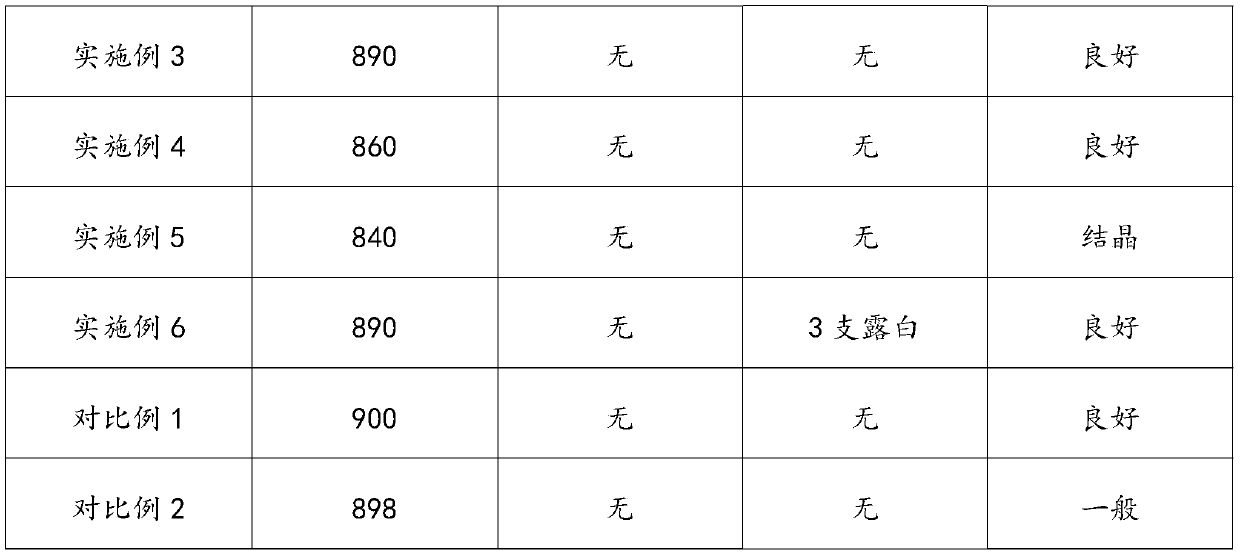

Patents

Literature

84results about How to "Increase unsaturation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

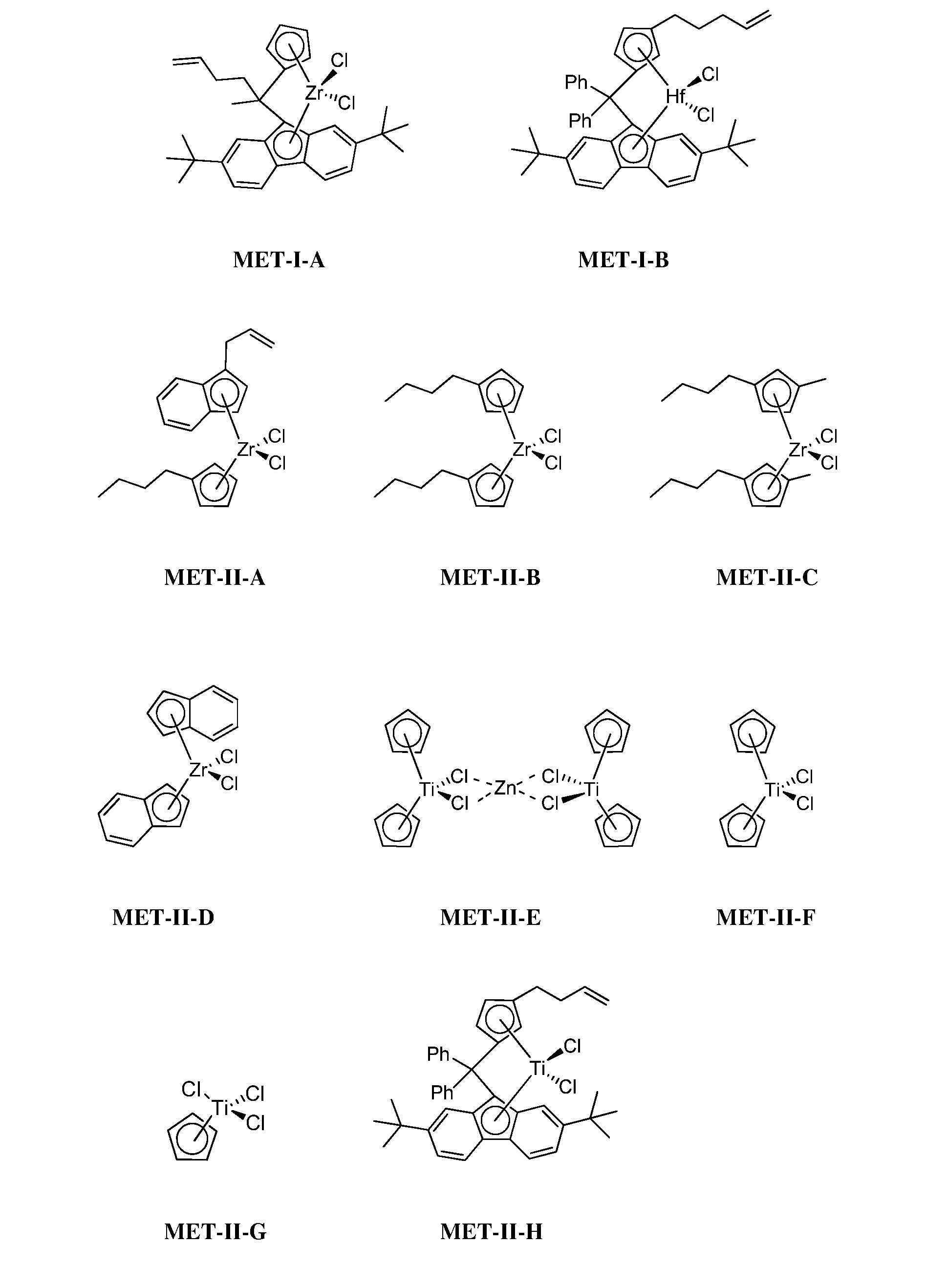

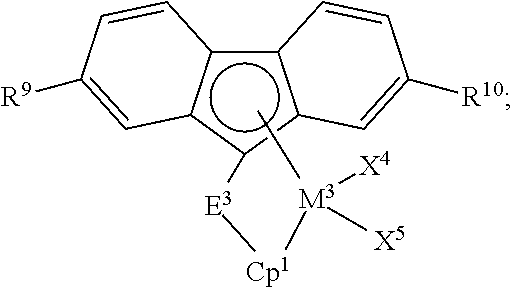

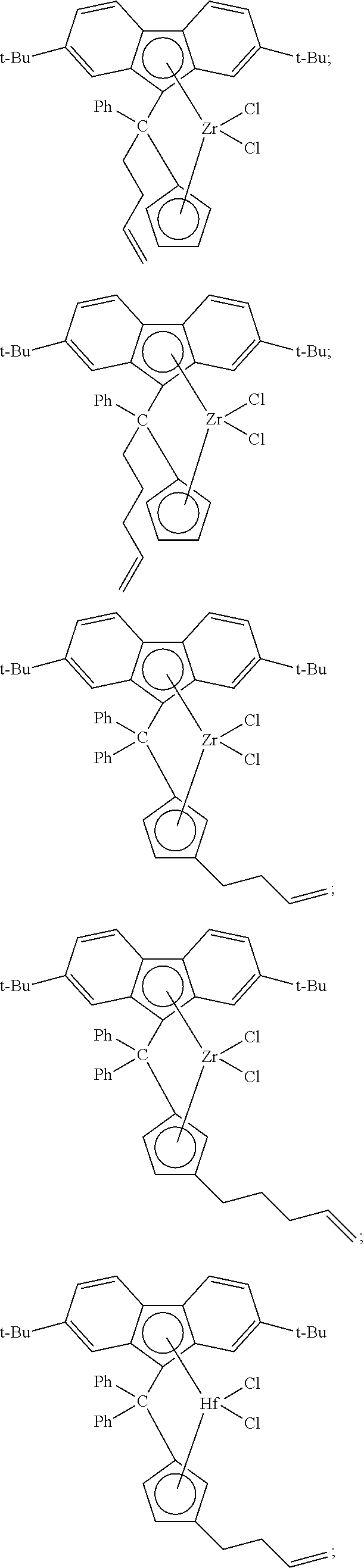

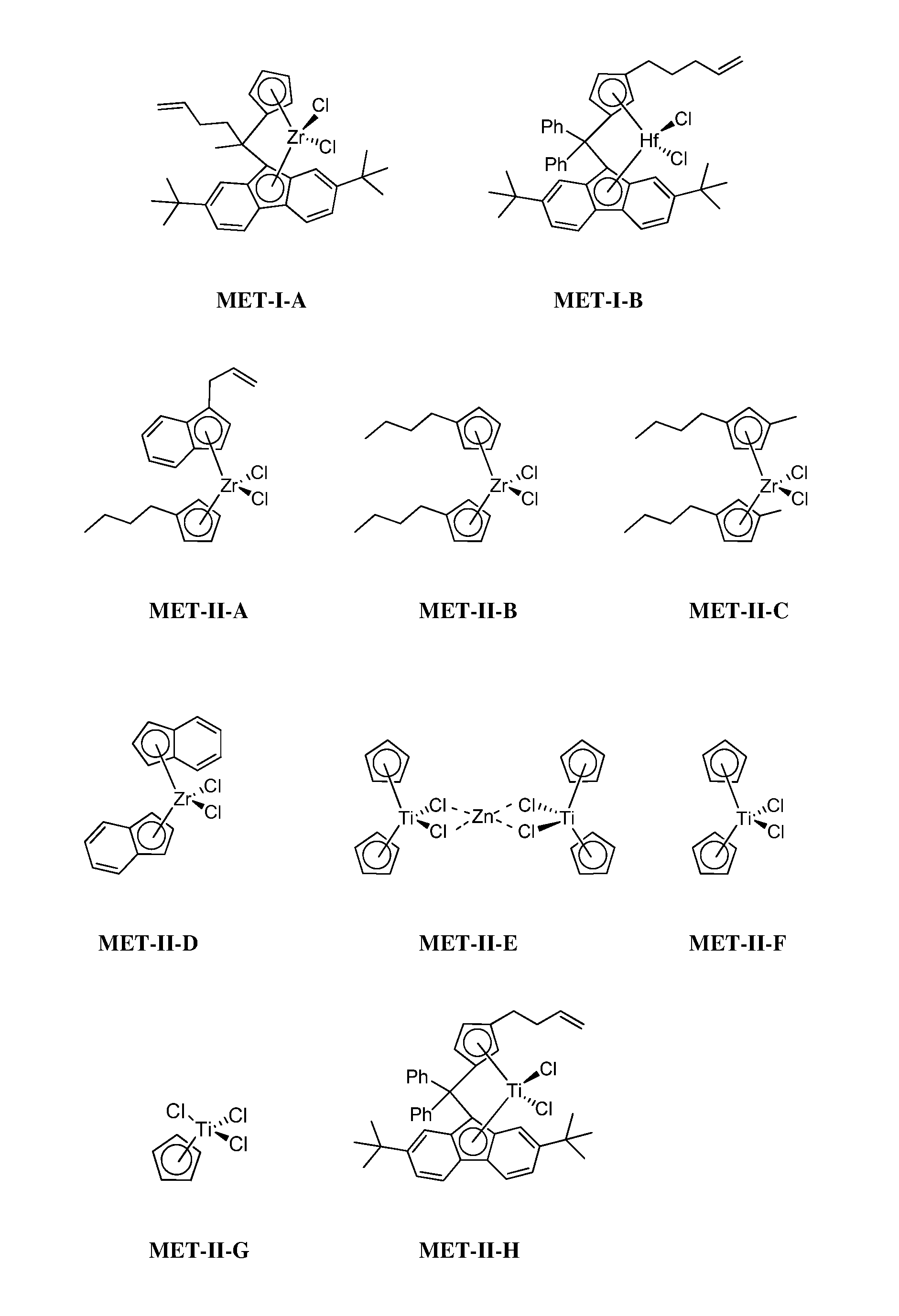

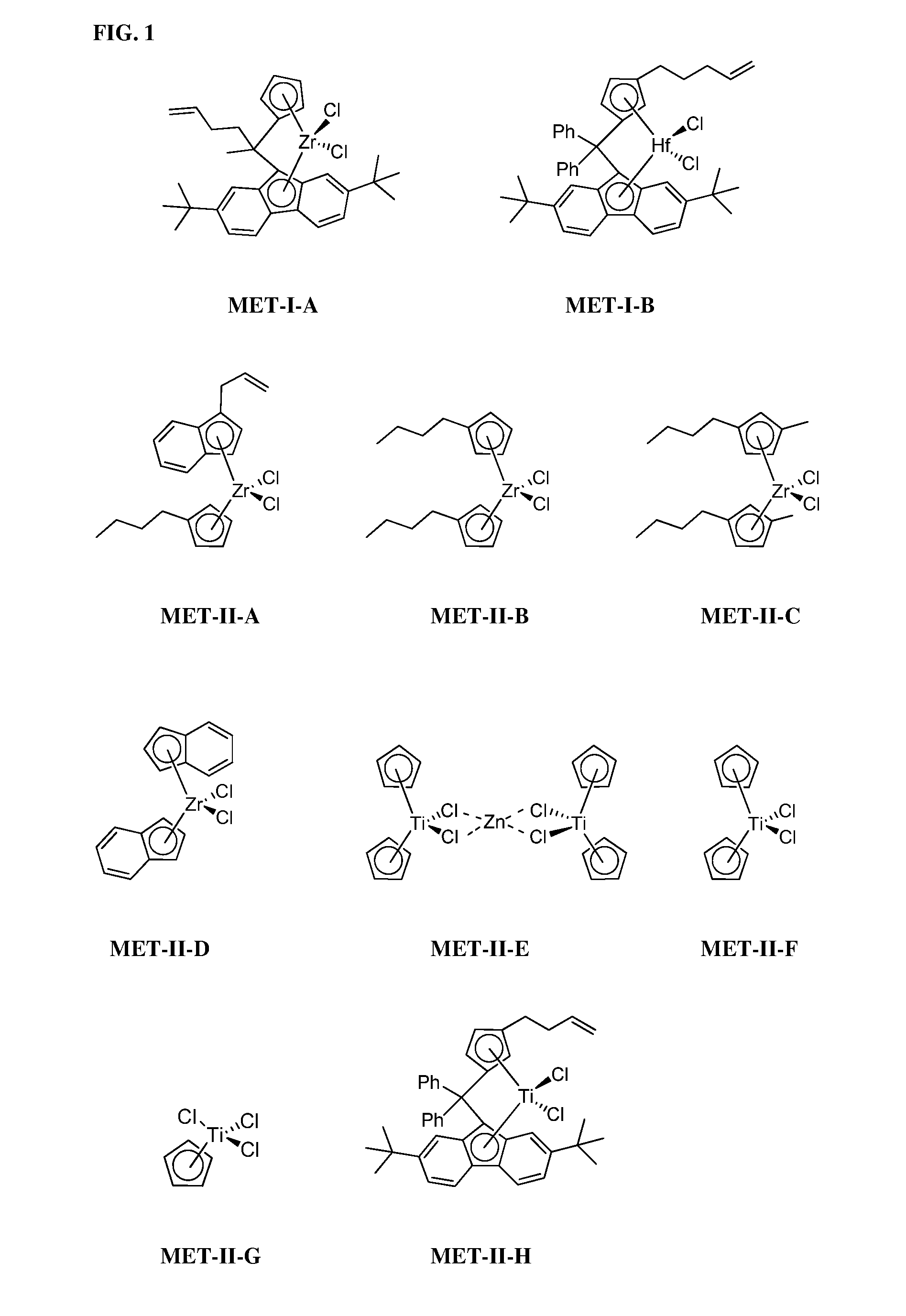

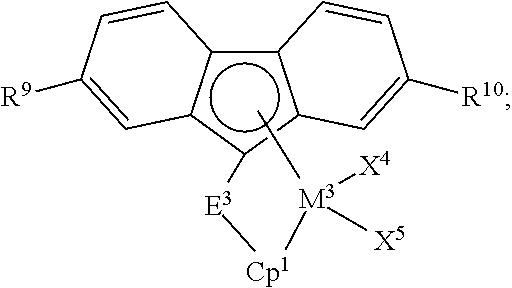

Use of hydrogen scavenging catalysts to control polymer molecular weight and hydrogen levels in a polymerization reactor

ActiveUS8207280B2High molecular weightReduce and control levelOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHydrogenPolymer science

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Use of hydrogen scavenging catalysts to control polymer molecular weight and hydrogen levels in a polymerization reactor

ActiveUS20100331501A1High molecular weightReduce and control levelOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer scienceHydrogen

The present invention provides dual catalyst systems containing a metallocene catalyst and a hydrogen scavenging catalyst, and polymerization processes employing these dual catalyst systems. Due to a reduction in hydrogen levels in the polymerization processes, olefin polymers produced from these polymerization processes may have a higher molecular weight, a lower melt index, and higher levels of unsaturation.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Radiation crosslinking polyvinyl chloride material and its prepn. method

A radiation cross-linked polyvinyl chloride material is prepared from polyvinyl chloride, nitrile rubber, cross-linking agent, plasticizer, stabilizer, lubricant, antioxidizing agent and filler through mixing and radiating by electronic accelerator. Its advantages are high gel content up to 84-95%, and better mechanical performance, and antiwear and refractory nature.

