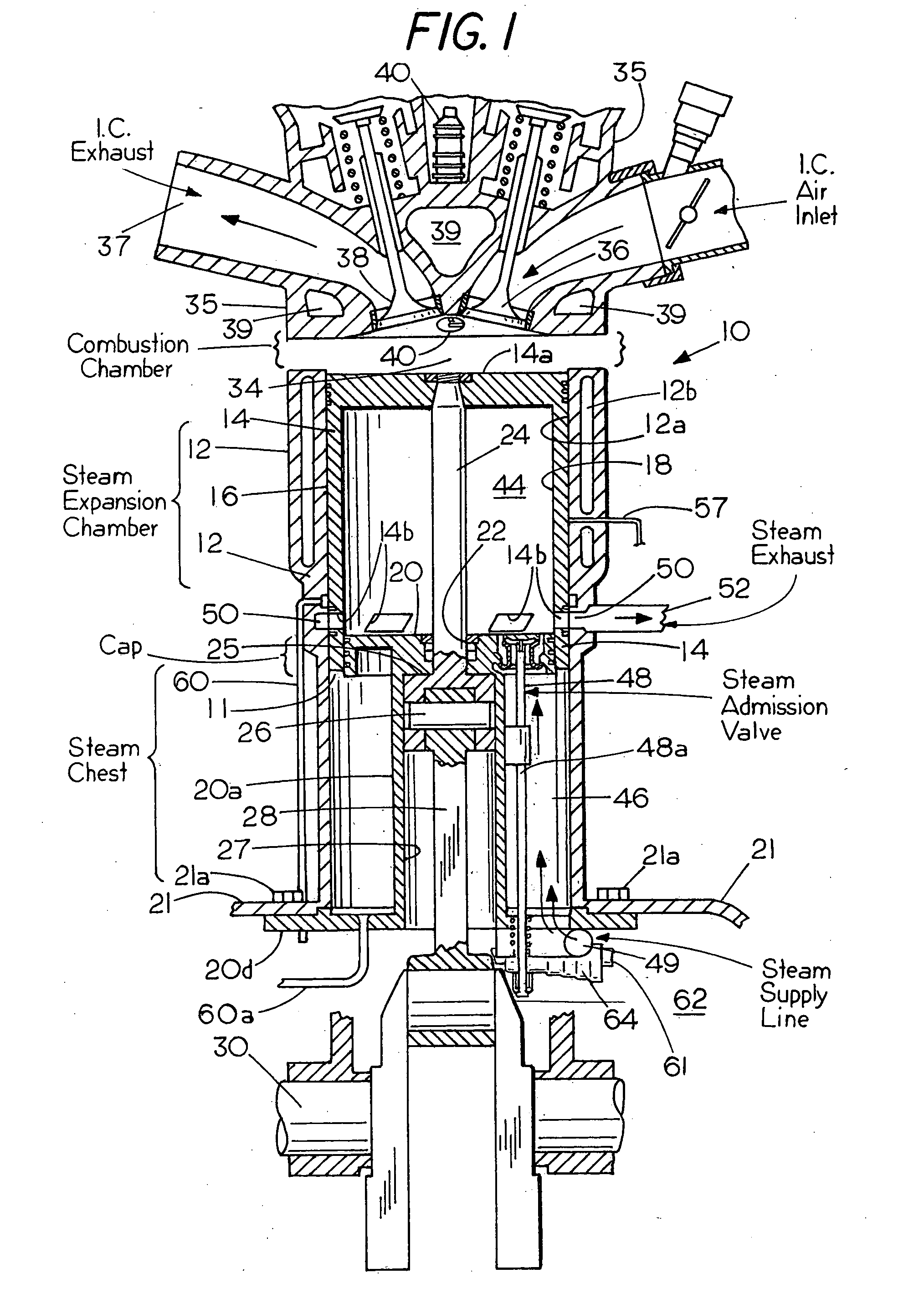

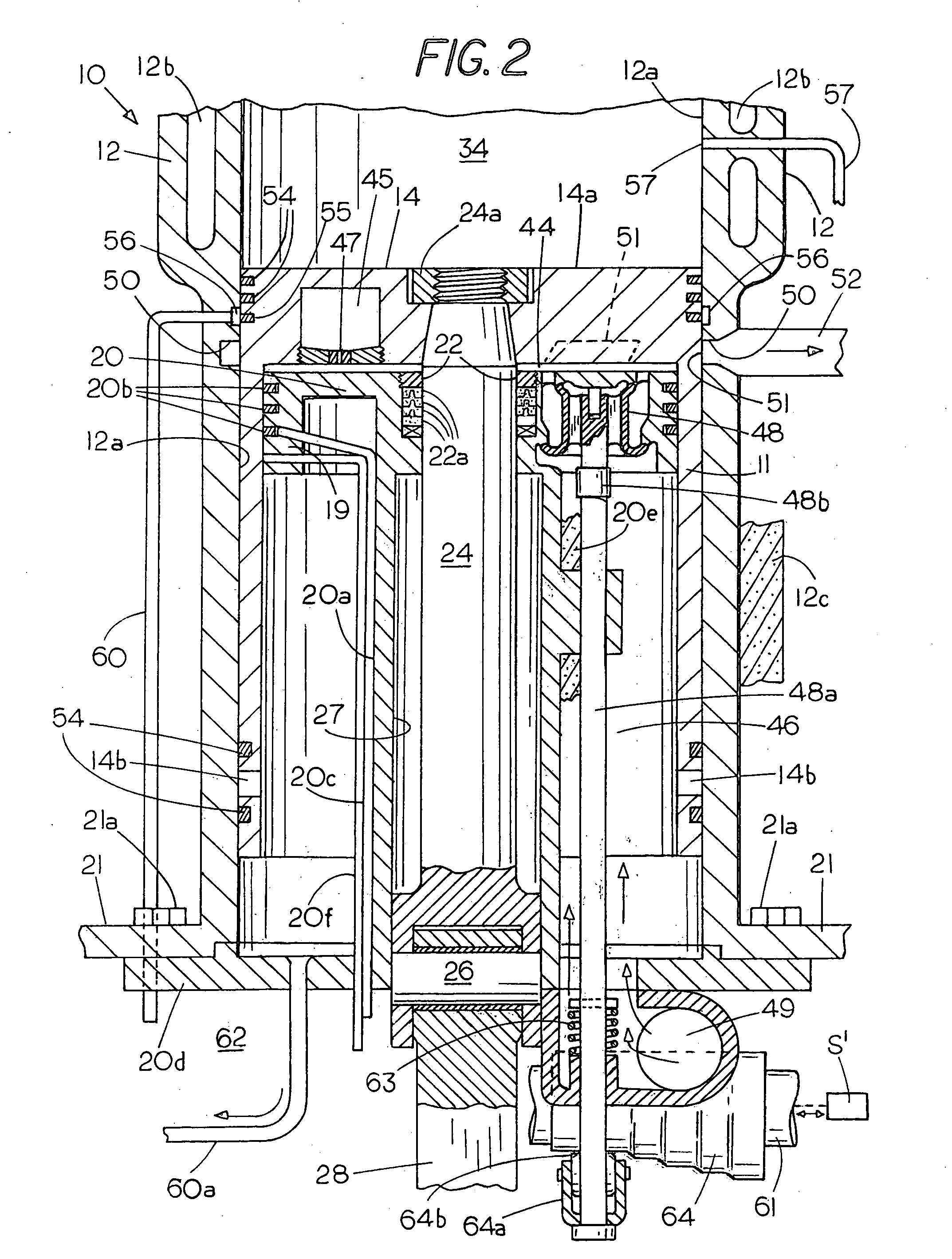

A high efficiency combined cycle internal combustion and steam engine includes a cylinder having a piston mounted for reciprocation therein with an internal combustion chamber outward of the piston, a fixed cylinder cap sealingly and slideably mounted within the piston and a steam expansion / recompression chamber inside the piston adjacent the cylinder cap. The cylinder cap can be unheated or heated externally to reduce condensation of steam entering the steam chamber from a steam generator fired by waste combustion heat. Steam remaining in the cylinder when a steam exhaust valve closes at the top center position is recompressed during an inward stroke of the piston up to admission pressure prior to admitting the next charge of steam. One valve or a pair of retractable steam inlet valves connected in series within the cylinder cap act in cooperation with steam recompression and clearance volume to achieve an effective zero steam chamber clearance and a gain in mean Rankine cycle temperature to maximize efficiency. The amount of steam admitted each outward stroke is continuously regulated, e.g. by shifting the phase of one steam admission valve of a pair to vary their overlap for determining the steam mass admitted during each cycle to reduce specific fuel consumption. Other valves balance steam displacement with the steam generator output to use steam more efficiently. Engine coolant can be evaporated in a combustion chamber cooling jacket to form steam which is then superheated in a combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

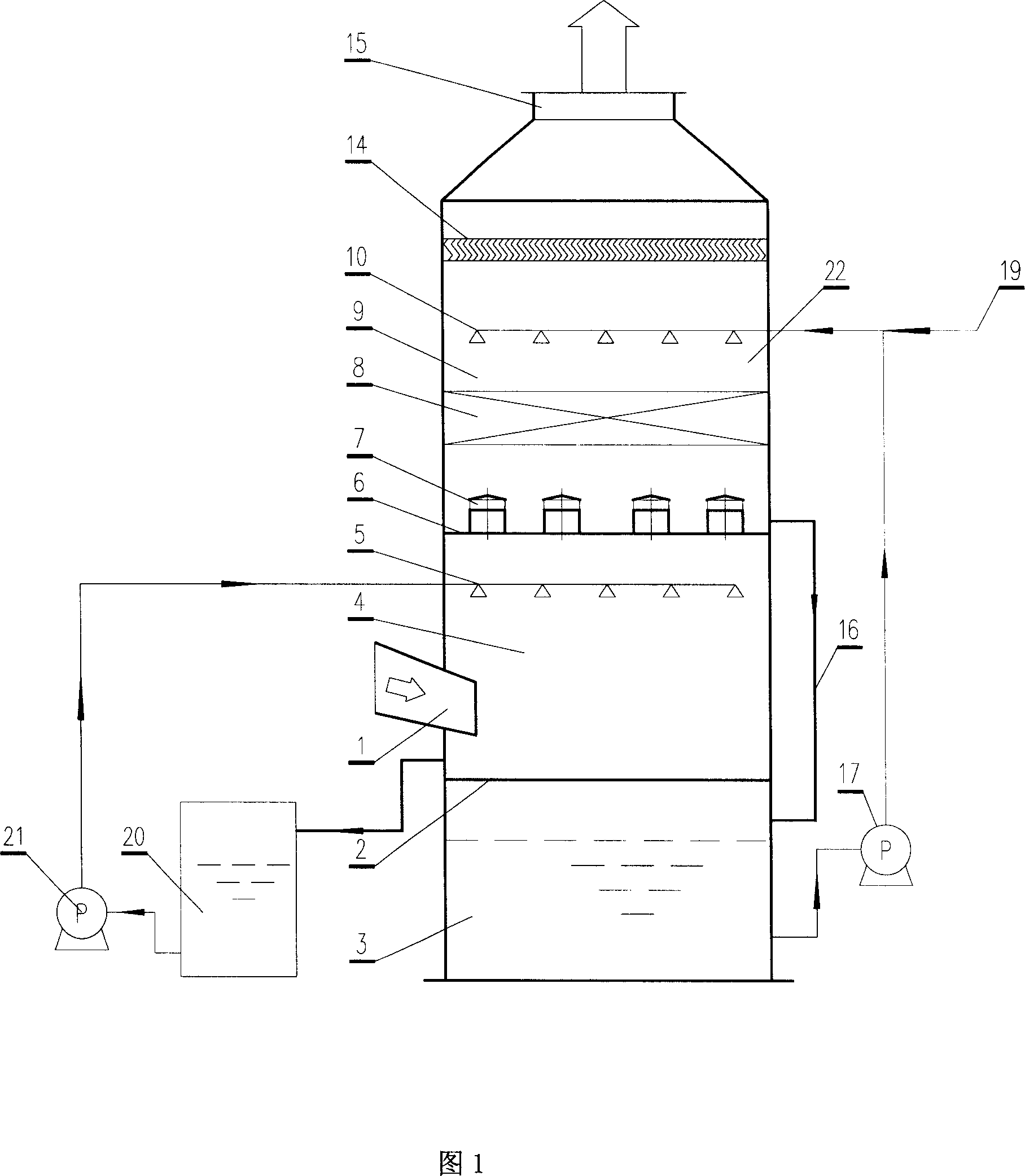

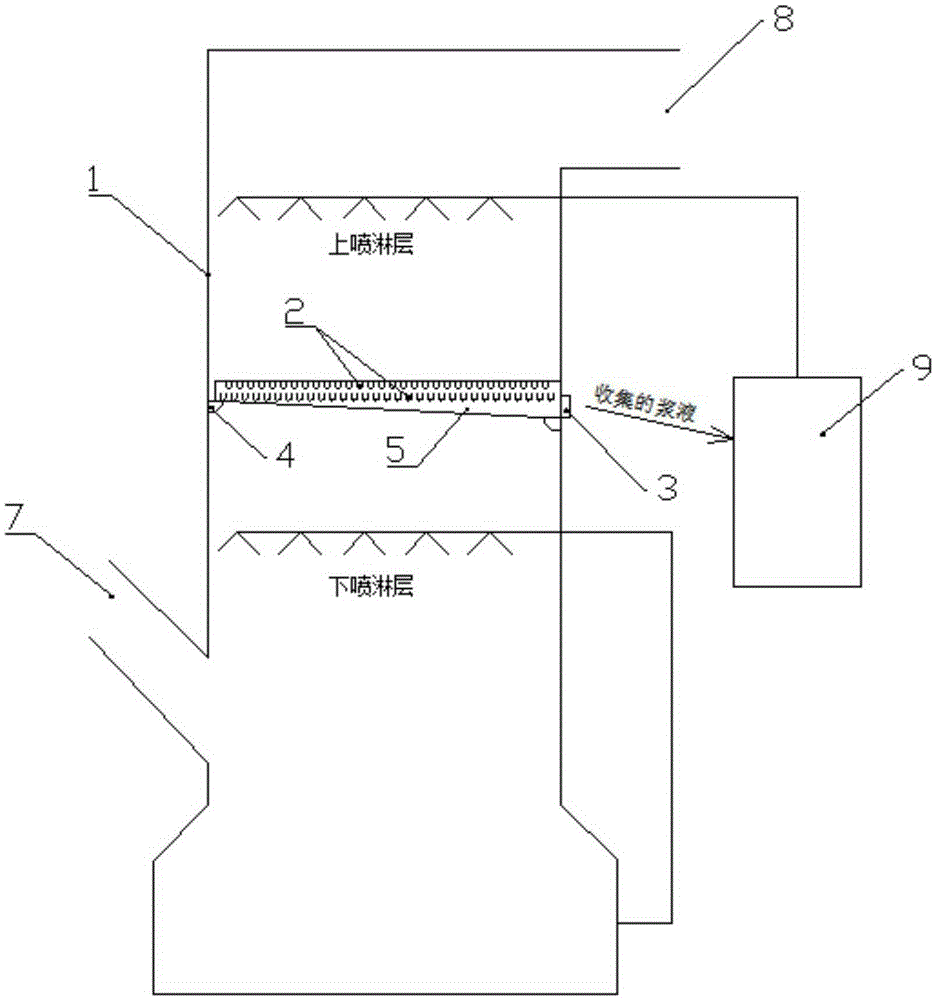

Process for flue gas desulfurization by limestone/lime-gypsum wet method and double circulation loop

InactiveCN1843571AImprove qualitySolve the problem of desulfurizationDispersed particle separationLow demandSlurry

The invention relates to a dual-cycle circuit limestone / lime-gesso wet smoke desulfuration method. It uses dual-circuit adsorption tower spray system while each system has independent spray layer, slurry cycle pump and slurry collector and two slurry collector are connected via connecting tubes. Said dual-circuit adsorption tower spray system are operated in different pH, while the pH of upper circuit is between 5.5-6.8 and the pH of lower circuit is between 4-5. The invention has strong adaptability to the change of coal kinds and the change of boiler load, with lower demand for limestone slurry preparing system. It can confirm the desulfuration efficiency without adding spray layer and increasing the height of adsorption height, and it can effectively reduce the cost. The invention especially apply the purification of the smoke whose sulfur content is above than 3.5% while the desulfuration efficiency is higher than 97%.

Owner:GUODIAN TECH & ENVIRONMENT GRP

Dried type outside and inside dual circulation fluidized bed desulfurizing device and desulfurizing method thereof

InactiveCN101053762ASimple structureSmall footprintDispersed particle separationCycloneFluidized bed

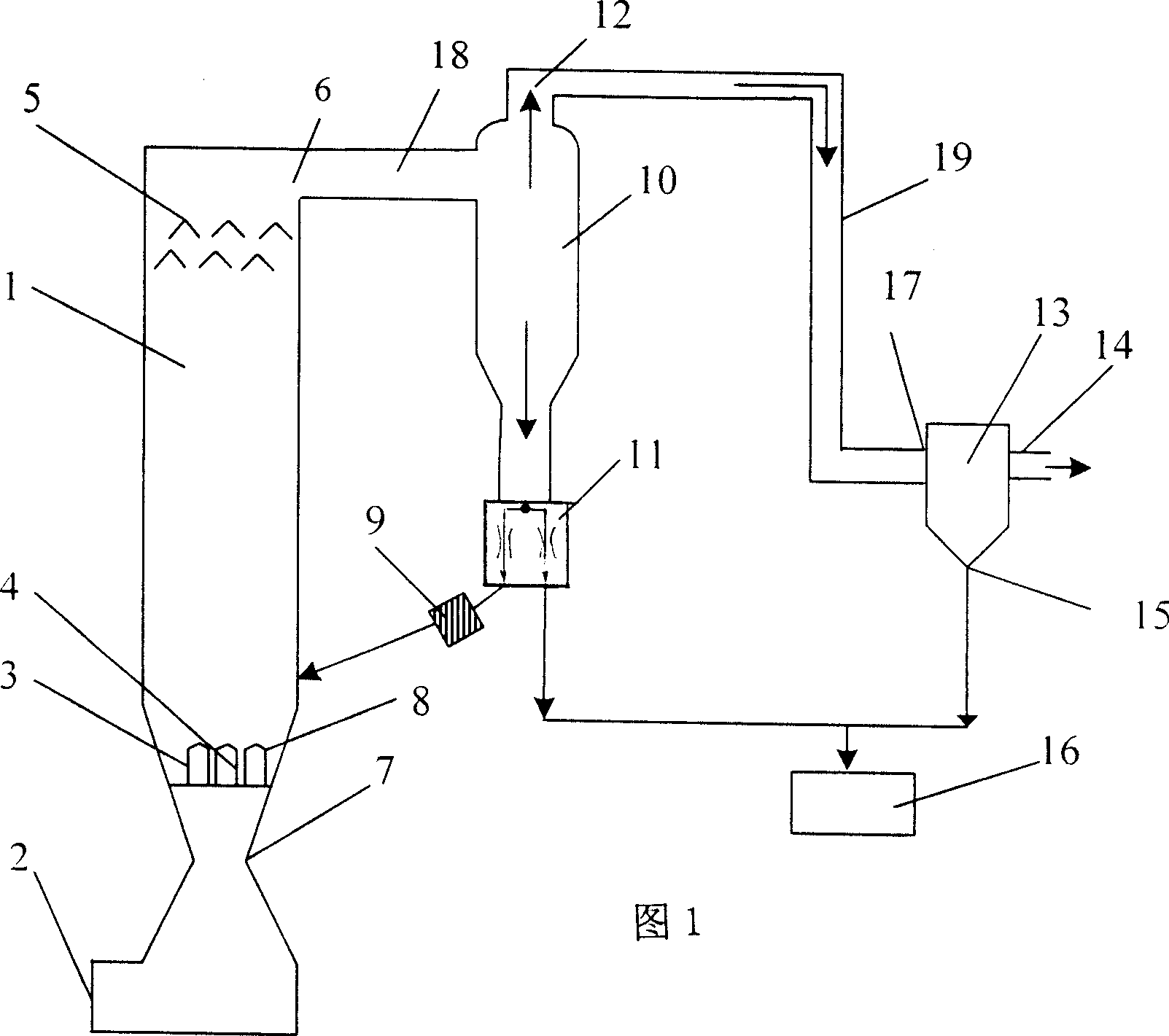

The invention relates to a dry inner-outer dual cycle fluidized bed desulphurization device and a method. The device comprises a flue gas intake mounted at the bottom of the inner cycle fluidized bed reaction tower, a desulfurizer nozzle, a diector nozzle and an air nozzle mounted at the bottom of inner wall; a cyclone is mounted between passing conduit for connecting the flue gas outlet and the dust collector conduit, the solid outlet of the cyclone is connect to a separating tank, of which the outlet on the top is connected to the inlet of the dust collector via the transport conduit, the cleanout door at the bottom of the dust collector is connected to the ash cellar, and the clear gas outlet of the dust collector is connected to the chimney. The flue gas with SO2 enter from the bottom of the thionizer, at the same time, powdery desulfurizer, air and water are sprayed form the bottom of the thionizer respectively, and they moves upwards together in the thionizer, when the SO2 reacts with desulfurizer to deprive the SO2 in the flue gas.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

