System for deeply eliminating white smoke of wet desulfurization flue gas

A wet desulfurization and flue gas technology, applied in gas treatment, separation methods, climate sustainability, etc., can solve the problems of limited increase in flue gas temperature and capacity to be improved, so as to increase the discharge temperature and reduce the content of fine particles. , the effect of increasing desaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

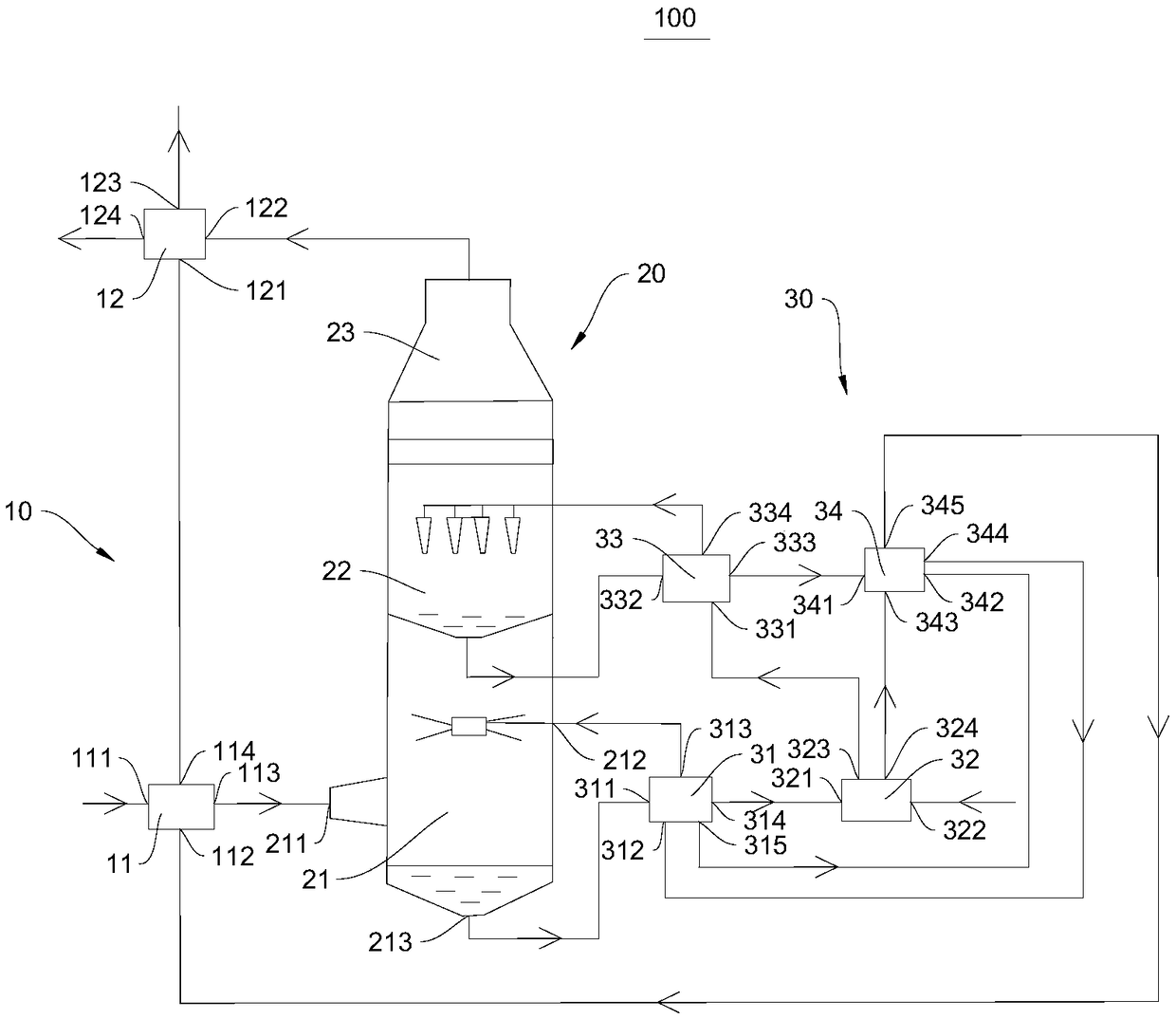

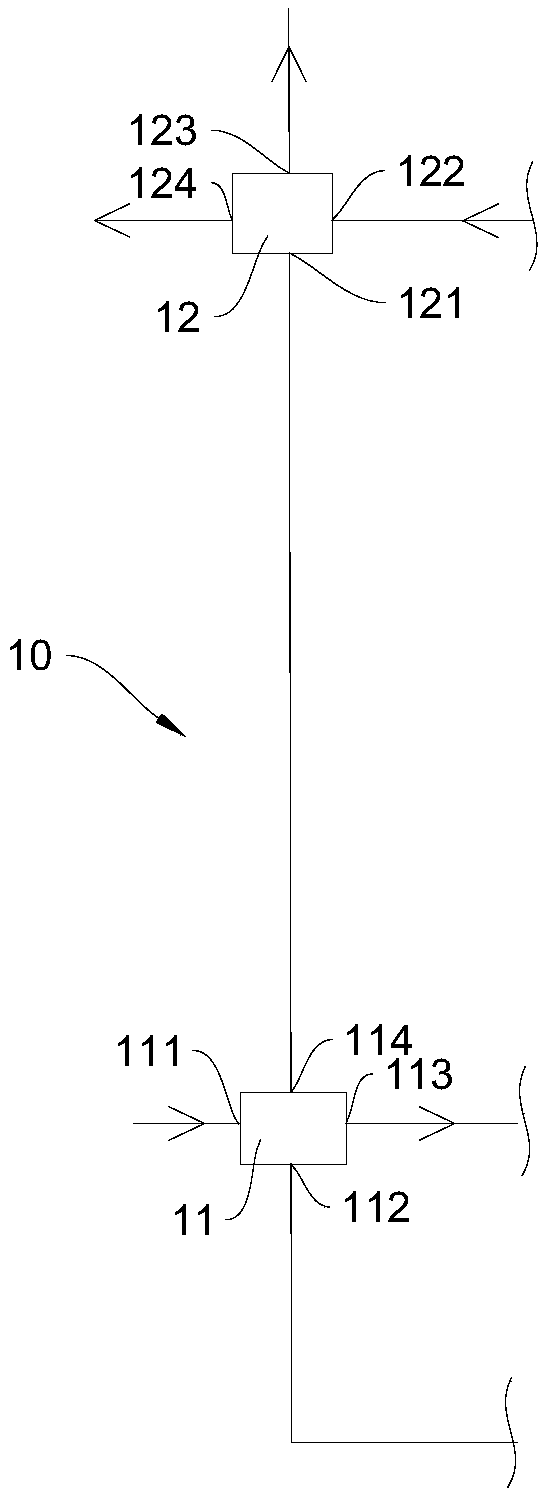

[0037] Please also refer to figure 1, the system 100 for deep elimination of wet desulfurization flue gas white smoke involved in this embodiment includes a flue gas heat exchange system 10 , a desulfurization system 20 and a heat pump circulation system 30 .