Owner:SHANGHAI CHLOR ALKALI CHEM

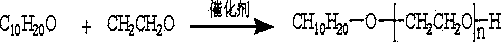

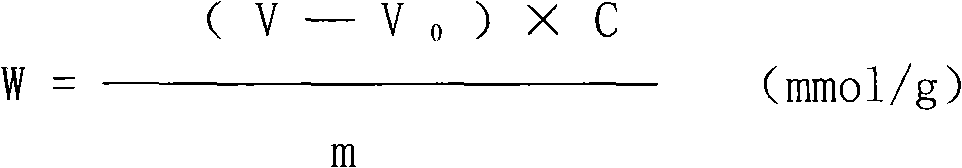

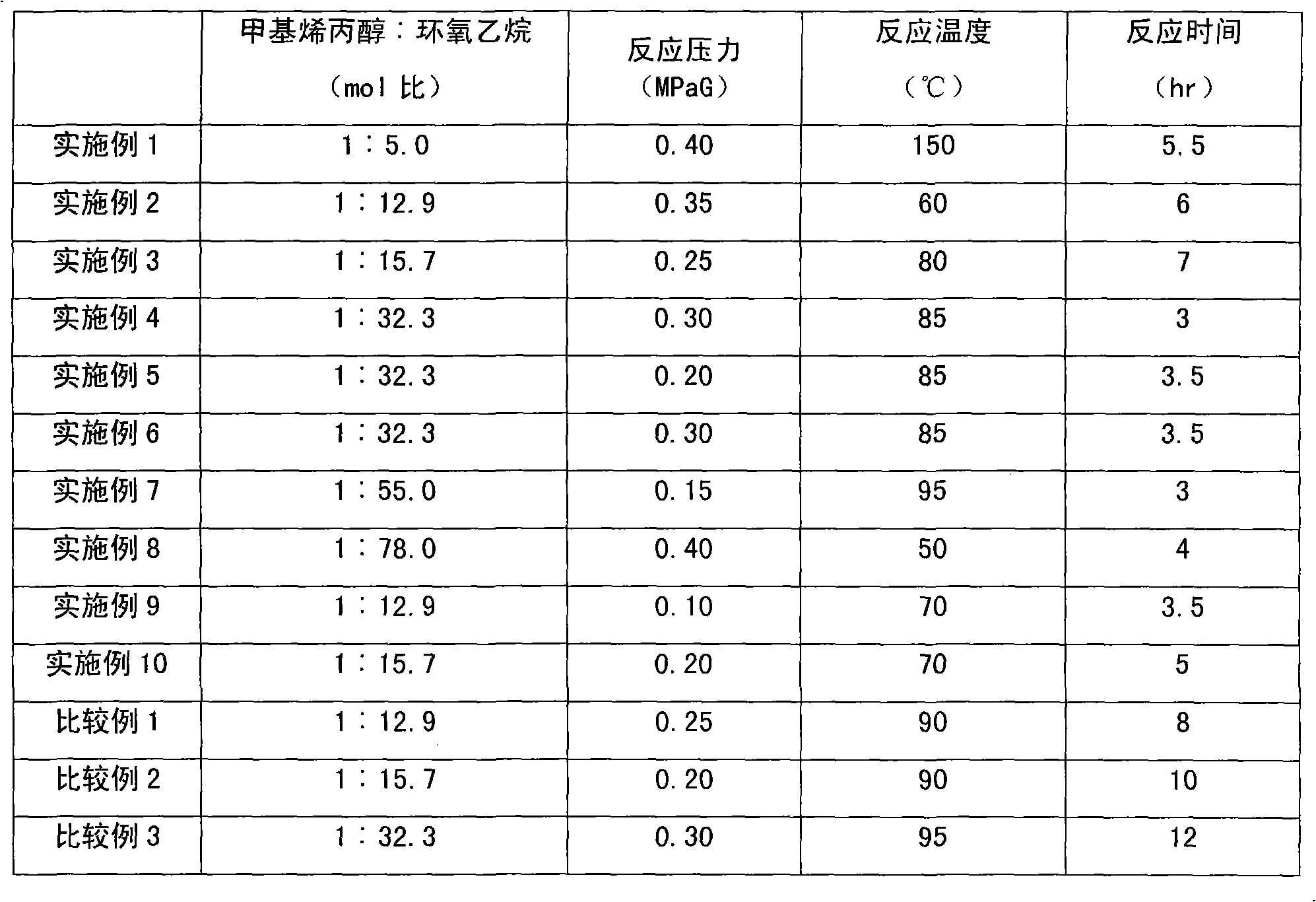

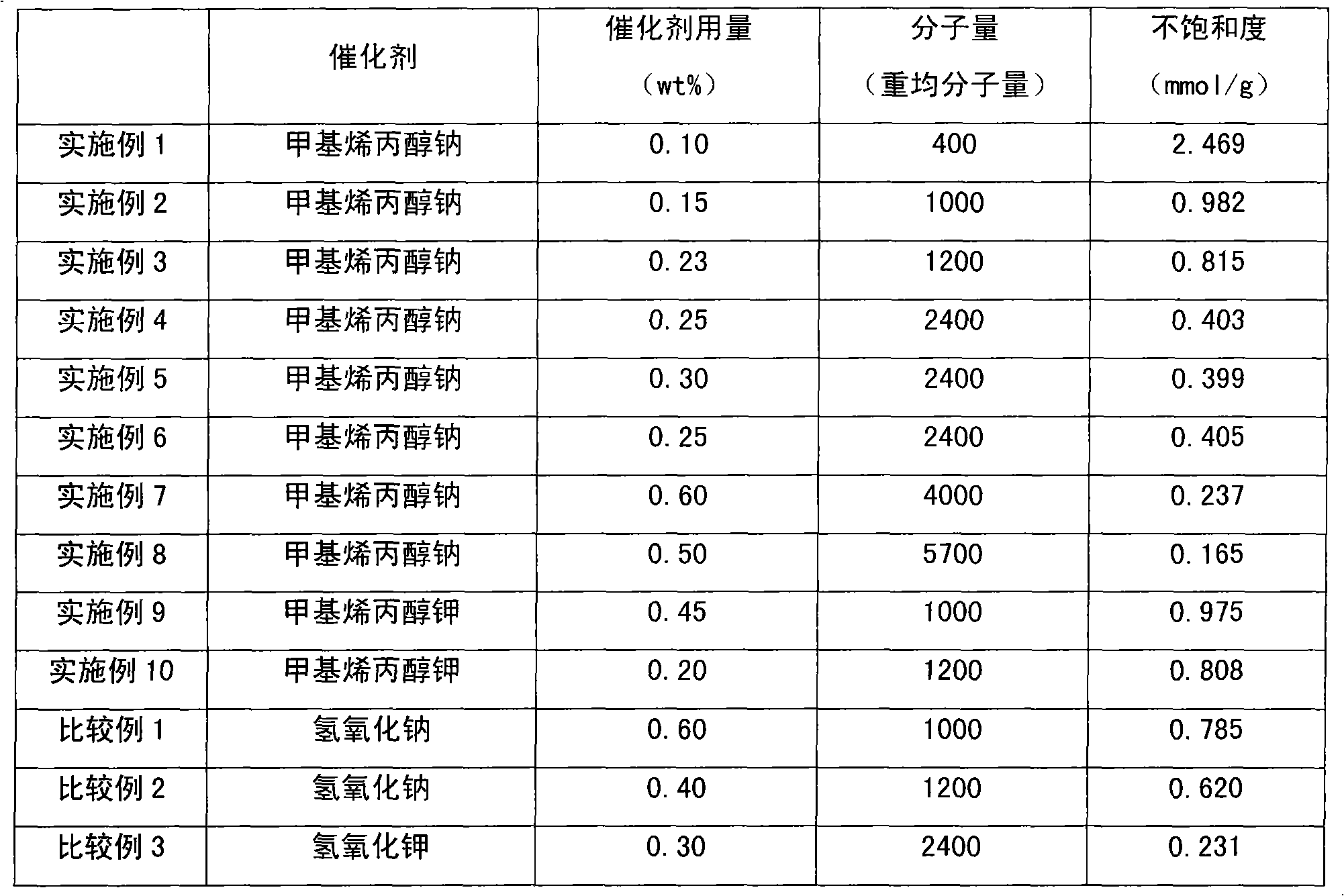

Method for preparing methyl allyl alcohol polyoxyethylene ether

The invention discloses a method for preparing methyl allyl alcohol polyoxyethylene ether. In the method, methallyl alcohol and ethylene oxide undergo a polymerization reaction in the presence of a catalyst to form the methyl allyl alcohol polyoxyethylene ether. The catalyst is sodium methyl allyl alcohol or potassium methyl allyl alcohol; the molar charge ratio of the methallyl alcohol to the ethylene oxide is 1.0:(5.0-78.0); the amount of the catalyst is 0.10 to 0.60 weight percent based on the methallyl alcohol; and the reaction pressure is 0.10 to 0.40MPaG, the reaction temperature is 50 to 150 DEG C, and the reaction time is 3 to 7 hours. The key technical point of the method is that the instauration of the product is increased by over 10 percent by using the more ideal catalyst. The method can be used for preparing methyl allyl alcohol polyoxyethylene ethers with a weight-average molecular weight of 150 to 6,000.

Owner:SHANGHAI DUOLUN CHEM

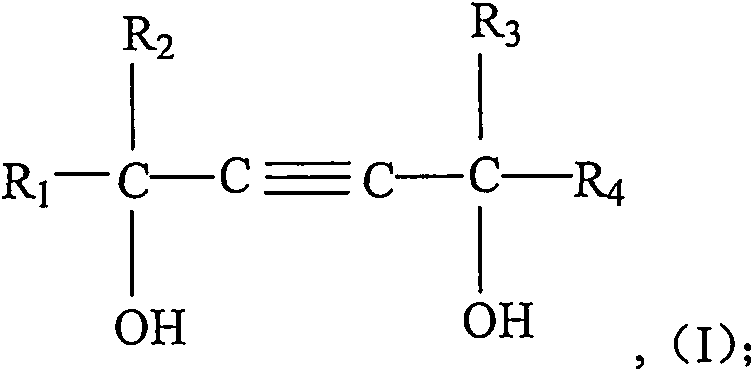

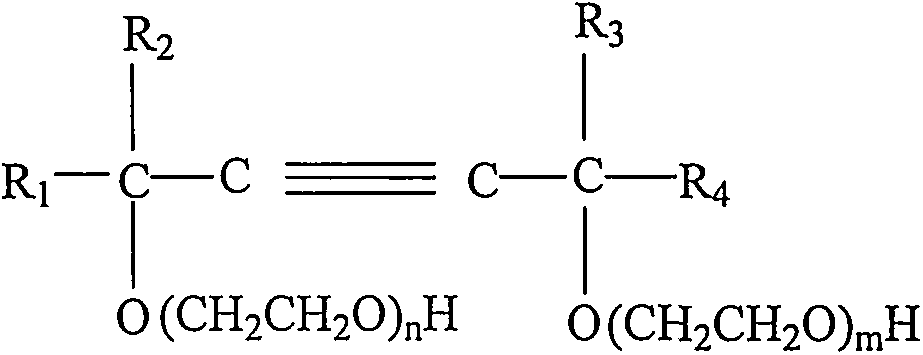

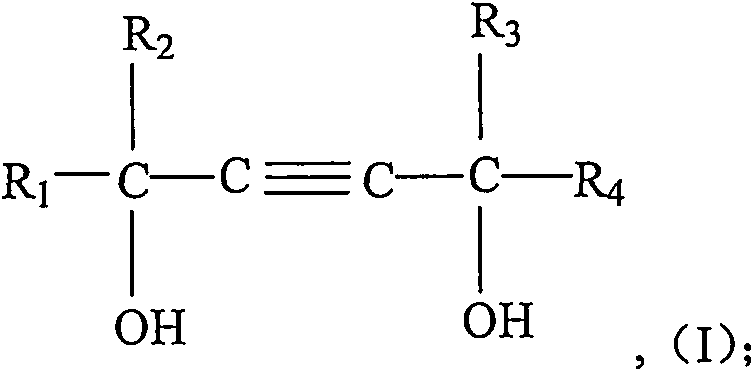

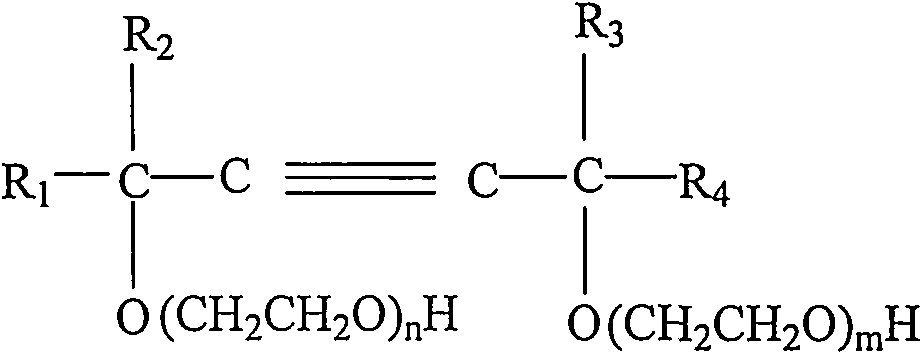

Method for synthesizing acetylene alcohol polyoxyethylene ether

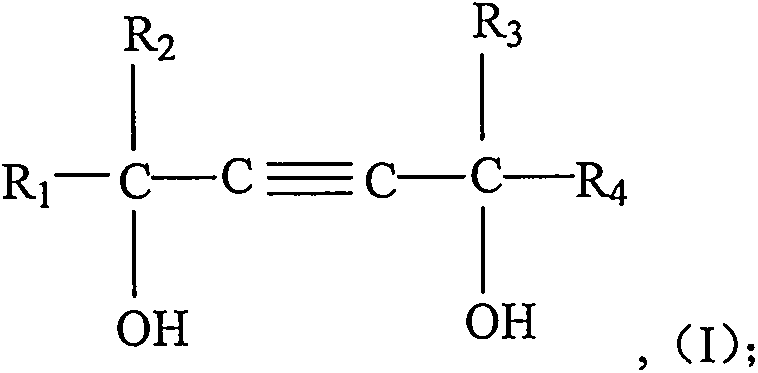

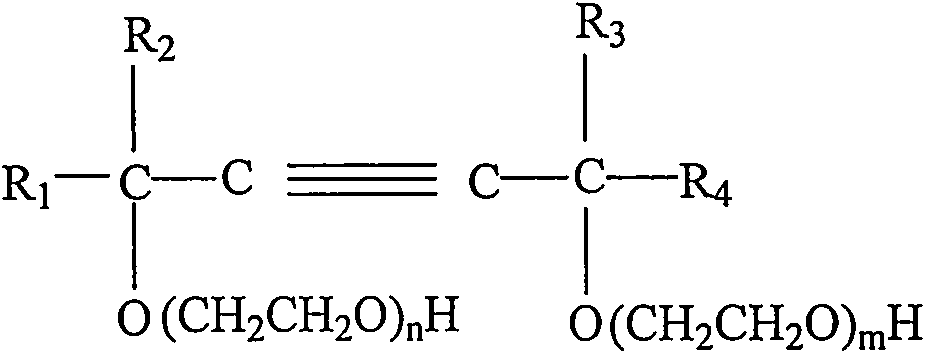

The invention relates to a method for synthesizing an acetylene alcohol polyoxyethylene ether. The technical problem of unsaturation loss of the acetylene alcohol polyoxyethylene ether, caused by the existing synthesis method, is mainly solved. According to the method for synthesizing the acetylene alcohol polyoxyethylene ether, butynediol reacts with ethylene oxide in the presence of a catalyst to obtain the acetylene alcohol polyoxyethylene ether, wherein the catalyst comprises at least one of calcium hydroxide, a tertiary amine aliphatic compound and a protonic acid; the butynediol has a structure shown in a formula (I); R1 and R4 are independently selected from C3-C10 alkyl; R2 and R3 are independently methyl or ethyl. The technical problem is better solved, and the method can be applied to industrial production of the acetylene alcohol polyoxyethylene ether. The expression is as shown in the specification.

Owner:SHANGHAI DUOLUN CHEM

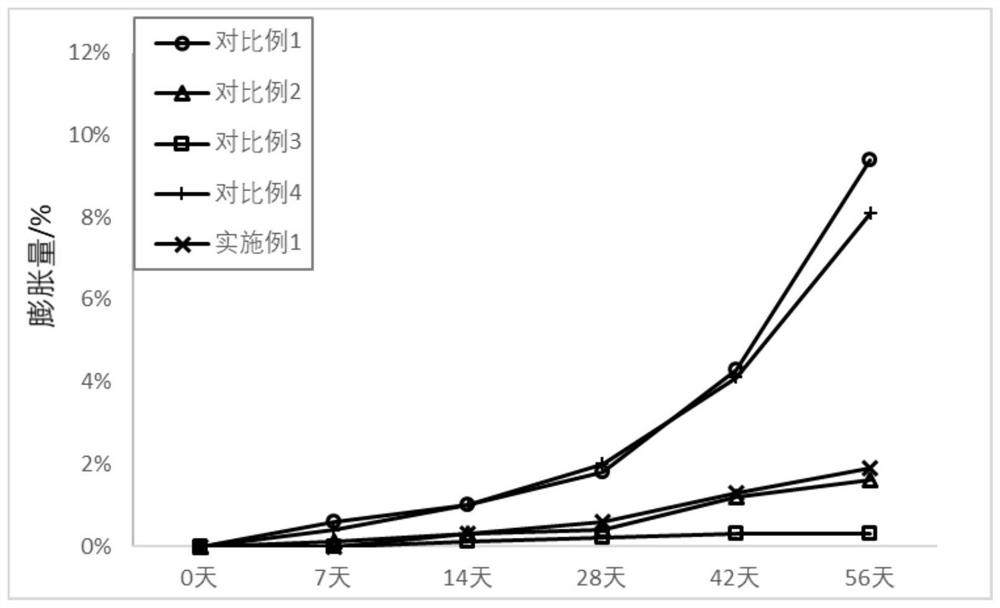

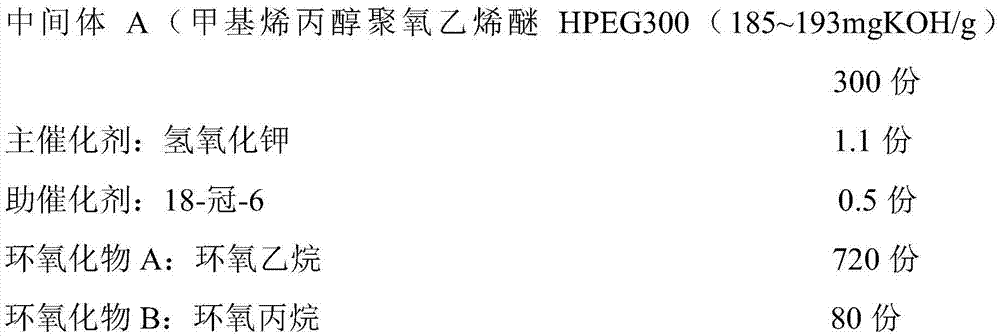

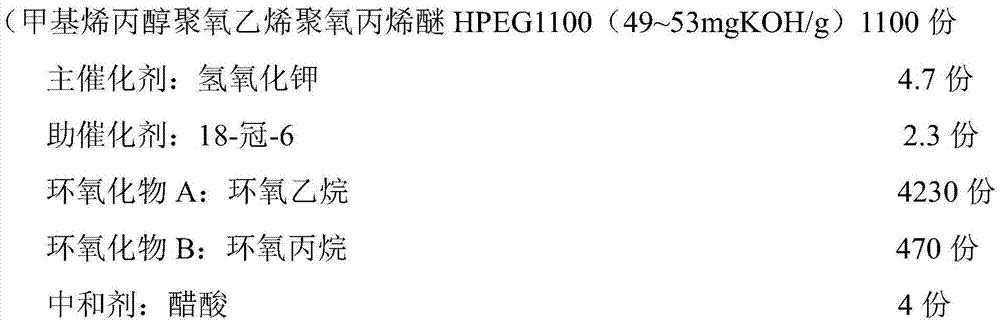

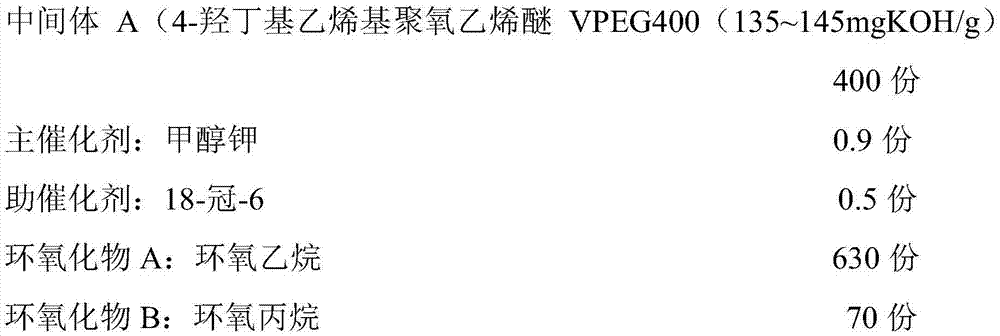

Polymonoether for polycarboxylate superplasticizer and polycarboxylate superplasticizer, and preparation methods thereof

The invention discloses polymonoether for a polycarboxylate superplasticizer and the polycarboxylate superplasticizer, and preparation methods thereof. The polymonoether for the polycarboxylate superplasticizer has a hydroxyl value of 9.5 to 11.5 mg KOH / g and is allylalcohol polyoxyethylene polyoxypropylene ether, methylallylalcohol polyoxyethylene polyoxypropylene ether, isopentenol polyoxyethylene polyoxypropylene ether or 4-hydroxybutylvinyl polyoxyethylene ether. The polymonoether for the polycarboxylate superplasticizer has high molecular weight, high degree of unsaturation and low impurity content, so the later application performance of the polymonoether is obviously improved; and the polymonoether enables cost for raw materials to be reduced compared with the prior art, so the profit rate of the produced polycarboxylate superplasticizer is increased, and the polymonoether has good industrial value.