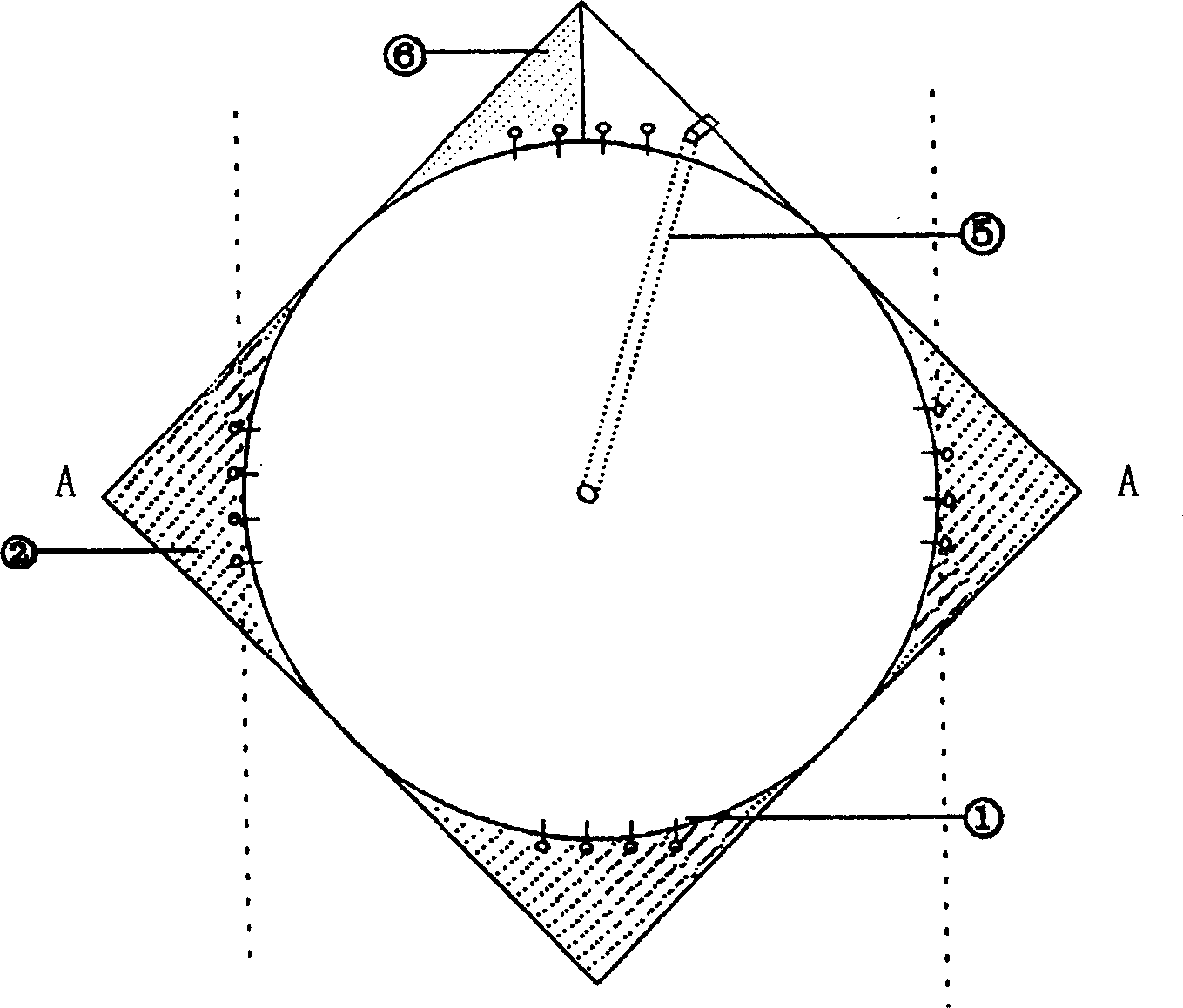

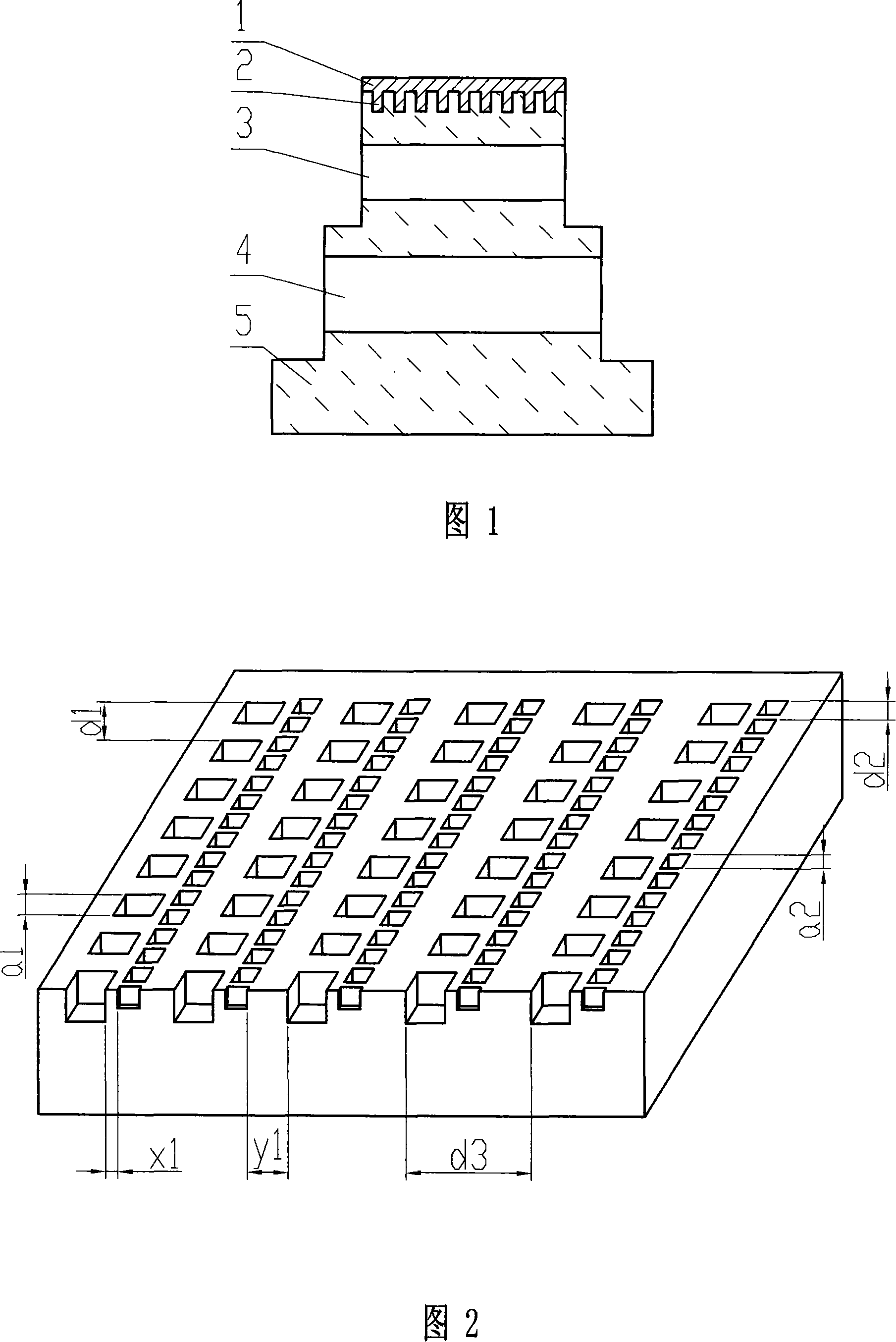

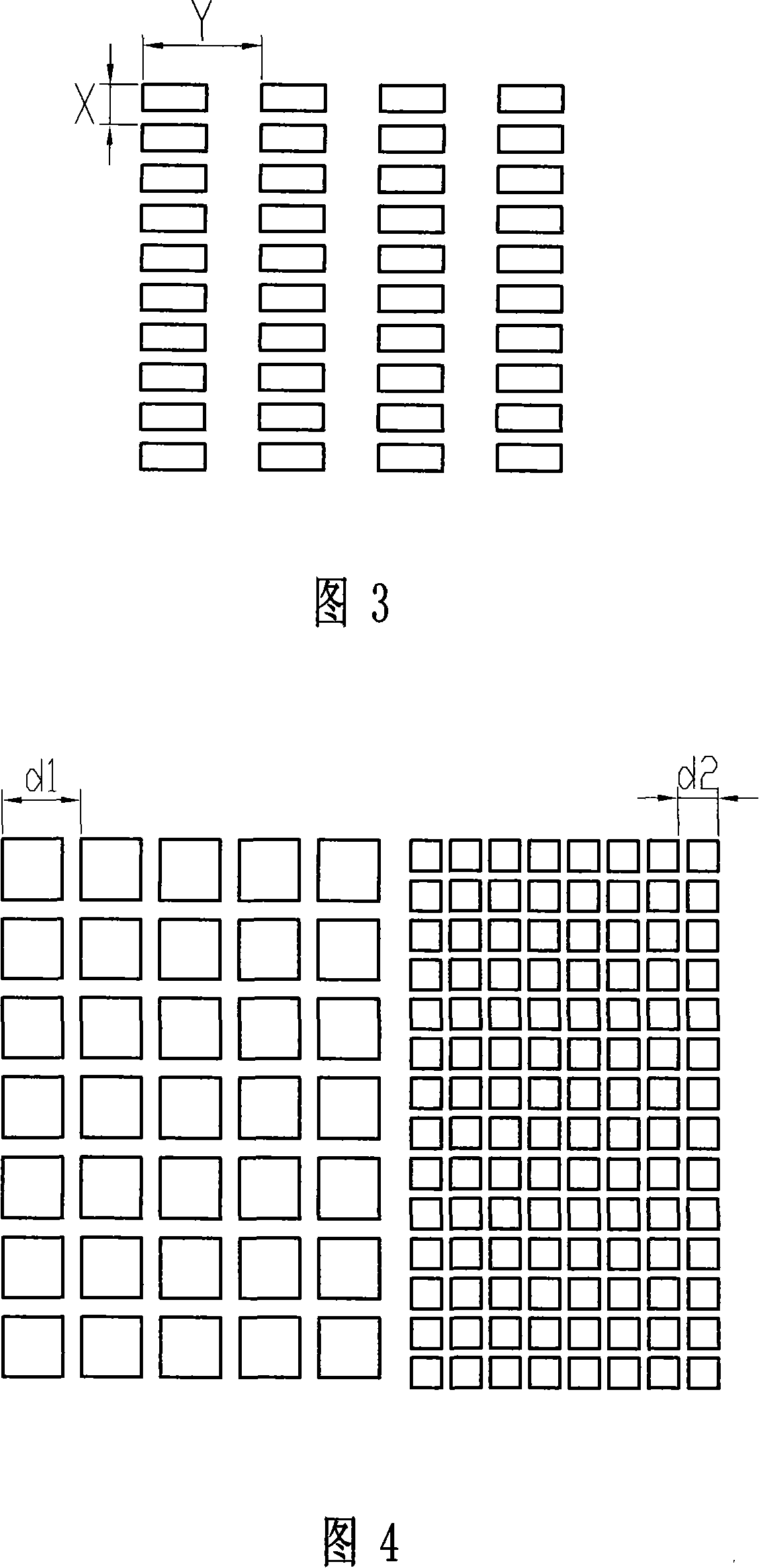

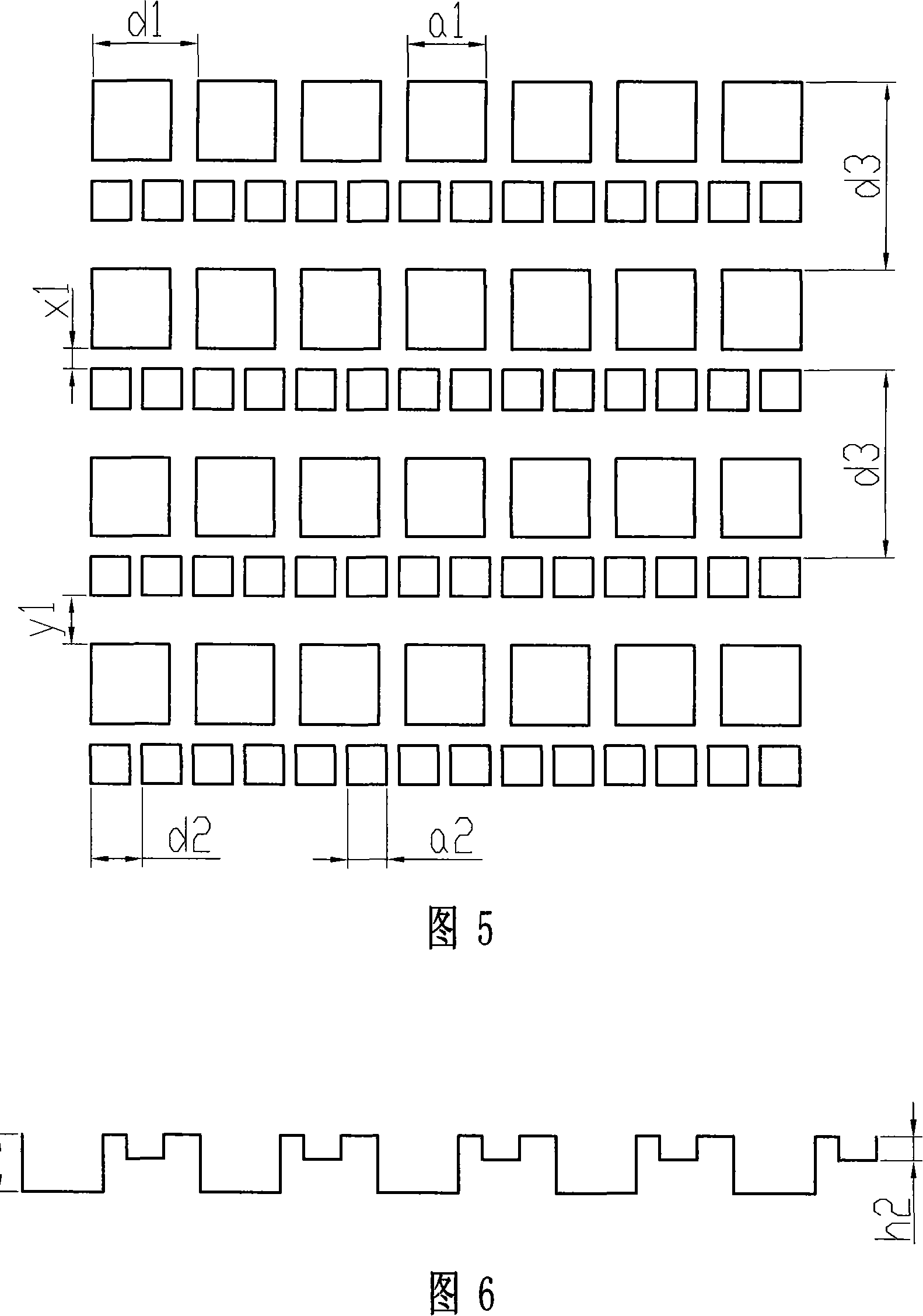

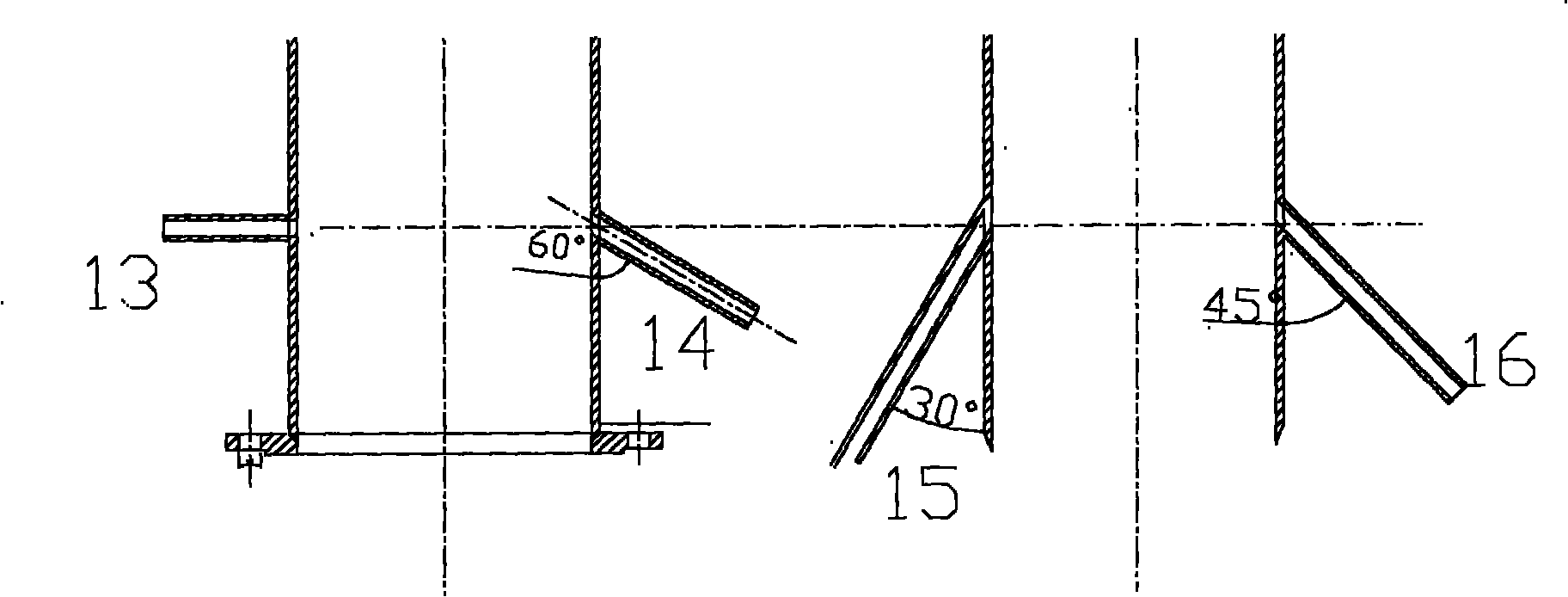

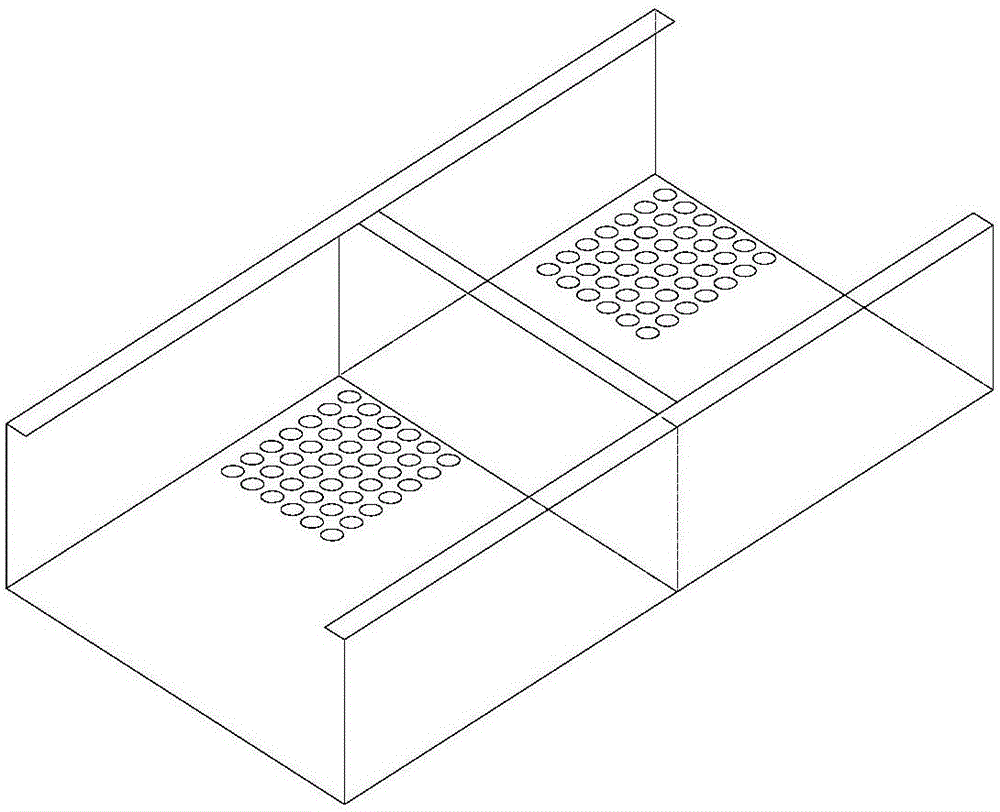

A crossed combined dual cycle grating for quanta trap infrared detector

ActiveCN101106164AImprove response rateImprove the detection rateFinal product manufacturePhotomechanical apparatusGratingDual cycle

The invention discloses a crossed combinational dual-period grating for quantum well infrared detector. By arranging two sizes of gates across, the invention responses to two wave bands and acquires the information of the two wave bands. The cross array makes a very good response uniformity of the new-type gates on the whole surface, and the two types of gates are distributed as the Chinese character 'pin', which makes the photolithography linewidth up to the maximum and thereby enhances the precision of photolithography patterns. The square gate hole is used to prevent astigmatism; the optimized parameter design enhances the coupling efficiency of the gates. The invention is applied to dual-color quantum well infrared detectors, is able to acquire the objective information more accurately in two wave bands simultaneously, more effectively inhibits the complicate background, and then enhances the detecting effect of objectives. The invention has the advantages of simple fabrication, low cost, and easy realization of mass and serial production.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