[0038] Wherein, the flue gas heat exchange system 10 includes a first heat exchanger 11 and a second heat exchanger 12 . As an option, both the first heat exchanger 11 and the second heat exchanger 12 can be selected from tube heat exchangers, plate heat exchangers or heat pipe heat exchangers. Preferably, both the first heat exchanger 11 and the second heat exchanger 12 are plate heat exchangers.

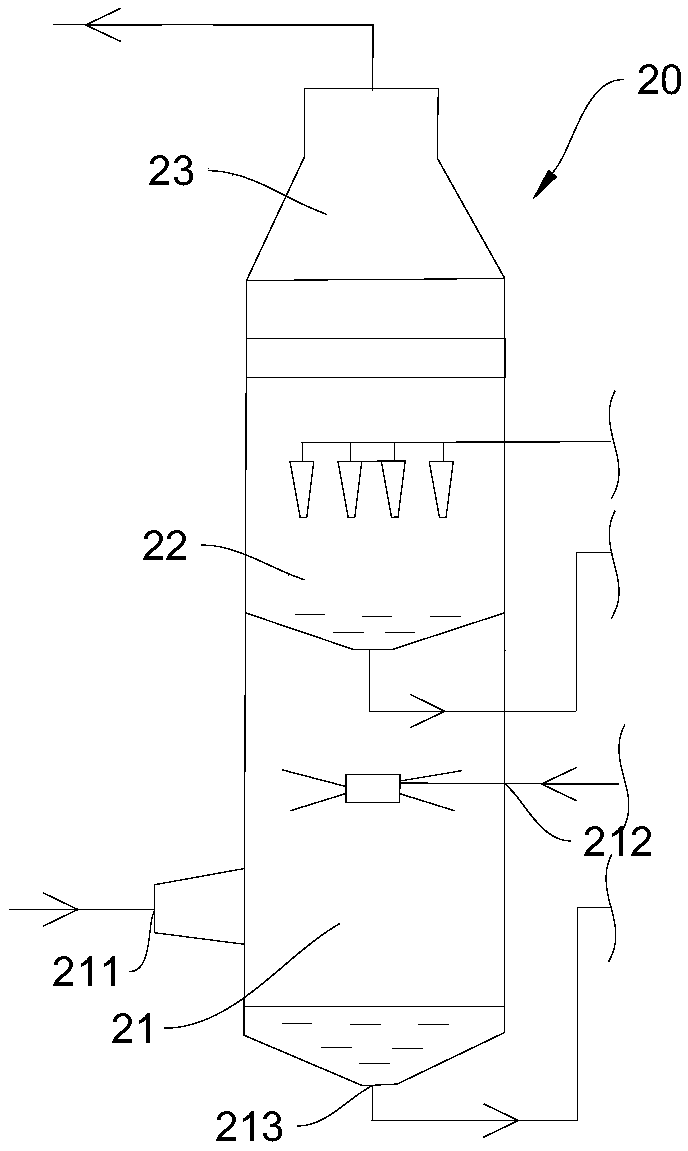

[0039] The desulfurization system 20 includes a desulfurization tower, and the desulfurization tower includes a cooling absorption section 21 at the bottom, an outlet section 23 at the top, and a washing and demister section 22 between the cooling absorption section 21 and the outlet section 23, the cooling absorption secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com