Owner:SHANGHAI DONGDA CHEM

Compounding method of allyl polyoxyethylene methyl acrylate

The invention discloses a compounding method of allyl polyoxyethylene methyl acrylate, which uses propyl ethylene polyoxyethylene and crylic acid as raw materials. The raw materials are subjected to esterification reaction under the function of a toluenesulfonic acid catalyst and a thiodiphenylamine polymerization resistor, and air dried by silicon gel is supplied to bring out the water generated by the reaction. The invention has the advantages that in the reaction process, the dried air is used for bringing out the water generated by the reaction, the reaction cost is effectively lowered, wet air is discharged, and the environmental pollution is avoided; the paratoluenesulfonic acid is used as the catalyst, the thiodiphenylamine and the oxygen molecules in the air are used as the polymerization resistor, the reaction condition is reasonable, the reaction time is short and the process is simple and easy to control; the allyl polyoxyethylene methyl acrylate compounded by the method has the characteristics of high unsaturation degree, high esterification degree, high reaction activity, and the like, and is suitable for the compounding field of high-performance polycarboxylic-acid water reducer.

Owner:JIAHUA CHEM +1

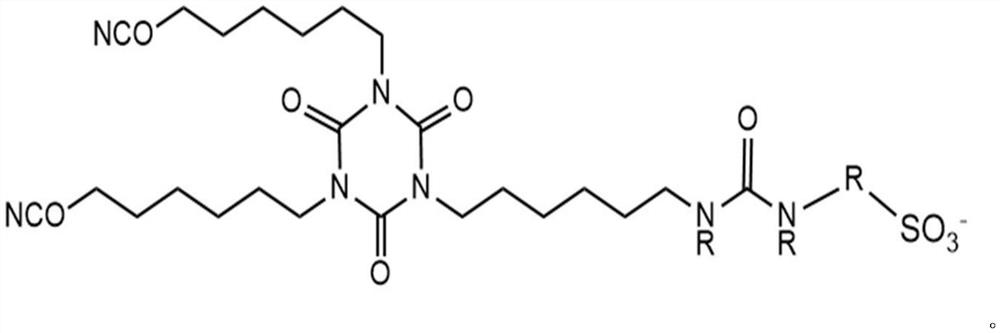

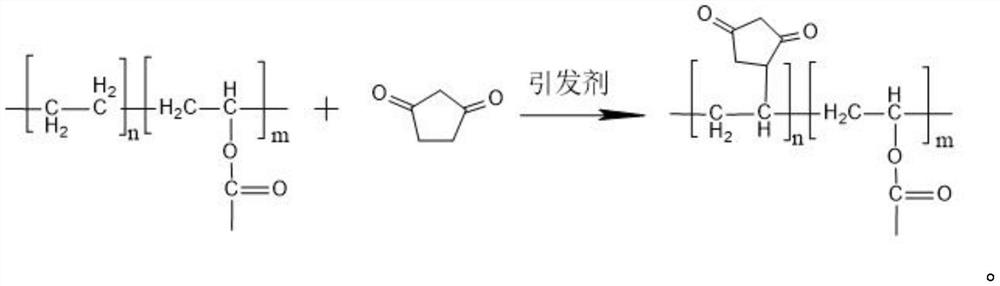

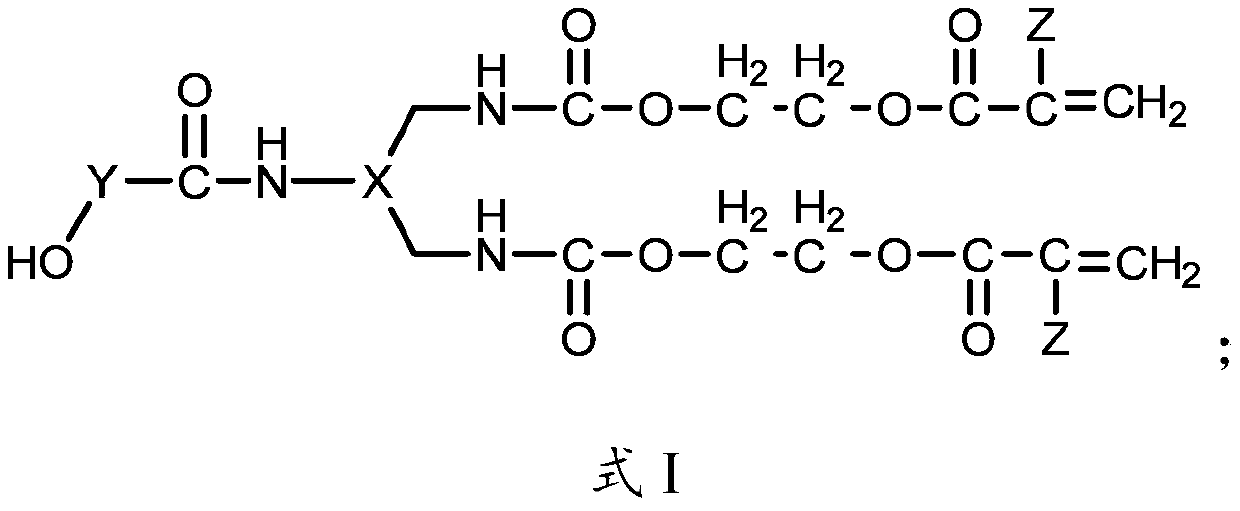

Stabilizer, preparation method thereof, preparation method and application of polymer polyhydric alcohol

The invention belongs to the technical field of stabilizer preparation, and particularly relates to a stabilizer and a preparation method thereof, and a preparation method and application of polymer polyhydric alcohol. The preparation method of the stabilizer comprises the following steps of: contacting and reacting hydroxyl acrylate or hydroxyalkyl methacrylate with multifunctional isocyanate toprepare a prepolymer, reacting the prepolymer with oligomer polyhydric alcohol. The polymer polyhydric alcohol is prepared by contacting base polyether polyhydric alcohol with an ethylenically unsaturated monomer for polymerization in the presence of an initiator and a stabilizer. According to the invention, the obtained polymer polyhydric alcohol has good dispersion stability and low viscosity characteristics, and a mixture containing the polymer polyhydric alcohol in a high-moisture polyurethane foaming system still has good fluidity.

Owner:WANHUA CHEM GRP CO LTD +1

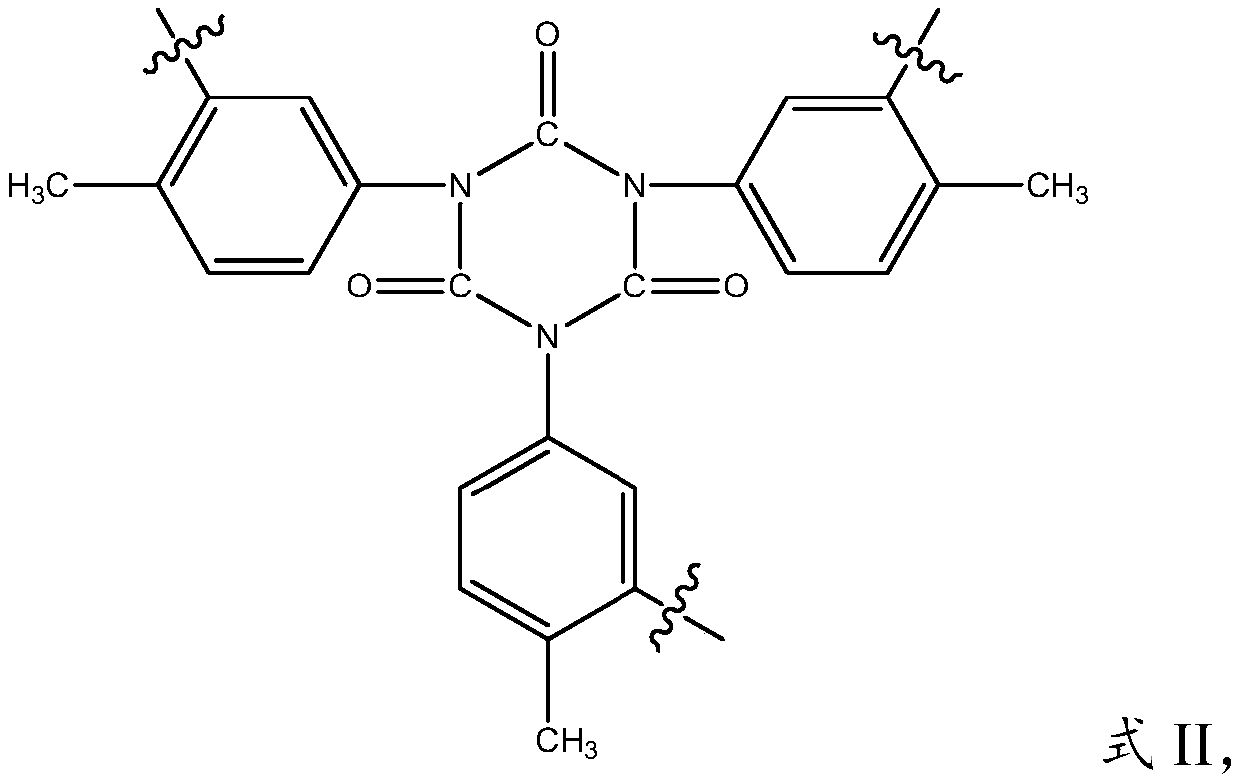

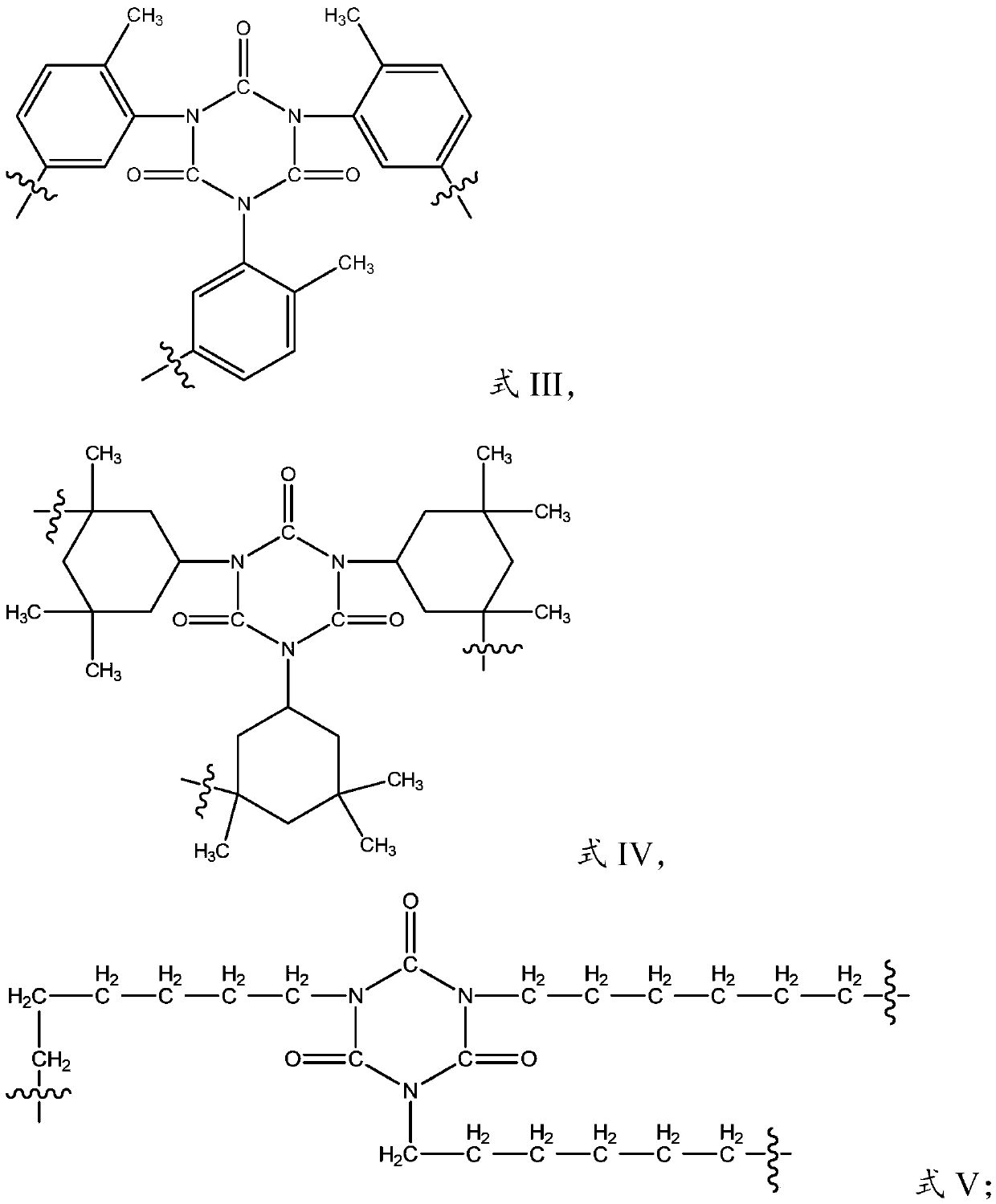

Maleic acid [beta]-cyclodextrin ester and preparation method thereof

The invention discloses a maleic acid [beta]-cyclodextrin ester and a preparation method thereof. A structure general formula of maleic acid [beta]-cyclodextrin monoester is represented as the formula I and a structure general formula of maleic acid [beta]-cyclodextrin diester is represented as the formula II. The method includes a following step of mixing maleic acid, [beta]-cyclodextrin and a polymerization inhibitor for carrying out an esterification reaction with a phosphate as a catalyst to obtain the maleic acid [beta]-cyclodextrin monoester represented as the formula I and / or the maleic acid [beta]-cyclodextrin diester represented as the formula II. The invention provides the environmental-friendly preparation method. In the method, the phosphate is employed as a catalyst and the polyunsaturated carboxylic acid and the [beta]-cyclodextrin are esterified so that not only is usage amount of an organic solvent is reduced but also an unsaturated degree of [beta]-cyclodextrin esterification derivatives is increased, thereby providing a new approach for the [beta]-cyclodextrin derivatives in high-molecular polymer molecule construction.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