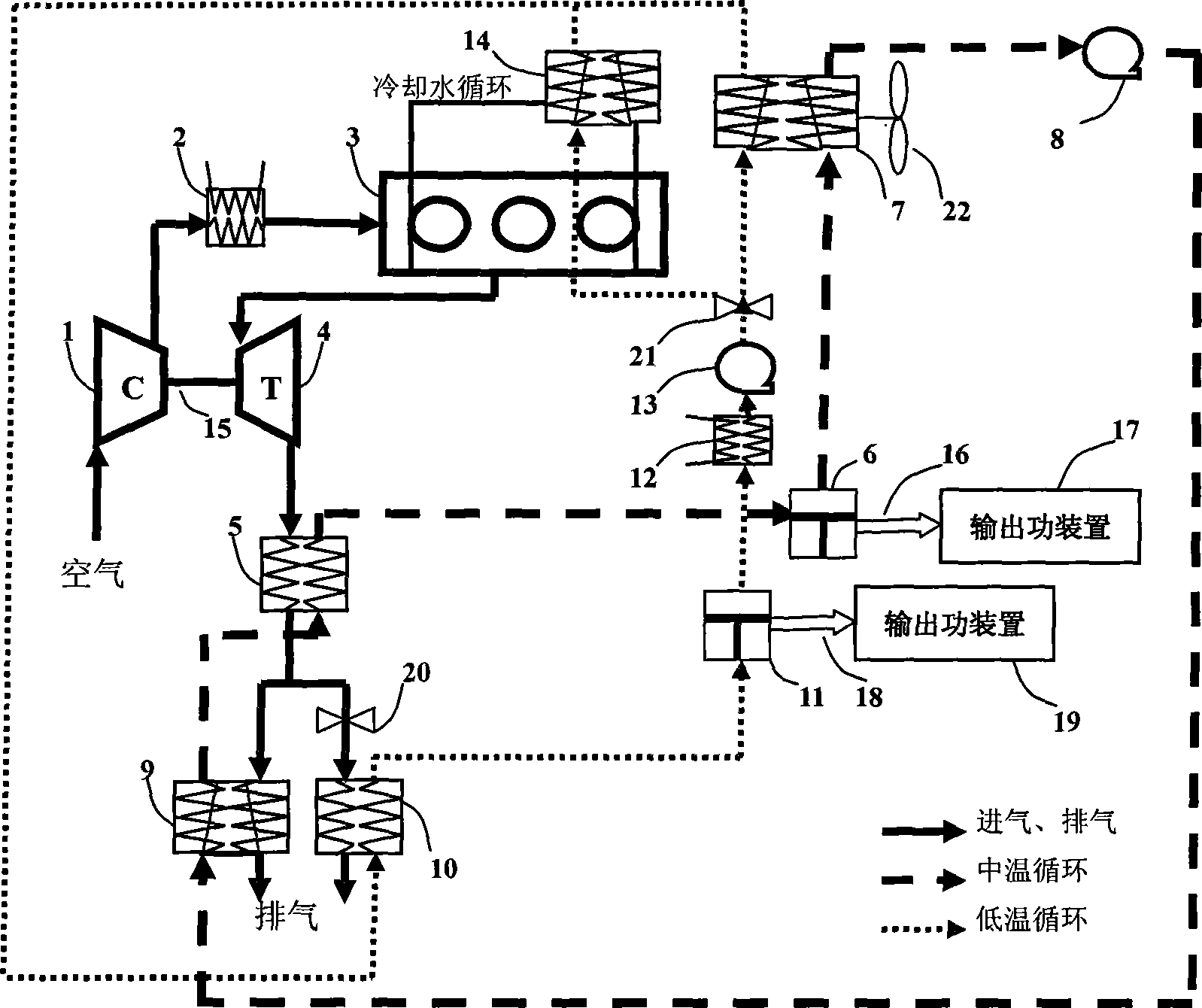

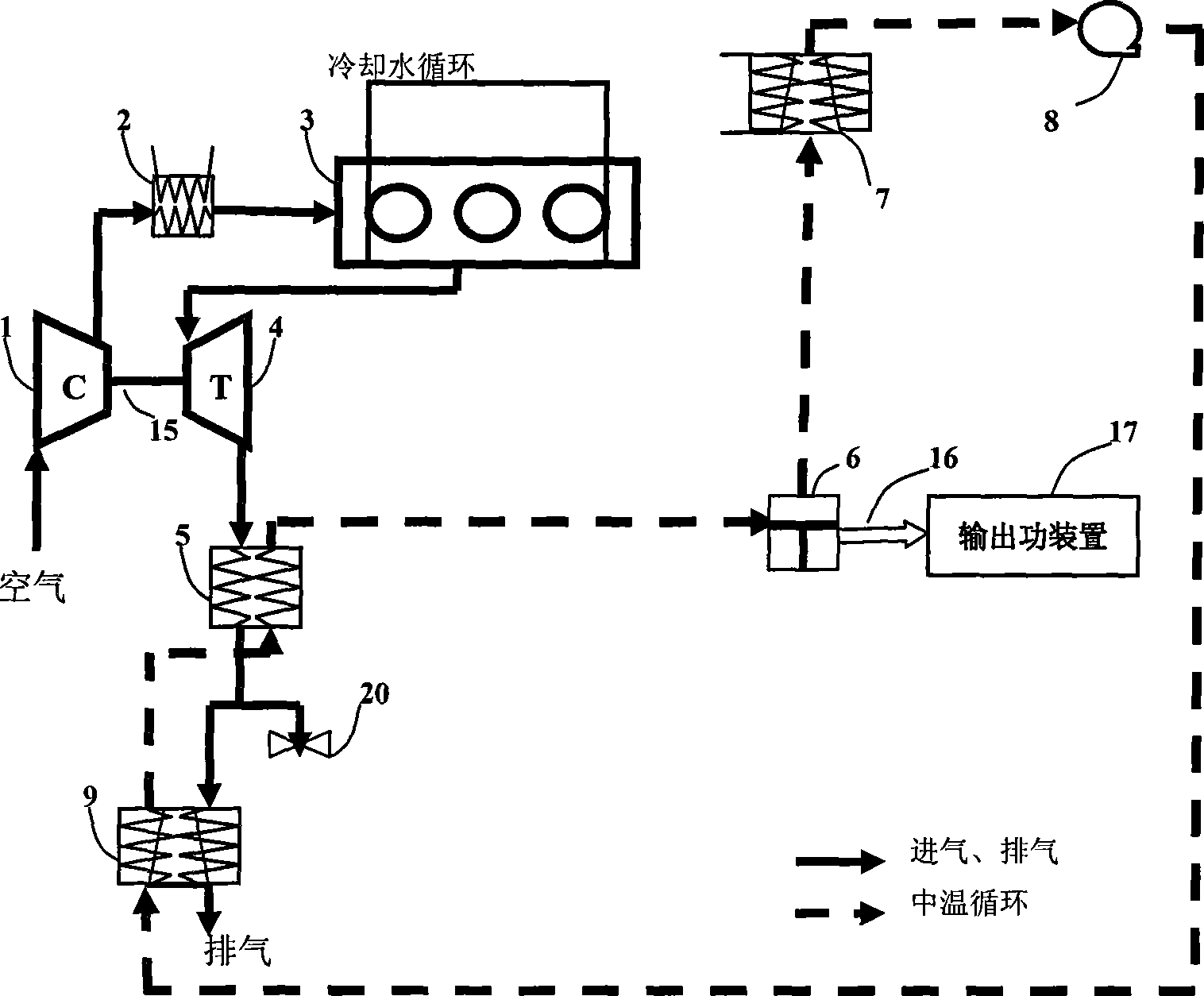

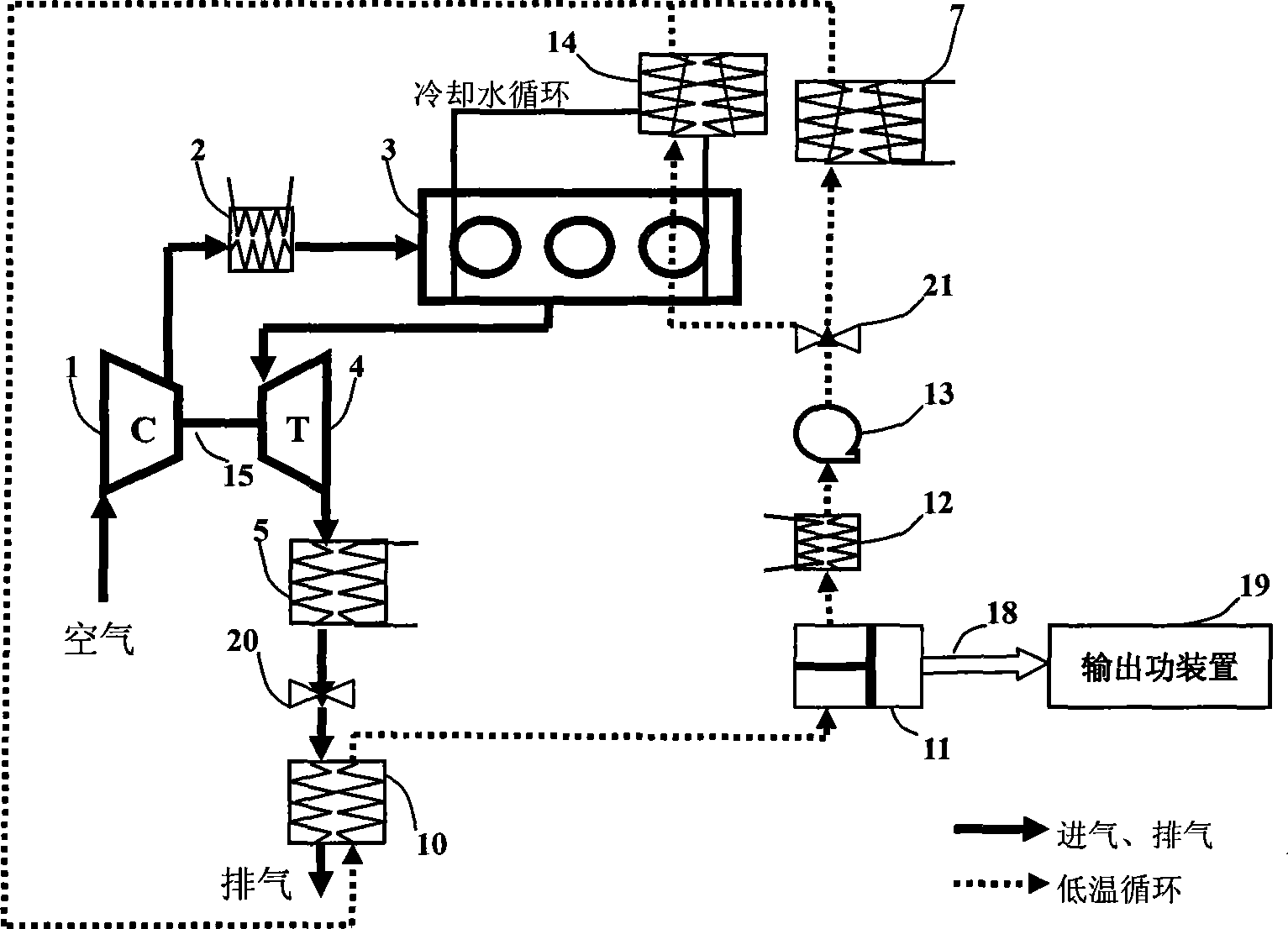

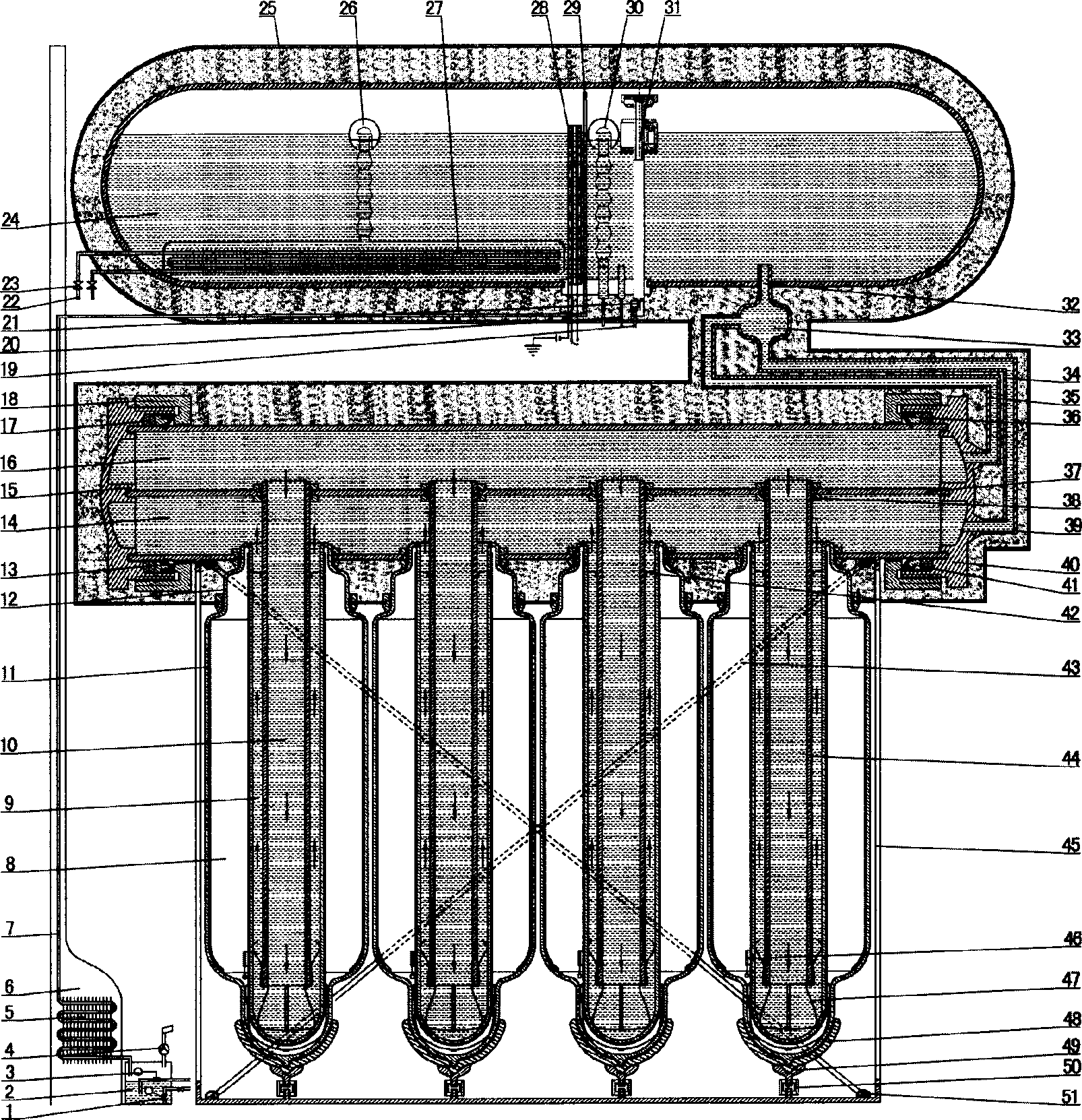

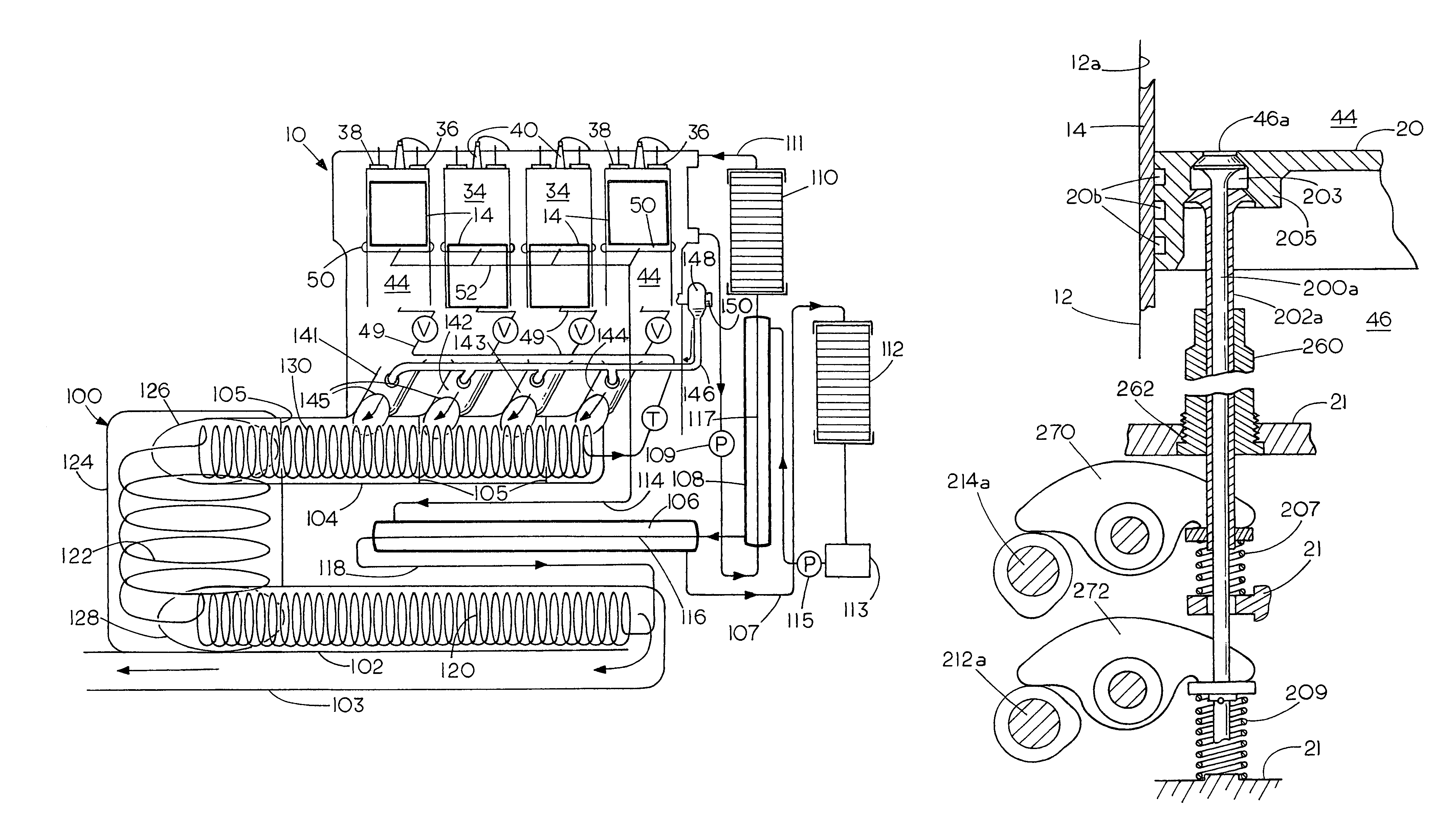

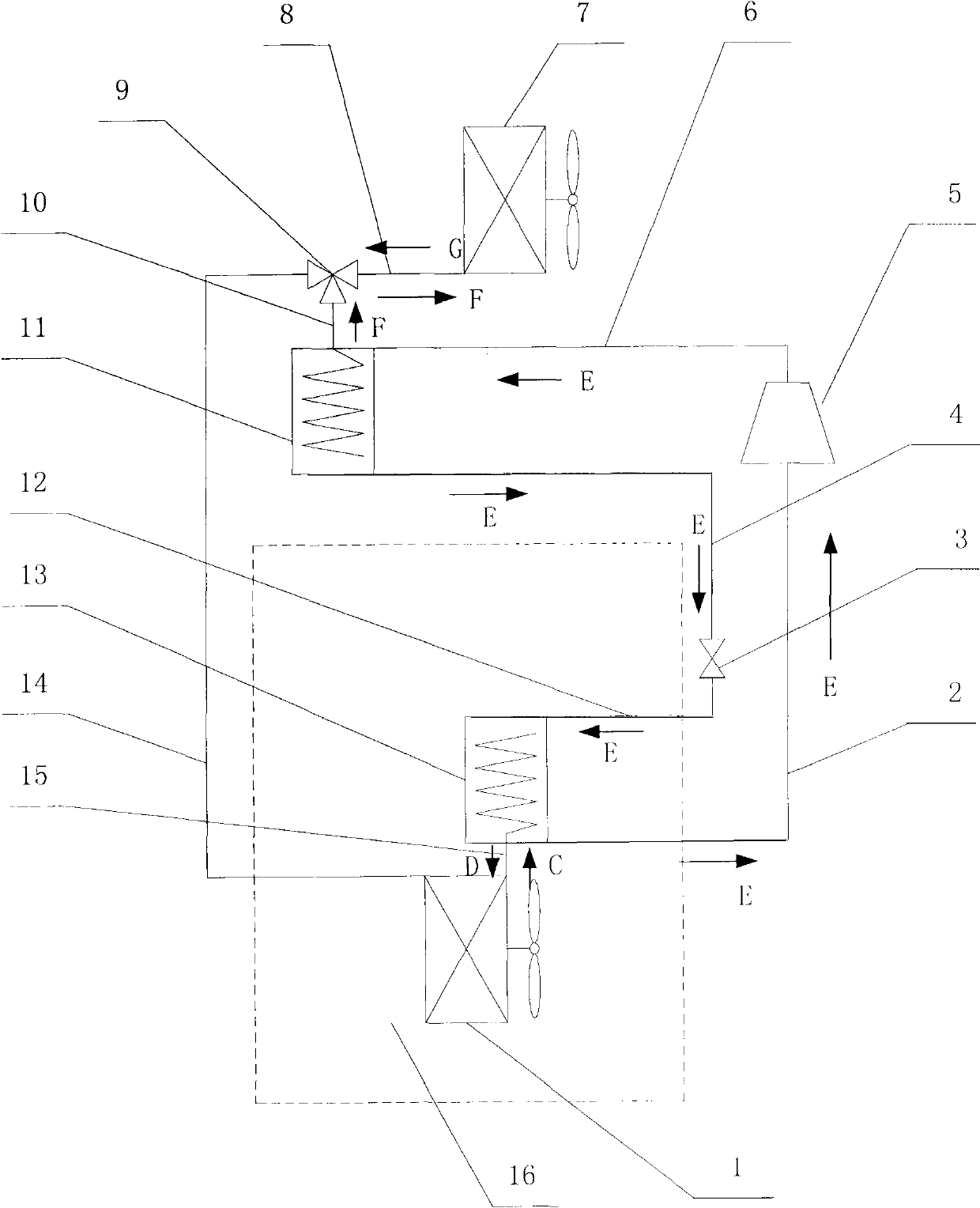

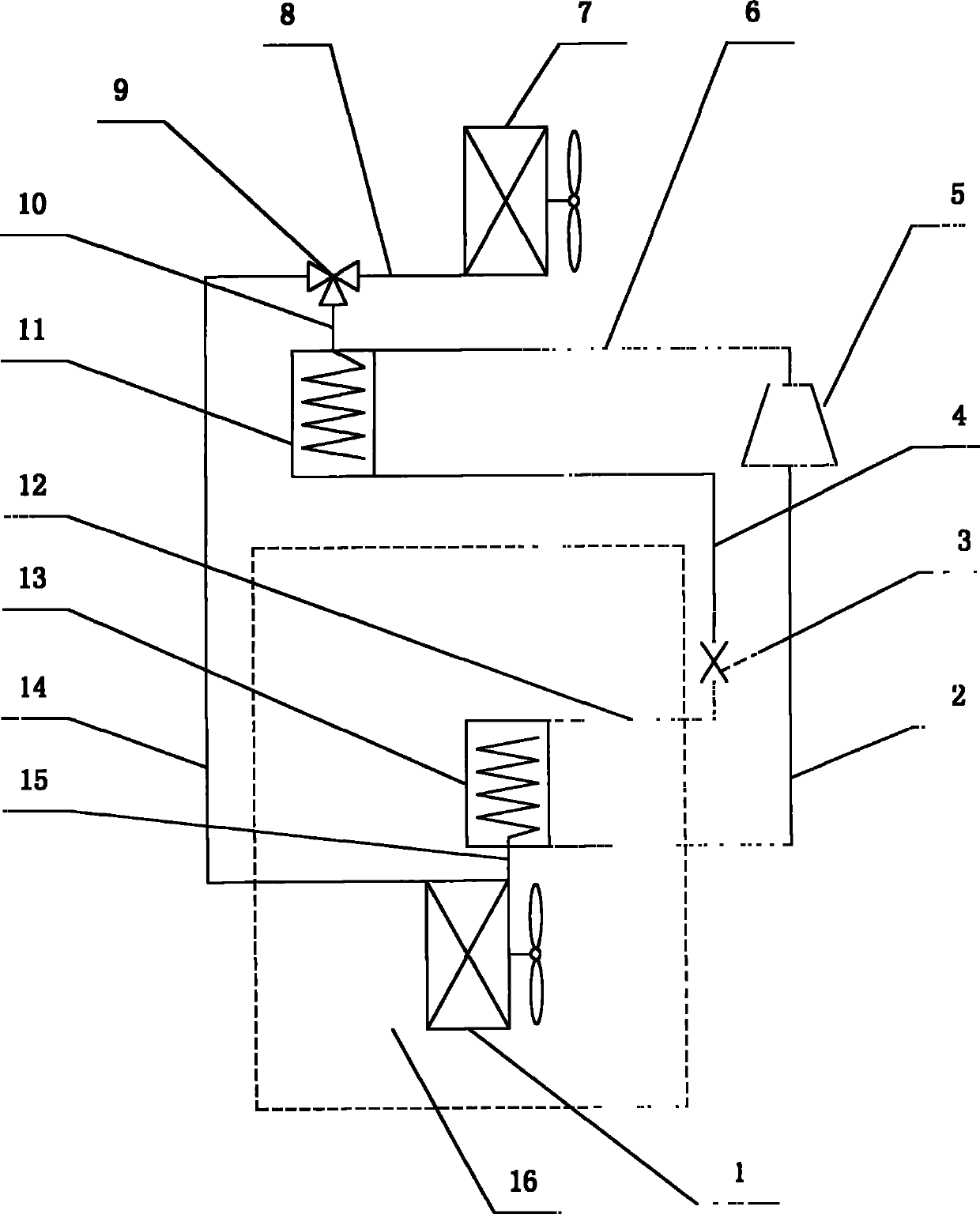

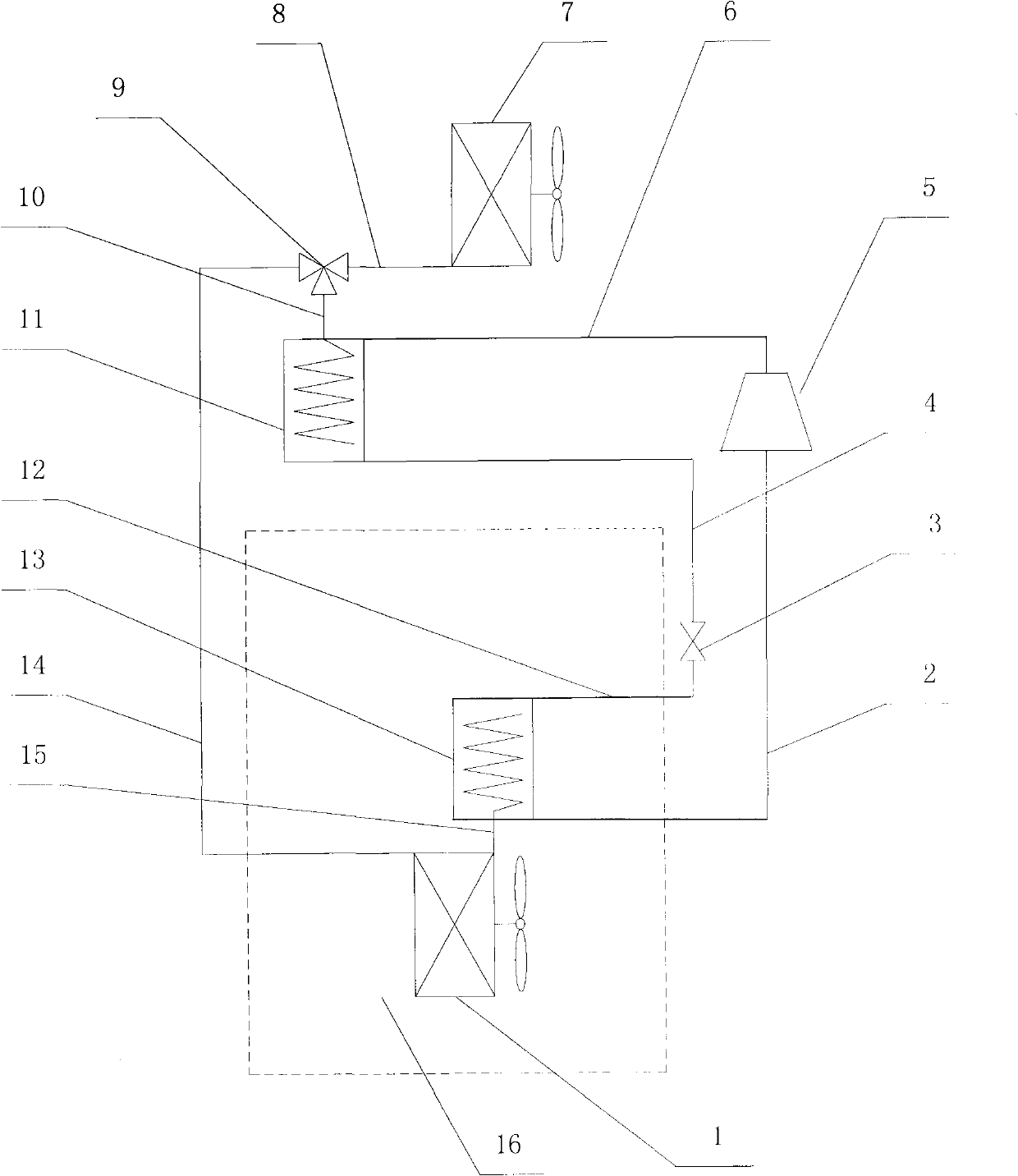

Supercritical organic Rankine double-circulation waste heat recovery system

InactiveCN101413407AImprove absorption efficiencyImprove qualitySteam engine plantsCombined combustion mitigationCompression PumpSuperheater

The invention relates to a supercritical organic Rankine dual cycle waste heat recycling system and belongs to the field a common heat exchange. The system comprises a medium temperature overheater, a medium temperature expander, a medium temperature condenser, a medium temperature compression pump, a medium temperature steam generator, a medium temperature expander crankshaft, a medium temperature output power device, a low temperature overheater, a low temperature expander, a low temperature condenser, a low temperature compression pump, a low temperature steam generator, a low temperature expander crankshaft, a low temperature output power device, an exhaust shunt valve, a low temperature shunt valve and so on. The connection of the elements is as follows: the medium temperature steam generator, the medium temperature overheater, the medium temperature expander, the medium temperature condenser and the medium temperature compression pump are connected in turn to form a loop to form a medium Rankine cycle; and the low temperature overheater, the low temperature expander, the low temperature condenser, the low temperature compression pump, the low temperature shunt valve and the low temperature steam generator are connected in turn to form a loop to form a low temperature Rankine cycle. The system is suitable to be used on road automotive engines which are variable in operating conditions and diversified in energy states for recycling waste heat.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Multifunction heat syphon convection double circulation solar water heater

InactiveCN1900621AAvoid visual pollutionScaling controlSolar heating energySolar heat devicesWater storageSolar water

The solar water heater is composed of solar energy heat collection device, multifunctional water storage installation, water circulated connecting insulated pipefittings, thermosiphon convective dual cycle plant, unit for feeding and catching water, and air inlet and exhaust unit. Thermosiphon convective dual cycle plant is composed of feed liquid pipe and drainpipe, liquid return pipe, liquid supply pipe, float type discharge pipe, and supply pipe of bottom liquid on throttle three way valve. Through pipes, thermosiphon convective dual cycle plant is installed between multifunctional water storage and solar energy heat collection device. Attaching unit for increasing function of multifunctional thermosiphon convective dual cycle solar water heater is installed on water circulated connecting insulated pipefitting.

Owner:徐宝安

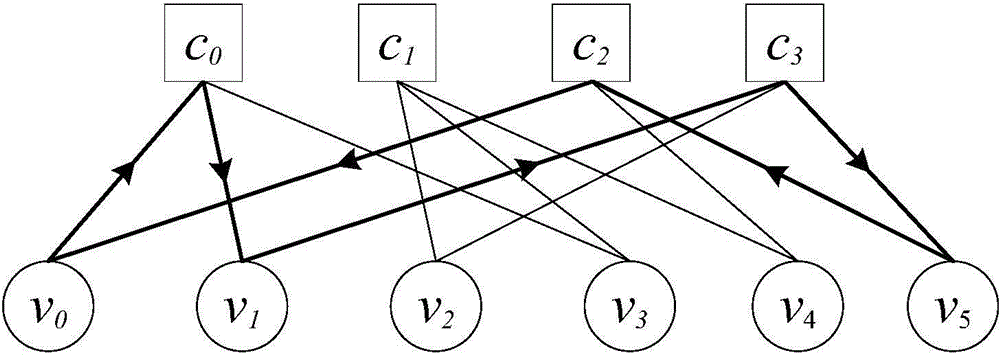

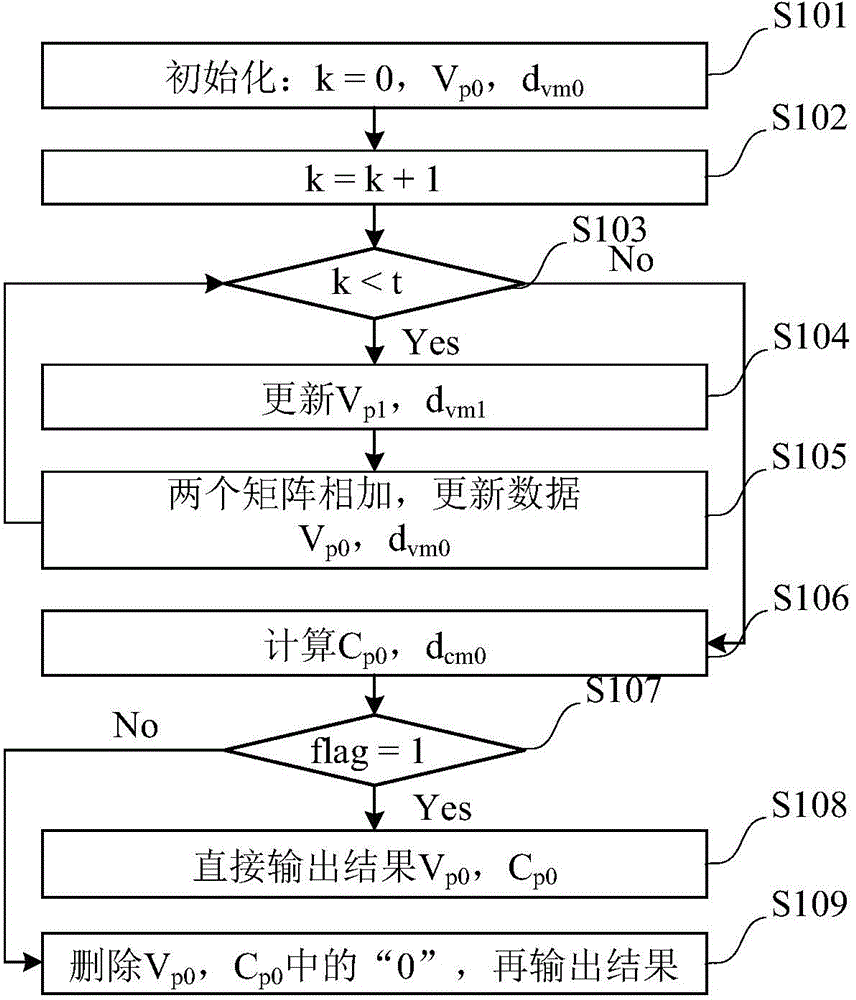

Dual cycle construction method suitable for high code rate quasi cyclic-low density parity check (QC-LDPC) code

ActiveCN104821831AImprove performanceImprove codeword performanceError correction/detection using multiple parity bitsZero matrixLow density

According to a quasi-cyclic low density parity check code basis matrix construction method, node distribution acquired through optimization of a density evolution algorithm is used, then a stretch factor Z is set, the circle length of the LDPC code check matrix and external message scale of the circle are jointed optimized, finally, a QC-LDPC code basis matrix with excellent performances is generated through extension. Each element in the basis matrix is corresponding to one Z*Z dimensional all-zero matrix, a unit matrix or a cyclic shift matrix of the unit matrix. But in construction of high code rate QC-LDPC code, the contradiction of limitation of matrix row number and maximum line number usually occurs, namely, the maximum line number is greater than the row number. To solve the problem, the invention provides construction of the basis matrix through a method increasing line number through superposition of a plurality of cyclic shift matrixes, namely, multiple cyclic shift matrixes are embedded in a single block matrix. The "superposition" operation is binary addition, the constructed basis matrix not only guarantees the cycle performance of the QC-LDPC code, but also meets the requirement of optimization of codon performance through increase of minimum code distance.

