System for producing micropowder of dense calcium carbonate

A heavy calcium carbonate, production system technology, applied in the direction of dyeing physical treatment, fibrous filler, etc., can solve the problems of high comprehensive power consumption of products, affecting the overall operating efficiency of enterprises, unreasonable product structure, etc. The effect of Taiwan-hour output, elimination of double peaks, and increased productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

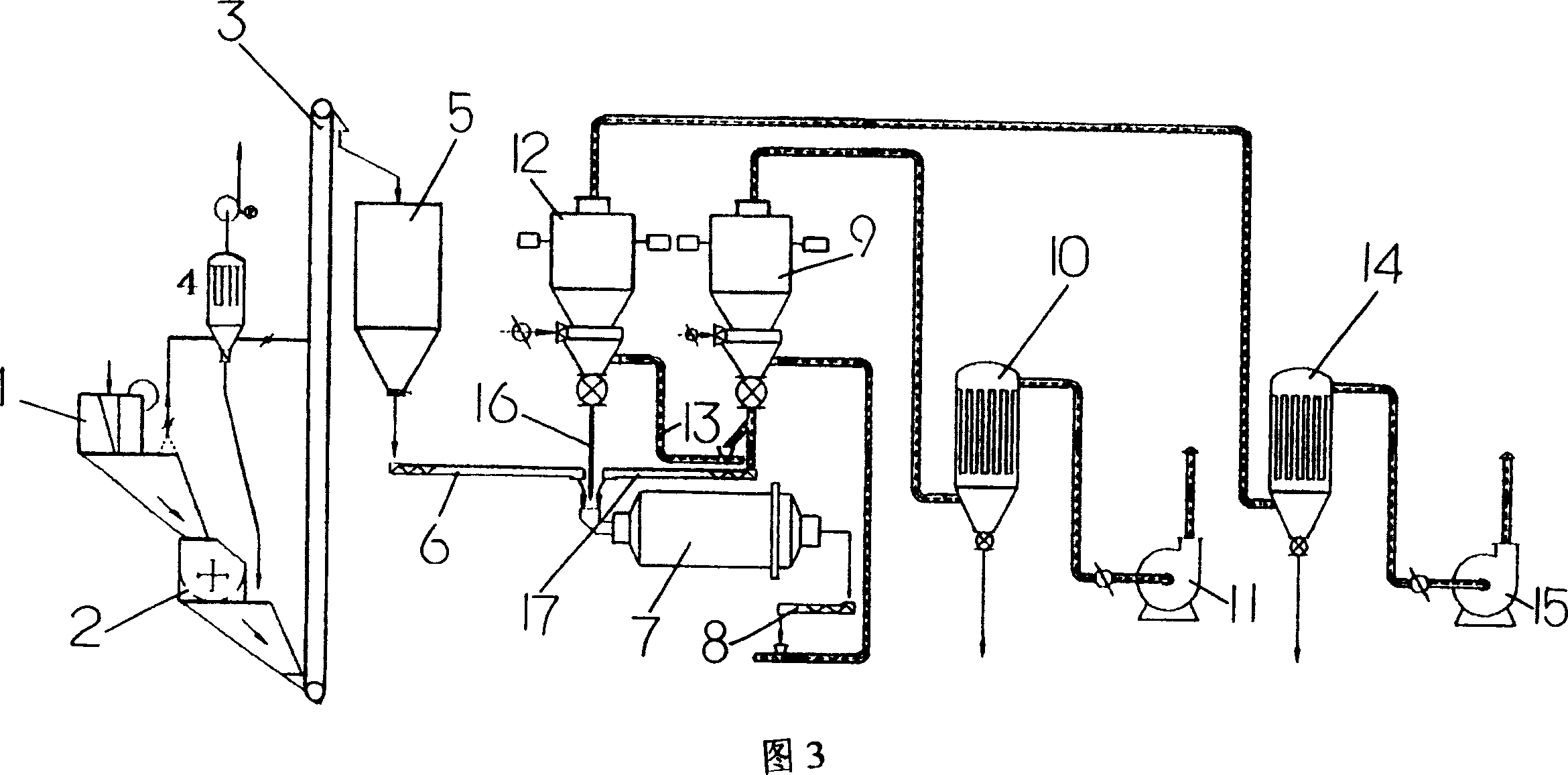

[0017] Referring to Fig. 3, the same as the prior art, the system of this embodiment consists of a raw material bin 5, a ball mill 7, a classifier and a collector according to the direction of raw materials.

[0018] The improvement to the existing technology is that the classifier in the system of this embodiment is at least two stages of multi-pole series connection, the output of the ball mill is used as the input of the first stage classifier, and the coarse material output of the previous stage classifier is used as the post-stage classifier. For the input of the first-level classifier, the coarse material output of the last-level classifier is used as the feedback input of the ball mill, and the fine material collector of the corresponding level is independently set at the fine material output port of each classifier.

[0019] In the present embodiment shown in Figure 3, the classifier is a two-stage series connection, including a first-stage polarizer 9 and a second-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com