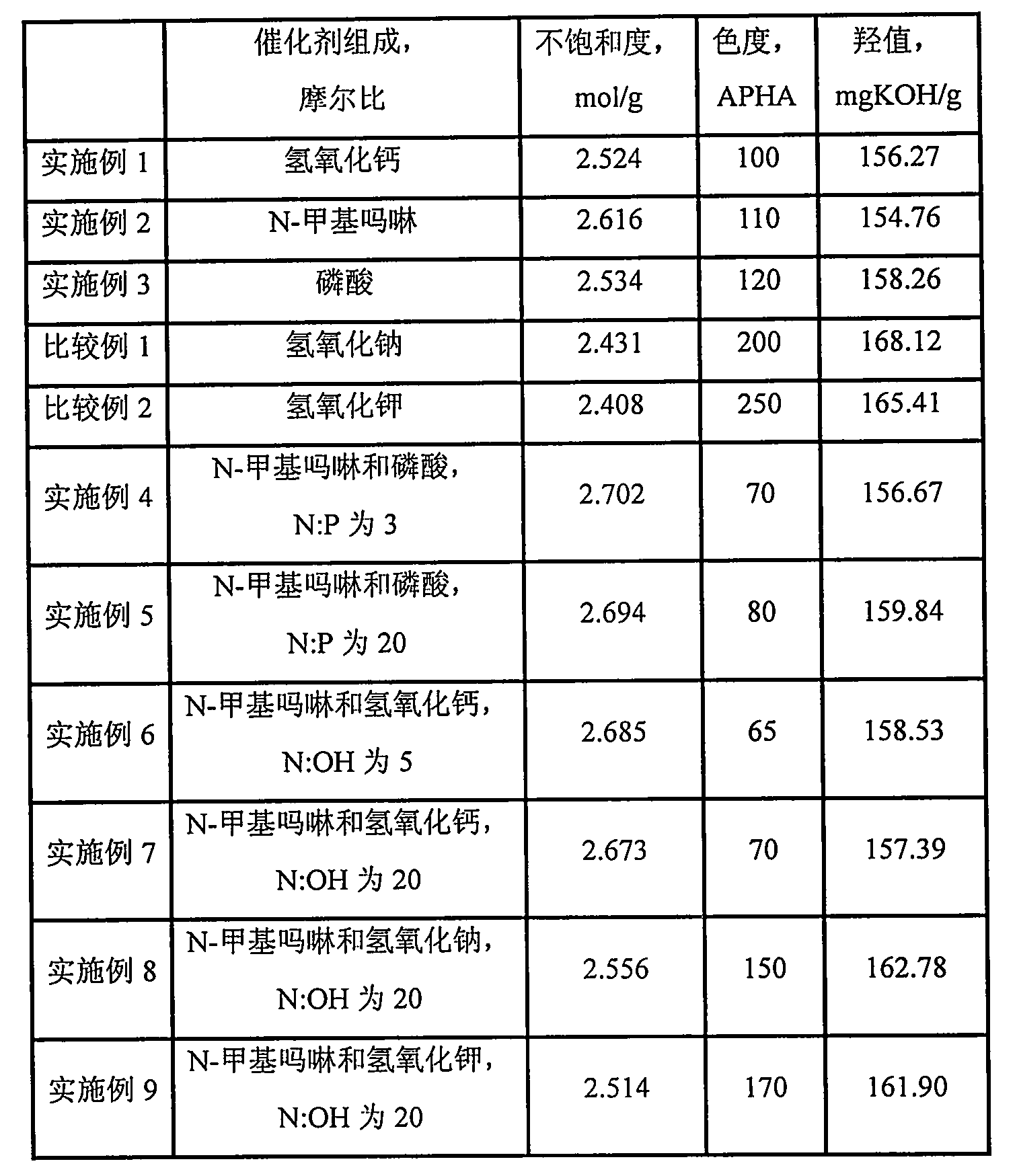

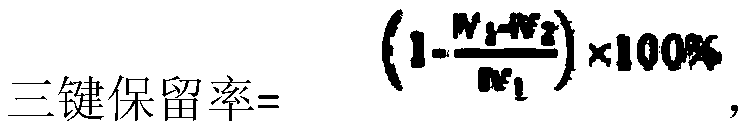

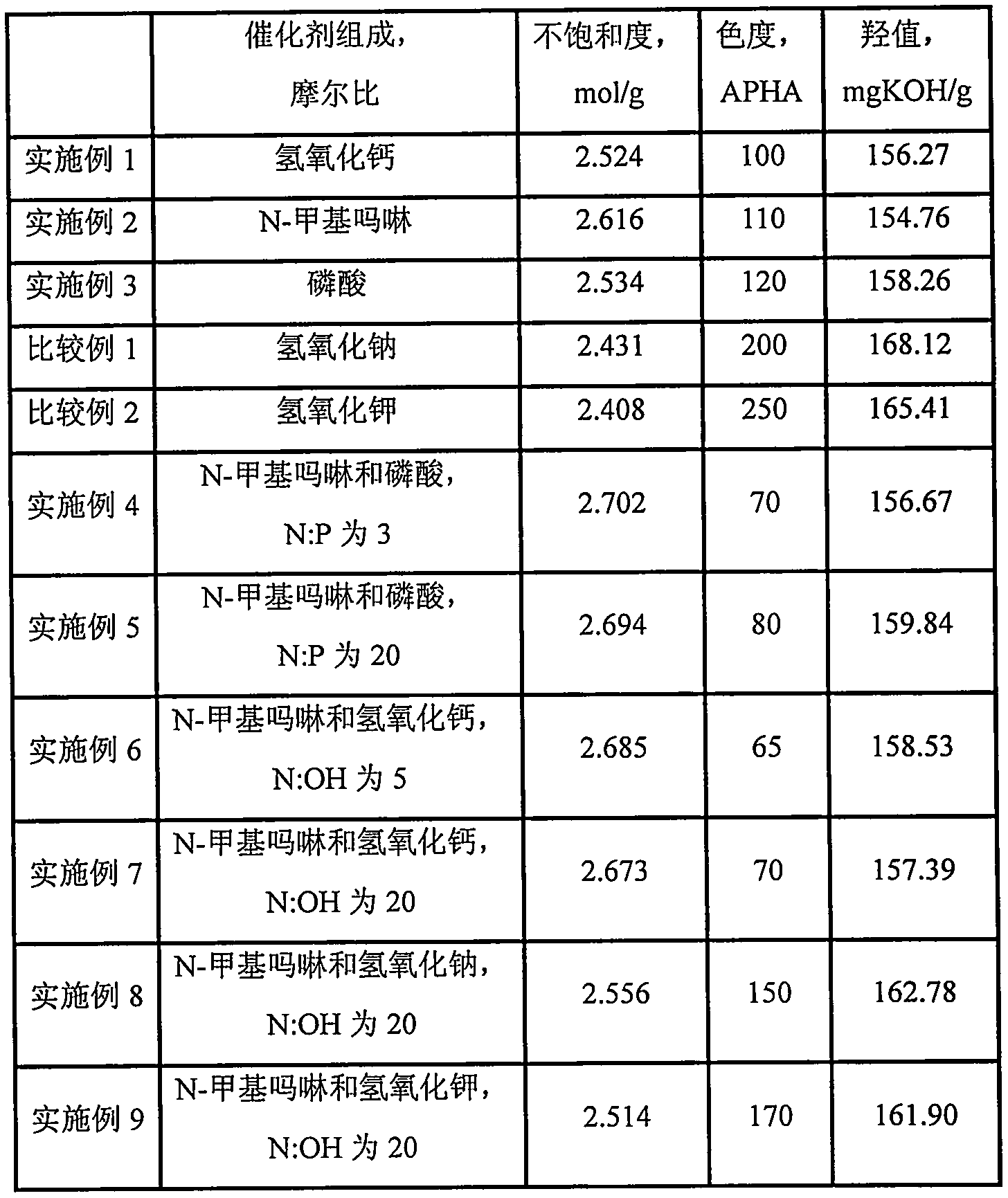

Catalyst for synthesis of acetylene alcohol polyoxyethylene ether

ActiveCN103965462AProcess loss is smallIncrease unsaturationOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesCalcium hydroxideAlcohol

The invention relates to a catalyst for synthesis of an acetylene alcohol polyoxyethylene ether, and mainly aims to solve the technical problem of unsaturation loss of the acetylene alcohol polyoxyethylene ether caused by the existing catalyst. The catalyst for synthesis of the acetylene alcohol polyoxyethylene ether comprises at least one of calcium hydroxide, a tertiary amine aliphatic compound and a protonic acid. Thus, the technical problem is well solved, and the catalyst can be applied to industrial production of the acetylene alcohol polyoxyethylene ether.

Owner:SHANGHAI DUOLUN CHEM

Preparation method of tert-alkynol polyether

ActiveCN109970964ASmooth responseMild conditionsEther preparation by compound dehydrationReaction temperatureFine chemical

The invention relates to a preparation method of tert-alkynol polyether, and belongs to the field of fine chemical engineering. The preparation method comprises following steps: (1) adding a catalystand tert-alkynol into a reactor, carrying out degassing for 1 hour at a certain temperature under a certain pressure, controlling the reaction temperature and reaction pressure, slowly and evenly adding part of olefin oxide into the reactor within a certain period, and after addition, maintaining the temperature until the pressure becomes stable; and (2) keeping on adding olefin oxide at a certaintemperature until the reactions are finished, maintaining the temperature until the pressure becomes stable, cooling to remove a little of unreacted olefin oxide, adding an acid to carry out neutralization, and discharging obtained tert-alkynol polyether. The invention provides a preparation method of tert-alkynol polyether, which has the advantages of light color, high unsaturation degree, narrow distribution, low residual raw materials, and low PEG / PPG content.

Owner:ZHEJIANG HUANGMA TECH +3

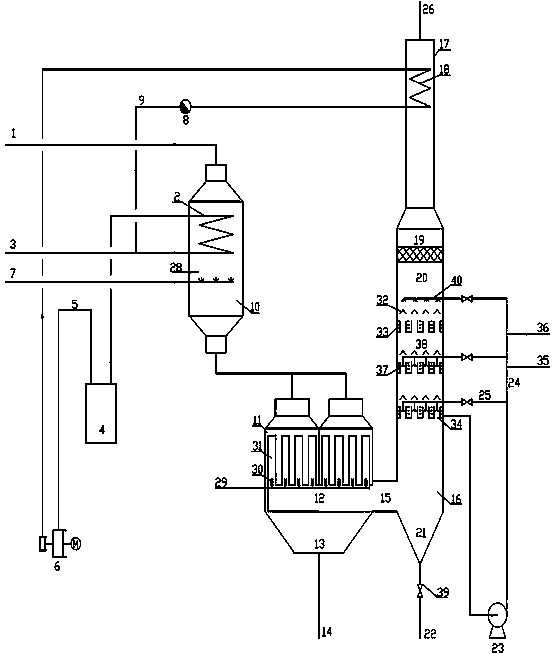

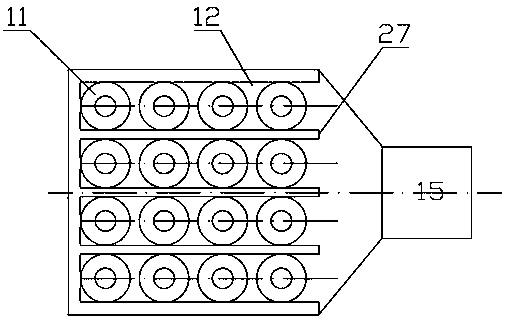

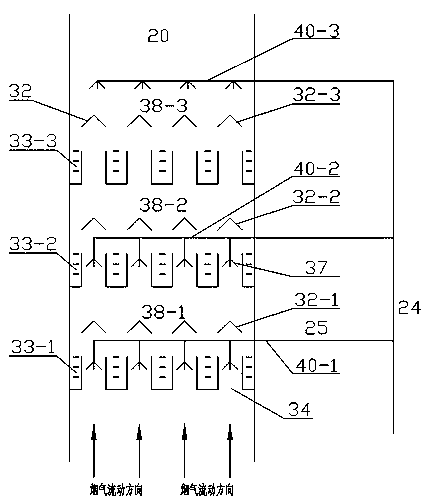

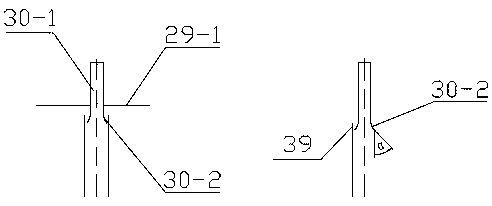

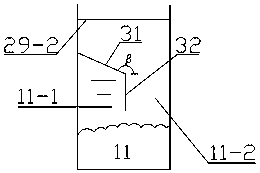

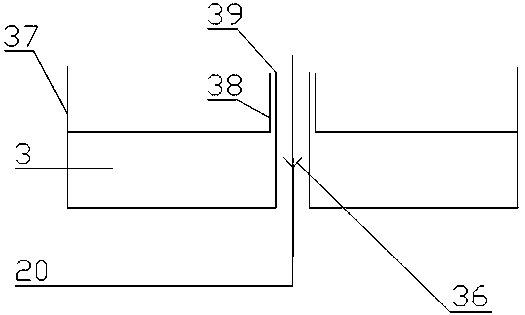

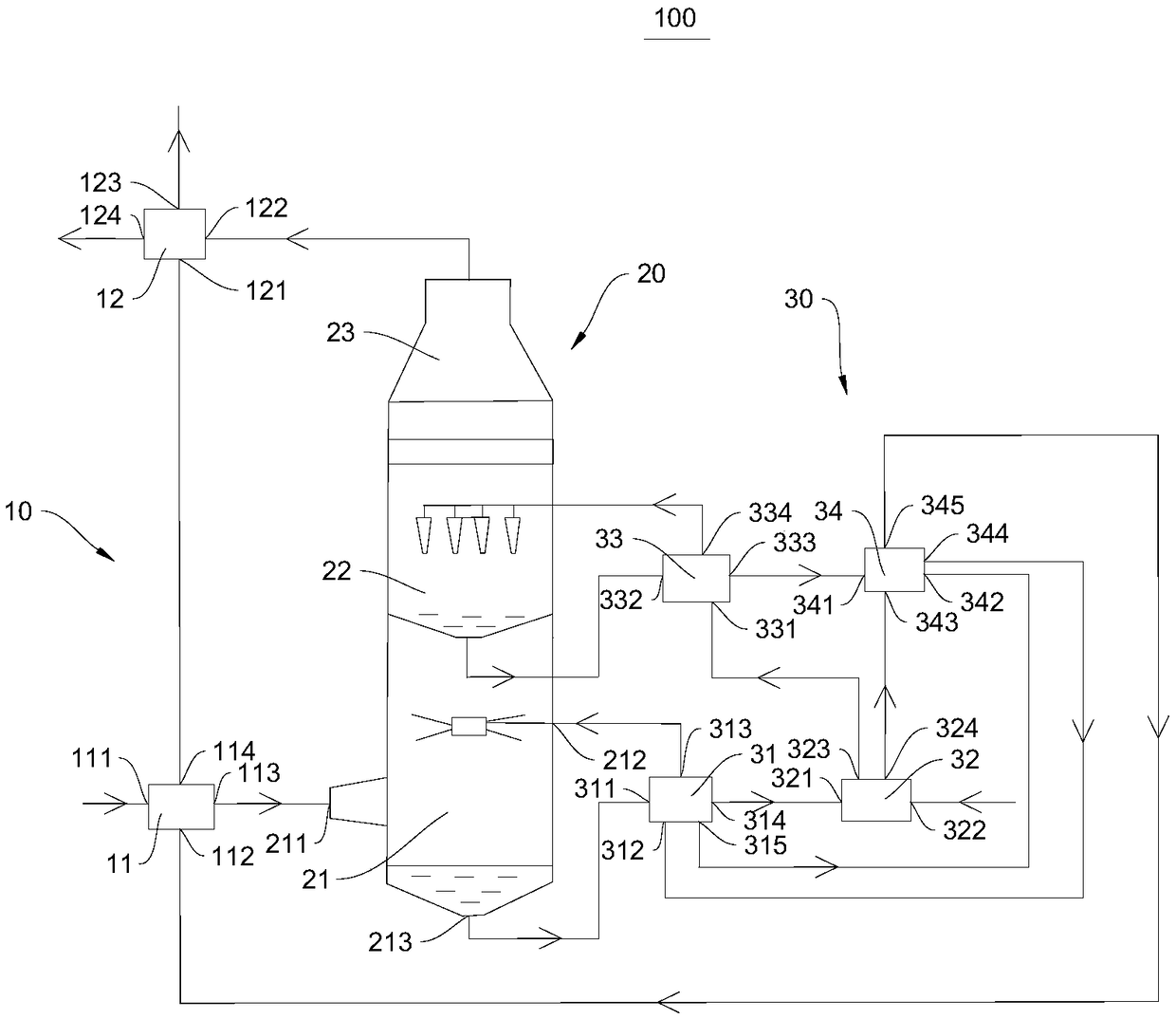

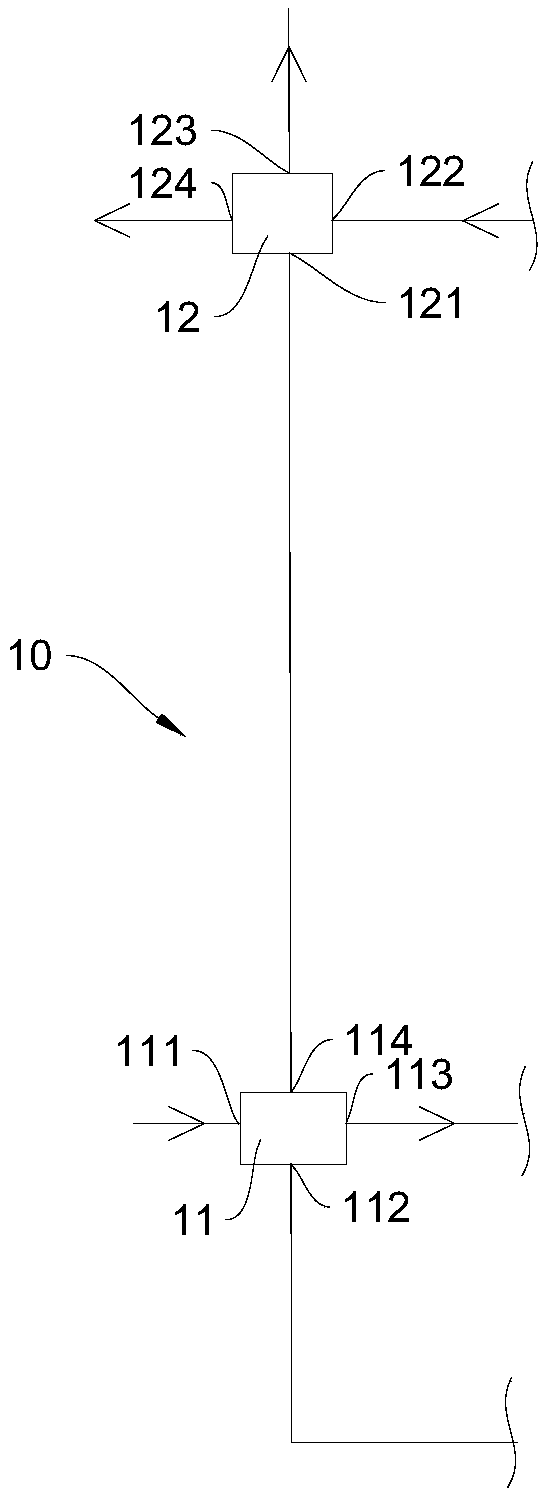

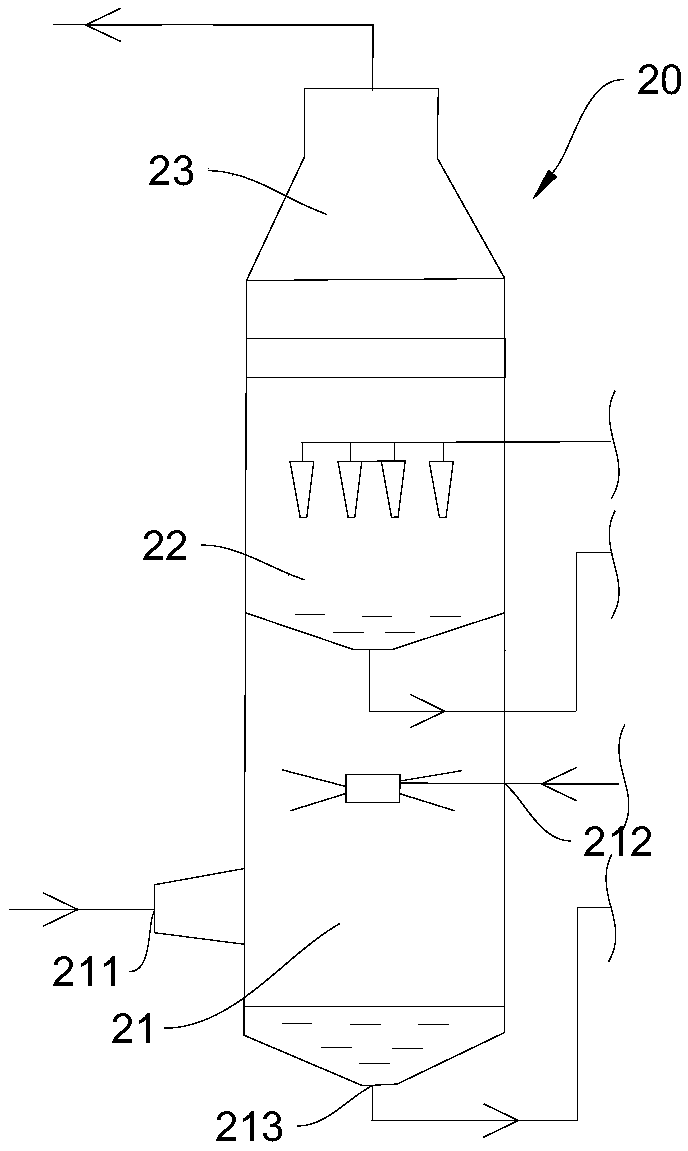

Flue gas desulfurization and desulfurization wastewater treatment method and flue gas desulfurization and desulfurization wastewater treatment apparatus

