Grader

A classifier and screening technology, applied in the field of sorting, can solve the problems of high failure rate of equipment and low screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

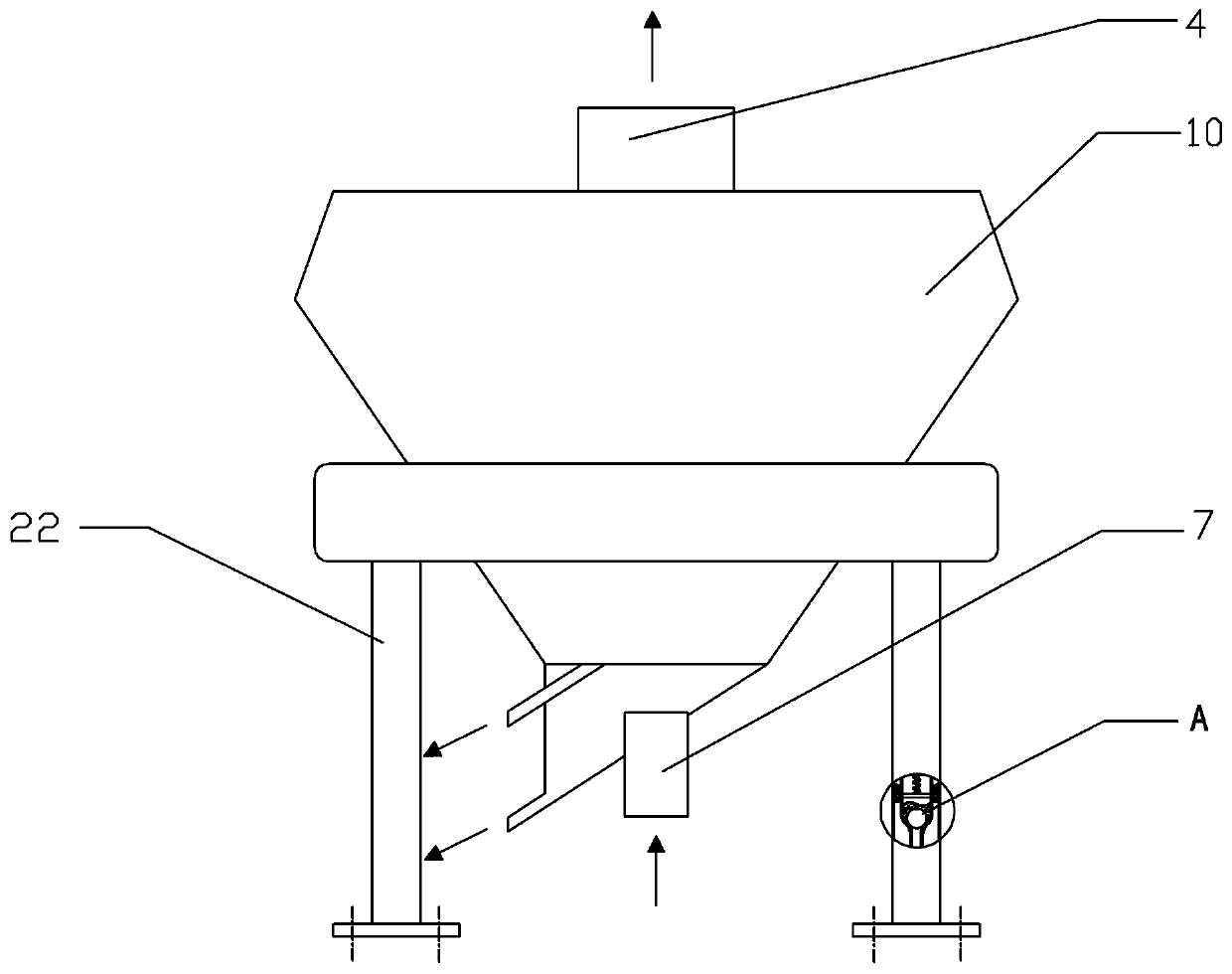

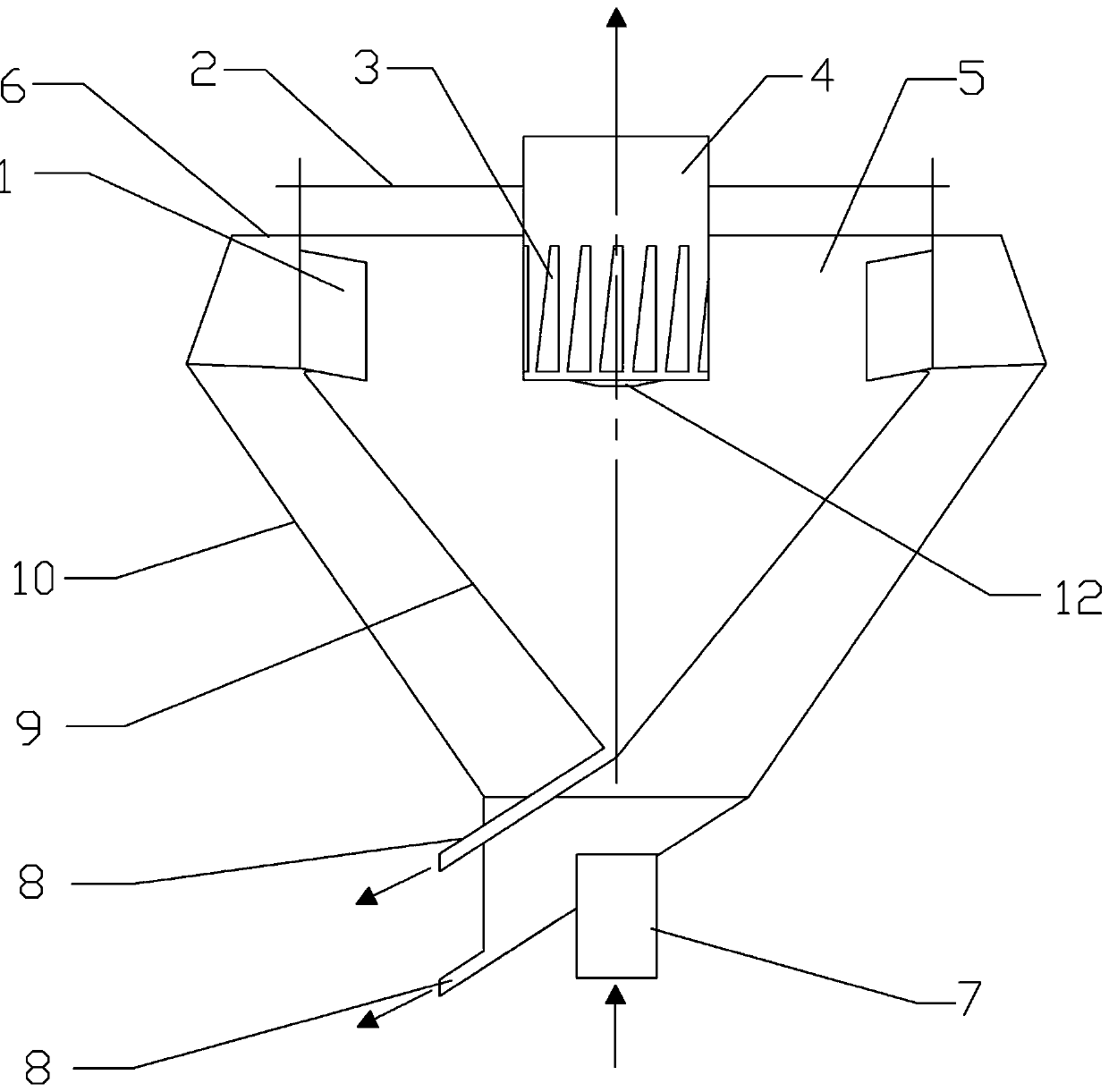

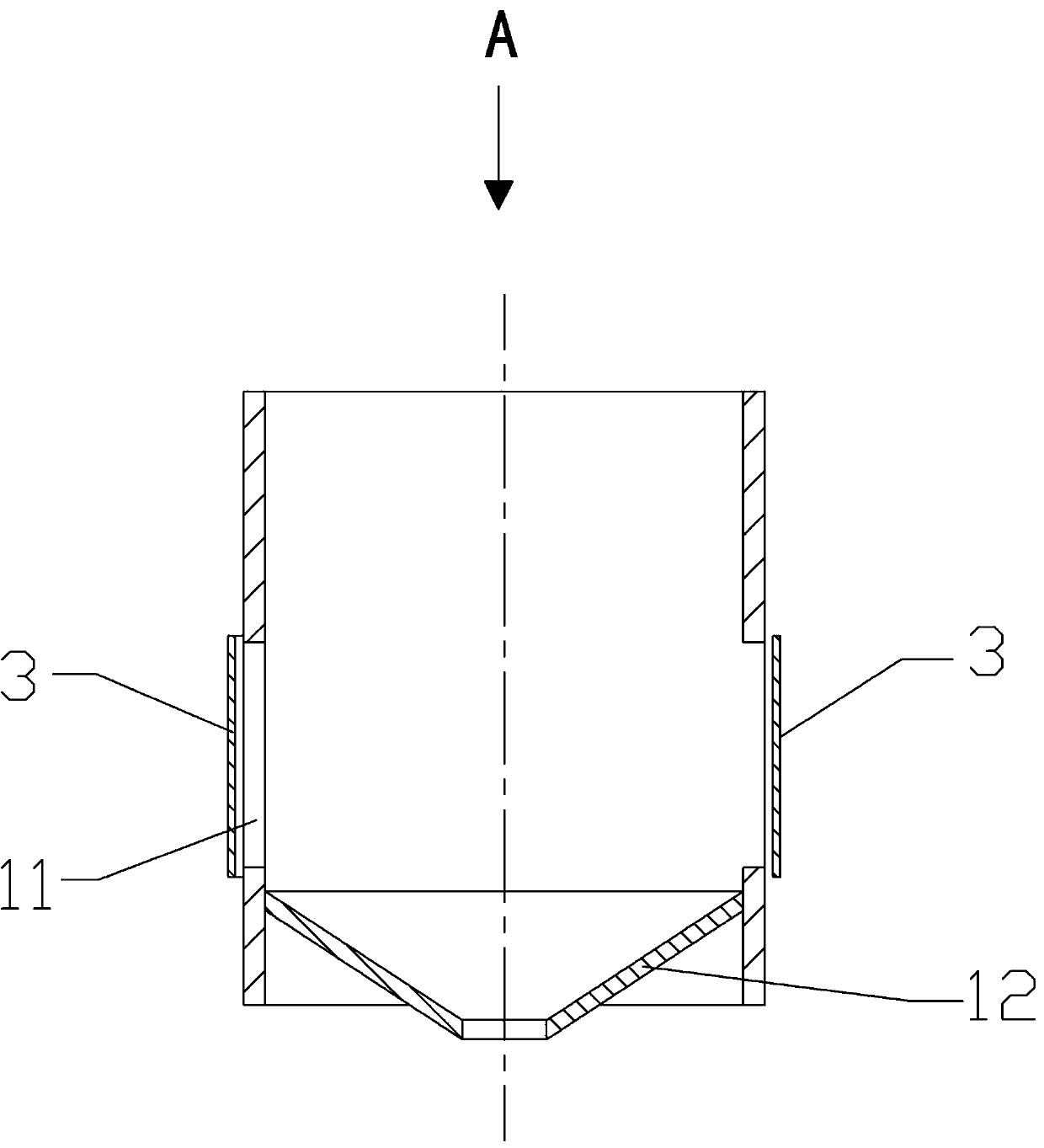

[0022] Example: The solution consists of an outer conical housing 10, a top cover 6, a seat, an inner conical housing 9, a supply pipe 7 for the raw material to be screened and a discharge pipe 4 for discharging the fine-grained product , discharge product chute 8, swirl vane 1, screening area 5. Such as figure 1 , the support has four legs, the bottom of the swirl vane 1 is rotatably connected to a vertical shaft, the vertical shaft is arranged on the top edge of the inner casing, and the swirl vane 1 is driven by a common drive mechanism 2. The screening area is enclosed between the swirl vanes 1 and the discharge pipe 4 , and the discharge pipe 4 is provided with many screen holes within the height range of the screening area 5 , and the shape of the screen holes is vertical slots 11 . The top of the conical cap 12 is provided with a ventilation hole, the conical cap 12 is provided with a long hole 13, the long hole 13 has a screening function, and the discharge pipe 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com