Multifunction heat syphon convection double circulation solar water heater

A multi-functional, thermosiphon technology, applied in the field of solar energy applications, to solve visual pollution, realize pressure-bearing operation, and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

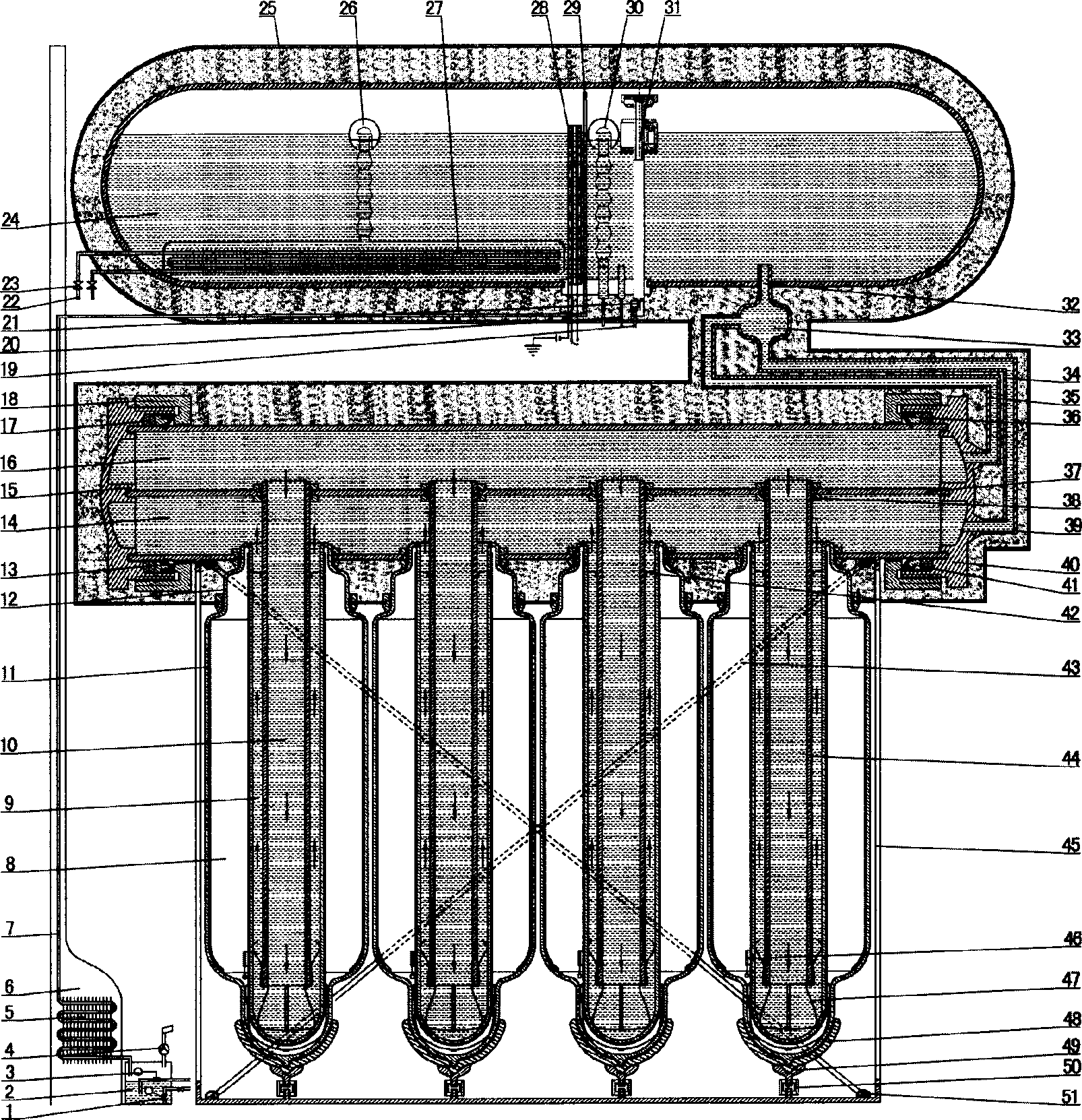

[0033] The first embodiment: the single-layer tube deflector 44 is suspended and fixedly installed in the lumen of the single-pass variable-diameter reflective concentrated solar vacuum heat collection tube 8 through the support clip 42 and the metal elastic clip 47, and the heat-collecting element is a single-pass variable-diameter Reflecting and concentrating solar energy vacuum heat collecting tubes are composed of 8 heat collecting elements, and the top of the heat collecting tubes is sealed and fixed on the header by a header opening sealing ring 38. The two ends of the header frame are a locking head device composed of a sealing ring 17, a pipe plug 15, a support ring 41, a locking expansion ring 36, a tightening device 18, and a header 40 of the header. In the water tank 24, a floating control pressure-bearing and non-pressure-bearing automatic switchover valve 31 is installed, which can realize pressure-bearing and non-pressure-bearing automatic conversion. The floating...

