Acoustic damping composite material and preparation method thereof

A composite material and noise reduction technology, applied in the field of materials, can solve problems such as poor sound absorption effect, and achieve the effect of good elasticity, improved mechanical properties and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

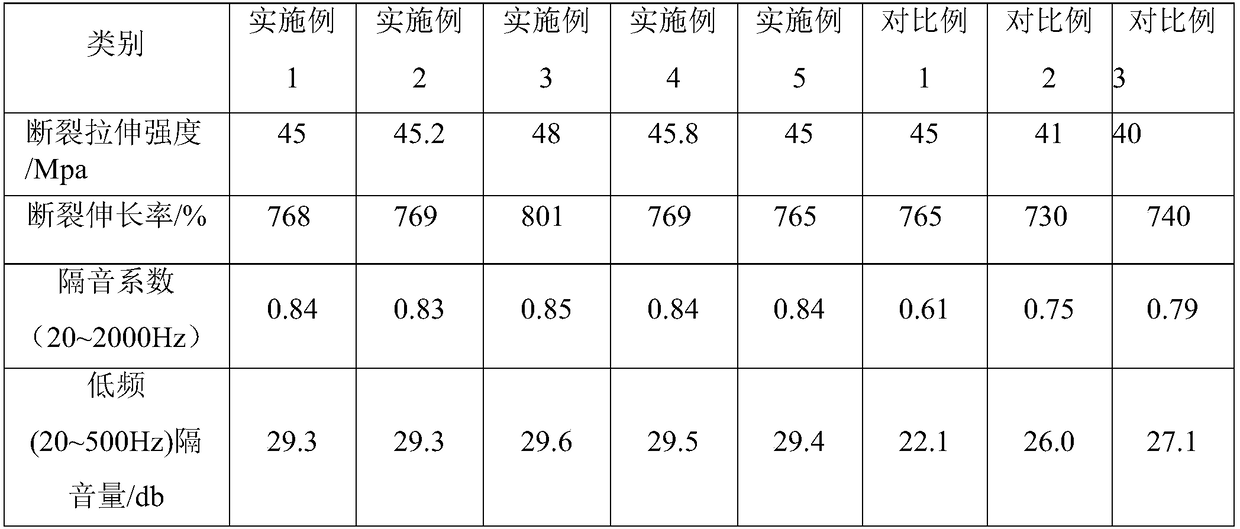

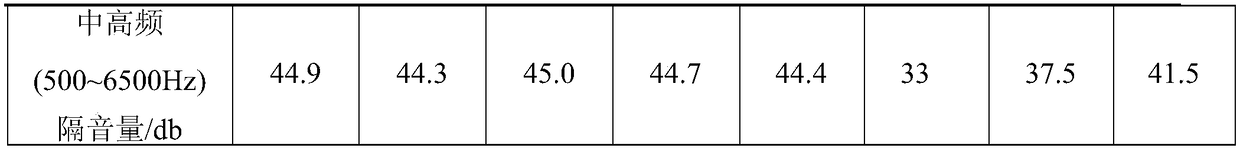

Examples

Embodiment 1

[0022] A noise reduction composite material, consisting of the following raw materials in parts by weight: 15 parts of textile fibers, 10 parts of mixed sol, 1 part of surfactant; 20 parts of thermoplastic polyurethane, 10 parts of melamine, 5 parts of lignocellulose, and 4 parts of white carbon black 1 part, 1 part of carbon nanotube, 1 part of acetyl tributyl citrate, 1 part of boron nitride, 1 part of hydroxypropyl starch, 1 part of glycerin and 8 parts of n-octane; the mixed sol includes that the composite sol is silicon 15 parts of sol, 25 parts of aluminum sol, 25 parts of zirconium sol and 30 parts of titanium sol, wherein the solid content is greater than 25%; the surfactant is aqueous sodium bicarbonate solution with a mass fraction of 5%.

[0023] The present invention also provides the preparation method of the noise reduction composite material as follows:

[0024] 1) First mix white carbon black, carbon nanotubes, boron nitride and hydroxypropyl starch at 50°C and...

Embodiment 2

[0030] A noise-reducing composite material, consisting of the following raw materials in parts by weight: 20 parts of textile fibers, 15 parts of mixed sol, 2 parts of surfactants; 25 parts of thermoplastic polyurethane, 15 parts of melamine, 10 parts of lignocellulose, and 6 parts of white carbon black 2 parts of carbon nanotubes, 2 parts of acetyl tributyl citrate, 2 parts of boron nitride, 2 parts of hydroxypropyl starch, 2 parts of glycerin and 10 parts of n-octane.

[0031] The mixed sol includes 20 parts of silica sol, 35 parts of aluminum sol, 35 parts of zirconium sol and 40 parts of titanium sol, wherein the solid content is greater than 25%.

[0032] The surfactant is 5% sodium bicarbonate aqueous solution in mass fraction.

[0033] The present invention also provides the preparation method of the noise reduction composite material as follows:

[0034] 1) First mix white carbon black, carbon nanotubes, boron nitride and hydroxypropyl starch at 60°C and 800r / min for ...

Embodiment 3

[0041] A noise reduction composite material, consisting of the following raw materials in parts by weight: 17 parts of textile fibers, 12 parts of mixed sol, 1.5 parts of surfactants; 22 parts of thermoplastic polyurethane, 12 parts of melamine, 7 parts of lignocellulose, and 5 parts of white carbon black 1.5 parts of carbon nanotubes, 1.5 parts of acetyl tributyl citrate, 1.5 parts of boron nitride, 1.5 parts of hydroxypropyl starch, 1.5 parts of glycerin and 9 parts of n-octane.

[0042] The mixed sol includes 17 parts of silica sol, 30 parts of aluminum sol, 30 parts of zirconium sol and 35 parts of titanium sol, wherein the solid content is greater than 25%.

[0043] 11. Described tensio-active agent is the sodium bicarbonate aqueous solution that mass fraction is 5%.

[0044] The present invention also provides the preparation method of the noise reduction composite material as follows:

[0045] 1) First mix white carbon black, carbon nanotubes, boron nitride and hydroxypr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com