Owner:南京融星智联信息技术有限公司

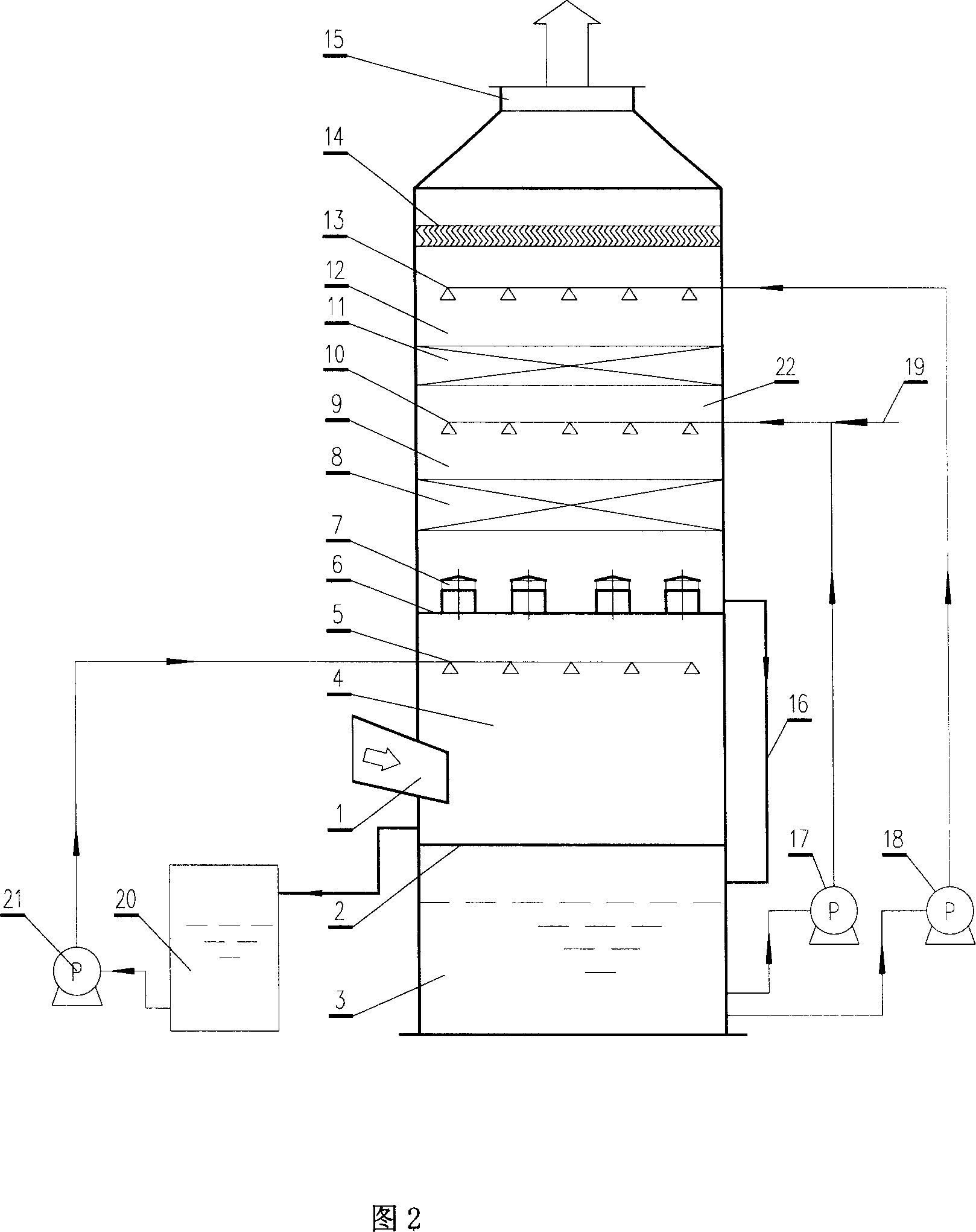

Ammonia-ammonium sulfate method dual circulation three segments desulfurizing tower

InactiveCN101053759AAvoid formingOptimum Oxidation ConcentrationDispersed particle separationEngineeringDual cycle

The invention relates to the field of wet flue gas desulfurization, especially to a flue gas thionizer of ammonia-ammiaonia sulfate method. The thionizer is divided into three segments, wherein the lower segment of the thionizer is a circulation fluid-absorbing tank, the middle segment of the thionizer is a concentration cooling segment, and the upper segment is an absorbing segment. The concentration cooling segment is separated to the absorbing segment and the circulation fluid-absorbing tank by tower-separating plate at the two end planes upper and lower. The dual cycle three-segment thionizer of ammonia-ammiaonia sulfate method of the invention resolves the design disadvantage of general single-tower and multi-tower. The byproduct that is ammiaonia sulfate is concentrated by high-temperature flue gas to reduce the temperature to a temperature propitious to absorb. The dual cycle design of the thionizer makes the cycle absorbing liquid to be not contacted directly with the high-temperature flue gas to control the cycle absorbing liquid at a low concentration, and is beneficial to the desulfurization clear flue gas to avoid the condition forming aerosol and make the solution sent to the oxidation ditch approaching to the optimal oxidation concentration. The composite cost for flue gas desulfurizing can be reduced, using the quantity of heat of the flue gas in the entrance to cycle concentrate the diluted solution of ammonia-ammiaonia.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

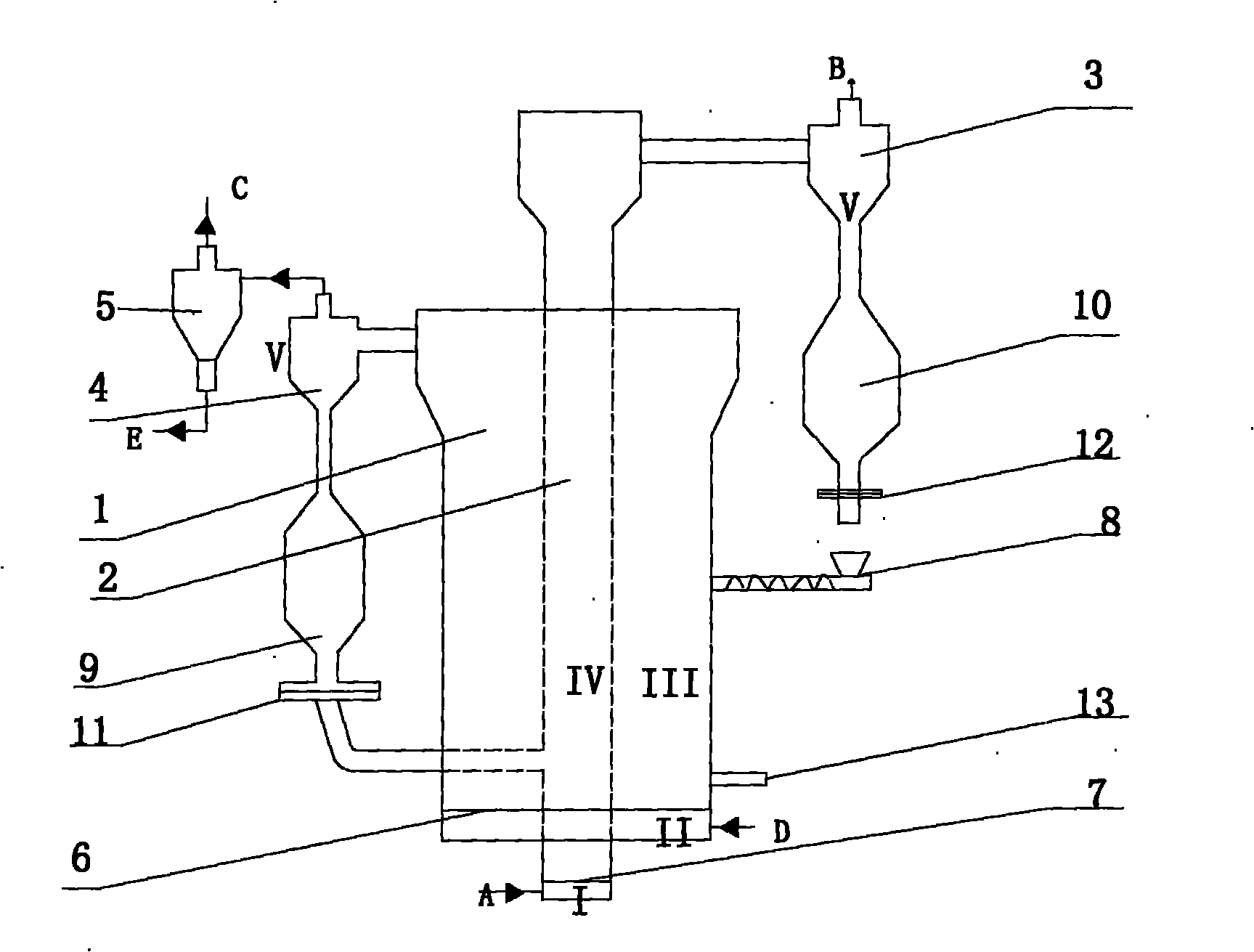

Dual-cycle fluidized bed device for coal-based chemical chain process

ActiveCN101975395AReasonable useReduce operational complexityFluidized bed combustionApparatus for fluidised bed combustionFluidized bedProduct gas

The invention belongs to the technical field of coal utilization, and relates to a dual-cycle fluidized bed device for a coal-based chemical chain process. Coal ash obtained after reaction at a high temperature, a reduced oxygen carrier and a generated gas are separated by a cyclone separator; pure CO2 or synthetic gas is obtained by cooling the gas; the reduced oxygen carrier obtained by the cyclone separator enters a material storage device; the reduced oxygen carrier enters an oxygen reactor by adjustment of a control valve; the reduced oxygen carrier and air react at the high temperature in the oxygen reactor to prepare an oxidized oxygen carrier; the oxidized oxygen carrier is separated by the cyclone separator and fed into the material storage device; the oxidized oxygen carrier is fed into a reduction reactor through a helical feeder by the control valve; the burning of coal or preparation of the synthetic gas from the coal is finished by repeatedly circulating the steps; and the device has a novel and simple structure, good reaction effect and high gas yield, is convenient to operate and use and saves energy.

Owner:水煤浆气化及煤化工国家工程研究中心 +1

High efficiency dual cycle internal combustion engine with steam power recovered from waste heat

ActiveUS8109097B2Valve arrangementsInternal combustion piston enginesCombustion chamberExhaust valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder with a combustion chamber outward of a piston, a cylinder cap slideably mounted within the piston and a steam expansion chamber inside the piston. The cap can be heated to reduce condensation of steam. Steam remaining when a steam exhaust valve closes can be recompressed prior to admitting the next charge of steam. One valve or a pair of steam inlet valves connected in series act in cooperation to help maximize efficiency. The amount of steam admitted each stroke is regulated by shifting the phase of one steam admission valve of a pair to vary their overlap for determining the steam mass admitted each cycle. Other valves balance steam displacement with the steam generator output to use steam more efficiently.

Owner:THERMAL POWER RECOVERY

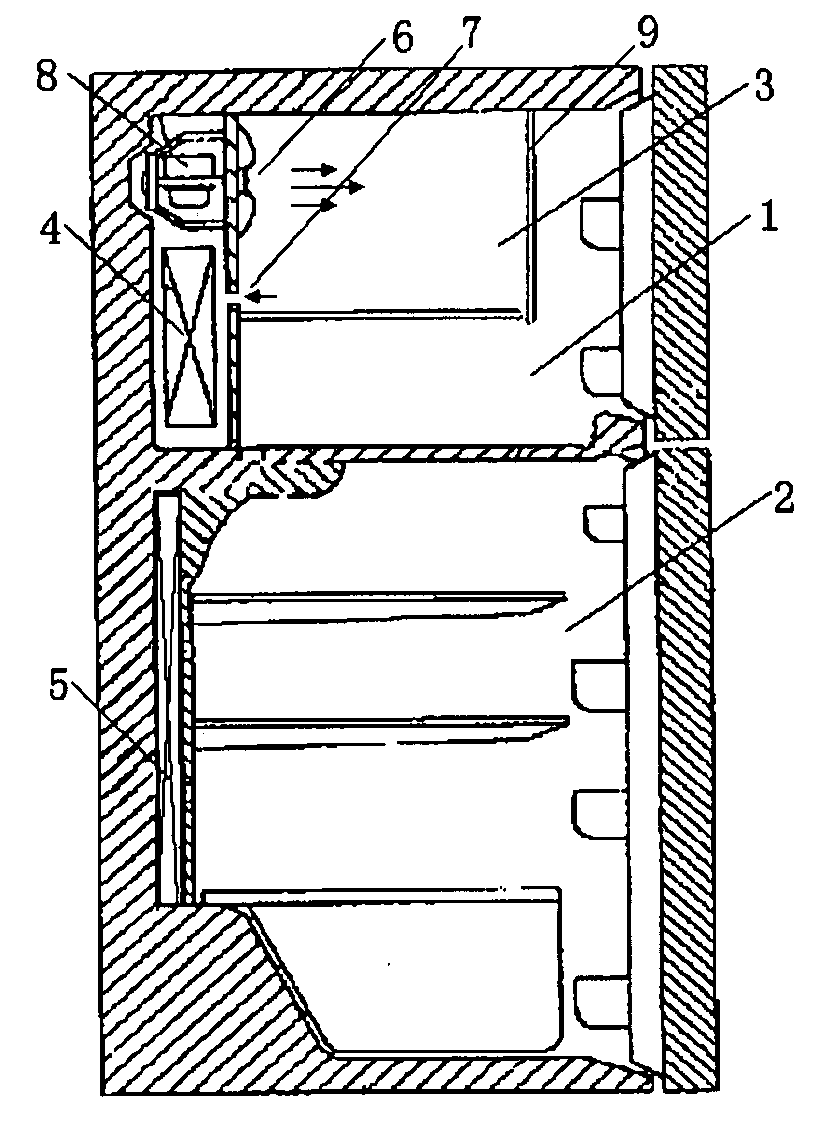

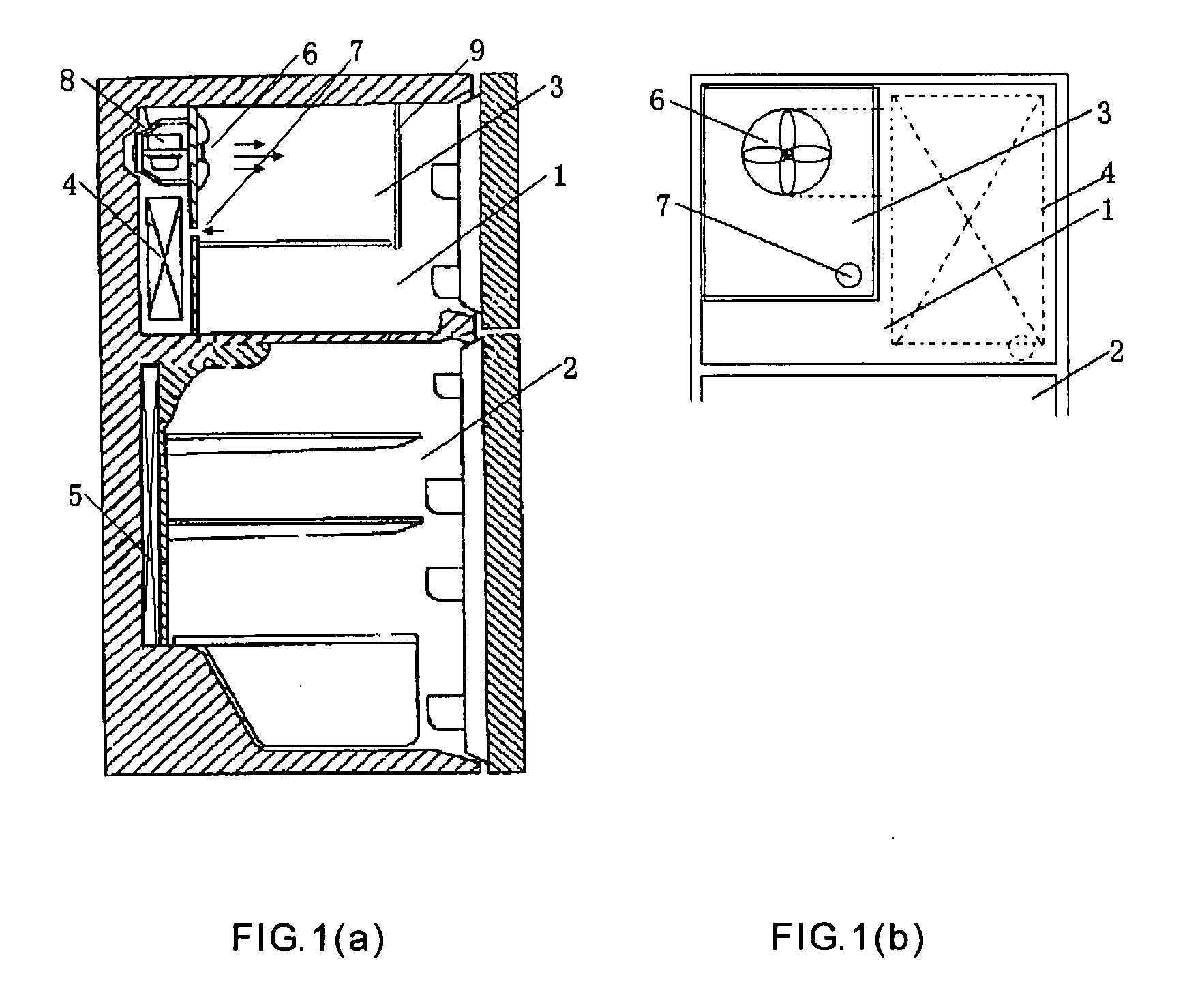

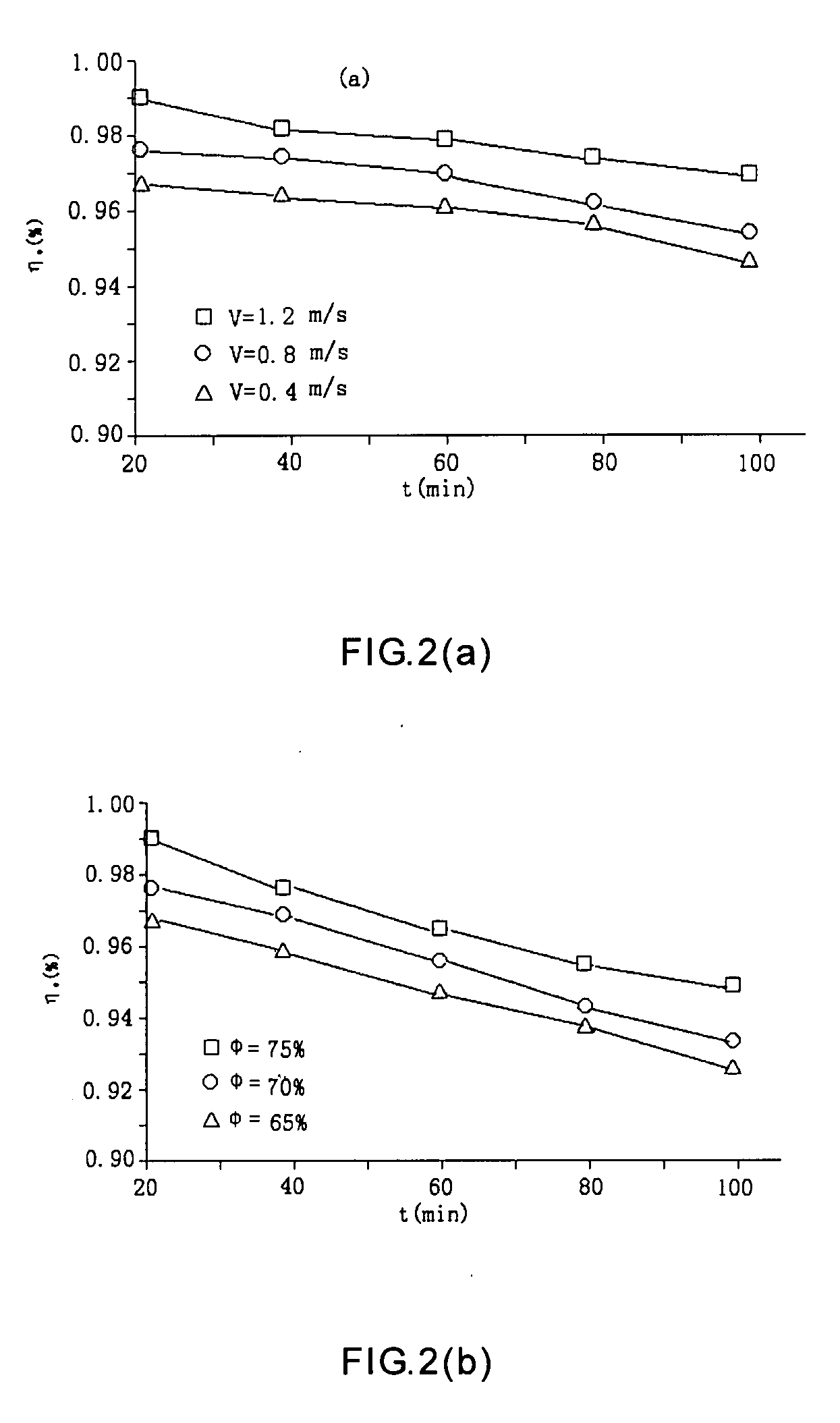

Multi-Temperature Control Refrigerator Comprising an Ice Machine

InactiveUS20080148745A1Avoid flowDomestic refrigeratorsEvaporators/condensersTemperature controlMarine engineering

The present invention relates to a multi-temperature control refrigerator, in which an ice machine is installed and the cooling mode of the refrigerator is a mixed air-cooling and direct cooling mode. Particularly, the present invention relates to a refrigerator having ice-making function, in which the refrigeration cycle is a dual cycle and two different evaporators are included. Due to that the ice making room of the of the refrigerator of the present invention adopts a mixed air-cooling and direct cooling mode, and that impulse solenoid valves and dual temperature control device are introduced to the dual cycle system, the energy is optimally distributed and utilized, the fluctuation of temperature is small and the ice making efficiency of the ice making room and the quality of the ice cubes are much improved. And the whole refrigerator makes less noise, consumes fewer refrigerants and makes ice of good quality rapidly.

Owner:HAIER GRP CORP +1

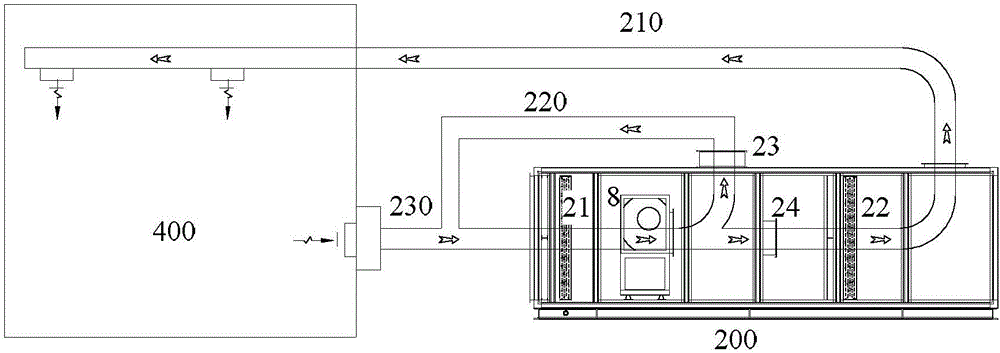

Control method and control device of heat pump type dual-cycle hot air drying system

ActiveCN106643107AImprove energy efficiencyGuaranteed temperature change requirementsMechanical apparatusHeat pumpsAir volumeEngineering

The invention provides a control method and a control device of a heat pump type dual-cycle hot air drying system and relates to an air or gas supply or control device for drying a solid material or product, in particular to a control method and a control device of a heat pump type dual-cycle hot air drying system. The control method comprises the following steps that a temperature control parameter is configured, and a preset temperature control curve parameter is saved; air outlet temperature and drying room temperature and humidity are detected and monitored; the set temperature is dynamically adjusted according to a preset temperature control curve; a dual-cycle dynamic operating mode of the system is selected according to current set temperature. The control device utilizes a microprocessor to achieve program control, an inner cycle loop for large-volume circulation is established, condensing latent heat of a refrigerant is fully absorbed to improve basic air temperature, and high-temperature hot air is obtained through secondary heat exchange of an air supply circulation loop; the air outlet volume is automatically adjusted and controlled by adopting dual-path air volume to ensure the change demand for air outlet temperature and drying room temperature. The reliability of the product can be ensured, the unit energy efficiency can be also achieved, and the purpose of energy consumption is reduced.

Owner:JIANGSU TENESUN ELECTRICAL APPLIANCE

High efficiency dual cycle internal combustion steam engine and method

ActiveUS8661817B2Efficient and improved heat transferImprove heat transfer performanceReciprocating combination enginesInternal combustion piston enginesCombustion chamberWorking fluid

The coolant in the cooling jacket of a dual cycle internal combustion steam engine is intentionally maintained at an elevated temperature that may typically range from about 225° F.-300° F. or more. A non-aqueous liquid coolant is used to cool the combustion chamber together with a provision for controlling the flow rate and residence time of the coolant within the cooling jacket to maintain the temperature of the coolant at a selected elevated temperature that is substantially above the boiling point of water but below the boiling point of the coolant. The coolant is passed from the jacket through a heat exchanger in a first circuit to transfer heat to a vaporizable working fluid such as water and is then returned. An optional second circuit is an intrajacket perturbation circuit within the engine can be used to disrupt and disperse pockets of vapor that may tend to form before damaging hot spots can develop around the combustion chamber. A cooling jacket design is tailored to extract heat at the highest possible temperature from each heat transfer zone as by having the coolant follow a circuitous helical pathway to achieve more efficient and improved heat transfer from the combustion chamber to the cooling medium.