no. 2 Embodiment

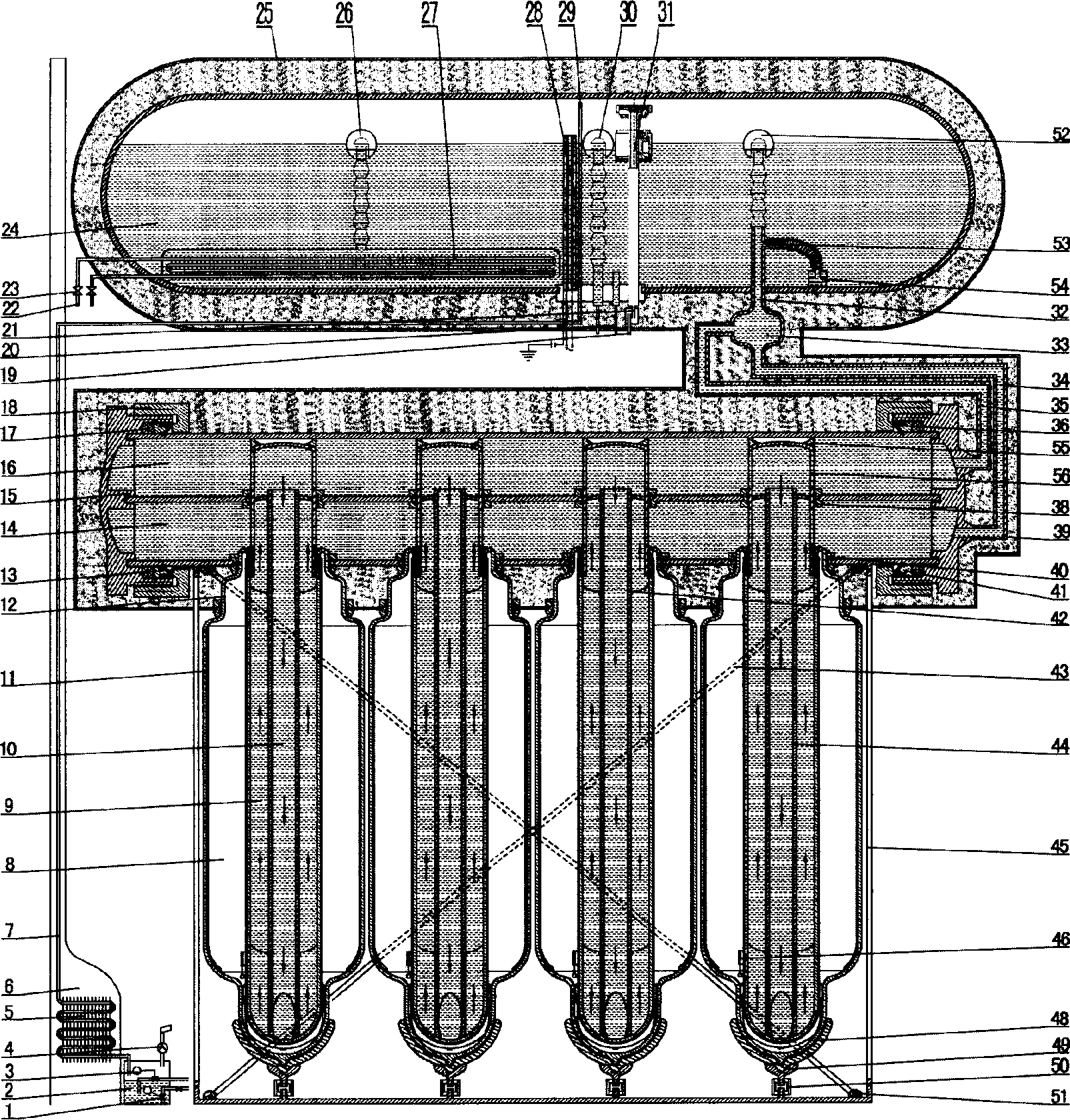

[0035] The second embodiment: the single-layer pipe deflector 44 is inserted and fixedly installed in the lumen of the single-pass variable-diameter reflective concentrating solar vacuum heat collection tube 8 through the oblique opening of the support card 42, and the single-pass variable-diameter reflective concentrating solar vacuum collector A pressure balance device 56 is connected to the top of the heat pipe 8, and a suction cap 55 is installed on the pressure balance device 56, which can realize the pressure-bearing operation of the vacuum heat collecting tube. The floating type fluid discharge pipe 52 is connected and fixed on the float, and the discharge port is below the water surface, and the fluid supply pipe 54 makes its water intake at the bottom of the water tank 24 through the counterweight device. Cold water is taken from the bottom of the water tank 24 through the fluid supply pipe 54, and the water is poured into the water supply pipe 35, the return pipe 34 a...

