Method for preparing methyl allyl alcohol polyoxyethylene ether

A technology of methallyl alcohol polyoxyethylene ether and methallyl alcohol, which is applied in the field of preparation of methallyl alcohol polyoxyethylene ether, can solve the limitation of conversion rate, grafting rate, polycarboxylic acid molecular weight and The molecular structure is difficult to meet the design requirements, etc., to achieve the effect of increasing the degree of unsaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

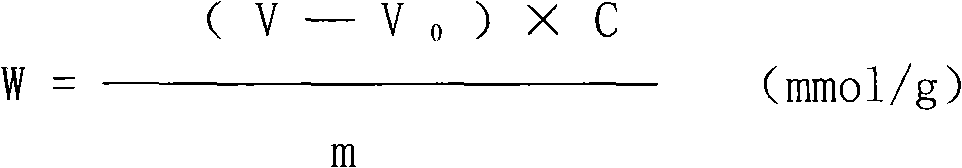

Method used

Image

Examples

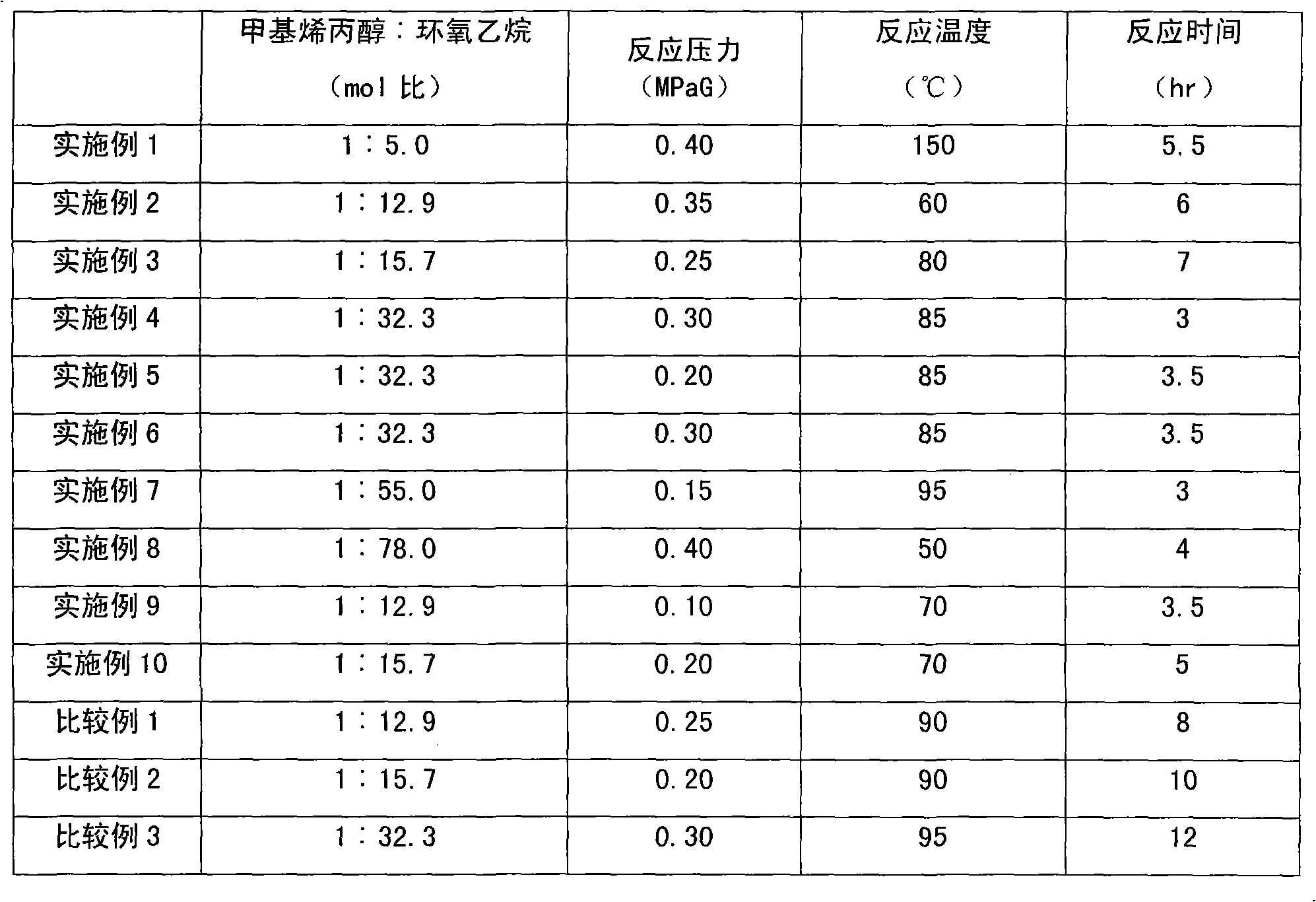

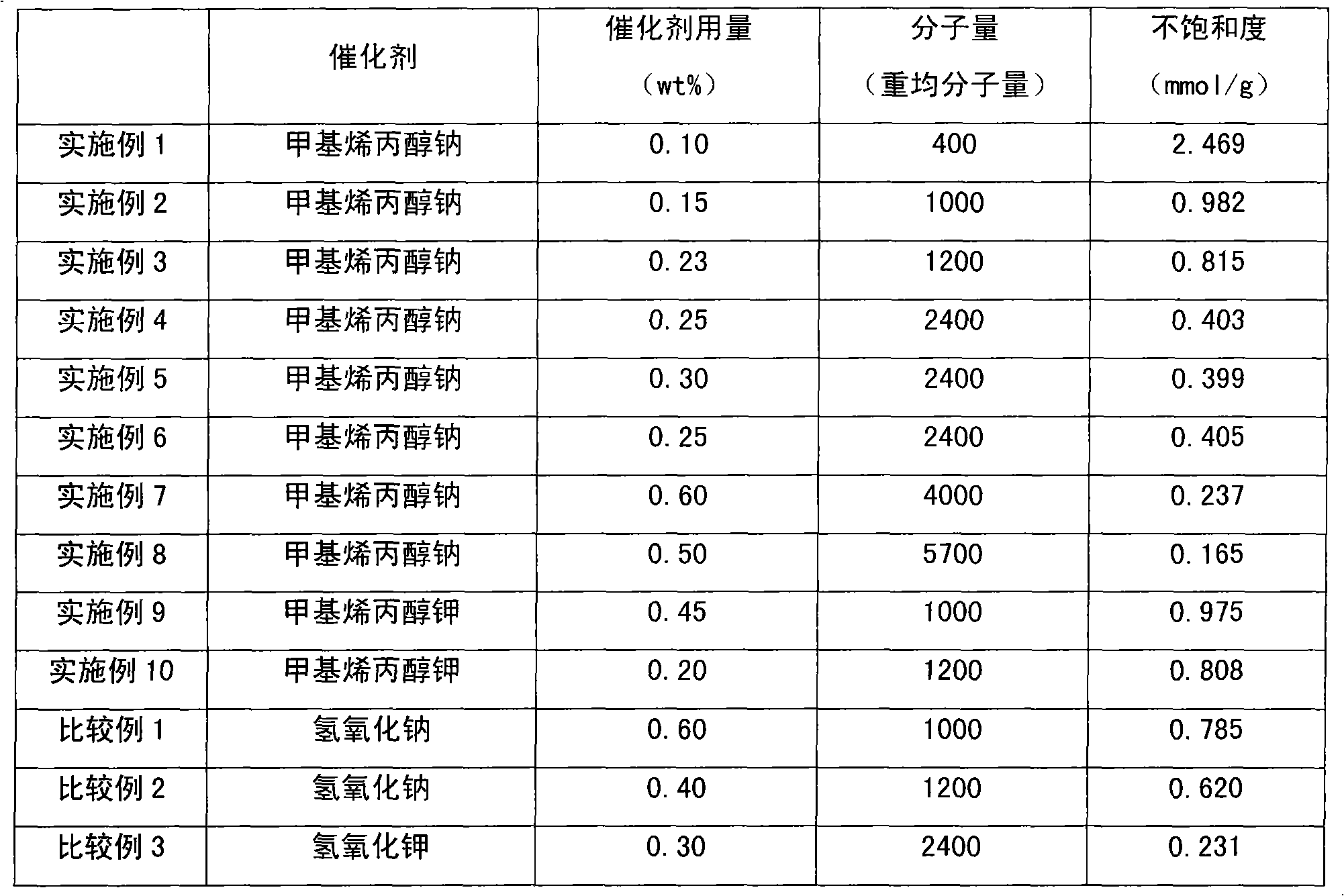

Embodiment 1~10

[0019] The polymerization reaction was carried out in a tank reactor with a volume of 4 L equipped with a stirring and heating device. First replace the air in the reactor with nitrogen, add 72g of methallyl alcohol, and add the required amount of catalyst. Then replace the air in the reactor with nitrogen at room temperature, start stirring, heat up to the set reaction temperature, then feed the required amount of ethylene oxide (EO) gas, and simultaneously control the system pressure to the set value. Maintain the set reaction temperature for aging reaction until the set reaction time is reached to end the polymerization reaction.

[0020] After the polymerization reaction, neutralize the product with acetic acid, filter the product with a liquid filter bag with a precision of 35-75 μm after cooling, and remove the solid matter to obtain the methallyl alcohol polyoxyethylene ether product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com