ActiveCN108686478AIncrease unsaturationDissipate in timeGas treatmentDispersed particle filtrationGas phaseTreatment costs

The invention relates to a flue gas desulfurization and desulfurization wastewater treatment method. According to the flue gas desulfurization and desulfurization wastewater treatment method, a flue gas pre-treatment tower comprises a flue gas / desalted water heat exchanger and a spraying unit; liquid-state desalted water is converted into gas-state desalted water by using flue gas in the flue gas / desalted water heat exchanger, and the gas-state desalted water enters a gas-liquid separator and is separated; the gas phase is compressed, the compressed gas phase enters the gas discharge cylinderon the top of a desulfurization tower to heat and purify the flue gas; the spraying unit is used for spraying a NaOH solution to reduce the flue gas temperature to below the dew point temperature of an acid, the cooled flue gas enters a bag type dust removing device and is treated, and the treated flue gas enters the desulfurization tower; and on the bottom of the desulfurization tower, a proper amount of desulfurization wastewater is subjected to spraying drying by using the flue gas, and the flue gas enters a desulfurization zone and is subjected to desulfurization purification. The invention further relates to a treatment apparatus of the treatment method. With the method and the apparatus of the present invention, the purified flue gas meets the discharge requirement, and the zero discharge of the flue gas desulfurization wastewater is achieved, the white smoke and the blue smoke are simultaneously eliminated, and the flue gas desulfurization and desulfurization wastewater comprehensive treatment cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

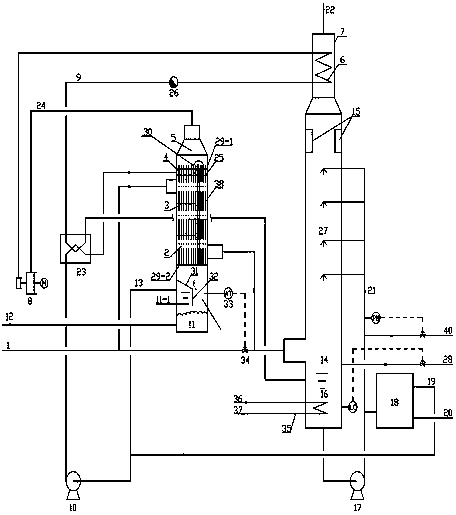

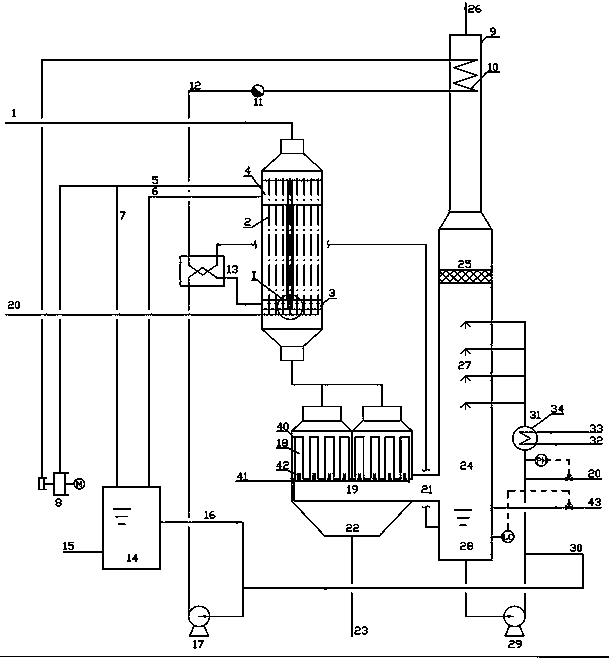

Treating method and treating apparatus for waste liquid produced in flue gas desulfurization

ActiveCN108117210AAvoid cloggingSmall footprintWater/sewage treatment by centrifugal separationWater treatment parameter controlFlue gasTreatment costs

The invention relates to a treating apparatus for waste liquid produced in sodium-process flue gas desulfurization. The treating apparatus mainly comprises a flue gas / desulfurization waste liquid heatexchanger, a dust-removal and desulfurization tower, a solid-liquid separator, a plate heat exchanger and a steam compressor, wherein the flue gas / desulfurization waste liquid heat exchanger is divided into an upper heat exchange zone and a lower crystallization zone; the upper heat exchange zone comprises a steam chamber, an upper tube plate, a partition plate, a heat exchange tube and a lower tube plate from top to bottom; a desulfurization waste liquid feeding box is arranged between the upper tube plate and the partition plate; a liquid film former is arranged at the heat exchanger tube end of the desulfurization waste liquid feeding box; the lower crystallization zone is provided with an inclined drainage plate, a sealing plate and a crystallization tank; and the sealing plate is inserted into a position located below the liquid level of the crystallization tank. Through adoption of the specific treating apparatus and a specific treating method, the dual purposes of allowing purified flue gas to meet emission requirements and realizing zero discharge of waste liquid produced in flue gas desulfurization are achieved on the basis of full use of the waste heat of flue gas; and in particular, the supplementation amount of fresh water for a flue gas desulfurization system is reduced, and overall treatment cost of flue gas desulfurization and desulfurization waste liquid is lowered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flue gas and flue gas desulfurization wastewater treatment method and device

ActiveCN108619871AIncrease water vapor contentRaise the acid dew pointCombination devicesGas treatmentLiquid wasteSteam condensation

The invention relates to a flue gas and flue gas desulfurization wastewater treatment method and device. The flue gas is used to exchange heat and raise the temperature of desulfurization wastewater in a flue gas / desulfurization wastewater heat exchanger, a spray nozzle is arranged in a flue gas outlet to spray an NaOH solution, the temperature of the flue gas is reduced to the temperature of theacid dew point, then the flue gas enters a bag filter to remove dust and a sulfate / sulfuric acid liquid drop and then falls into a desulfurizing tower; the flue gas is desulfurized, purified and heated and the temperature is raised in the desulfurizing tower, the wastewater part at the bottom part of the desulfurizing tower serves as a circulating absorption liquid, other wastewater enters a plateheat exchanger in the form of desulfurization wastewater; and the plate heat exchanger uses steam condensation water produced in a heating coil in an exhaust funnel to preheat the desulfurization wastewater, and the preheated wastewater enters the flue gas / desulfurization wastewater heat exchanger. The double purposes of purifying the flue gas and meeting the emission requirement and achieving zero emission of the flue gas desulfurization waste liquid are achieved on the basis that the waste heat of the flue gas is fully used, meanwhile, the white smoke and the blue smoke are eliminated, andthe comprehensive treatment costs for the flue gas desulfurization and the desulfurization waste liquid are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Slippery resistant safe shoe rubber sole and preparation method thereof

ActiveCN106589499AExcellent anti-oil performanceImprove gripSolesPersonal protective equipmentVulcanization

The invention relates to a rubber sole and provides a slippery resistant safe shoe rubber sole and a preparation method thereof. The provided rubber sole has a strong performance on resisting slipping. The friction coefficient is not less than 0.45 and is obvious higher than the slippery resistant requirements (heelpiece 0.13, smoothness 0.18) of international standard BS EN ISO 20345:2011 personal protective equipment safe shoes. The rubber sole is composed of the following raw materials: high vinyl solution polymerized styrene-butadiene rubber, high acrylonitrile nitrile rubber, NBR / PVC emulsion co-precipitated alloy, white carbon black, an anti-aging agent, polyethylene glycol, a silane coupling agent, polyethylene wax, yellow resin, diglycol, zinc oxide, insoluble sulfur, and a vulcanization promoter.

Owner:MAOTAI FUJIAN SOLES CO LTD

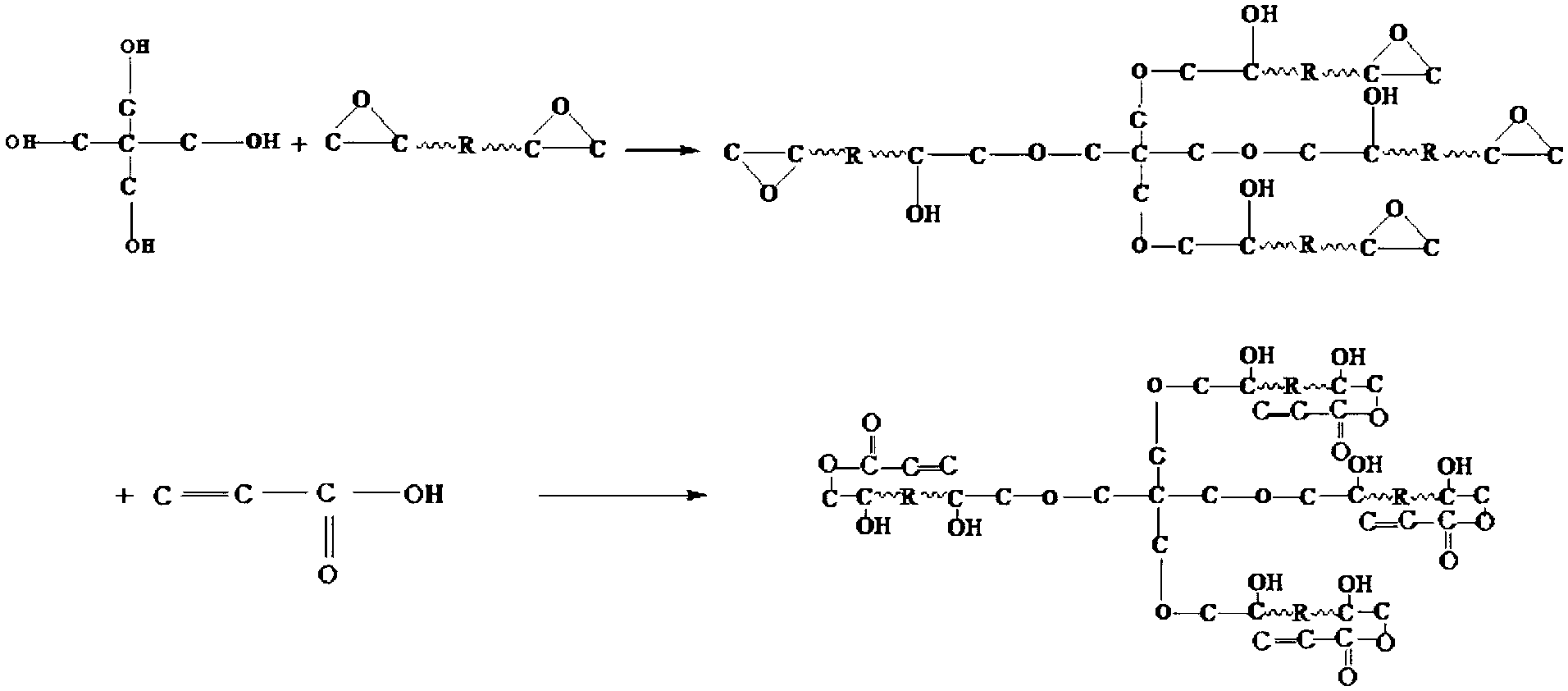

Low-viscosity epoxy acrylate paint for inner wall of food can and preparation method thereof

The invention relates to a low-viscosity epoxy acrylate paint for an inner wall of a food can and a preparation method thereof. The preparation method comprises the following steps: 1) preparation of low-viscosity epoxy acrylate resin: adding bisphenols A epoxy resin and a catalyst into a reaction vessel, stirring and heating, adding pentaerythritol, keeping the temperature and carrying out reflux condensation so as to prepare pentaerythritol epoxy ester; cooling, dropwisely adding a mixture of the catalyst, a polymerization inhibitor and acrylic acid, carrying out a thermostatic reaction, cooling and discharging so as to prepare low-viscosity epoxy acrylate resin; adding a leveling agent and an antifoaming agent, stirring and uniformly mixing so as to obtain the low-viscosity epoxy acrylate paint for the inner wall of the food can. The invention has the following beneficial effects: pentaerythritol epoxy acrylate has a hyper-branched characteristic, has advantages of high degree of unsaturation, low viscosity and good adhesive force, is suitable for electron beam curing, and is non-toxic; and a cured film has properties such as high crosslinking density, excellent glossiness, flexibility, hardness, acid resistance, alkali resistance, water resistance and the like.

Owner:武汉工大科技园发展有限公司

Dihydromyrcenol polyoxyethylene ether and synthetic method thereof

The invention discloses dihydromyrcenol polyoxyethylene ether and a synthetic method thereof. The dihydromyrcenol polyoxyethylene ether is synthesized from the following raw materials: dihydromyrcenol and ethylene oxide in the mol ratio of 1: (5-150) through two steps, in the presence of a catalyst accounting for 0.03-2% of the total weight of the raw materials dihydromyrcenol and ethylene oxide. The dihydromyrcenol polyoxyethylene ether having a large molecular weight is synthesized through two steps; the product is high in saturability and narrow in molecular weight distribution, and also increased in increase ratio and advantageous for synthesizing products higher in molecular weight. A high-performance polycarboxylic acid water reducing agent prepared from the dihydromyrcenol polyoxyethylene ether provided by the invention has good cement particle dispersity maintaining capability, and remains the advantages such as low dosage, high water-reducing rate, good collapse retaining property and environmental friendless; besides, as the high-performance polycarboxylic acid water reducing agent is enhanced in hydrophobicity in a large monomer structure and increased in molecular steric hindrance, the water reducing agent is remarkably enhanced in adaptability to dinas different in silt content and can be widely applied to high-silt content dinas districts.

Owner:SICHUAN SEDAR CHEM

Synthetic method of acetylene glycol polyoxyethylene ether

The invention relates to a method for synthesizing an acetylene alcohol polyoxyethylene ether. The technical problem of unsaturation loss of the acetylene alcohol polyoxyethylene ether, caused by the existing synthesis method, is mainly solved. According to the method for synthesizing the acetylene alcohol polyoxyethylene ether, butynediol reacts with ethylene oxide in the presence of a catalyst to obtain the acetylene alcohol polyoxyethylene ether, wherein the catalyst comprises at least one of calcium hydroxide, a tertiary amine aliphatic compound and a protonic acid; the butynediol has a structure shown in a formula (I); R1 and R4 are independently selected from C3-C10 alkyl; R2 and R3 are independently methyl or ethyl. The technical problem is better solved, and the method can be applied to industrial production of the acetylene alcohol polyoxyethylene ether. The expression is as shown in the specification.

