A water-saving switching cooling tower

A switching type, cooling tower technology, applied in the field of resources and environment, can solve the problems of increasing air stability, poor water saving effect, water evaporation loss, etc., to increase the gas-liquid heat exchange area, avoid water evaporation, and reduce operating energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

[0053] The water-saving switchable cooling tower of the present invention is mainly used for heat exchange and cooling of industrial circulating hot water, and at the same time reduces water evaporation in the heat exchange process of industrial circulating hot water and eliminates the white smoke phenomenon of the cooling tower.

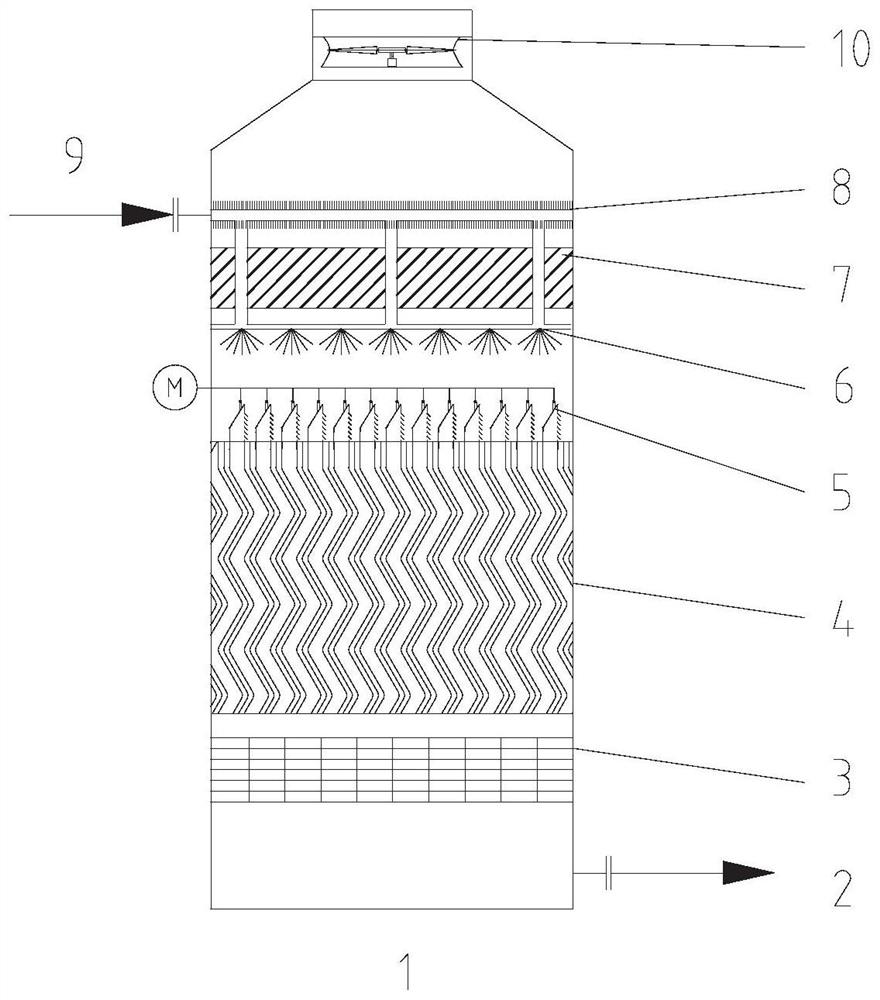

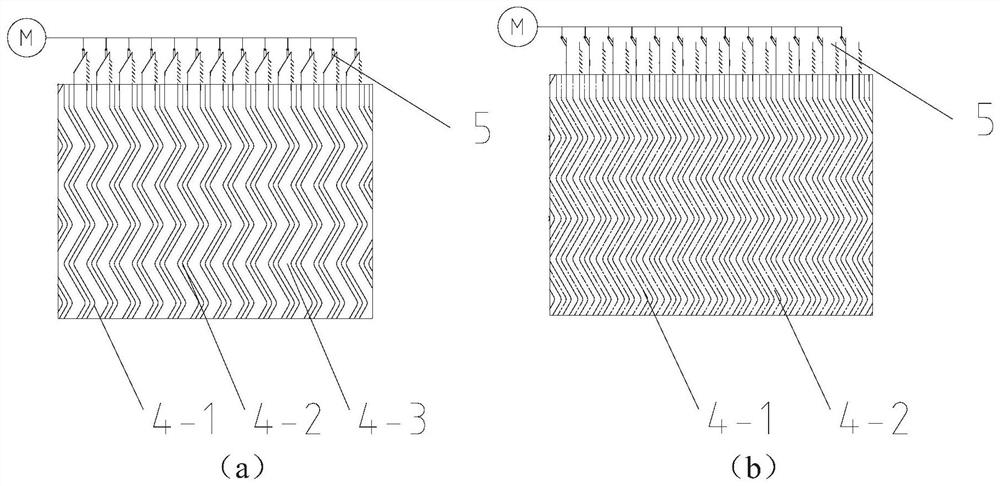

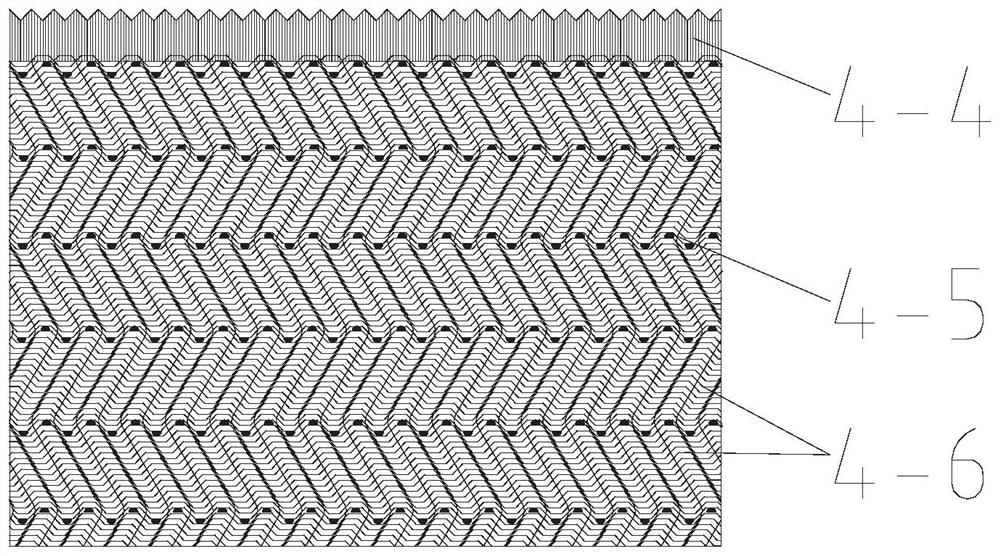

[0054] Such as figure 1 As shown, the water-saving switching cooling tower 1 includes a liquid discharge port 2, an air inlet 3, a multi-channel filler 4, a gas-liquid switching mechanism 5, a liquid distributor 6, a defoamer 7, a liquid distribution finned tube 8, Liquid inlet 9 and exhaust port 10; liquid outlet 2, air inlet 3, multi-channel filler 4, gas-liquid swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com