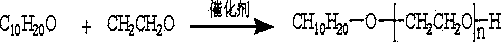

Dihydromyrcenol polyoxyethylene ether and synthetic method thereof

A technology of myrcenyl polyoxyethylene ether and dihydromyrcenol, which is applied in the field of dihydromyrcenyl polyoxyethylene ether and its synthesis, can solve the problem of large differences in mud content in sand and gravel, and the anti-contamination of water reducers. Problems such as poor mud and limited use, etc., to achieve the effects of narrow molecular weight distribution, high water reduction rate, and increased growth ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add 624g of dihydromyrcenol and 1.44g of potassium hydroxide solid into a 10L dry spray reactor, replace the air in the kettle with nitrogen for 3 times, raise the temperature to 80°C, and start adding ethylene oxide continuously under vacuum in the reactor Alkanes 1776g, control the flow rate and add in 2 hours, the reaction temperature is 80-120°C. Insulate and ripen until the pressure in the reactor no longer drops, about 1 hour. After the reaction is complete, lower the temperature to 80°C and vacuumize to remove low-boiling substances, then add glacial acetic acid to neutralize to pH 5-7 and discharge to obtain a paste.

Embodiment 2

[0035] Add 624g of dihydromyrcenol and 12.0g of potassium hydroxide solid into a 10L dry spray reactor, replace the air in the kettle with nitrogen for 3 times, raise the temperature to 80°C, and start adding ethylene oxide continuously under vacuum in the reactor Alkanes 1776g, control the flow rate and add in 3 hours, the reaction temperature is at 90-130°C. Insulate and ripen until the pressure in the reactor no longer drops, about 1 hour. After cooling down to 80°C and vacuuming out the low boiling point substances, release 1800g of low molecular weight dihydromyrcenol polyoxyethylene ether, then add 30.0g of potassium hydroxide solid, replace the air in the kettle with nitrogen for 3 times, then heat up to 90- After vacuum dehydration at 120°C for 60 minutes, start to add 2400g of ethylene oxide continuously, control the flow rate for 5 hours and complete the addition, the reaction temperature is 100-150°C, heat preservation and aging until the pressure in the reactor no ...

Embodiment 3

[0037] Add 624g of dihydromyrcenol and 3.6g of potassium hydroxide solid into a 10L dry spray reaction kettle, replace the air in the kettle with nitrogen for 3 times, raise the temperature to 80°C, and start adding ethylene oxide continuously under vacuum in the reaction kettle Alkanes 1776g, control the flow rate and add in 3 hours, the reaction temperature is at 80-100°C. Insulate and ripen until the pressure in the reactor no longer drops, about 1 hour. After cooling down to 80°C and vacuuming out the low boiling point substances, release 1800g of low molecular weight dihydromyrcenol polyoxyethylene ether, then add 9.0g of potassium hydroxide solid, replace the air in the kettle with nitrogen for 3 times, then heat up to 90- After vacuum dehydration at 120°C for 60 minutes, start to add 5400g of ethylene oxide continuously, control the flow rate for 9 hours and complete the addition, the reaction temperature is 90-130°C, heat preservation and aging until the pressure in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com