Water-based EVA treating agent and preparation method thereof

A treatment agent, water-based technology, applied in the field of water-based EVA treatment agent and its preparation, can solve the problems of the decrease of the applicability of the treatment agent base material, the decrease of the bonding strength and peel strength of the treatment agent, the decrease of the polarity of the treatment agent, etc. Mechanical strength and bonding properties, enhanced bonding treatment effect, effect of increasing the number and length of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

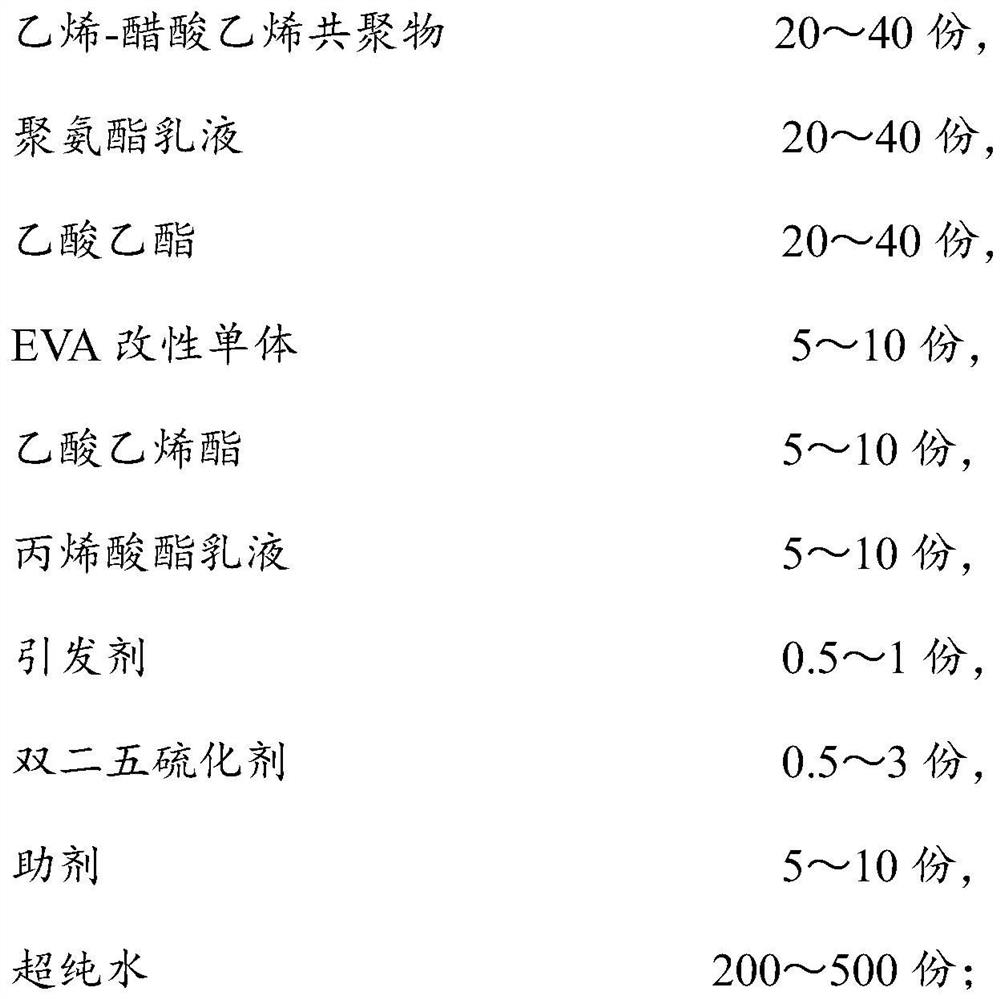

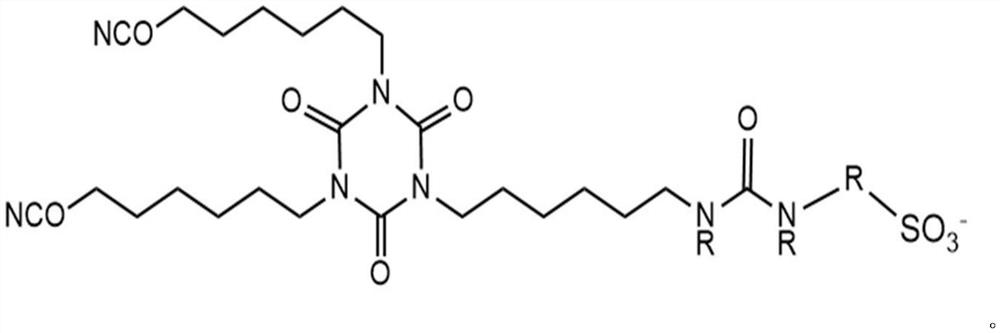

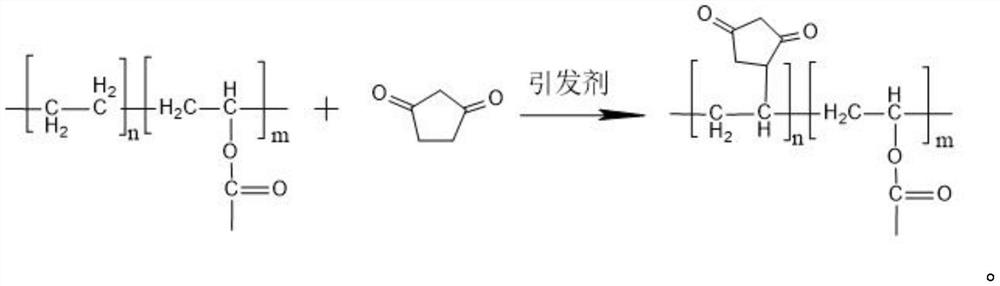

[0031] A water-based EVA treatment agent, comprising the following raw materials in parts by mass: 20 parts of ethylene-vinyl acetate copolymer, 20 parts of polyurethane emulsion, 20 parts of ethyl acetate, 5 parts of EVA modified monomer, 5 parts of vinyl acetate, acrylic acid 5 parts of ester emulsion, 0.5 part of initiator, 0.5 part of bis-pentasulfurizing agent, 5 parts of auxiliary agent, 200 parts of ultrapure water;

[0032] The EVA modified monomer is methyl methacrylate;

[0033] Described initiator is benzoyl peroxide;

[0034] The auxiliary agent is an anti-hydrolysis agent and an adhesion promoter, and the mass part ratio is 1:1; wherein the anti-hydrolysis agent is monomeric carbodiimide; wherein the adhesion promoter is a silane coupling agent;

[0035] The preparation method of described aqueous EVA treatment agent, comprises the following steps:

[0036] Step 1: Add mass parts of ethylene-vinyl acetate copolymer into the reaction vessel, then add mass parts o...

Embodiment 2