Owner:THERMAL POWER RECOVERY

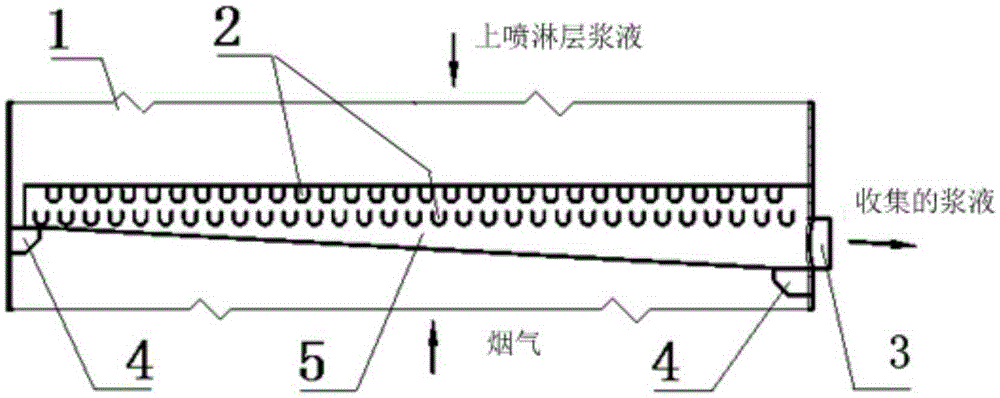

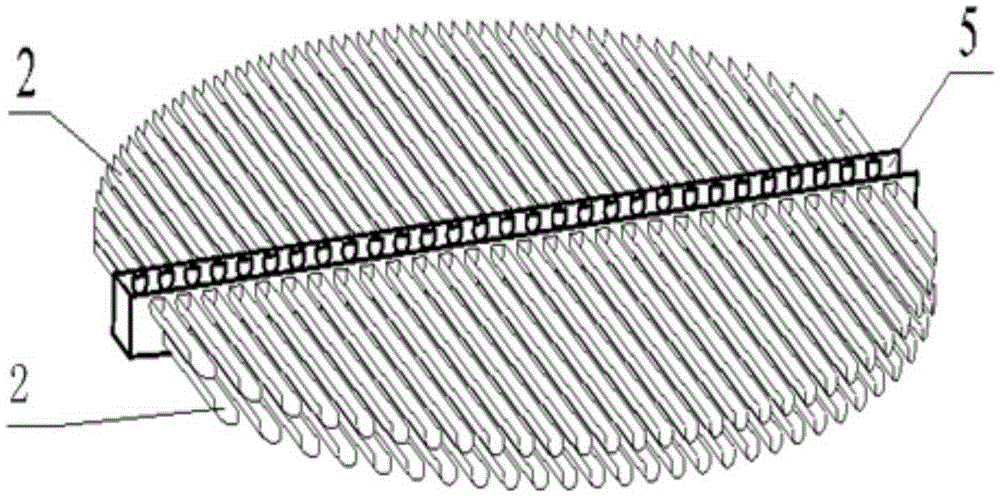

Single-tower dual-cycle wet flue gas desulfurization tower and tube groove type liquid collection device

ActiveCN105413444ALittle resistance lossReduce resistanceGas treatmentDispersed particle separationFlue gasFriction loss

The invention provides a single-tower dual-cycle wet flue gas desulfurization tower and a tube groove type liquid collection device, and belongs to the technical field of flue gas desulfurization. The desulfurization tower comprises a tower body, the bottom of the tower body is provided with a flue gas inlet, the top of the tower body is provided with a flue gas outlet, an upper spray layer and a lower spray layer are arranged on the portion, between the flue gas inlet and the flue gas outlet, inside the tower body, and the tube groove type liquid collection device is installed between the upper spray layer and the lower spray layer and separates slurry of the upper spray layer from slurry of the lower spray layer; the tube groove type liquid collection device comprises multiple liquid collection tube grooves which are formed for multiple layers in the longitudinal direction, the two adjacent layers of the liquid collection tube grooves are arranged in a staggered mode, the liquid collection tube grooves are arranged in an inclined mode, and the lower ends of the liquid collection tube grooves are communicated with a diversion groove. According to the single-tower dual-cycle wet flue gas desulfurization tower and the tube groove type liquid collection device, the flow field is uniformly distributed, the resistance loss of the structural design is small, and the contact effect between the gas and liquid is good. Therefore, the slurry of the upper spray layer can be collected, the system resistance can be reduced, and the desulphurization efficiency is improved.

Owner:SHANDONG UNIV

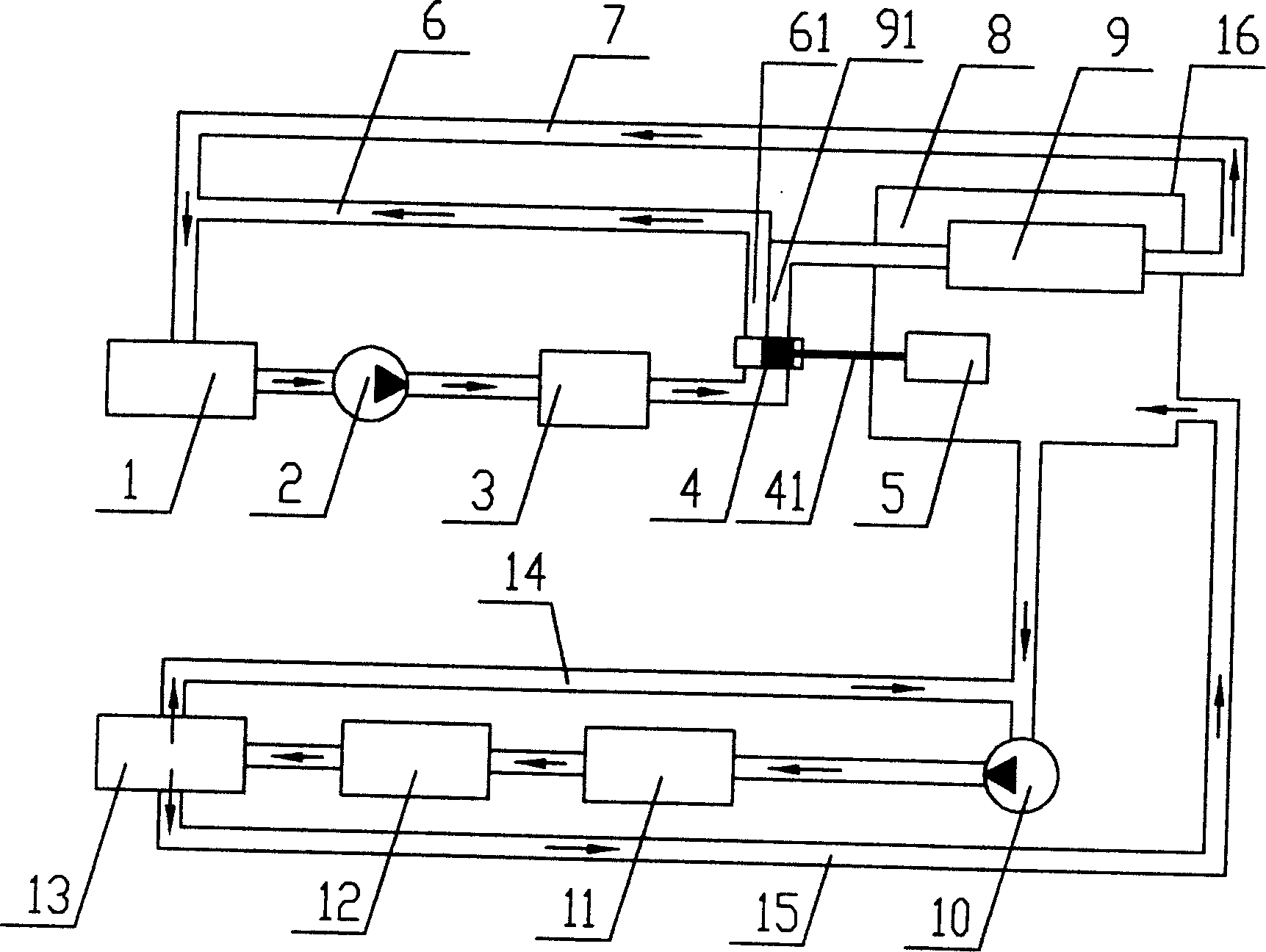

Engine dual-cycle forced cooling system

InactiveCN1891994AShorten the timeTake advantage ofLiquid coolingCoolant flow controlEngineeringControl valves

The invention discloses an engine double circulation forced cooling system, comprising internal circulation cooling subsystem and external circulation cooling subsystem, where the pipeline of the external circulation cooling subsystem connects to the external circulation water cavity of a heat exchanger and that of the internal circulation cooling subsystem connects to the internal circulation water cavity of the heat exchanger, the pipeline of the external circulation cooling subsystem is equipped with a flow control valve able to control the flow of external circulation cooling medium passing through the heat exchange, and a temperature sensing device sampling from the internal circulation water cavity, and the temperature sensing device drives the flow control valve; when a machine is in the 'warming-up' course, the temperature sensing device controls the flow control valve to control the quantity of external circulation cooling medium entering the heat exchanger so as to achieve the purposes of fully using heat energy, shortening warming-up time, and reducing heat energy losses.

Owner:WEICHAI POWER CO LTD

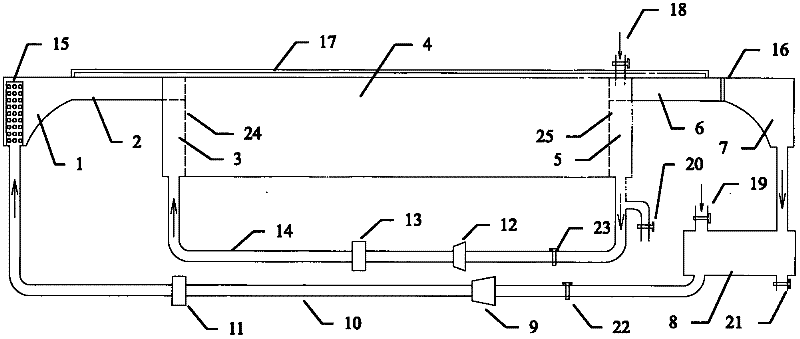

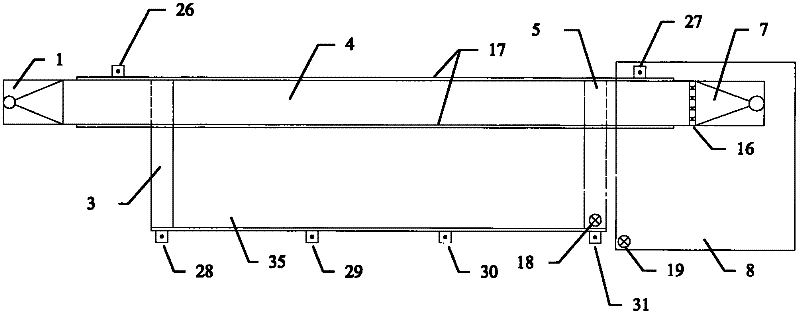

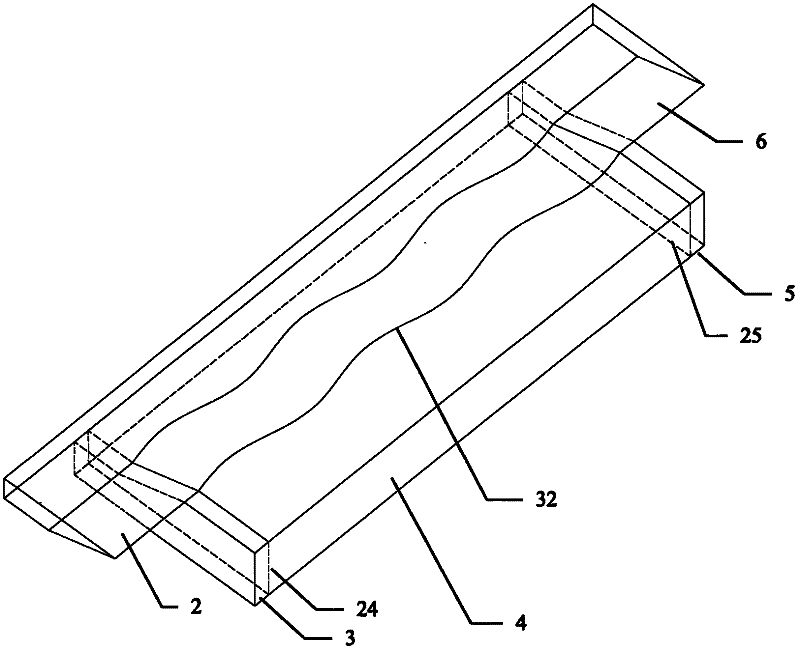

Experimental tank system of riparian zone

InactiveCN102507135AMeet the riverConform to the environmentHydrodynamic testingPhysical modelEngineering

The invention relates to an experimental tank system of a riparian zone, belonging to the field of physical model experiments in hydraulic engineering. The experimental tank system comprises a tank control platform, an experimental composite-type tank, dual-cycle water supply systems, a dual-level flow control system and a switching system. According to the invention, a cyclic surface water supply system and a cyclic underground water supply system which are independent can be used for effectively controlling surface water of rivers to circulate at a higher speed and underground water to circulate at a low speed, and thus river and river bank water flow environments which further accord with natural conditions are provided for a riparian zone experiment; the dual-level flow control system can be used for adjusting and controlling level and flow boundary conditions of the surface water of the rivers and the underground water of the river bank simultaneously, so that the problems that level and flow conditions of the rivers can be independently adjusted only in the traditional river dynamics experiment and level and flow conditions of the underground water can be independently adjusted only in the traditional underground water experiment; and the electronic intelligent switching system can be used for intelligently adjusting and controlling switch-on and switch-off as well as openness of relative power supply switches, valves, tail gates and the like of the experimental tank system. The experimental tank system disclosed by the invention has high automation degree and is provided with an experiment control platform which is simple and easy to operate, so that a user can finish related operations of the experimental tank system of the riparian zone in the same control interface; and the experimental tank system has a fault prompt function and is convenient for emergent measure taking and equipment overhauling.

Owner:HOHAI UNIV

Multi-cycle internal combustion engine

InactiveCN103925075ASimple structureImprove power densityInternal combustion piston enginesCombustionExternal combustion engine

The invention discloses a small-size and high-power multi-cycle internal combustion engine in the field of internal combustion engines. Multiple sets of four-stroke cycles can be finished in one four-stroke cycle process, repeating acting is achieved in one cycle period, but the advantages of oil conservation and environmental protection of a prior four-stroke internal combustion engine are kept at the same time, and compared with a four-stroke internal combustion engine the same as the multi-cycle internal combustion engine, the multi-cycle internal combustion engine is much smaller in size and higher in power intensity. The multi-cycle internal combustion engine is composed of a dual-cycle internal combustion engine body (please see the abstract figure) which finishes two sets of four-stroke cycles within one cycle period through one cylinder; the internal structure of the multi-cycle internal combustion engine is symmetrical, acting cycle is also symmetrical, the multi-cycle internal combustion engine does not need balance weight, and the higher the motion frequency is, the lower the noise is. The multi-cycle internal combustion engine is small in size, high in power, low in noise and environmentally friendly.