Owner:SHANGHAI DUOLUN CHEM

Polymer composition for crosslinked pipes

InactiveUS20120128912A1Improves crosslinking responseGood cross-linking effectLayered productsRigid pipesCrosslinked polymersEthylene Polymers

Owner:BOREALIS AG

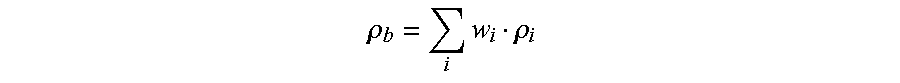

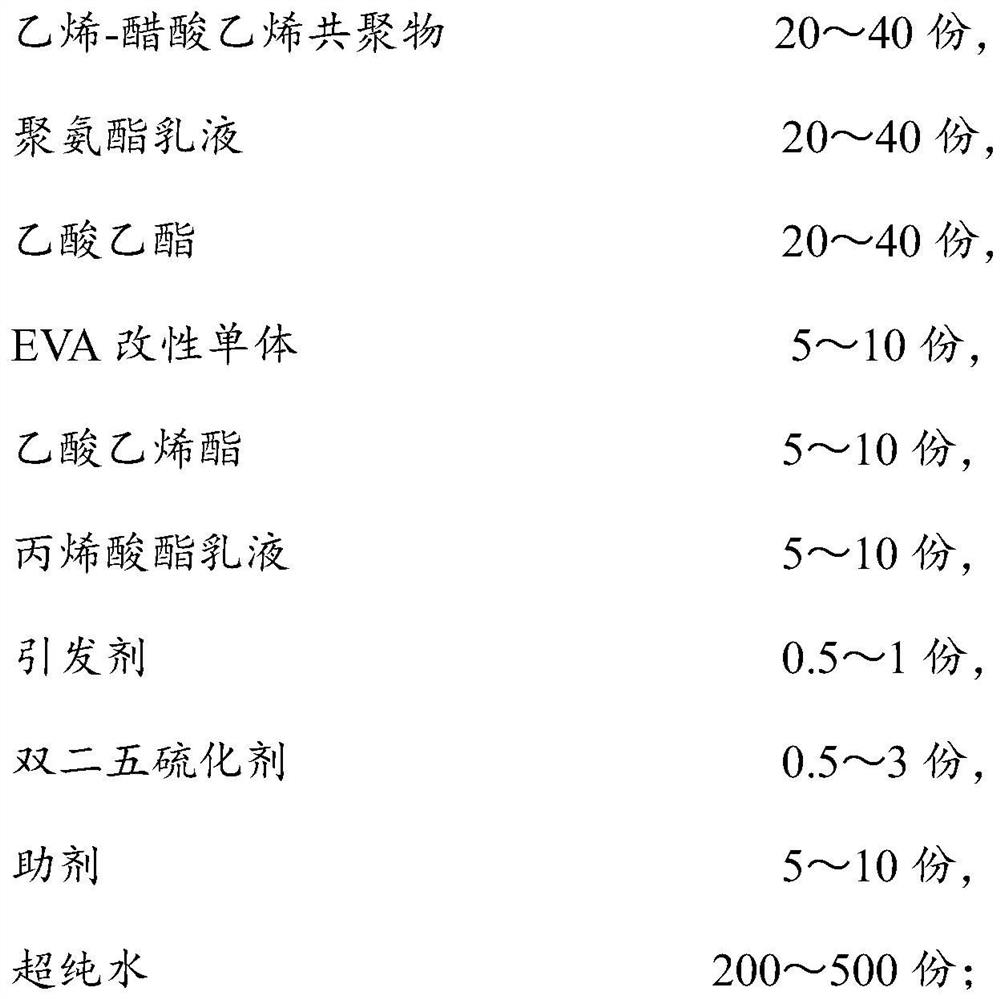

Water-based EVA treating agent and preparation method thereof

InactiveCN113969091AEnhanced bonding effectAdhesiveAdhesive processes with surface pretreatmentPolyurea/polyurethane coatingsPolymer scienceAdhesive

The invention relates to the technical field of high polymer materials, in particular to a water-based EVA treating agent and a preparation method thereof. The EVA treating agent comprises the following raw materials in parts by mass: 20-40 parts of an ethylene-vinyl acetate copolymer, 20-40 parts of a polyurethane emulsion, 20-40 parts of ethyl acetate, 5-10 parts of an EVA modified monomer, 5-10 parts of vinyl acetate, 5-10 parts of an acrylate emulsion, 0.5-1 part of an initiator, 0.5-3 parts of a 2, 5-bis(tert-butylperoxy)hexane vulcanizing agent, 5-10 parts of an auxiliary agent and 200-500 parts of ultrapure water. According to the invention, the polarity of the EVA treating agent is enhanced, the compatibility of an EVA substrate and an adhesive is good through the prepared water-based EVA treating agent, the mechanical strength and the adhesive property of the water-based EVA treating agent can be improved, use of volatile organic solvents is reduced, and environmental pollution is reduced.

Owner:全叶娟

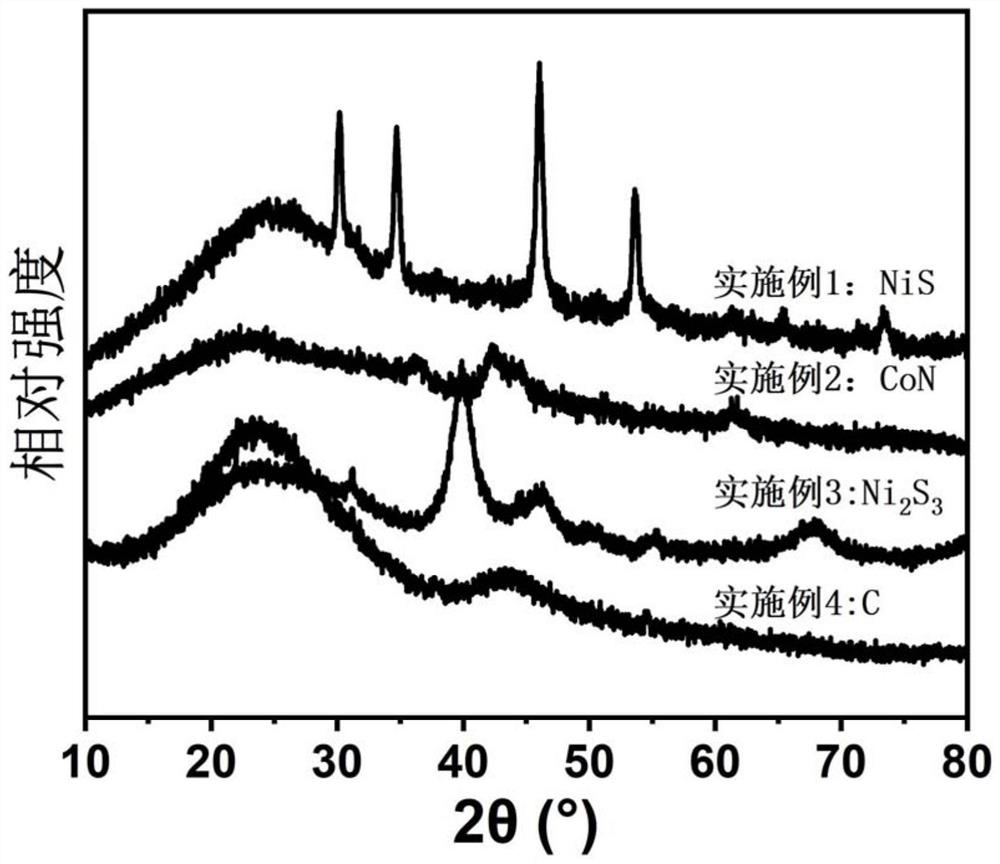

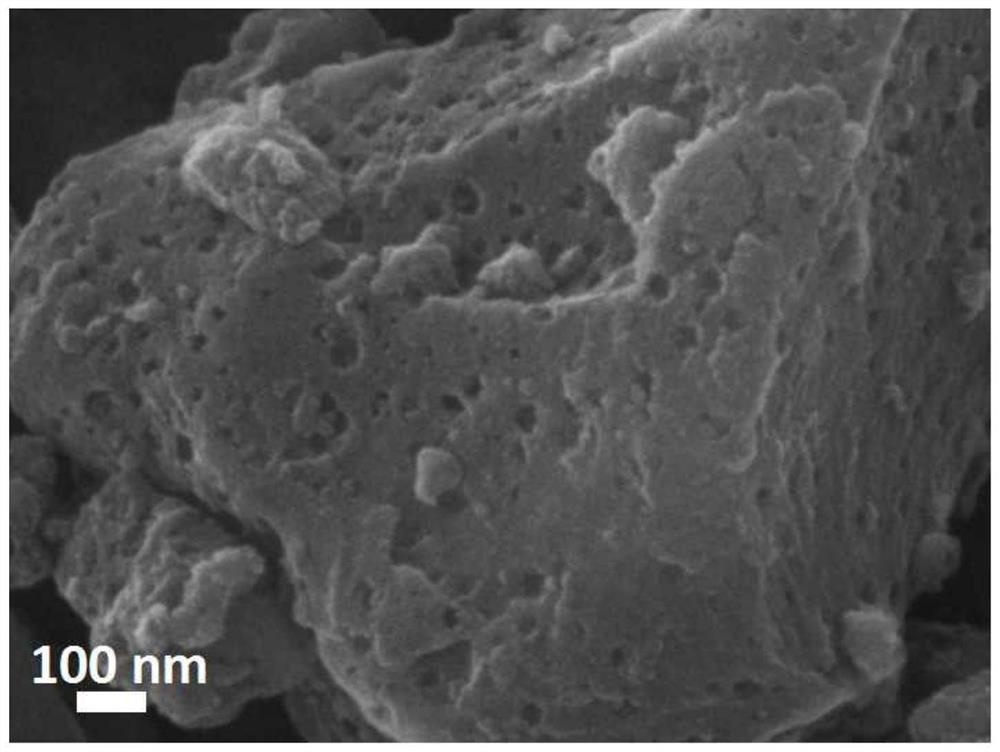

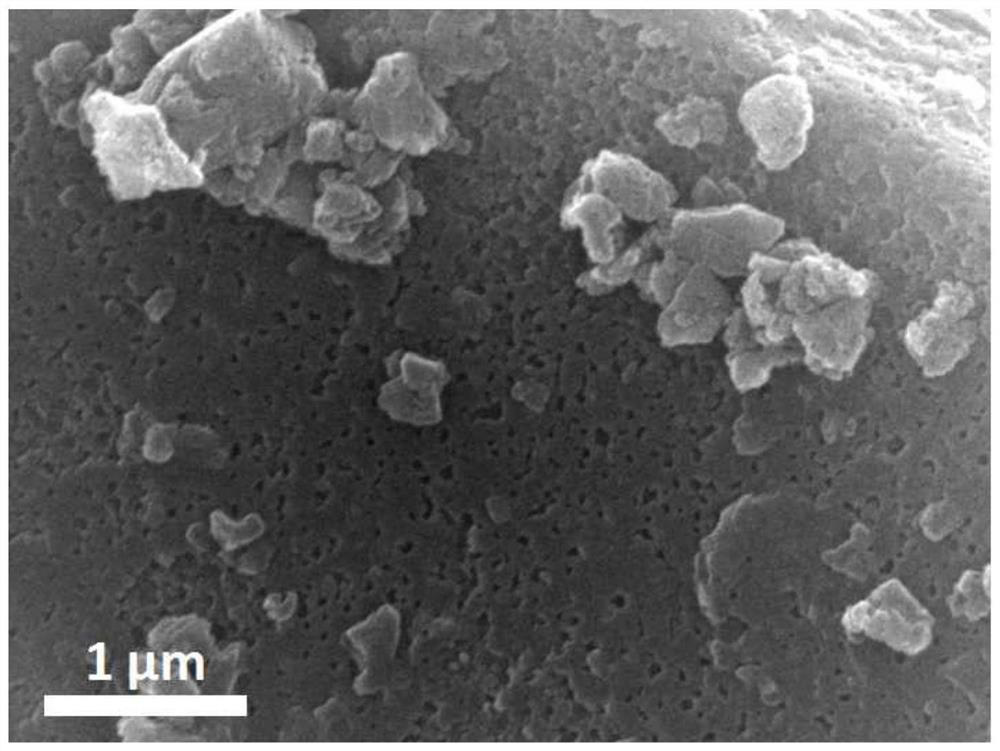

Preparation method of mesoporous carbon-based electrocatalyst

ActiveCN112023945ASimple processShort timePhysical/chemical process catalystsCarbon preparation/purificationPtru catalystCarbonization

The invention discloses a preparation method of a mesoporous carbon-based electrocatalyst. The preparation method comprises the following steps: 1) subjecting an amino compound to reacting with aromatic aldehyde to obtain Schiff base; 2) carrying out a reaction on the Schiff base and transition metal salt to obtain a transition metal Schiff base complex; and 3) carrying out infrared pre-carbonization and carbonization on the transition metal Schiff base complex to obtain the mesoporous carbon-based electrocatalyst. According to the method, a template agent does not need to be added, process issimple, consumed time is short, and the prepared mesoporous carbon-based electrocatalyst contains a large number of mesopores and is large in specific surface area, adjustable in types of active metal compounds and suitable for various electrocatalytic reactions.

Owner:GUANGZHOU UNIVERSITY

System for deeply eliminating white smoke of wet desulfurization flue gas

ActiveCN109432935AReduce fine particle contentReduce moisture contentGas treatmentHeat pumpsWater vaporFlue gas

The invention provides a system for deeply eliminating white smoke of a wet desulfurization flue gas, and belongs to the technical field of the flue gas desulfurization application. The system comprises a flue gas heat exchanging system, a desulfurization system and a heat pump circulating system. The flue gas heat exchanging system comprises a first heat exchanger and a second heat exchanger. Thedesulfurization system comprises a desulfurization tower. The desulfurization tower comprises a cooling absorbing section, an outlet section and a washing demisting section which are communicated. The heat pump circulating system comprises a generator, a condenser, an evaporator and an absorber. The system does not need an additional high-temperature heat source, and is capable of cooling desulfurization tower circulating liquid by using a heat pump technology, reducing moisture content of the purified flue gas, and through using circulating slurry heat and high-temperature inlet flue gas heat, improving a discharging temperature of the purified flue gas, greatly improving an unsaturation degree of the purified flue gas, thereby achieving a purpose of deeply eliminating the white smoke, and further reducing content of fine particulate matters in the flue gas through using condensation of water vapor.

Owner:SINOPEC ENG GRP CO LTD

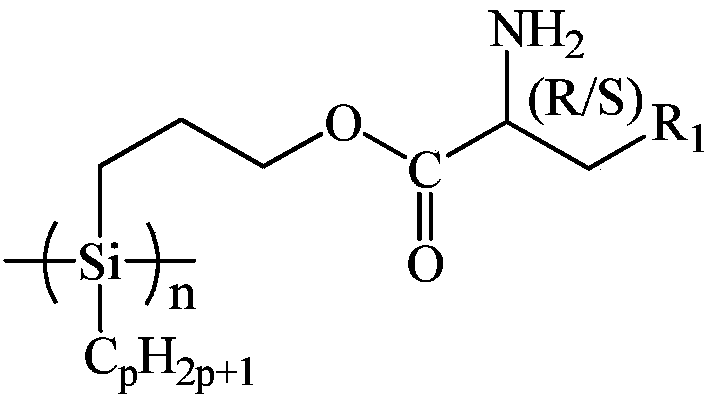

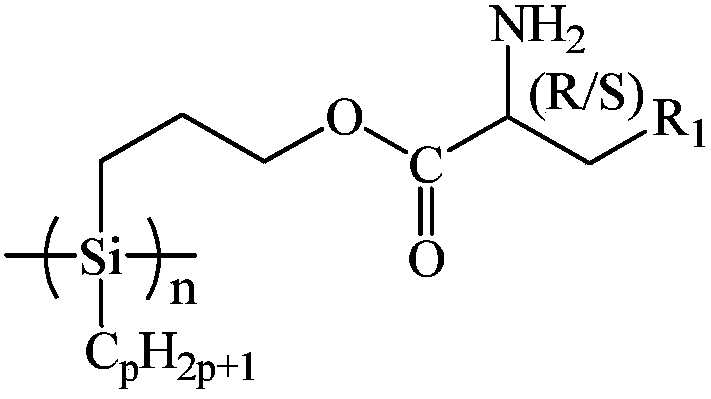

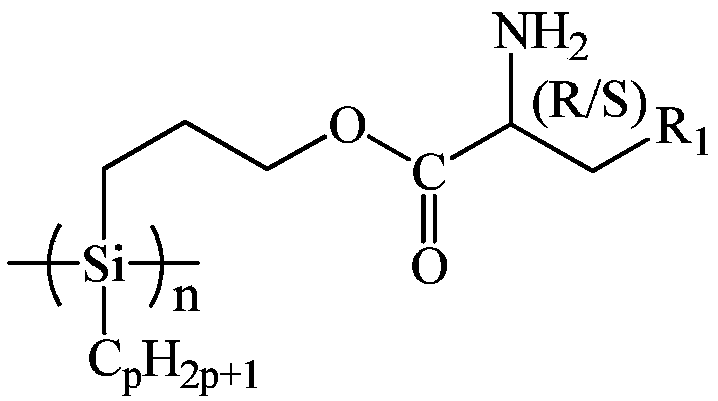

Amino acid spiral polysilane infrared absorption material and preparation method thereof

The invention provides an amino acid spiral polysilane infrared absorption material and a preparation method thereof. The material is obtained through catalytic addition of L or D-2-amino acid propylene ester and alkyl hydrogen polysilane, the structural general formula of the material is as shown in the description. The degree of polymerization n is 10 to 5000; p is 10 to 12; and R1 is one of formulas as shown in the description. The glass transition temperature of the material is 35 to 70 DEG C, the thermal decomposition temperature is 300 to 450 DEG C, the absolute value of specific rotation is 10 to 70 degrees (25 DEG C), and the infrared emitting ability of 8 to 14 microns is 0.4 to 0.8 (25 DEG C). The material can be used for preparing infrared stealth materials, and can also be usedas a binder in continuous phases of photoelectric function materials.