[0040] A water-based EVA treatment agent, comprising the following raw materials in parts by mass: 40 parts of ethylene-vinyl acetate copolymer, 40 parts of polyurethane emulsion, 40 parts of ethyl acetate, 10 parts of EVA modified monomer, 10 parts of vinyl acetate, acrylic acid 10 parts of ester emulsion, 1 part of initiator, 3 parts of bis-pentasulfurizing agent, 10 parts of auxiliary agent, 500 parts of ultrapure water;

[0041] Described EVA modified monomer is maleic anhydride;

[0042] Described initiator is diisopropyl peroxydicarbonate;

[0043] The auxiliary agent is an anti-hydrolysis agent and an adhesion promoter, and the mass part ratio is 1:1; wherein the anti-hydrolysis agent is polycarbodiimide; wherein the adhesion promoter is a silane coupling agent;

[0044] The preparation method of described aqueous EVA treatment agent, comprises the following steps:

[0045] Step 1: Add mass parts of ethylene-vinyl acetate copolymer into the reaction vessel, then add m...

Embodiment 3

[0049] A water-based EVA treatment agent, comprising the following raw materials in parts by mass: 30 parts of ethylene-vinyl acetate copolymer, 30 parts of polyurethane emulsion, 30 parts of ethyl acetate, 8 parts of EVA modified monomer, 8 parts of vinyl acetate, acrylic acid 8 parts of ester emulsion, 0.8 parts of initiator, 2 parts of bis-pentasulfurizing agent, 7 parts of auxiliary agent, 300 parts of ultrapure water;

[0050] The EVA modified monomer is sulfamic acid;

[0051] Described initiator is tert-butyl peroxybenzoate;

[0052] The auxiliary agent is an anti-hydrolysis agent and an adhesion promoter, and the mass part ratio is 1:1; wherein the anti-hydrolysis agent is monomeric carbodiimide; wherein the adhesion promoter is a silane coupling agent;

[0053] The preparation method of described aqueous EVA treatment agent, comprises the following steps:

[0054] Step 1: Add mass parts of ethylene-vinyl acetate copolymer into the reaction vessel, then add mass part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com