Owner:韩鑫岗

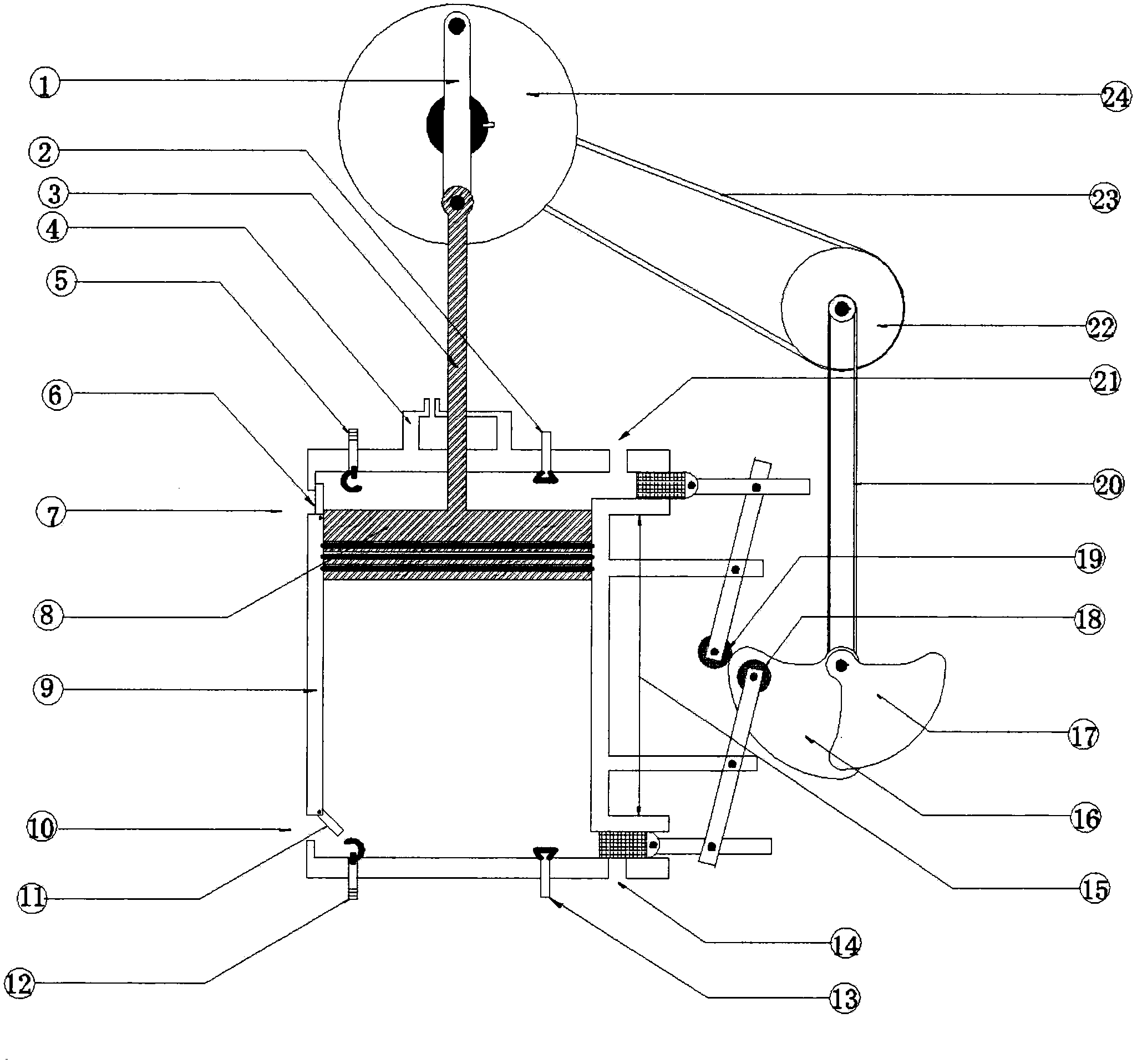

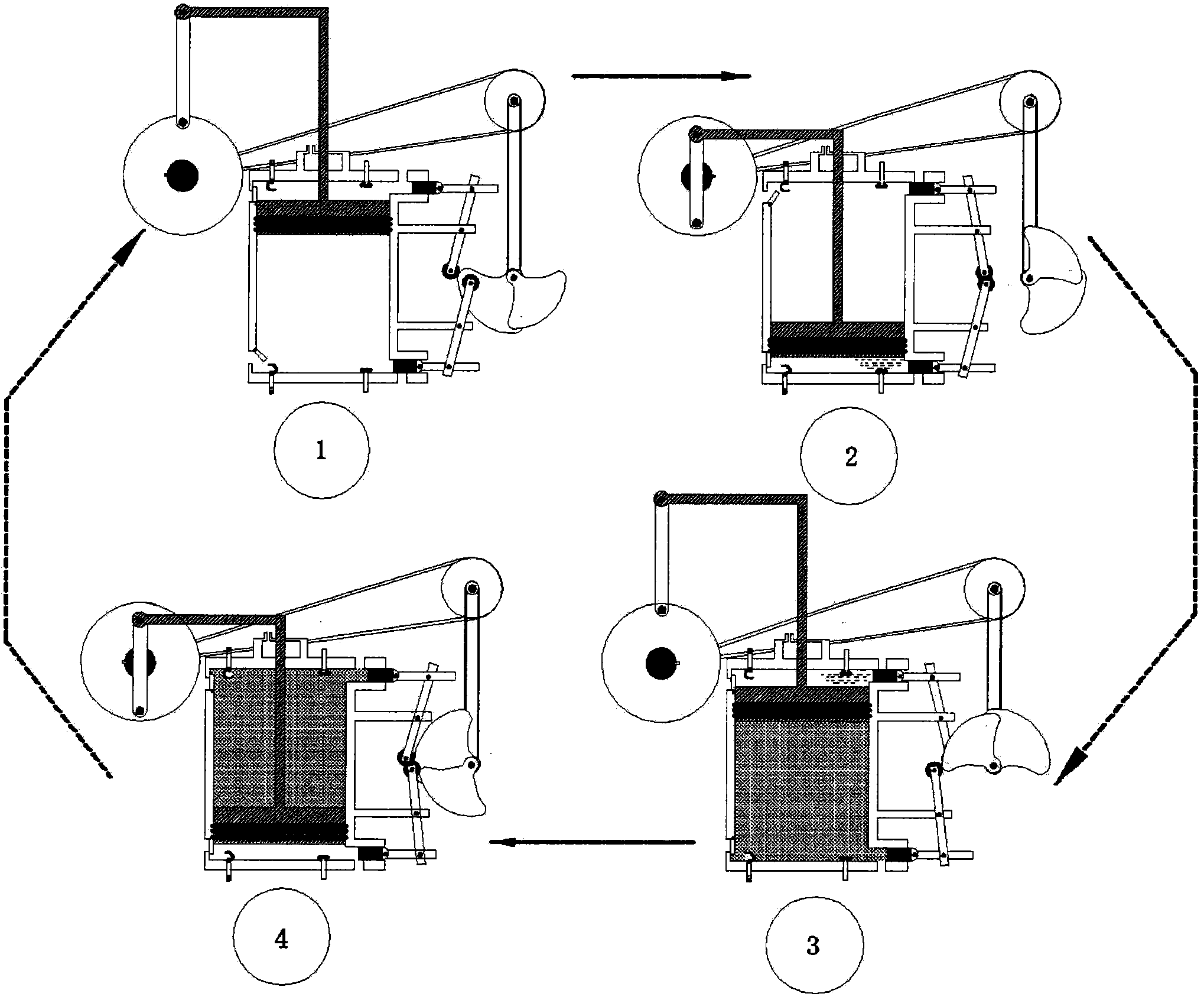

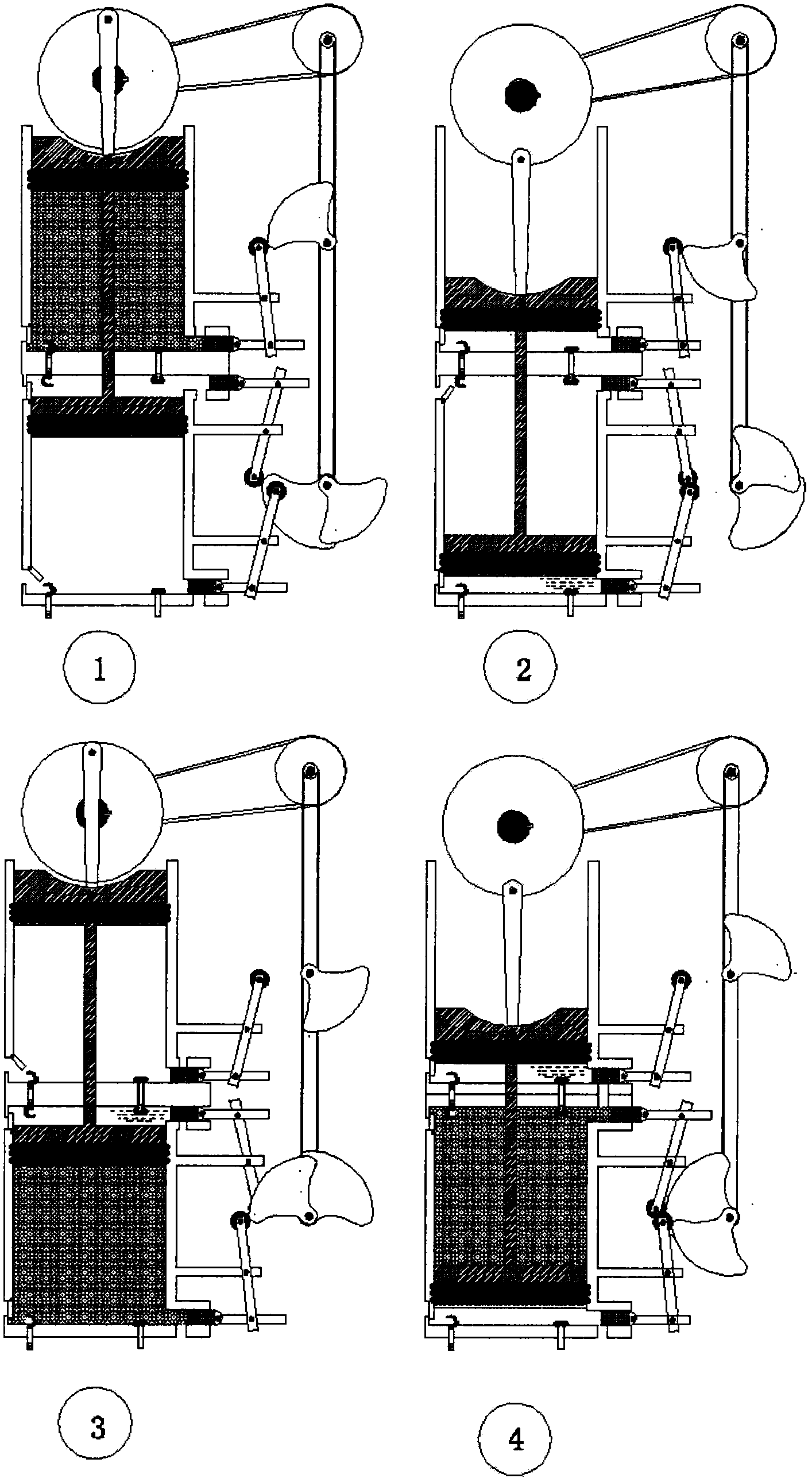

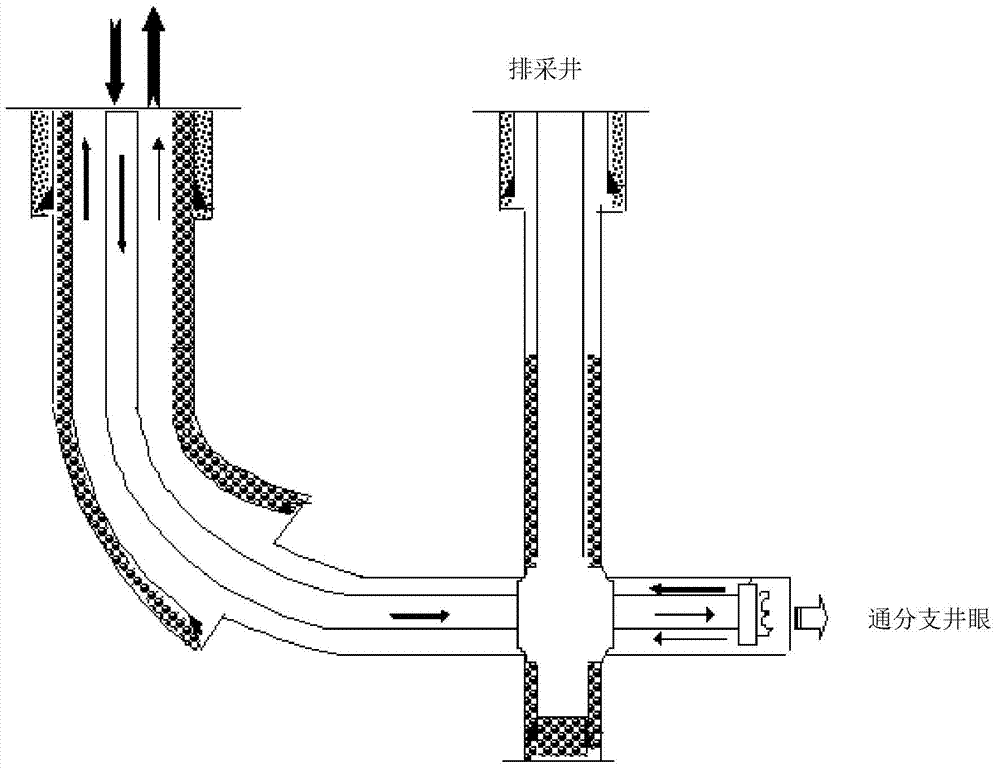

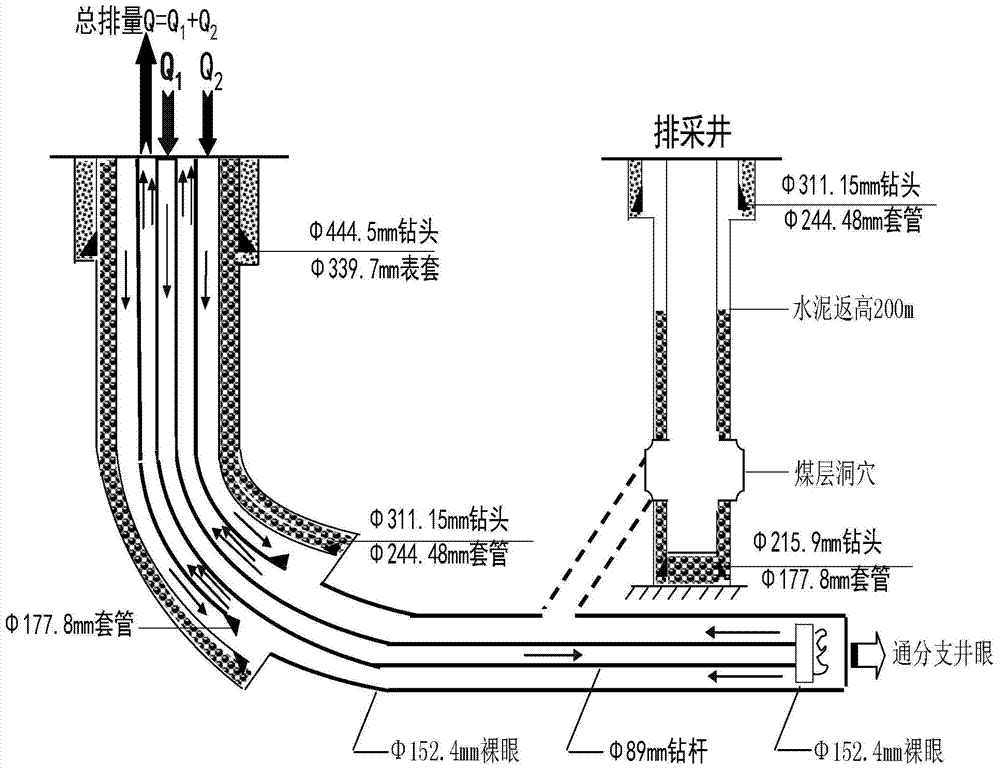

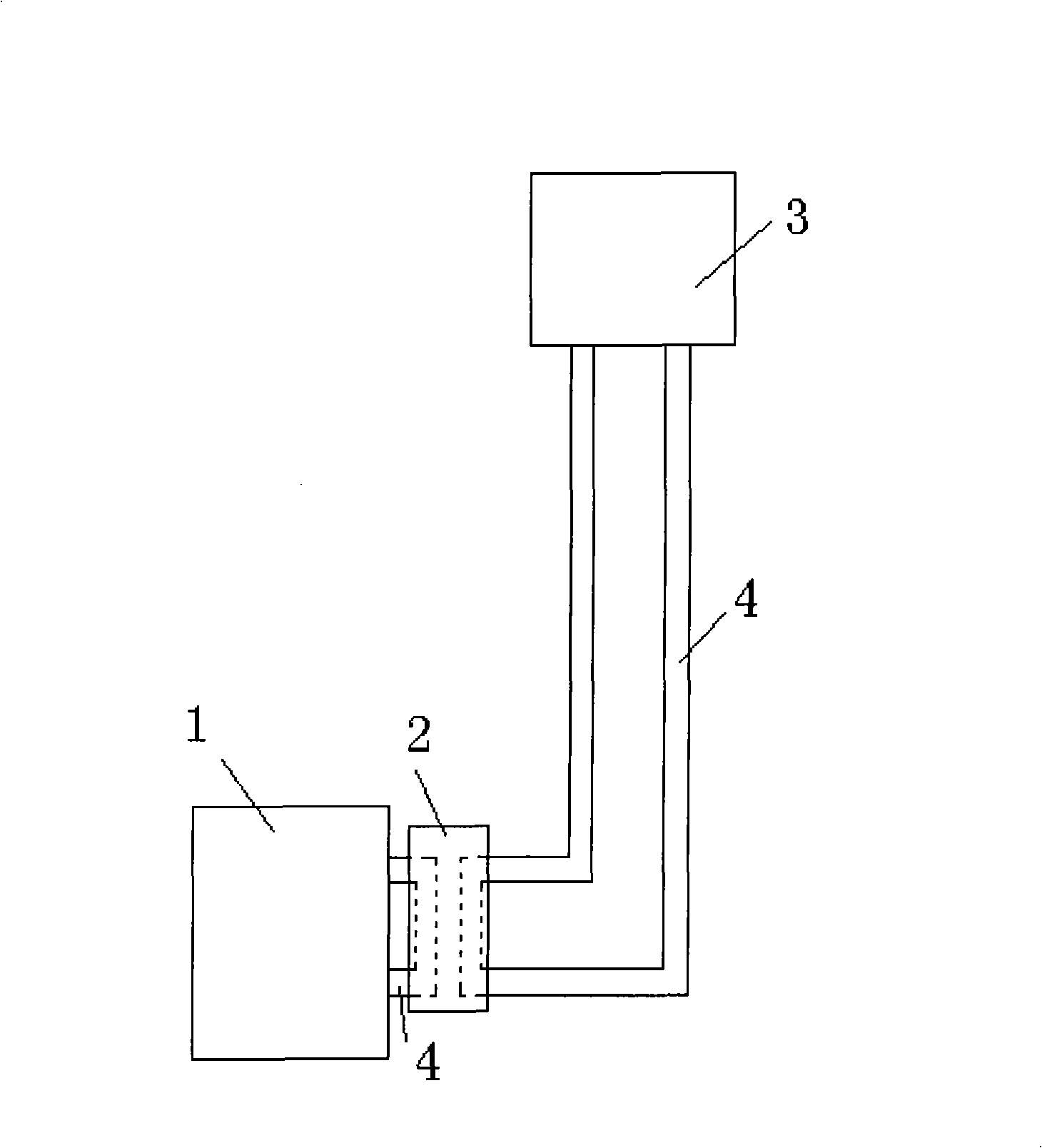

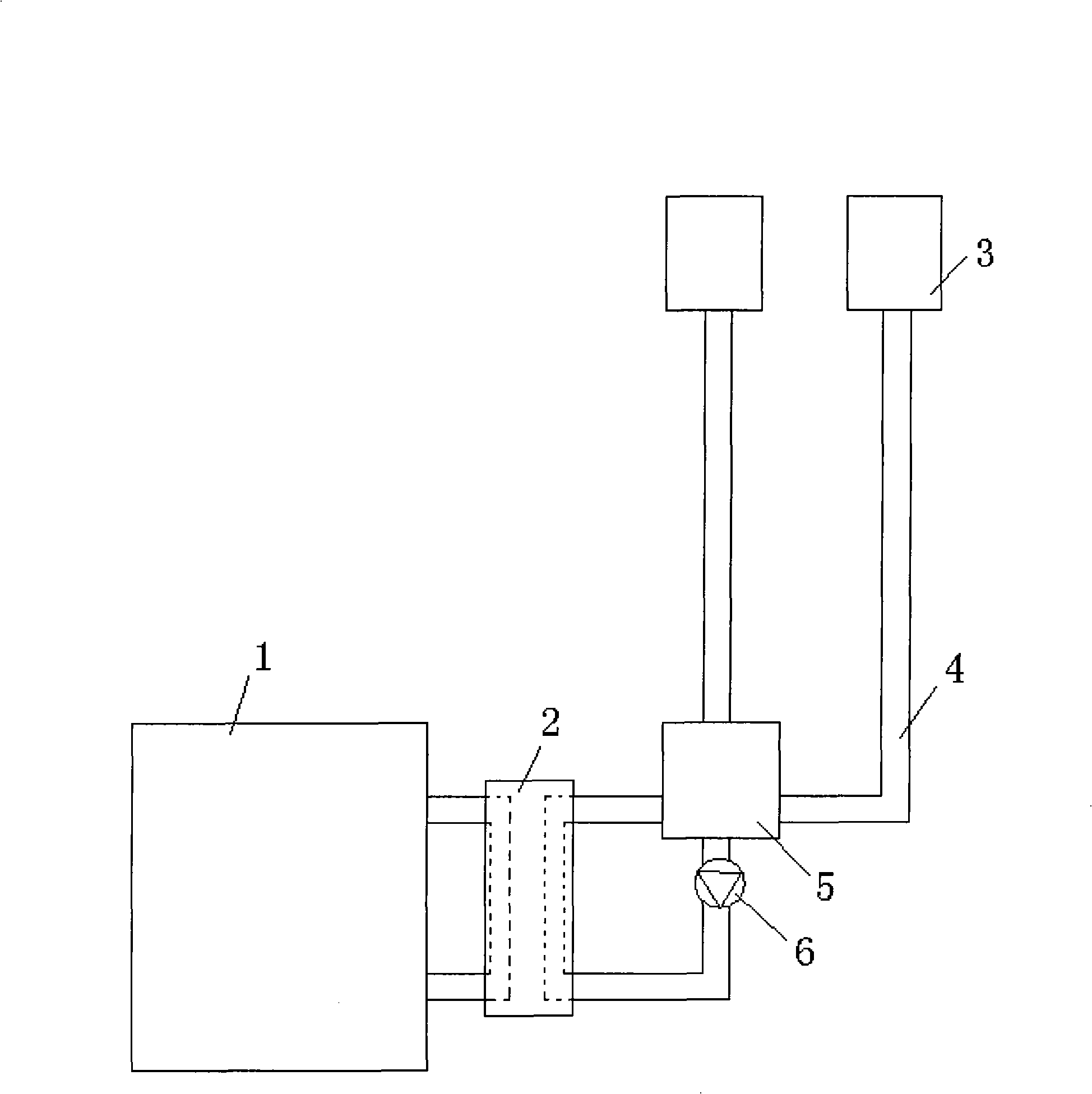

Dual-cycle relay coal bed well drilling method

ActiveCN103670271AAvoid the effects of collapseImprove stabilityFlushingDrilling machines and methodsCarrying capacityWell drilling

The invention discloses a dual-cycle relay coal bed well drilling method. The method comprises the following steps: (1) drilling and extracting: carrying out well cementation and enlarging a cave in a coal bed after drilling and completion twice and running casing; (2) drilling a horizontal multilateral well: through drilling and completion twice, after the second drilling and completion, running dual-casing to suspend and center an internal casing in an external casing, and placing the terminal of an internal casing on a place which is 0.5-10m far away from the casing shoe of the external casing; bypassing an extraction well while the third drilling is carried out, disconnecting the extraction wheel, and then drilling the extraction wheel after the construction of a horizontal multilateral well is finished; and (3) shutting in the well and putting into production in commission: cementing a plug, sealing the well head of the horizontal multilateral well, and pumping, draining and producing coal gas by using the extraction well. According to the drilling method, the double circulation above the casing shoe is formed, and coal dust at a horizontal naked eye section accelerates upward movement by virtue of the dual-circulation effect after the coal dust reaches the casing shoe, so that the stability and return flow of the drilling returning fluid can be improved, the sand-carrying capacity can be improved, and pipe-sticking accidents can be reduced or eliminated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

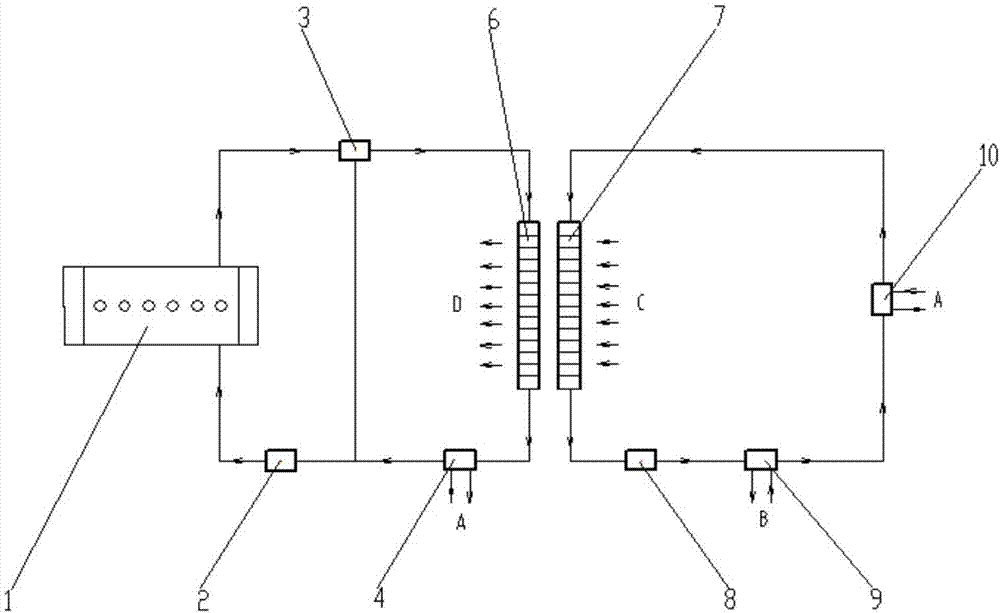

Oil-immersed type transformer cooling method and its system

InactiveCN101286408AWon't penetrateReduce noiseTransformers/inductances coolingLow noiseLiquid state

The invention relates to a cooling method for an oil-immersed transformer and a system thereof, and aims at providing a two-cycle cooling method for the oil-immersed transformer; the transformer oil of the oil-immersed transformer transmits heat to liquid evaporation cooling medium with low temperature by a heat exchanger, and the liquid evaporation cooling medium is vaporized after the temperature thereof rises; gaseous evaporation cooling medium is condensed into liquid by a condensing device, and the liquid reflows to the heat exchanger; another purpose of the invention is a cooling system of the oil-immersed transformer, and the oil-immersed transformer, the heat exchanger and the condensing device are connected together by a pipeline; the transformer oil is stored in the oil-immersed transformer and passes through the oil line part full of the heat exchangers of the pipelines, and the liquid evaporation cooling medium is stored in the evaporation cooling medium part of the heat exchanger; the adopted evaporation cooling medium is fluorocarbon. The cooling method and the system for the oil-immersed transformer solves the problem of large occupying field of the transformer cooling device and outside natural environmental impact and have the advantages of small occupy area, low noise, low energy consumption, safety and reliability.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

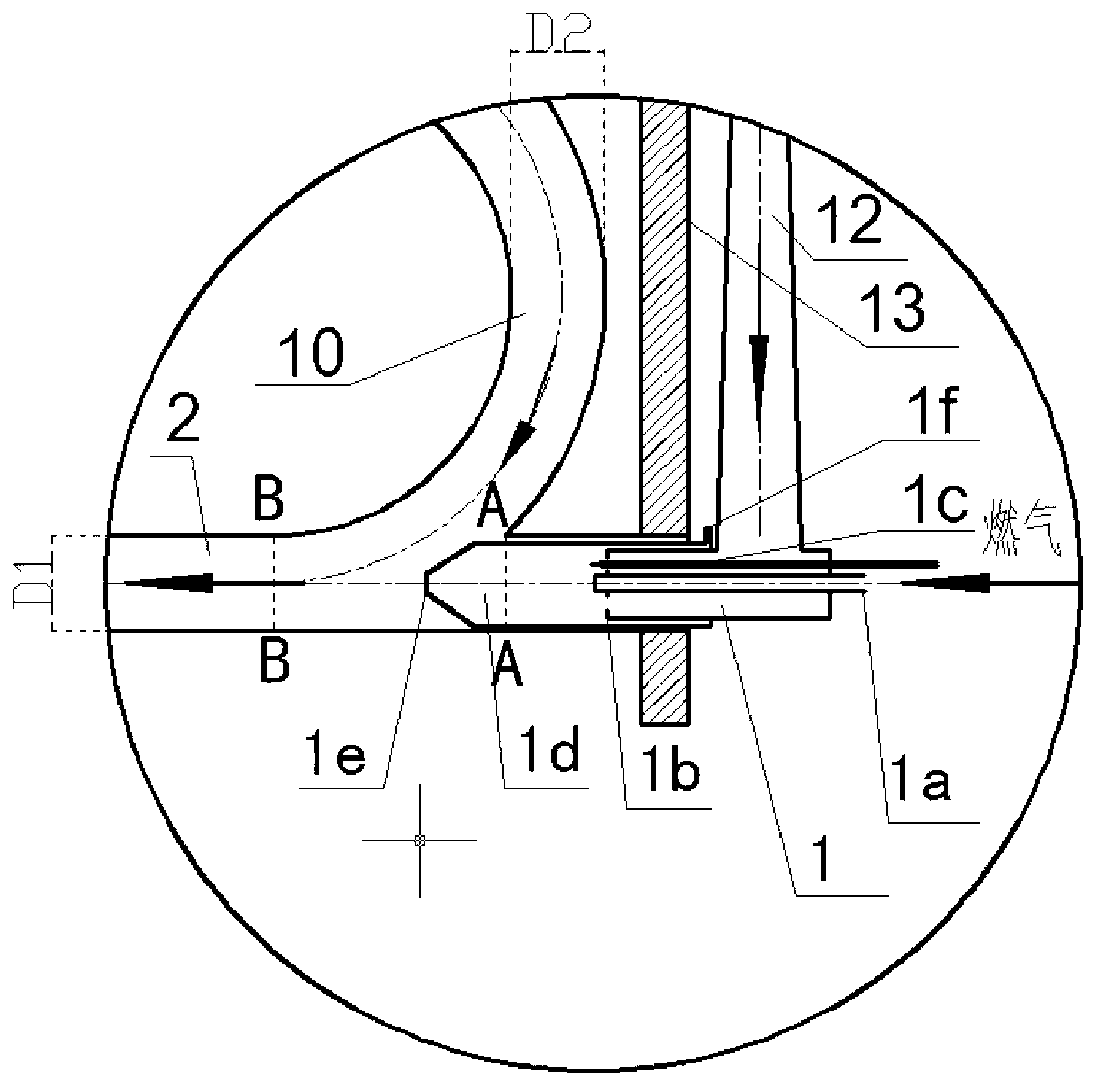

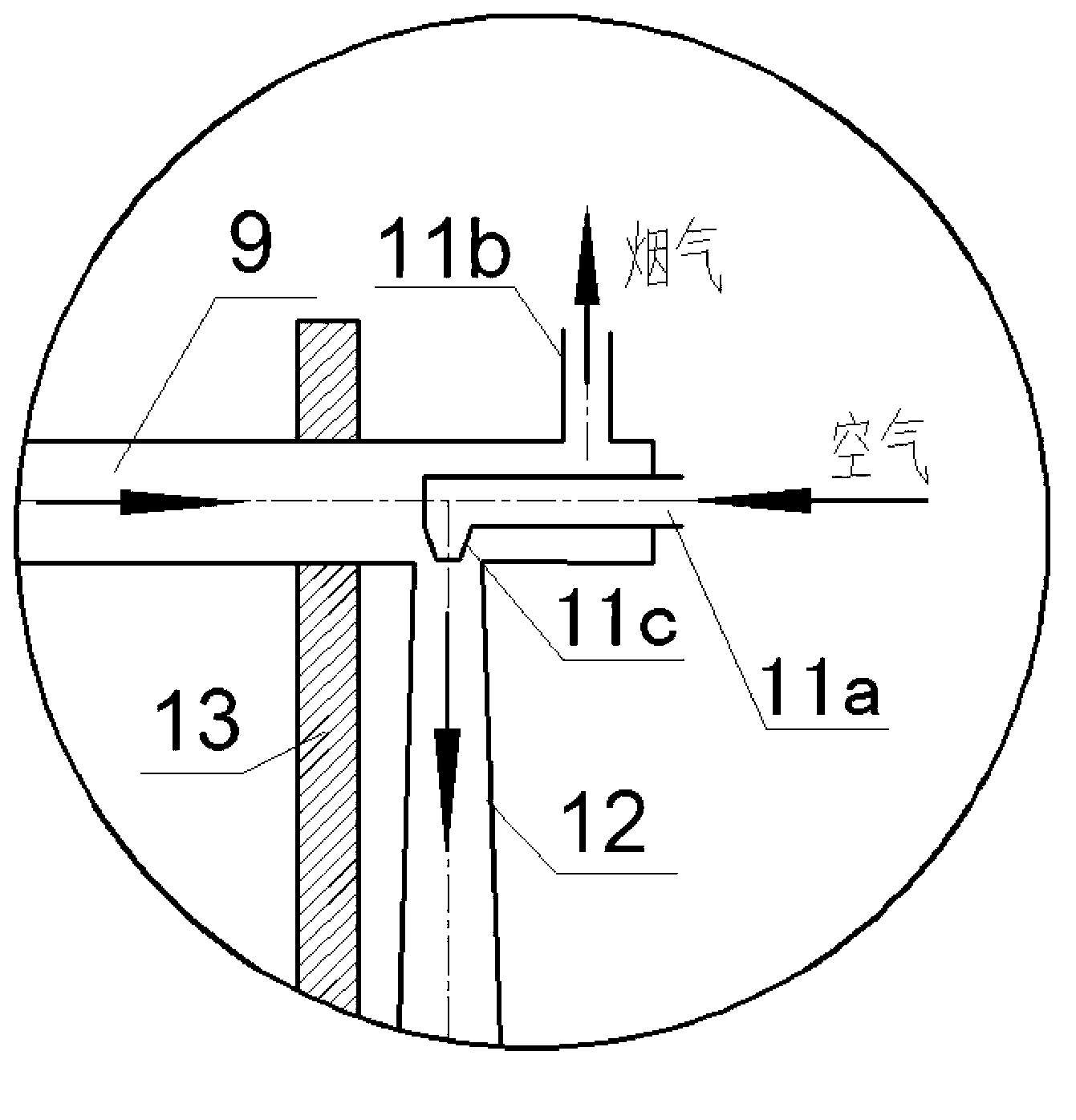

Gas dual-cycle radiant tube heating device

InactiveCN103255271ALower the preheat temperatureRaise the preheat temperatureEngineeringCore temperature

The invention discloses a gas dual-cycle radiant tube heating device. The part in a furnace of the device is a closed inner-ring gas circulating line composed of a first straight tube, a first bend, a second straight tube, a second bend, a third straight tube, a third bend, a fourth straight tube and an added smoke return tube, and the part outside the furnace of the device is an outer-ring gas circulating line composed of an empty smoke switching device, a mixed gas conveying tube and a nozzle. The heating device overcomes the defects that the temperature distribution of a radiant tube along the length direction is non-uniform and the local temperature is high. Returned smoke and combustion flame are mixed through inner-ring gas circulating so as to reduce the core temperature of flame, enhance the uniformity of the surface temperature distribution of the radiant tube, prolong the service life, and reduce the generation of thermal NOx; since the smoke return tube is added, the effective radiation heat exchange area in the furnace is enlarged, and the outer-ring gas circulating is capable of effectively improving the pre-heating temperature of gas, reducing the oxygen content in air and realizing low-temperature combustion, thereby increasing the heat efficiency while alleviating pollution.