Owner:SOUTHEAST UNIV

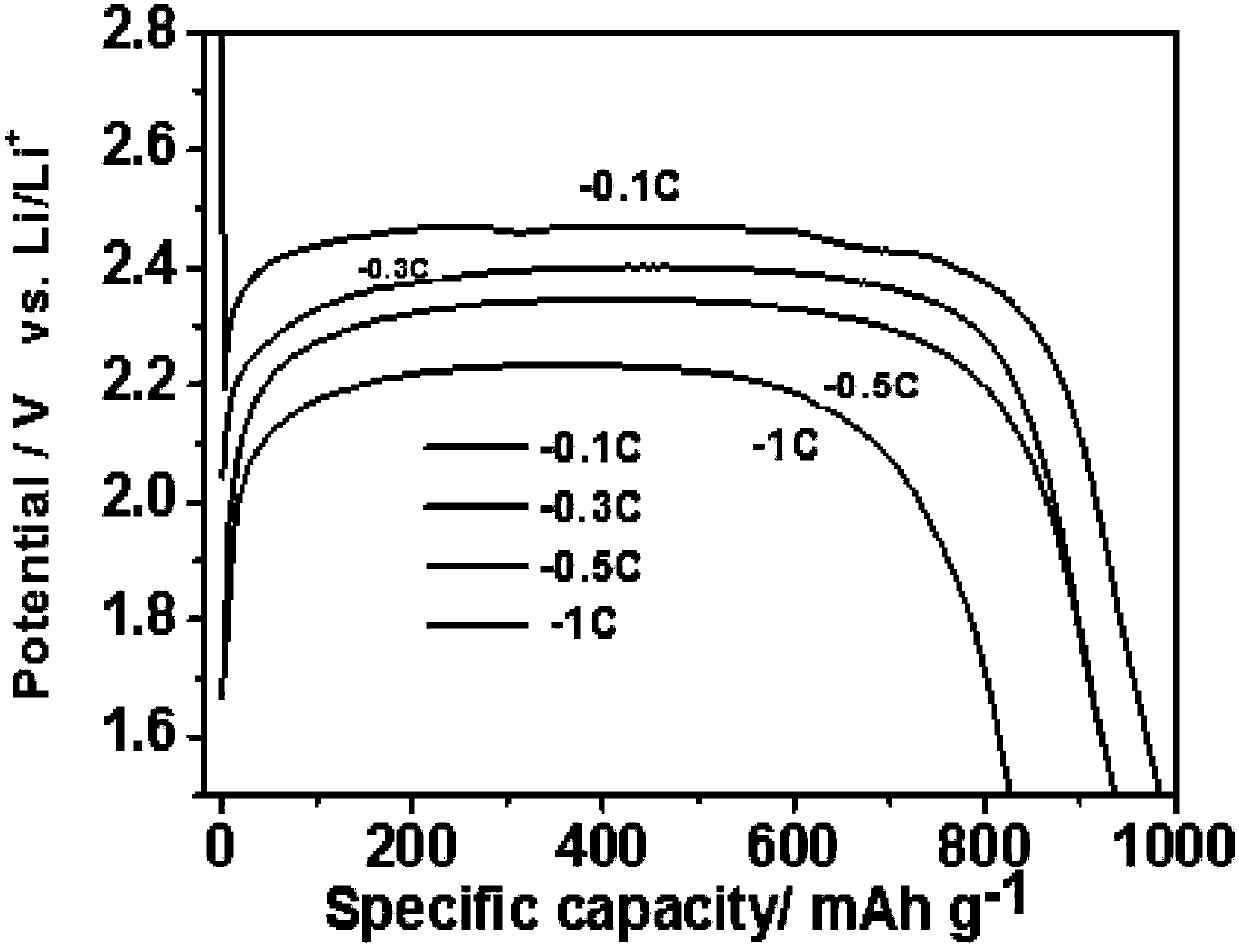

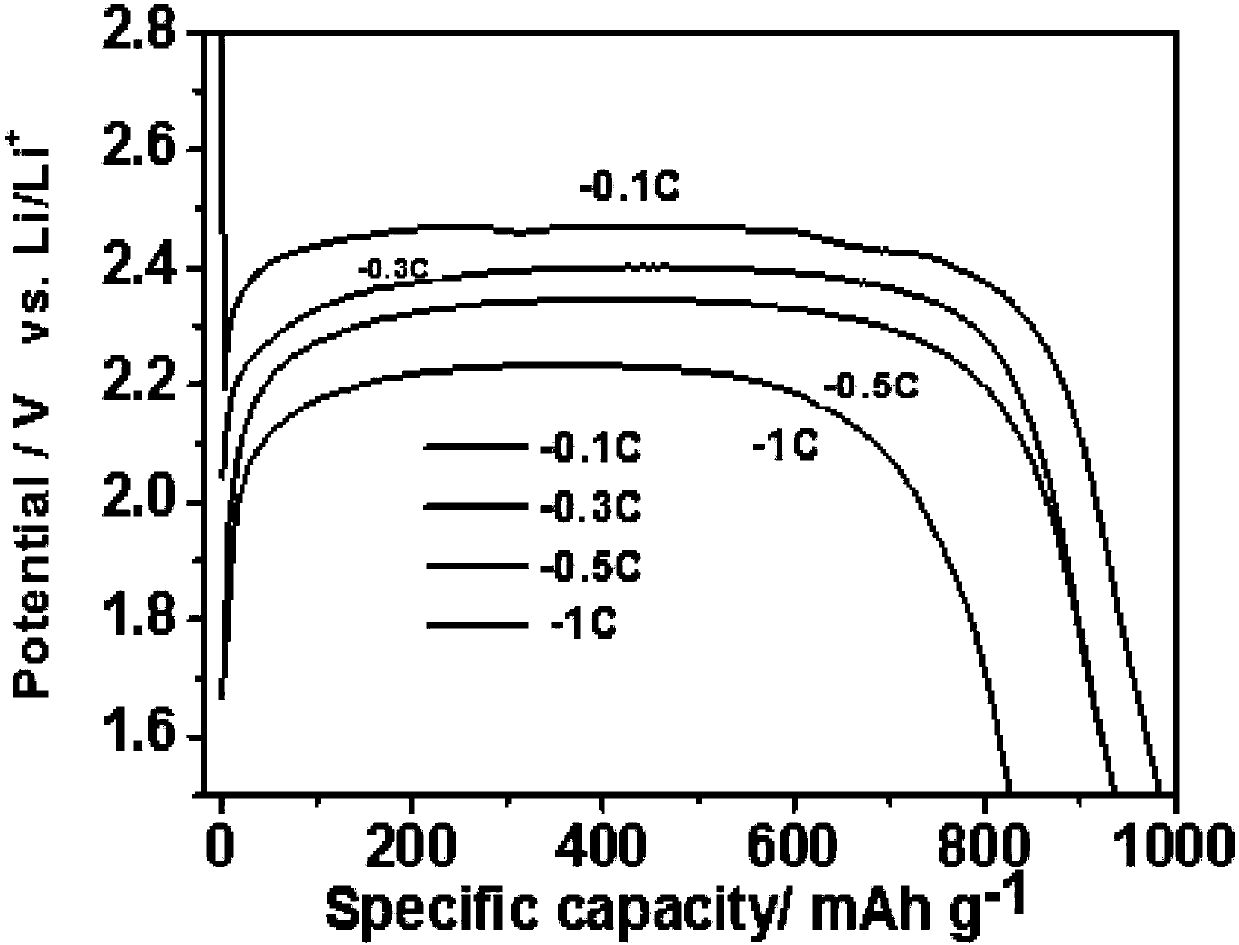

Heteroatom-modified fluorinated carbon quantum and preparation method thereof

ActiveCN109888283AImproved magnification performanceIncrease unsaturationMaterial nanotechnologyNon-aqueous electrolyte cellsChemical solutionModified carbon

The invention relates to a preparation method for preparing a carbon fluoride quantum dot of a high-specific capacity and low-dimensional fluorinated carbon material. Small organic molecules are polymerized with a chemical solution method and a microwave-assisted mode, the heteroatom-modified carbon quantum dot material is obtained through carbonization and graphitization, and the heteroatom-modified fluorinated carbon quantum dot material is prepared by precise and controllable fluorination technology.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for recovering byproducts generated in processing process of medicinal chrysanthemum flowers

InactiveCN103800415AIncrease unsaturationImprove qualityCosmetic preparationsAntipyreticSocial benefitsCooling tower

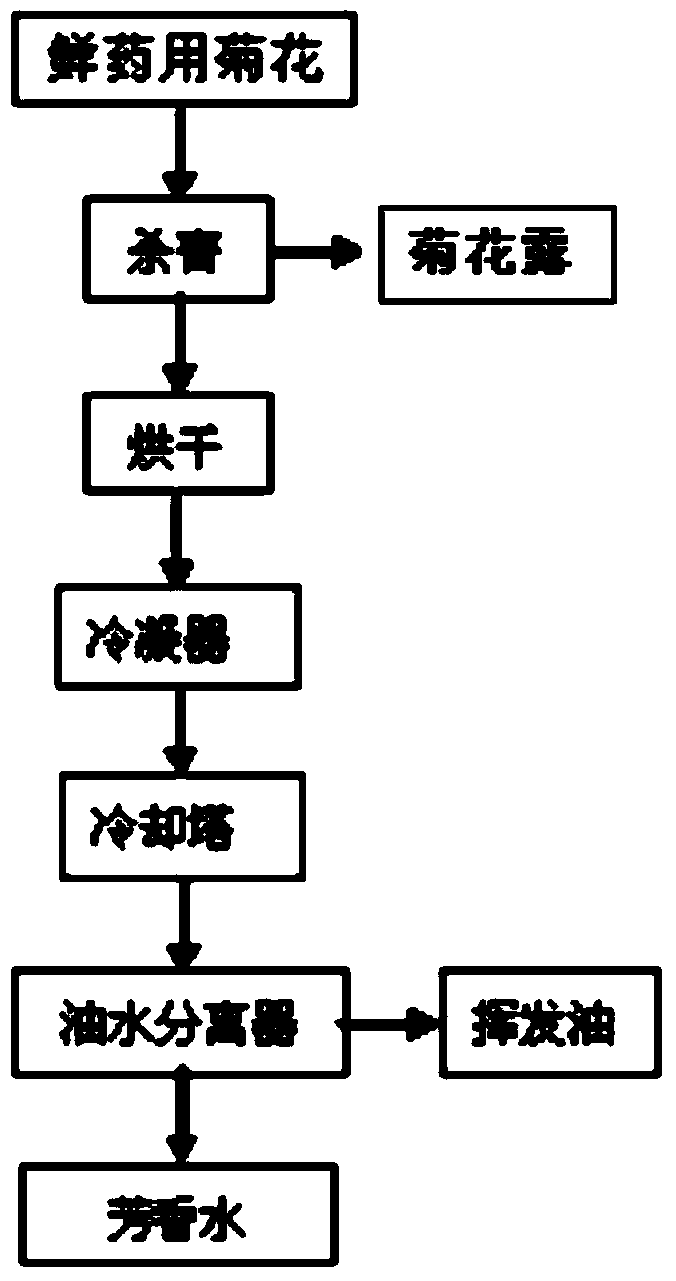

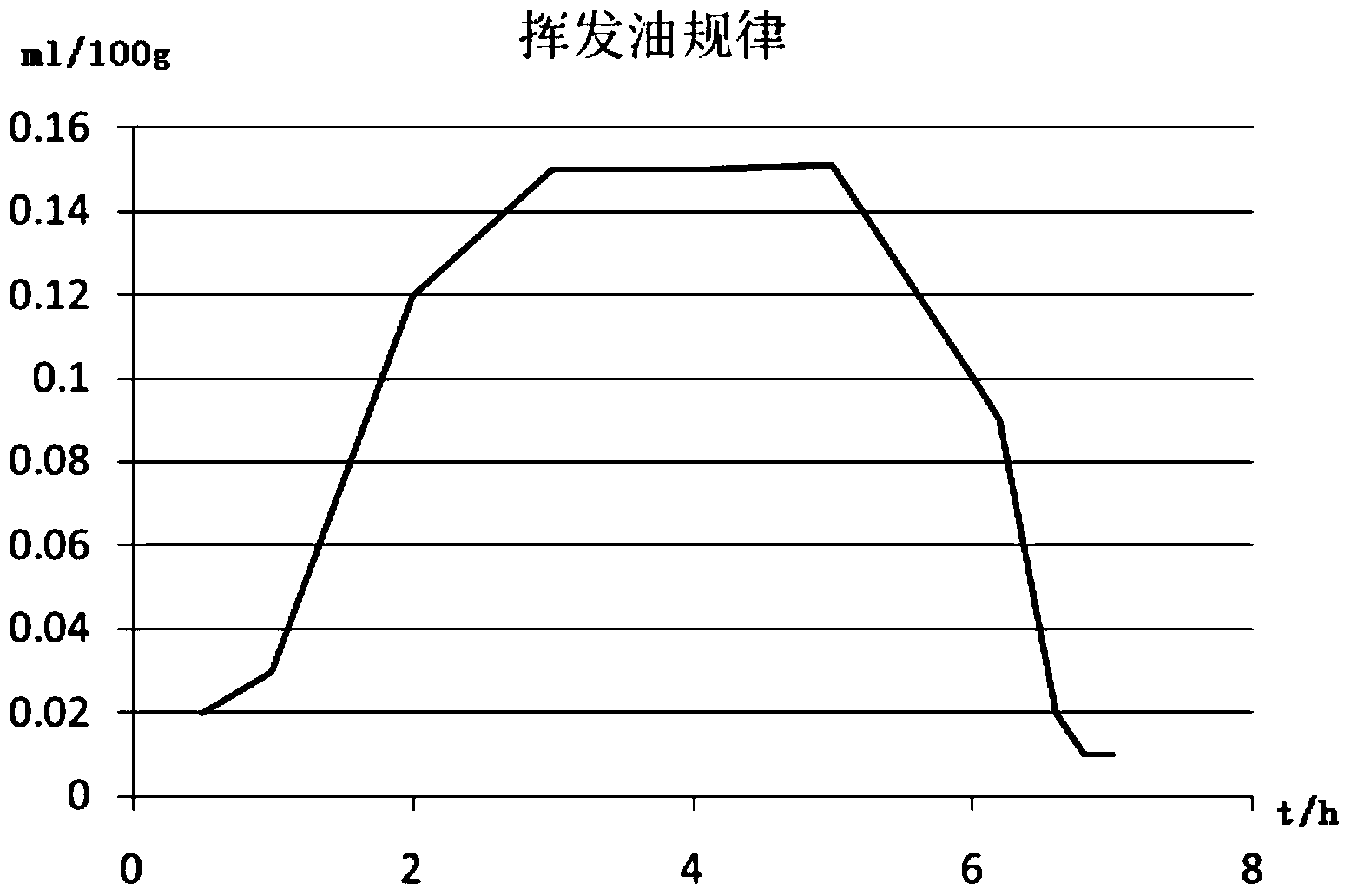

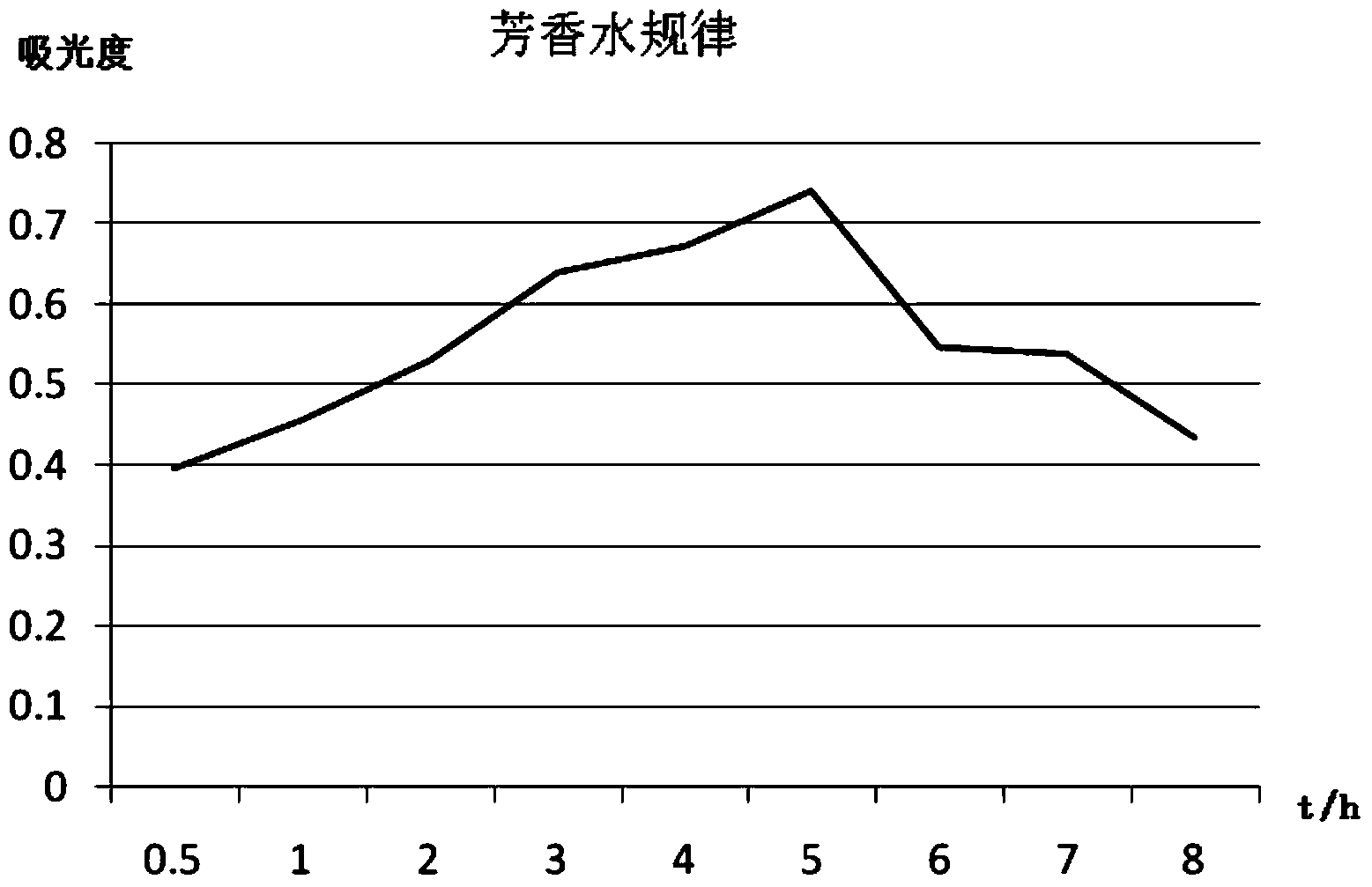

The invention discloses a method for recovering byproducts generated in processing process of medicinal chrysanthemum flower. The method comprises the following steps: deactivating enzymes of fresh medicinal chrysanthemum flowers at 100-110DEG C for 45-55 s, and drying medicinal chrysanthemum flowers at 70-75DEG C for 6.5-7.5 h, wherein water-oil mixed vapor generated in 2-6 h of drying is collected and fed into a condenser, a cooling tower and an oil-water separator in sequence, and after separation in the oil-water separator, the obtained upper oil layer is volatile oil, and the lower water layer is aromatic water. The method disclosed by the invention can reutilize the waste generated during processing process of chrysanthemum flowers, and extract volatile oil and other byproducts from the waste, does not need additional chrysanthemum flower raw material and heat energy, and can change waste into valuables and reduce waste and improve efficiency. The obtained volatile oil has good quality, and has good economic benefits and social benefits.