no. 3 Embodiment

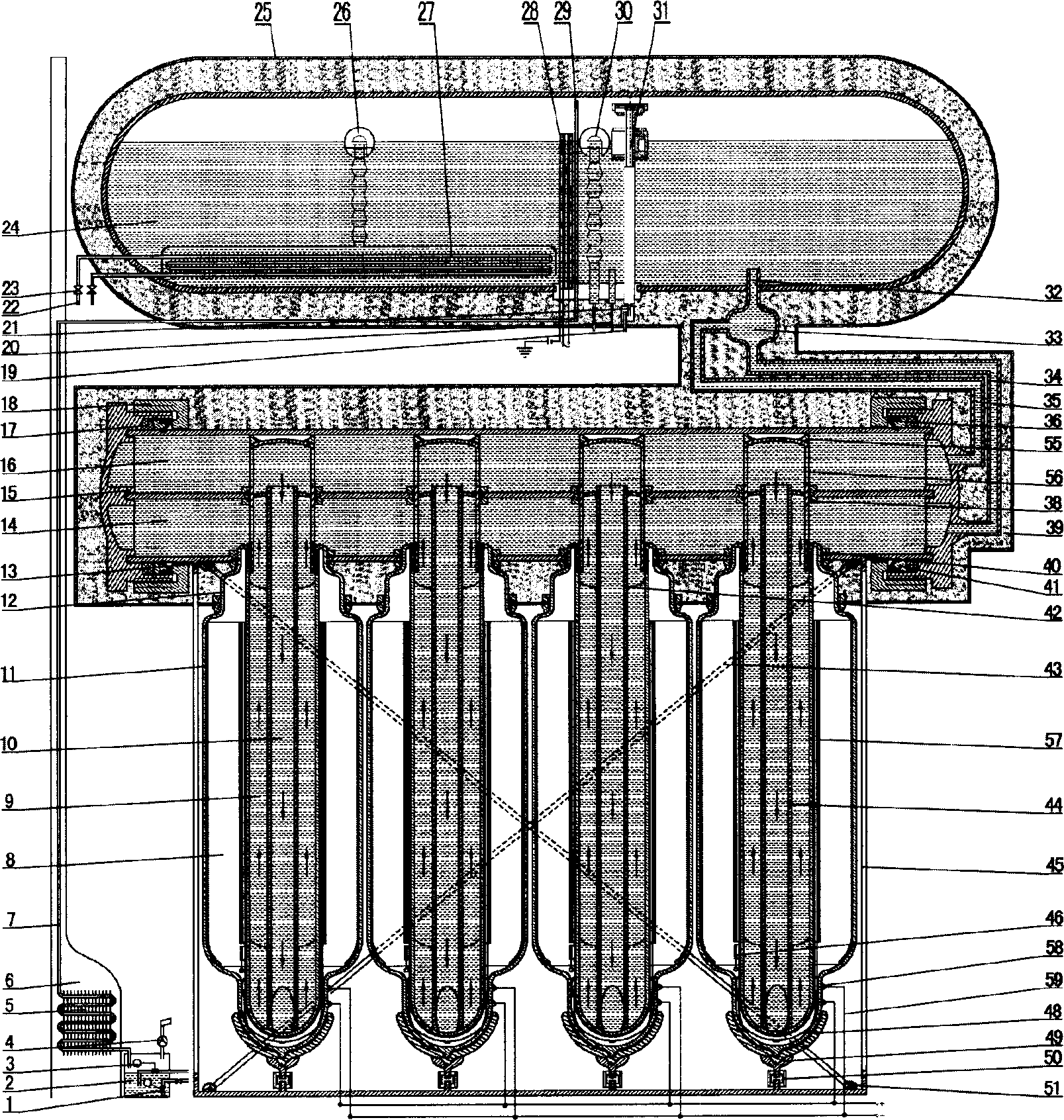

[0036] Embodiment 3: The single-layer tube deflector 44 is inserted and fixedly installed in the lumen of the single-pass variable-diameter reflective concentrating solar vacuum heat collection tube 8 through the oblique opening of the support card 42, and the single-pass variable-diameter reflective concentrating solar vacuum collector The heat pipe 8 is provided with a photovoltaic cell 57, and a wire 59 is drawn out through an electrical connection point 58 of the electrode heat-absorbing film. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com