Owner:UNIV OF SCI & TECH BEIJING

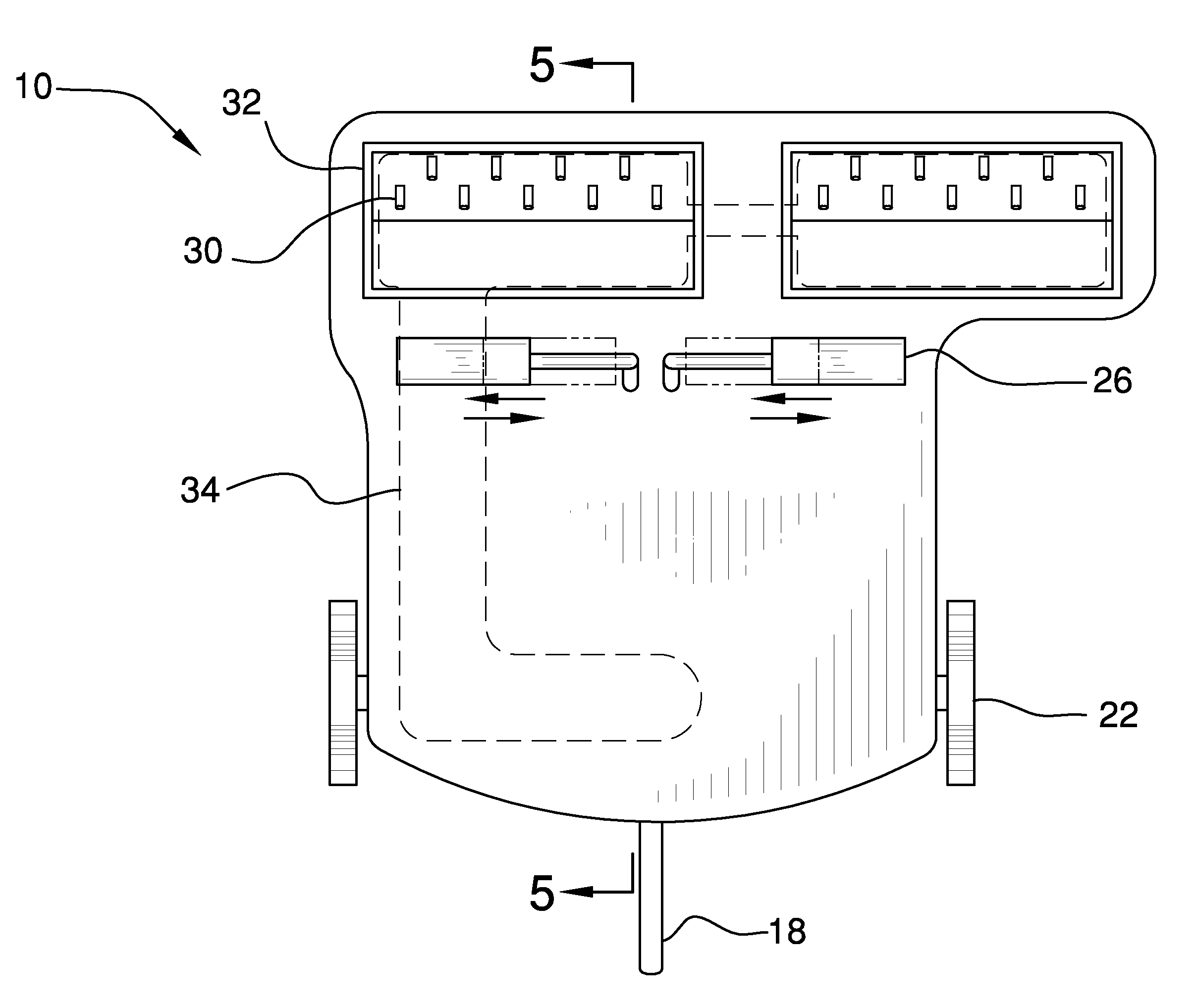

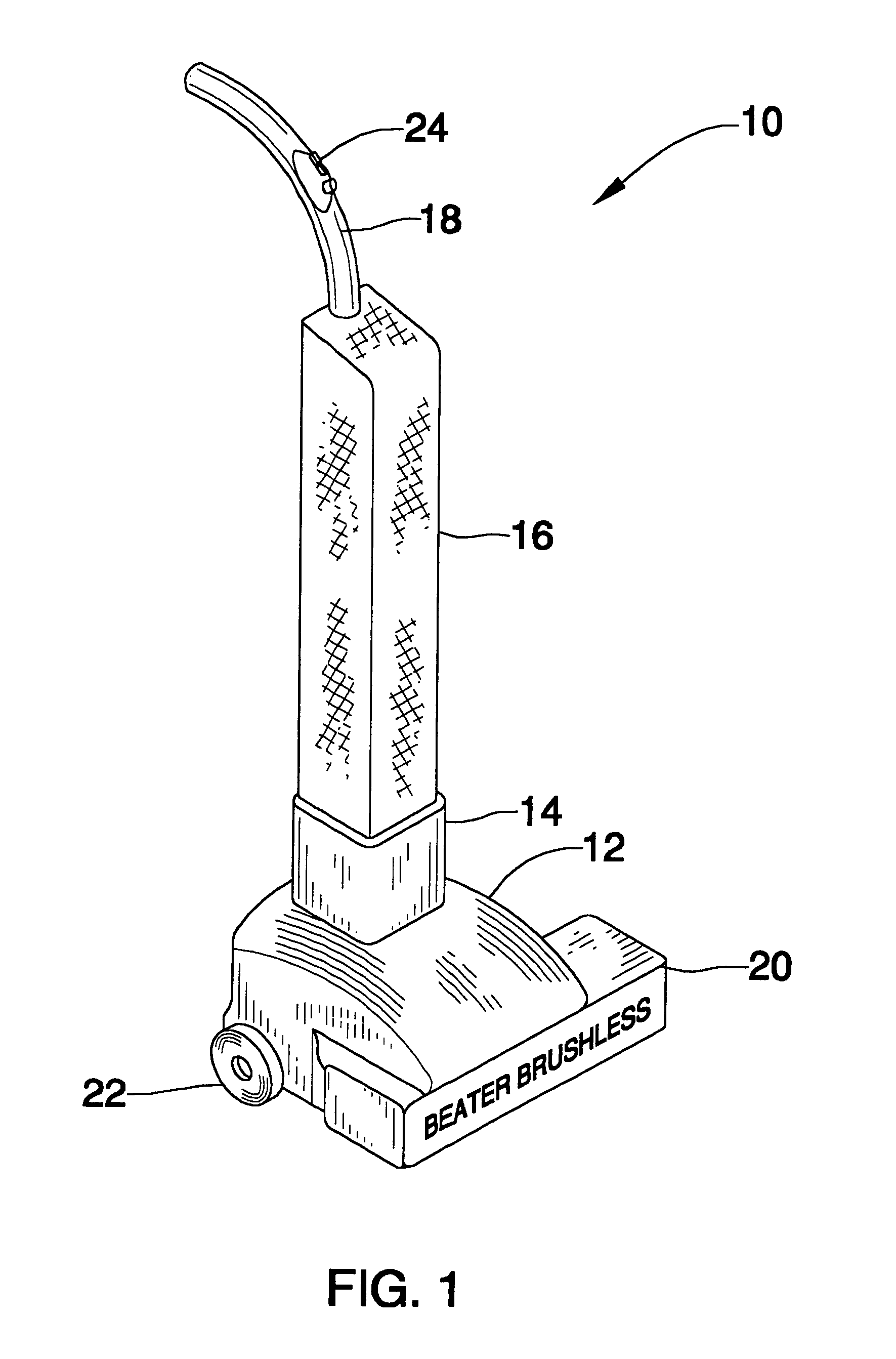

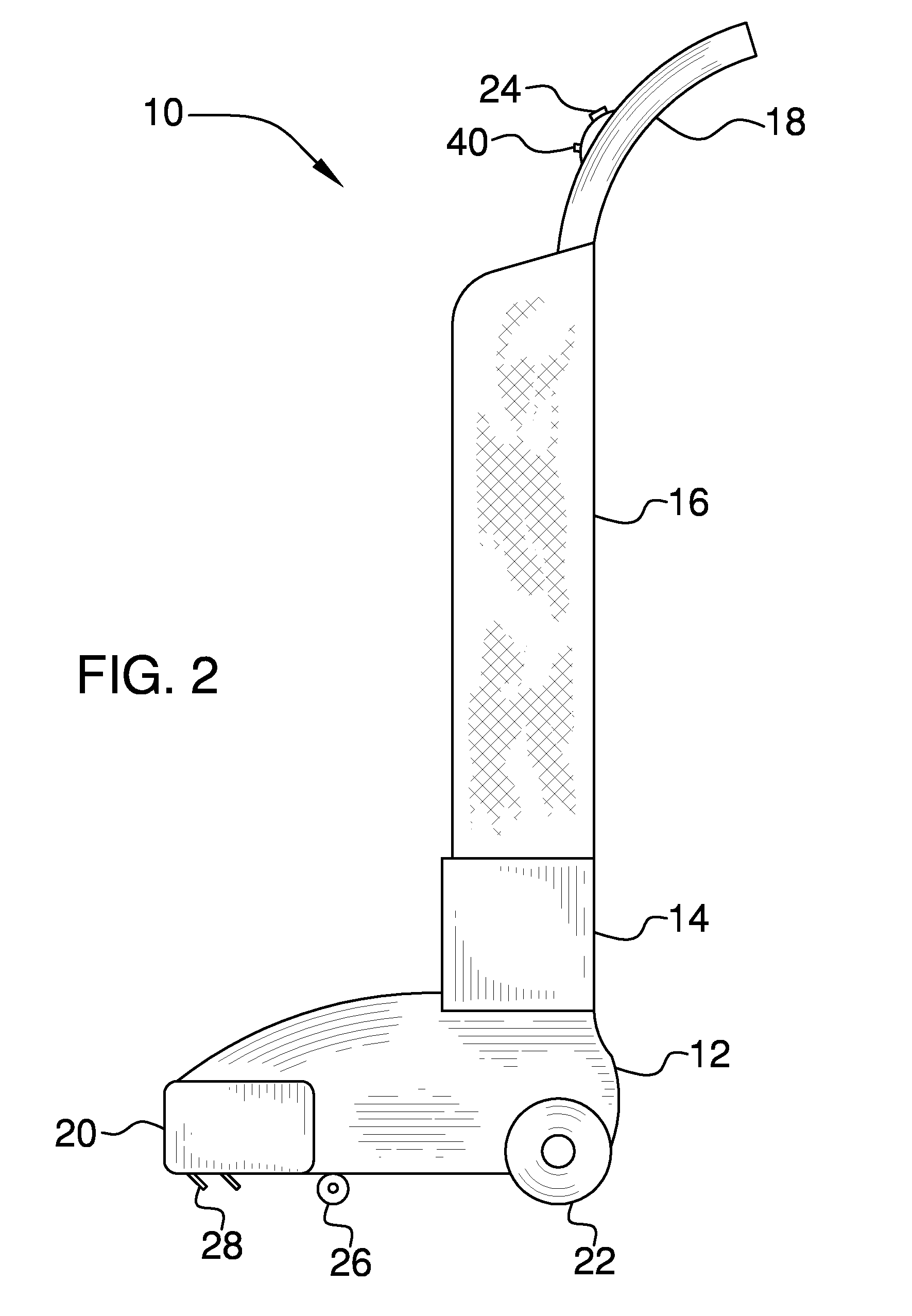

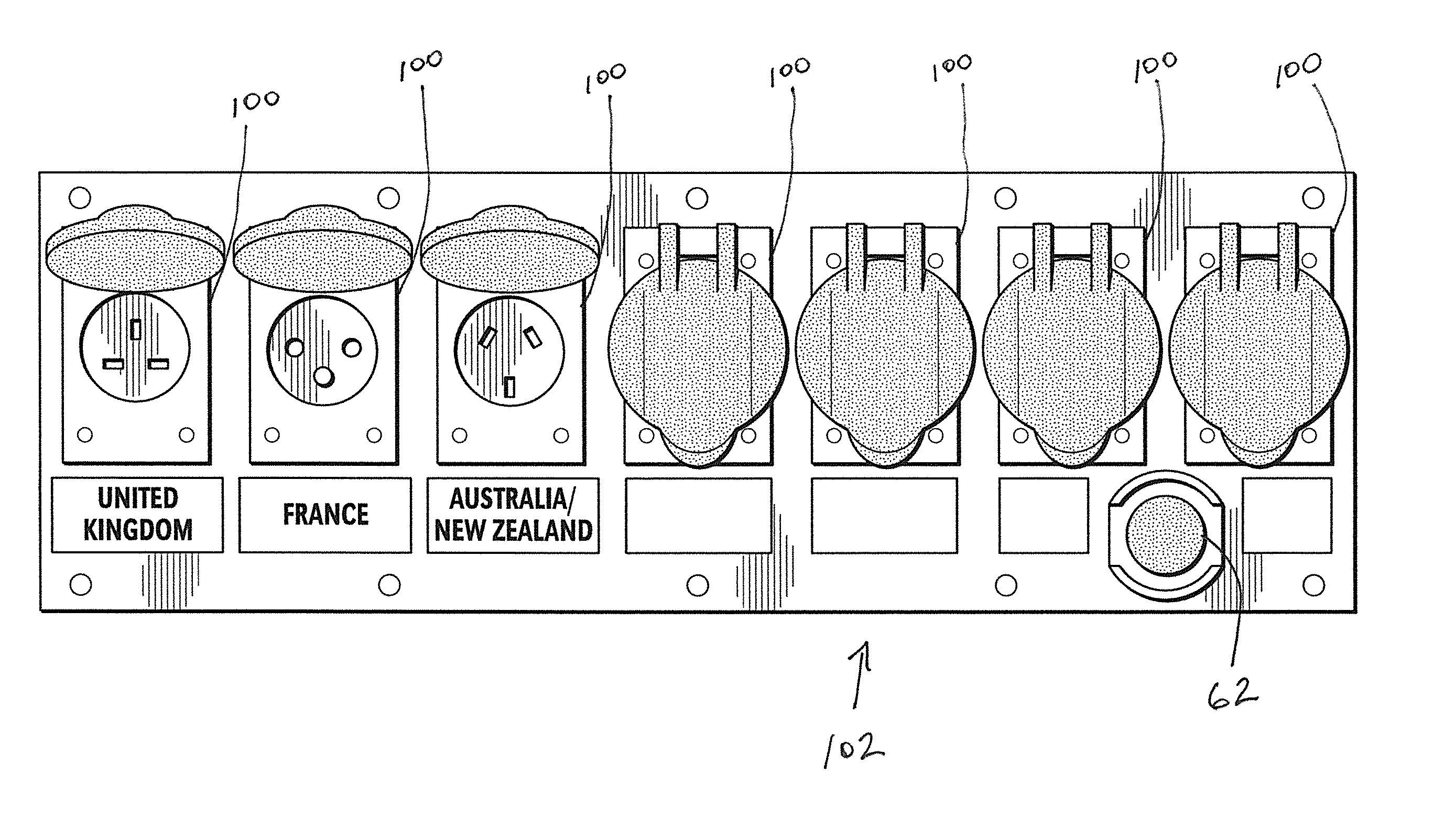

Brushless vacuum cleaner

InactiveUS7555812B1Easily and efficiently manufactured and marketedLow priceMechanical suction controlSuction nozzlesEngineeringForced-air

The brushless vacuum cleaner is an electrical cleaning device that would feature conventional components from traditional upright vacuum cleaners but would use forced air to agitate debris from the surface to be cleaned. The brushless vacuum cleaner would consist of a base unit with multiple air injectors on the bottom, a pump case located on top of the base unit, a collection unit extending upward from the pump case, a vacuum chamber connecting the bottom of the base unit to the collection unit, and a handle that features various control buttons. The pump case would contain an electrical motor which would operate a dual-cycle agitator responsible for pulsing air flow through alternating air injectors on every other cycle. This system would replace the beater brush found on conventional upright vacuum cleaners, thus creating less wear and tear to carpeting and prolonging the life of the carpet.

Owner:PINNEY CRAIG A

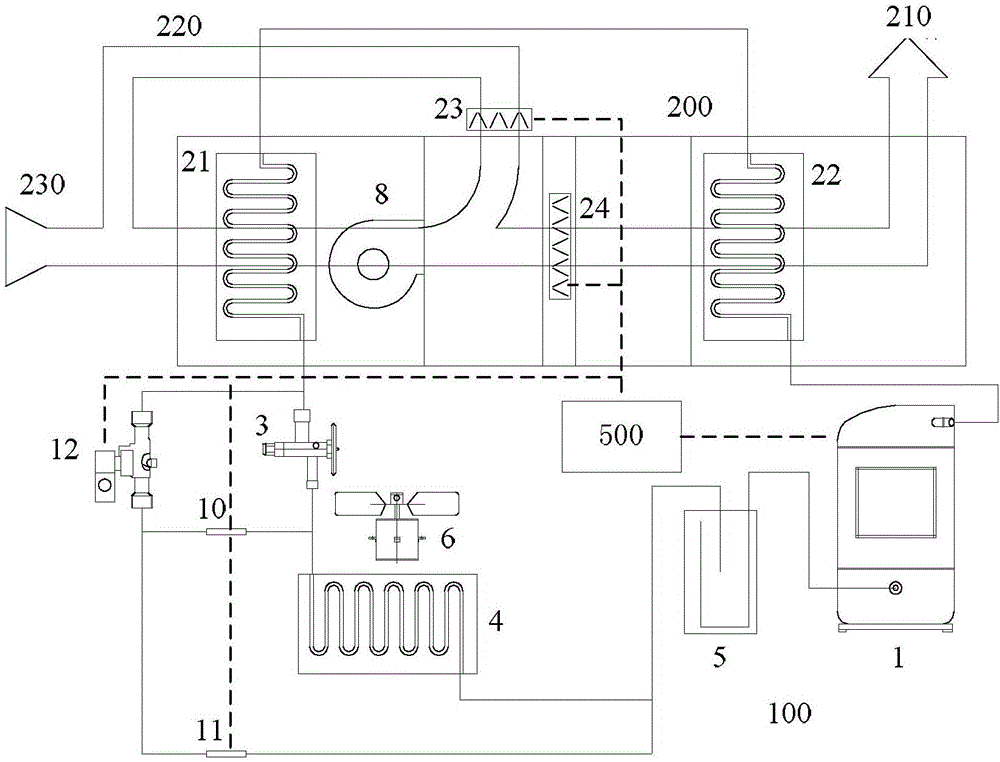

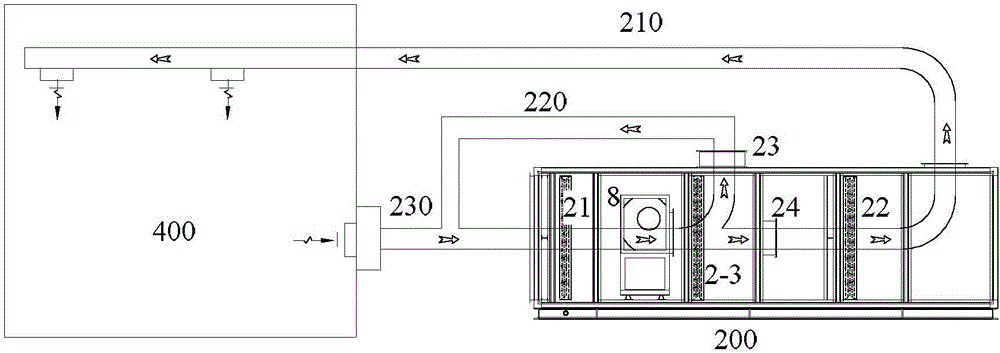

Dual-cycle machine room energy-saving air conditioner

ActiveCN101943449ASolve the problem of heat rejectionSolve the adjustmentSpace heating and ventilation safety systemsLighting and heating apparatusIntermediate heat exchangerTemperature difference

The invention provides a dual-cycle machine room energy-saving air conditioner which comprises an evaporator arranged in a machine room as well as a condenser, a compressor, a three-way valve, a first intermediate heat exchanger and a second intermediate heat exchanger which are arranged outside the machine room, wherein the three-way valve comprises a first inlet, a second inlet and an outlet, and the outlet is alternatively communicated with the first inlet or the second inlet; and the alternative communication of the three-way valve can realize the switching between a heat-tube heat exchange mode and a compression refrigerating cycle heat exchange mode. The dual-cycle machine room energy-saving air conditioner can flexibly select one heat exchange mode according to the temperature difference between the interior and the exterior of the machine room, thereby effectively solving the heat extraction problem of the machine room and achieving the advantages of low energy consumption, high reliability and long service life.

Owner:BEIJING NYF SCI & TECH DEV CO LTD

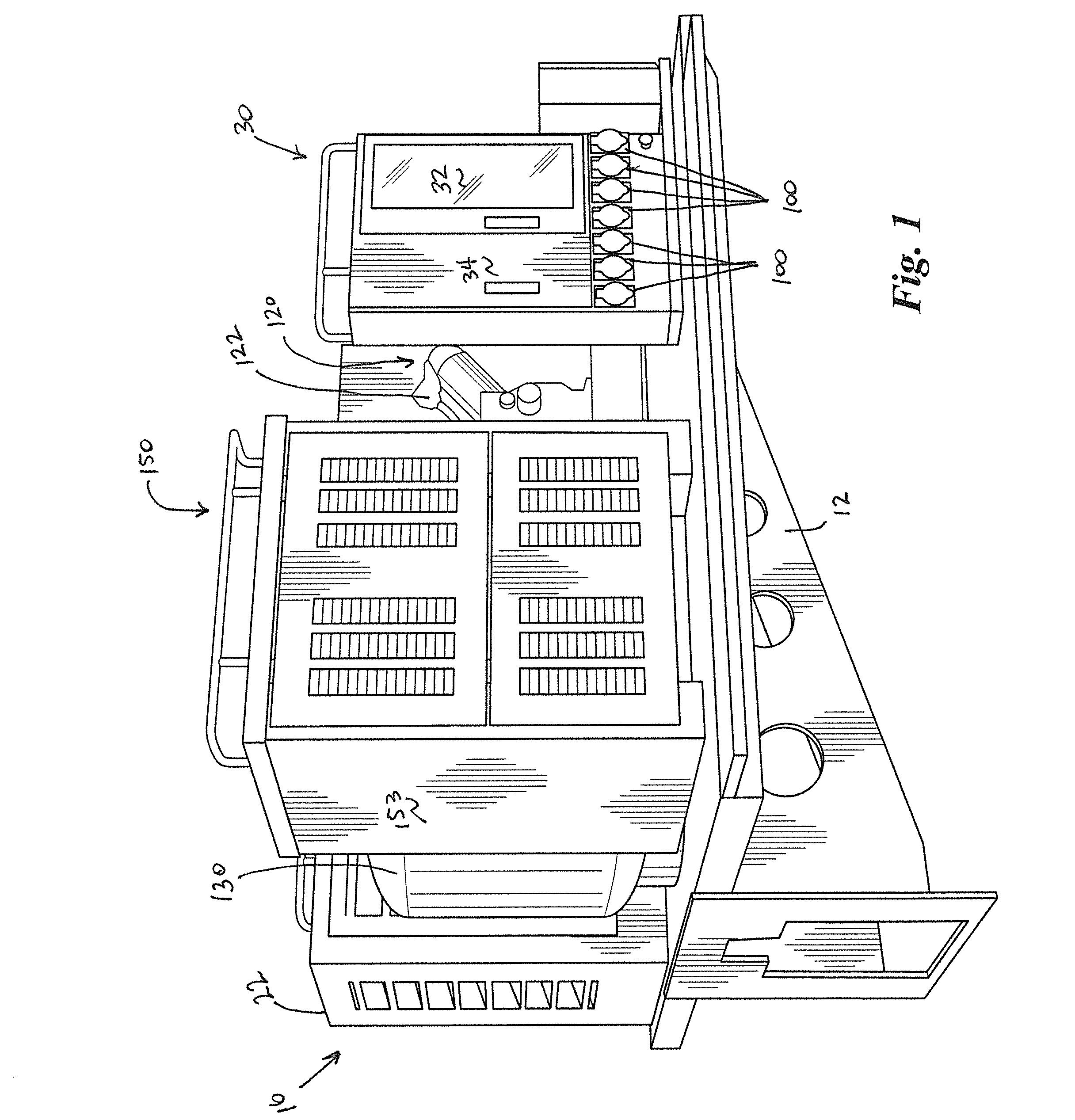

Dual-cycle mode catalytic cracking reaction regenerative system production technology and device

The invention belongs to the technical field of catalytic racking reaction and provides a dual-cycle mode catalytic cracking reaction regenerative system production device which is of a design structure consisting of a riser used for carrying out two-stage catalytic cracking reaction, a two-stage precipitator, a stripper and a high-and-low parallel reaction regenerator (8); a heavy oil riser (1) is of a riser structure used for carrying out the two-stage catalytic cracking reaction, and is provided with a heavy oil riser first reactor (9) and a heavy oil riser second reactor (11); a first precipitator (6) is arranged between the heavy oil riser first reactor (9) and the heavy oil riser second reactor (11), and with the adoption of the first precipitator (6), the reaction of the heavy oil riser is divided into a catalyst first cyclic system and catalytic cracking first reaction stage, and a catalyst second cyclic system and catalytic cracking second reaction stage; and according to the invention, the problems of large light oil yield deviation, high coking rate, coking influence, catalyst regeneration and the like found in the traditional riser production process are solved.

Owner:马俊杰

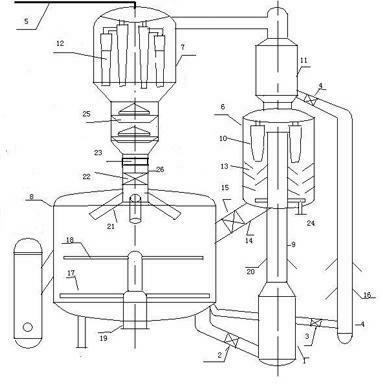

Welding module including dual cycle power system

InactiveUS20130099558A1Faster cycle timeExtend cycle timeDc network circuit arrangementsLine/current collector detailsElectricityTransformer

A device has an engine mechanically coupled to a generator, and a plurality of electrical receptacles coupled to the generator. The device also includes a transformer and a selector switch for selectively placing the transformer in a circuit containing at least one of the plurality of electrical outlets.