Owner:NANJING AGRICULTURAL UNIVERSITY

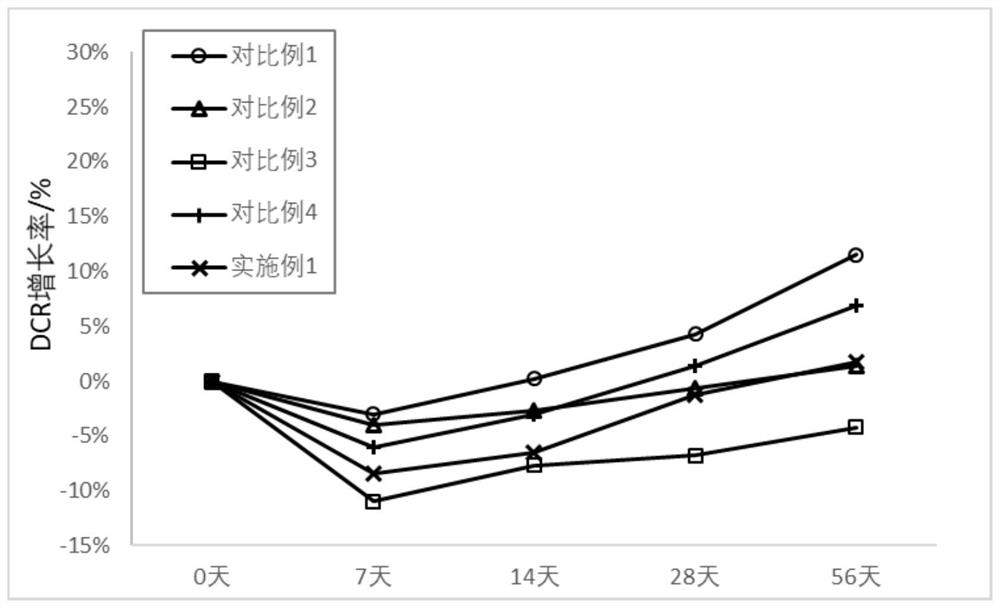

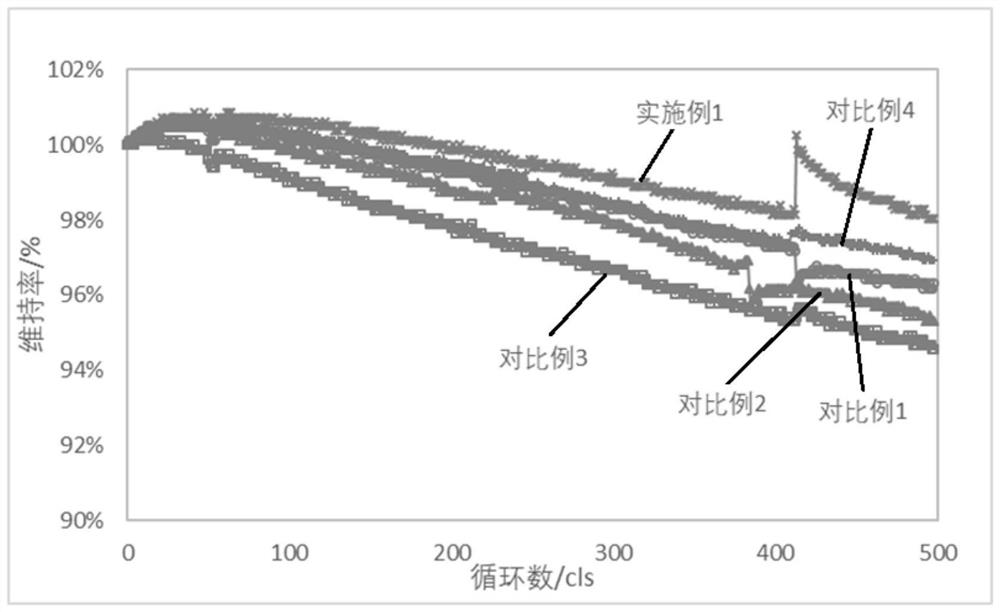

Non-aqueous electrolyte considering high-temperature characteristic and normal-temperature cycle, application thereof and lithium ion battery

InactiveCN112531213AExcellent lithium ion conductivityLow viscositySecondary cellsOrganic electrolytesElectrolytic agentOrganosolv

The invention relates to a non-aqueous electrolyte considering high-temperature characteristics and normal-temperature circulation, an application thereof and a lithium ion battery. Based on the totalweight, the non-aqueous electrolyte comprises the following components in percentage by mass: 70-90% of a non-aqueous organic solvent, 5-20% of electrolyte lithium salt and an additive, based on thetotal weight of the non-aqueous electrolyte, the additive comprises 0.1-2.5% of lithium difluorophosphate, 0.1-2.5% of propane sultone, 0.5-3% of lithium bis (fluorosulfonyl) imide, 0.1-1% of tetravinyl silane and 0.1-1.5% of lithium difluorobis (oxalato) phosphate. The non-aqueous electrolyte disclosed by the invention is good in stability under high voltage, relatively good in circularity, relatively small in gas production rate in the aspect of high-temperature storage and relatively small in DCR growth, and can improve the electrochemical characteristics of the lithium ion battery under high temperature and high pressure.

Owner:ENVISION DYNAMICS TECH (JIANGSU) CO LTD +1

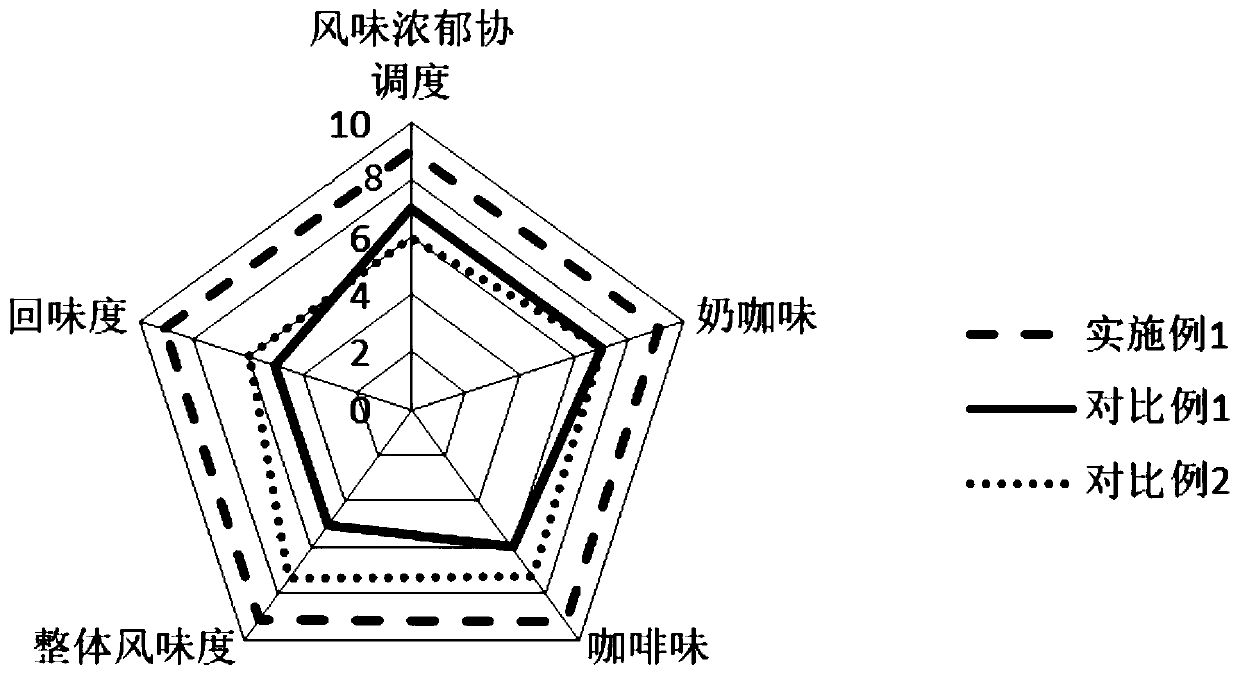

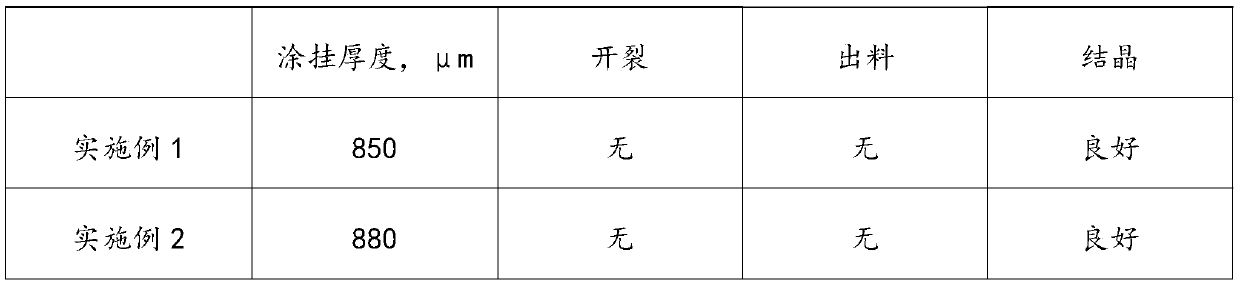

Coffee-flavored thin-layer coating chocolate composition and preparation method thereof

The present invention belongs to the technical field of food processing and particularly relates to a coffee-flavored thin-layer coating chocolate composition and a preparation method thereof. Based on total mass of the coffee-flavored thin-layer coating chocolate composition, the coffee-flavored thin-layer coating chocolate composition comprises the following components in mass percentages: 32-35% of a sweetener, 3.0-3.4% of milk powder, 46-50% of edible fat, 12-15% of cocoa powder, 0.1-0.13% of coffee and 0.5-1.0% of an emulsifier. By adding coffee, cooperated effects of the coffee with eachcomponent, especially a synergistic effect of the coffee and cocoa powder, can promote release of chocolate flavor, enables the chocolate flavor to be mellow, and avoids a defect of insufficient chocolate flavor due to reduced coating amount. In addition, properties of the prepared chocolate composition are no different from those of the conventional chocolate composition in the prior art, and problems of cracking, material discharging and wax feeling do not occur after coating. The provided chocolate composition can be applied to coating of frozen drink, water ice, ice cream, bread, biscuits, etc., and has a wide application range.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Food health-preserving tea electuary for delaying aging

The invention discloses a food health-preserving tea electuary for delaying aging and belongs to the field of nutritional foods. The food health-preserving tea electuary has good effects and produces the effects fast. The food health-preserving tea electuary is prepared from mushroom, Chinese angelica, soybean, barley bran and black tea, has effects of supporting body resistance, reinforcing qi and nourishing blood, and delaying aging, and has the advantages of good effects and fast onset.

Owner:BEIJING LVYUAN QIUZHENG SCI & TECH DEV

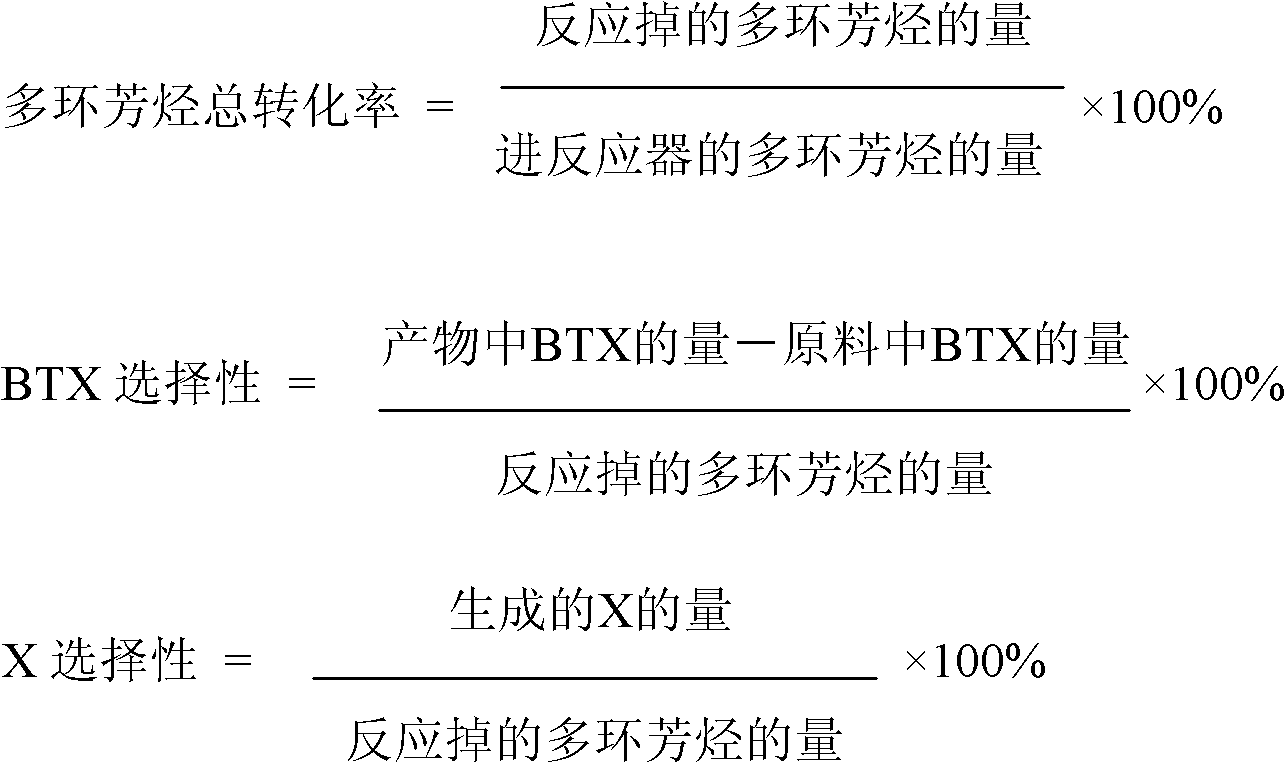

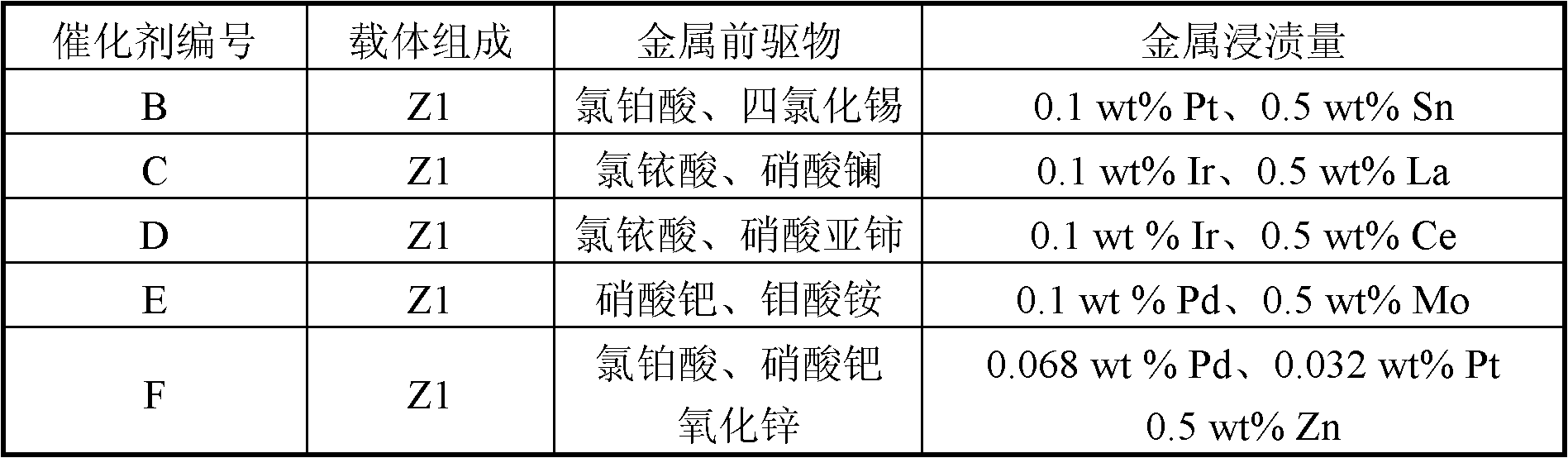

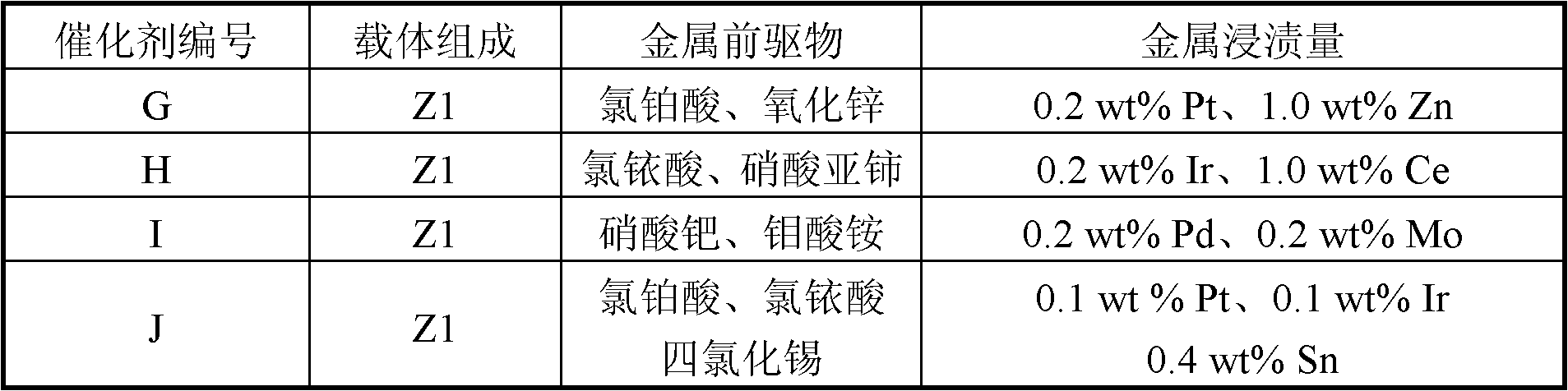

Method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons to produce more dimethylbenzene

ActiveCN103121907AReduced inactivation rateExtended service lifeMolecular sieve catalystsBulk chemical productionPolycyclic aromatic hydrocarbonHydrogen

The invention relates to a method for converting polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons to produce more dimethylbenzene, mainly solving the problems in the prior art that the conversion level of polycyclic aromatic hydrocarbons is low, the dimenthylbenzene yield and selectivity are low and the catalyst deactivation rate is high. The problems are better solved by adopting the technical scheme that polycyclic aromatic hydrocarbon mixtures and hydrogen are taken as the raw materials and are contacted with a catalyst in a fixed bend reactor to react under the conditions that the reaction temperature is 330-420 DEG C, the reaction pressure is 4-7MPa, the weight hourly space velocity is 1-3hr<-1> and the hydrogen-hydrocarbon mole ratio is 5.0-8.0 to generate monocyclic aromatic hydrocarbon mixtures producing more dimethylbenzene. The method can be used in the industrial production of increasing production of dimethylbenzene by converting heavy polycyclic aromatic hydrocarbons into monocyclic aromatic hydrocarbons.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Maleic acid [beta]-cyclodextrin ester and preparation method thereof Maleic acid [beta]-cyclodextrin ester and preparation method thereof](https://images-eureka.patsnap.com/patent_img/1ec45480-ef49-4979-82b3-dfdc9e43f76f/DEST_PATH_IMAGE001.PNG)

![Maleic acid [beta]-cyclodextrin ester and preparation method thereof Maleic acid [beta]-cyclodextrin ester and preparation method thereof](https://images-eureka.patsnap.com/patent_img/1ec45480-ef49-4979-82b3-dfdc9e43f76f/HDA0000505680560000011.PNG)

![Maleic acid [beta]-cyclodextrin ester and preparation method thereof Maleic acid [beta]-cyclodextrin ester and preparation method thereof](https://images-eureka.patsnap.com/patent_img/1ec45480-ef49-4979-82b3-dfdc9e43f76f/HDA0000505680560000012.PNG)