Owner:VANGUARD EQUIP

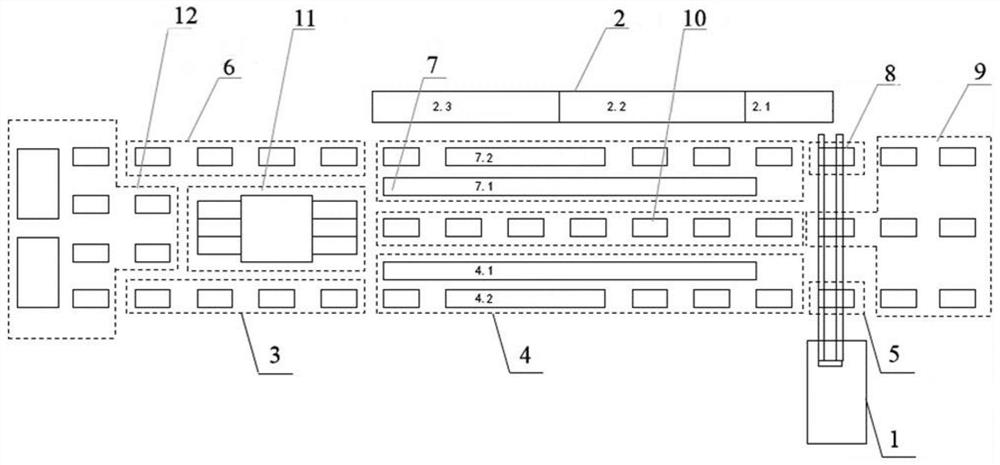

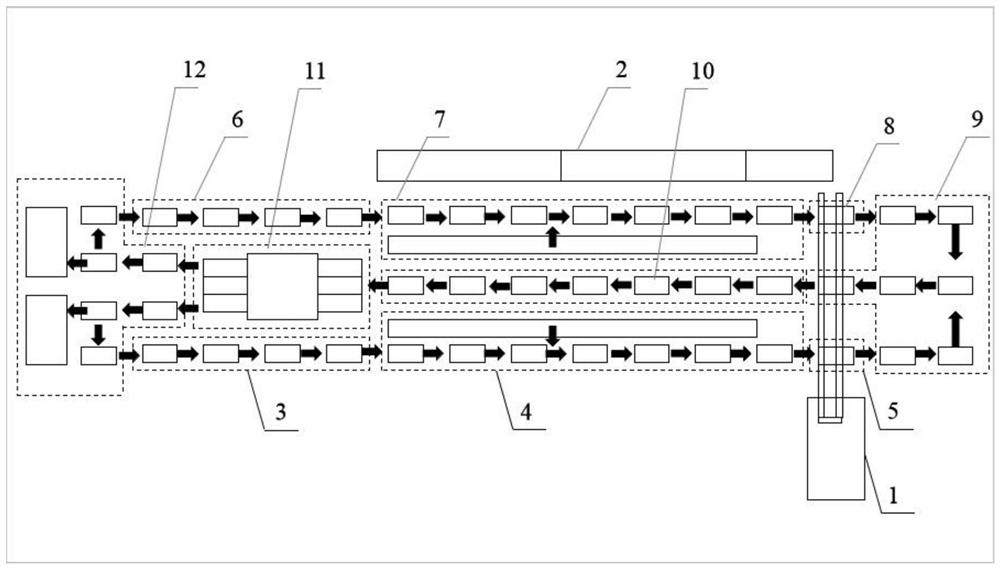

Double-cycle production line and production process of prefabricated building prefabricated parts

PendingCN111975974AImprove performanceSolving inefficienciesCeramic shaping plantsFeeding arrangmentsProduction lineConstruction engineering

The invention provides a double-cycle production line and production process of prefabricated building prefabricated parts, and belongs to the technical field of production of the prefabricated building prefabricated parts. The technical problems that in the prior art, the occupied area is large, and the production efficiency is low are solved. According to the solution, the double-cycle production line of the prefabricated building prefabricated parts comprises a formwork removal hoisting area, a steam curing area, a part pre-curing area and a ferry rest area which are sequentially arranged in the horizontal direction of a workshop from left to right, wherein the double-cycle production line further comprises a first machining preparation area, a second machining preparation area, a firstpouring preparation area, a second pouring preparation area, a first pouring vibration area and a second pouring vibration area; the first machining preparation area and the second machining preparation area are symmetrically arranged on the two sides of the steam curing area correspondingly; the first pouring preparation area and the second pouring preparation area are symmetrically arranged onthe two sides of the part pre-curing area correspondingly; and the first pouring vibration area and the second pouring vibration area are symmetrically arranged on the two sides of the left end of theferry rest area correspondingly. Compared with the prior art, the double-cycle production line and production process of the prefabricated building prefabricated parts can meet the production requirements of various prefabricated building prefabricated parts and have the advantages that the working efficiency is high, design is reasonable, and the occupied site is saved.

Owner:山西建投晋西北建筑产业有限公司

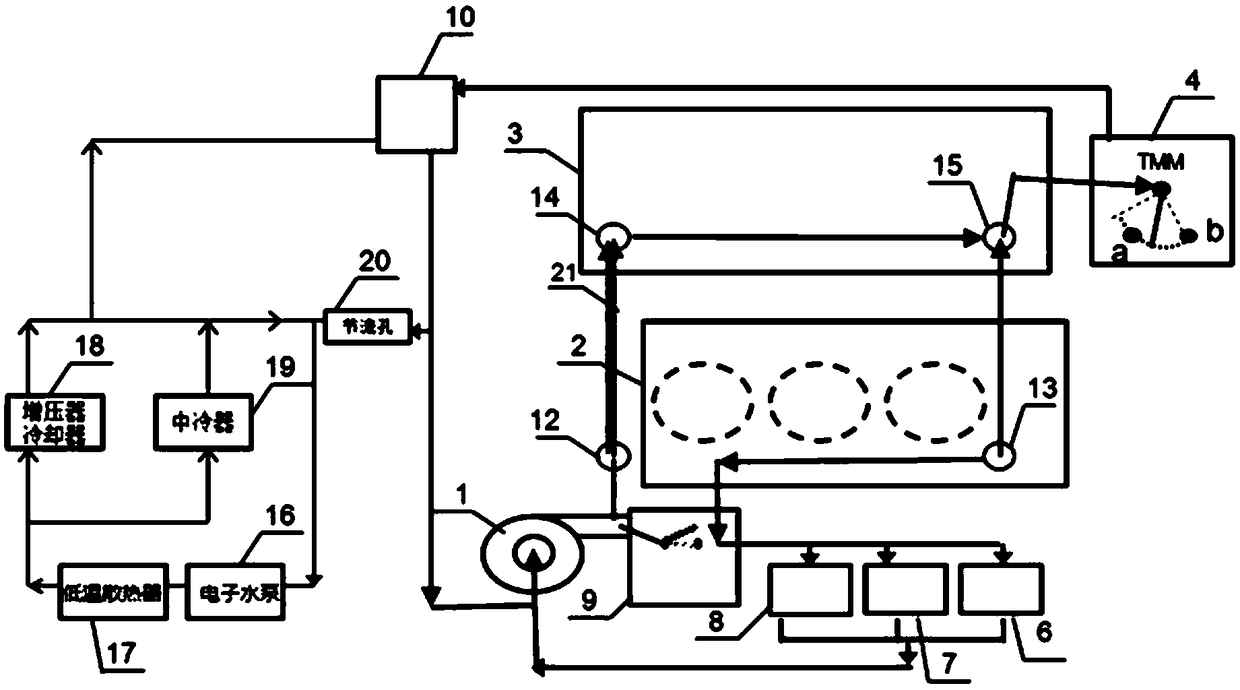

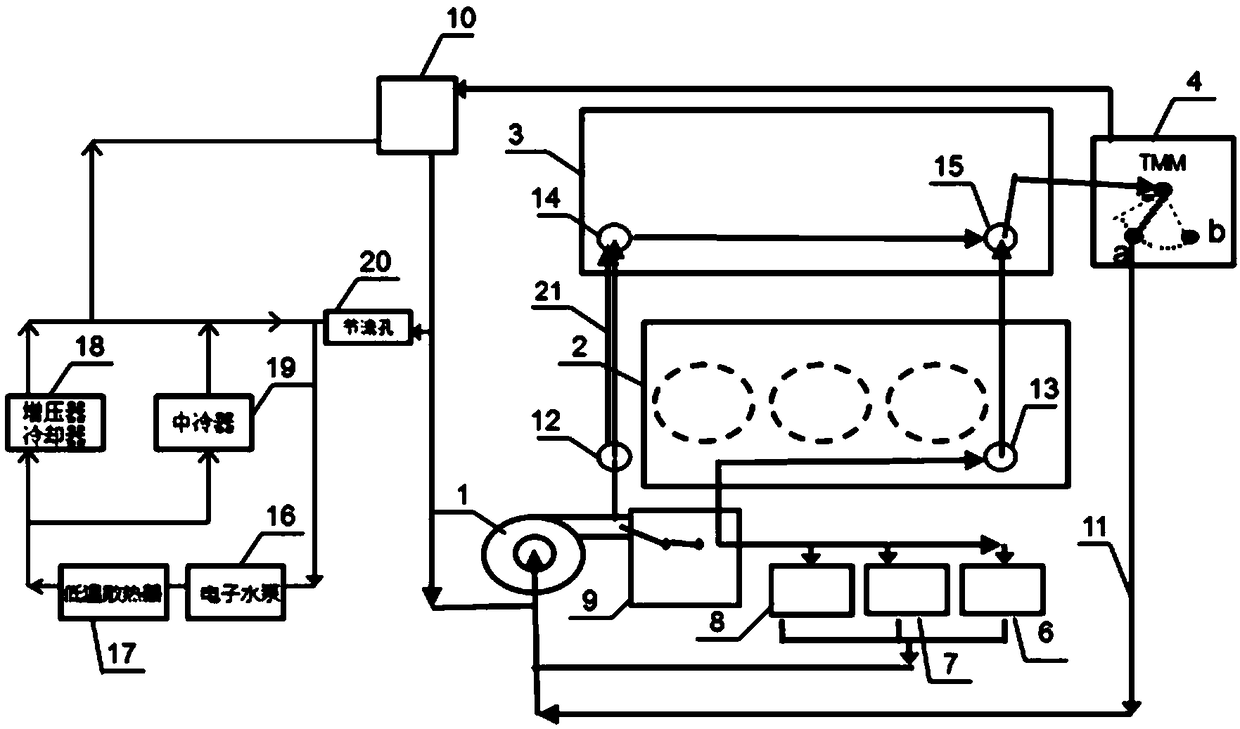

Dual cycle cooling system for engineering vehicle

PendingCN107882624ASmall structure sizeImprove cooling efficiencyLiquid coolingInternal combustion piston enginesCirculator pumpIntercooler

The invention belongs to the technical field of cooling of vehicles and relates to a dual cycle cooling system for an engineering vehicle. The problems that in the prior art, the heat dissipation efficiency is low, the structure size is large, and cooling energy consumption is large are solved. The dual cycle cooling system is composed of a high-temperature cycle cooling system and a low-temperature cycle cooling system. The high-temperature cycle cooling system is composed of an engine, an engine water pump, a liquid-liquid radiator a and a high-temperature radiator. High-temperature cycle cooling liquid sequentially flows through an inner cooling cavity of the engine and the liquid-liquid radiator a. The low-temperature cycle cooling system is composed of a low-temperature radiator, a low-temperature cycle pump, a water cooling intercooler and a liquid-liquid radiator c. After low-temperature cycle cooling liquid passes through the low-temperature radiator, the low-temperature cyclecooling liquid sequentially flows through the water cooling intercooler and the liquid-liquid radiator c. Cooling air firstly flows through the low-temperature radiator and then flows through the high-temperature radiator, and heat exchange between heat of the systems of the vehicle and air is achieved. By means of the dual cycle cooling system for the engineering vehicle, the structural size of the radiators is reduced, the cooling efficiency of the cooling air is improved, and energy consumption of the vehicle cooling system is reduced.

Owner:JILIN UNIV +2

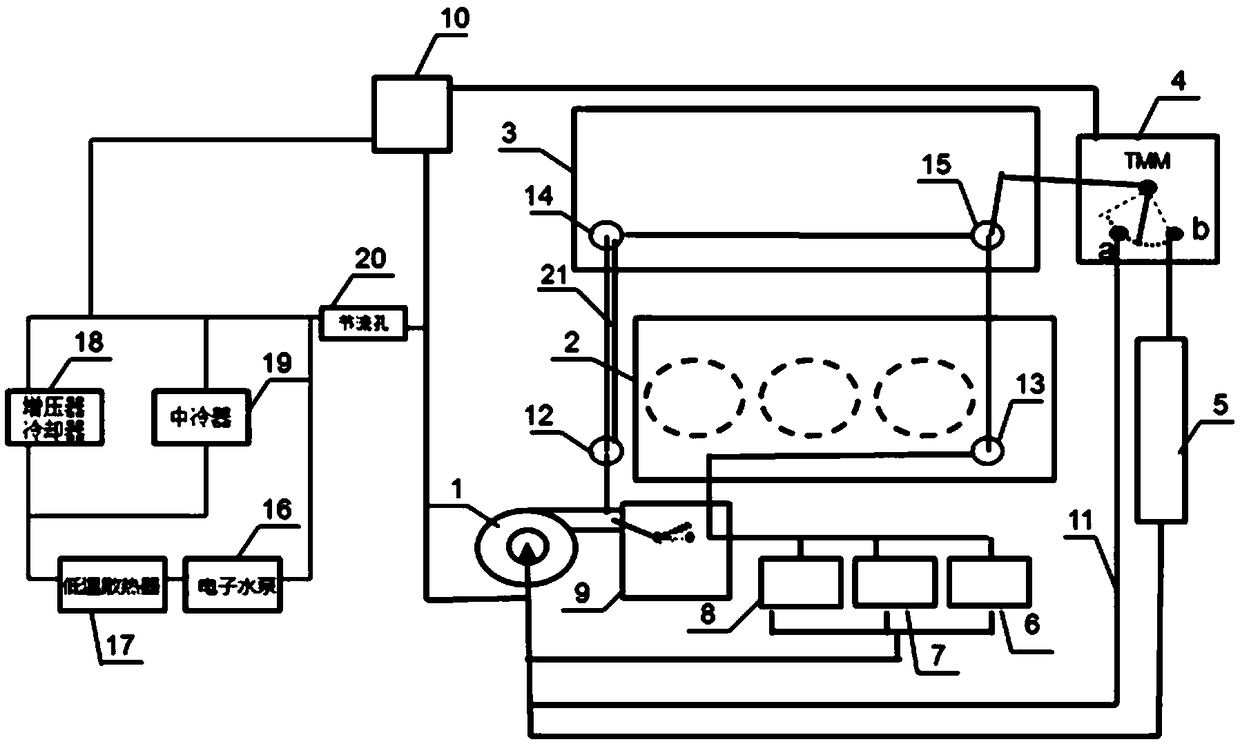

High/low-temperature cooling system of dual-cycle engine

InactiveCN109139223AReduce friction workLarge water flowCoolant flow controlMachines/enginesEngineeringWater circulation

The invention discloses a high / low-temperature cooling system of a dual-cycle engine. The system comprises high-temperature and low-temperature water circulating cooling systems. The high-temperaturesystem is selectively opened or closed through a temperature adjuster and an electromagnetic valve to switch the flowing direction of cooling water according to engine loads so as to realize quick machine warming and reduction of the oil consumption. A cylinder cover and a cylinder block water jacket are maintained in serial connection in the cold starting phase of an engine, so that twice heatingis performed in one cycle of the cooling water to accelerate heating of the cooling water to the greatest extent. In the machine warming and high-temperature phase with higher engine temperature, thecylinder cover and the cylinder block water jacket are maintained in parallel connection to increase the water flow of the engine to the greatest extent; and respective water flows of a cylinder block and the cylinder cover can be controlled to achieve optimal temperature so as to reduce the knocking and the oil consumption. The low-temperature cycle system adopts an electronic water pump and a common water storage kettle; and a throttling hole is formed between the water storage kettle and the low-temperature system, so that the arrangement space and cost are reduced, the influence on the low-temperature system by the high-temperature system is reduced as far as possible, the intake temperature and the intake efficiency of the engine are effectively guaranteed, the dynamic property of the engine is exerted, and the knocking is prevented.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Multi-description speech coding and decoding methods and systems based on linear predictive residual classified quantization

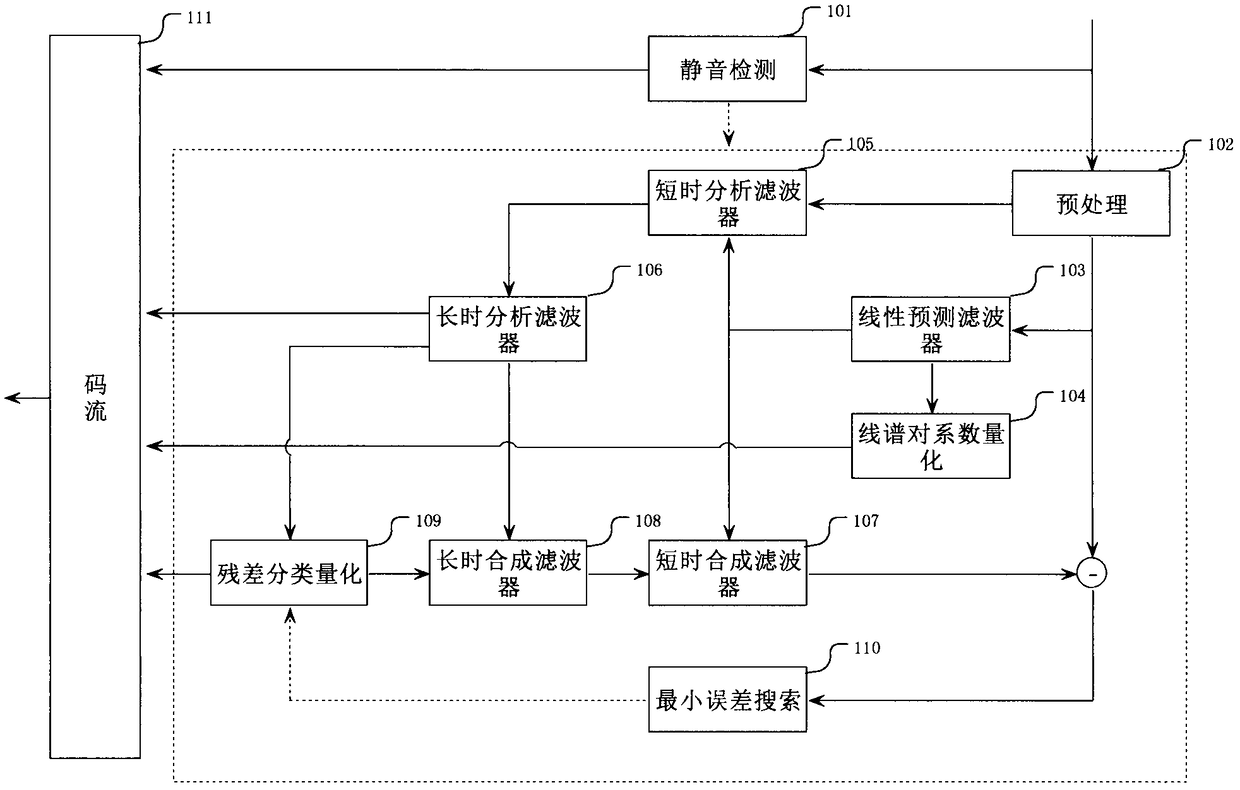

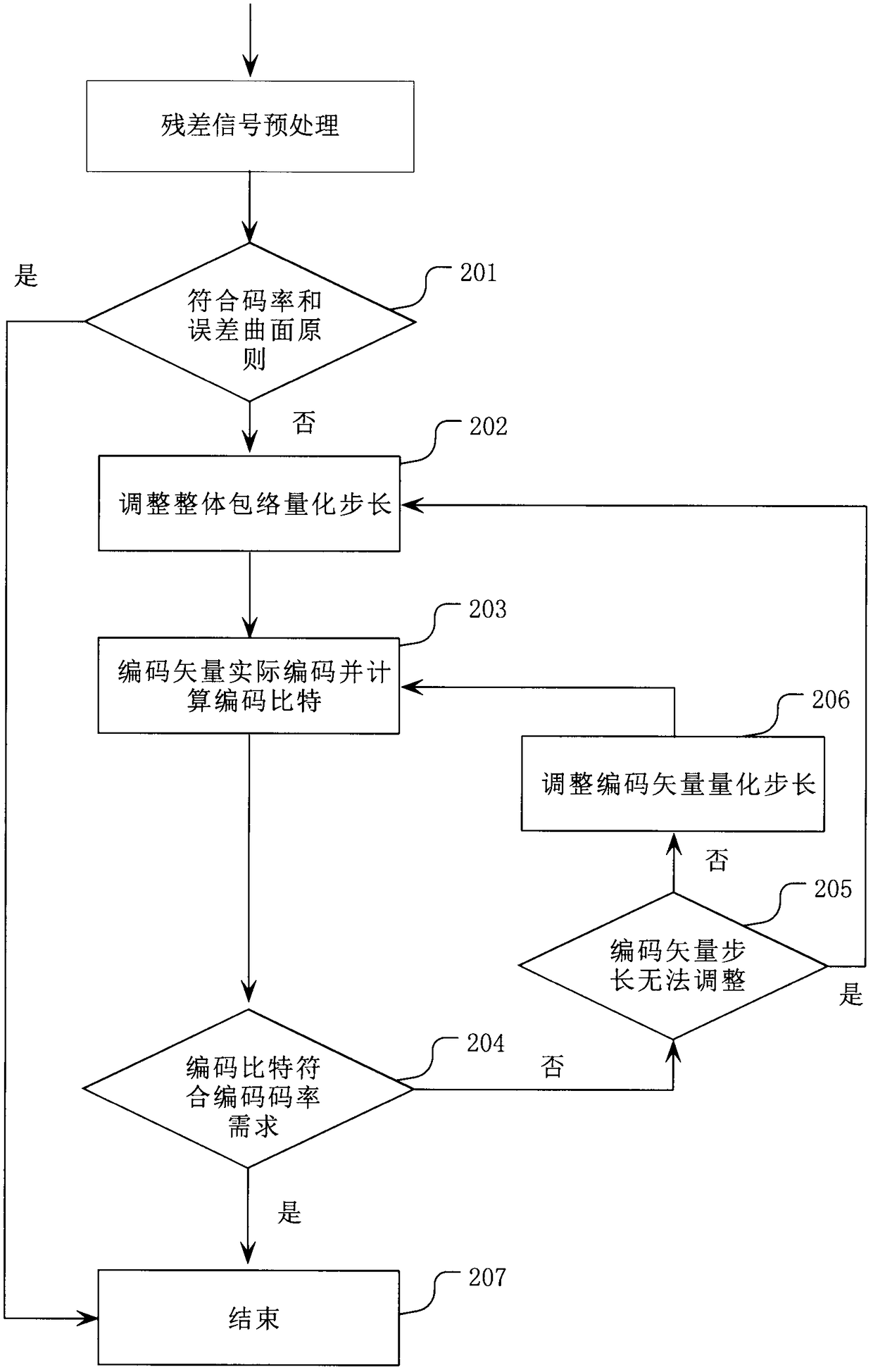

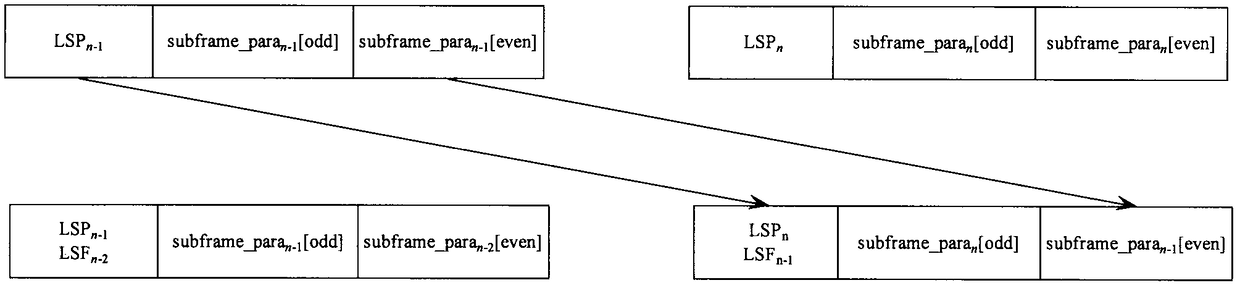

Multi-description speech coding and decoding methods and systems based on linear predictive residual classified quantization are provided. Short-time prediction parameters, long-time prediction parameters and a time-domain predictive residual signal are obtained through short-time prediction analysis and long-time prediction analysis of a to-be-coded voice stream, the residual signal is divided into multiple multidimensional coding vectors, the energy envelope of each coding vector is calculated for bit allocation, and dual-cycle vector quantizing and coding is carried out on the time-domain coefficient of each coding vector; and interlaced multi-description grouped packaging is carried out on the short-time prediction parameters and the long-time prediction parameters, and multiplexed packaging is carried out on the predictive residual quantization indexes and the coded bits of the vector quantization values of quantized coded signals.

Owner:NANJING UNIV

Single-column dual-cycle efficient desulfurization process system and method

InactiveCN106422735AImprove qualityImprove desulfurization efficiencyGas treatmentDispersed particle separationProcess systemsSulfate

The invention relates to a single-column dual-cycle efficient desulfurization process system. The system comprises a main absorption tower, a main slurry tank and an auxiliary slurry tank, wherein a flue gas inlet is formed in one side of the lower part of the main absorption tower, and a flue gas outlet is formed in the upper part of the main absorption tower; a gypsum slurry oxidizing slurry tank is arranged at the bottom of the main absorption tower as the main slurry tank; and two absorption regions including a main cycle spraying region and an auxiliary cycle spraying region are arranged in a spraying region of the main absorption tower. The single-column dual-cycle efficient desulfurization process system has the characteristics and beneficial effects that spraying slurry of the main spraying region and the auxiliary spraying region absorbs SO2, absorbed and fused SO2 is strengthened by virtue of mass transfer components arranged between the main spraying region and the auxiliary spraying region, and finally the pH value of the mixed slurry is 4.5-5.0, so that calcium sulfite in the slurry of the main slurry tank is helped to be oxidized into calcium sulfate by virtue of forced-oxidation air and finally crystallizes to form gypsum, and the gypsum slurry is discharged by virtue of a gypsum discharging pump.

Owner:ZHEJIANG TIANDI ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com